door switch HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 229 of 1413

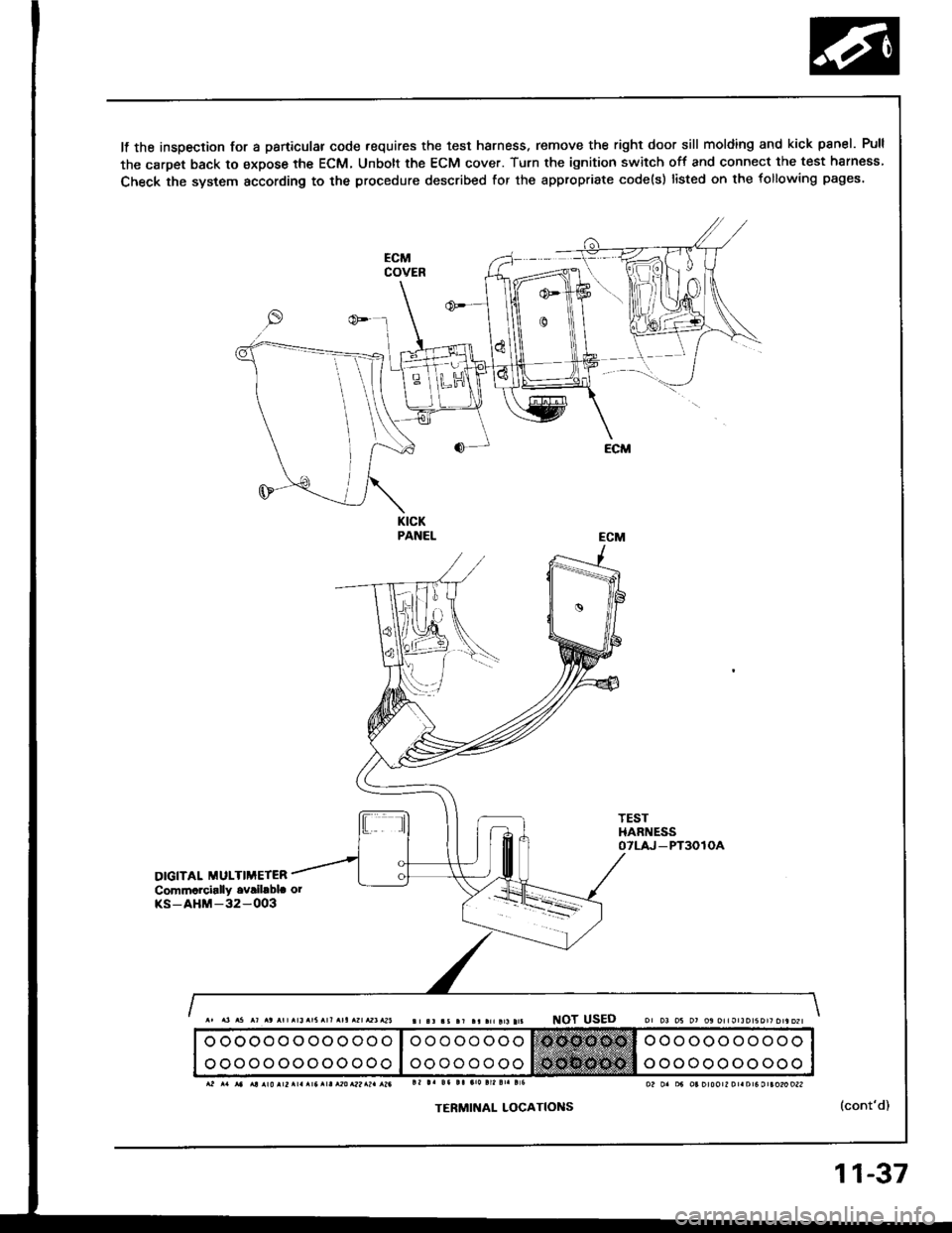

It the inspection for a particular code requires the test harness. remove the right door sill molding and kick panel. Pull

the carpet back to expose the ECM, Unbott the ECM cover. Turn the ignition switch off and connect the test harness

Check the system according to the procedure described for the appropriate code(s) listed on the following pages.

KICKPANEL

TESTHARNESSOTLAJ _PT3OlOA

DIGITAL MULTIMETERCommarcially ovribbla orKS-AHM-32-OO3

NOT USED

TERMINAL LOCATIONS(cont'd)

o oooooooooooo

ooooooooooooo

oo o oo ooo

oooooooo

ooooooooooo

ooooooooooo

11-37

Page 244 of 1413

PGM-FI System

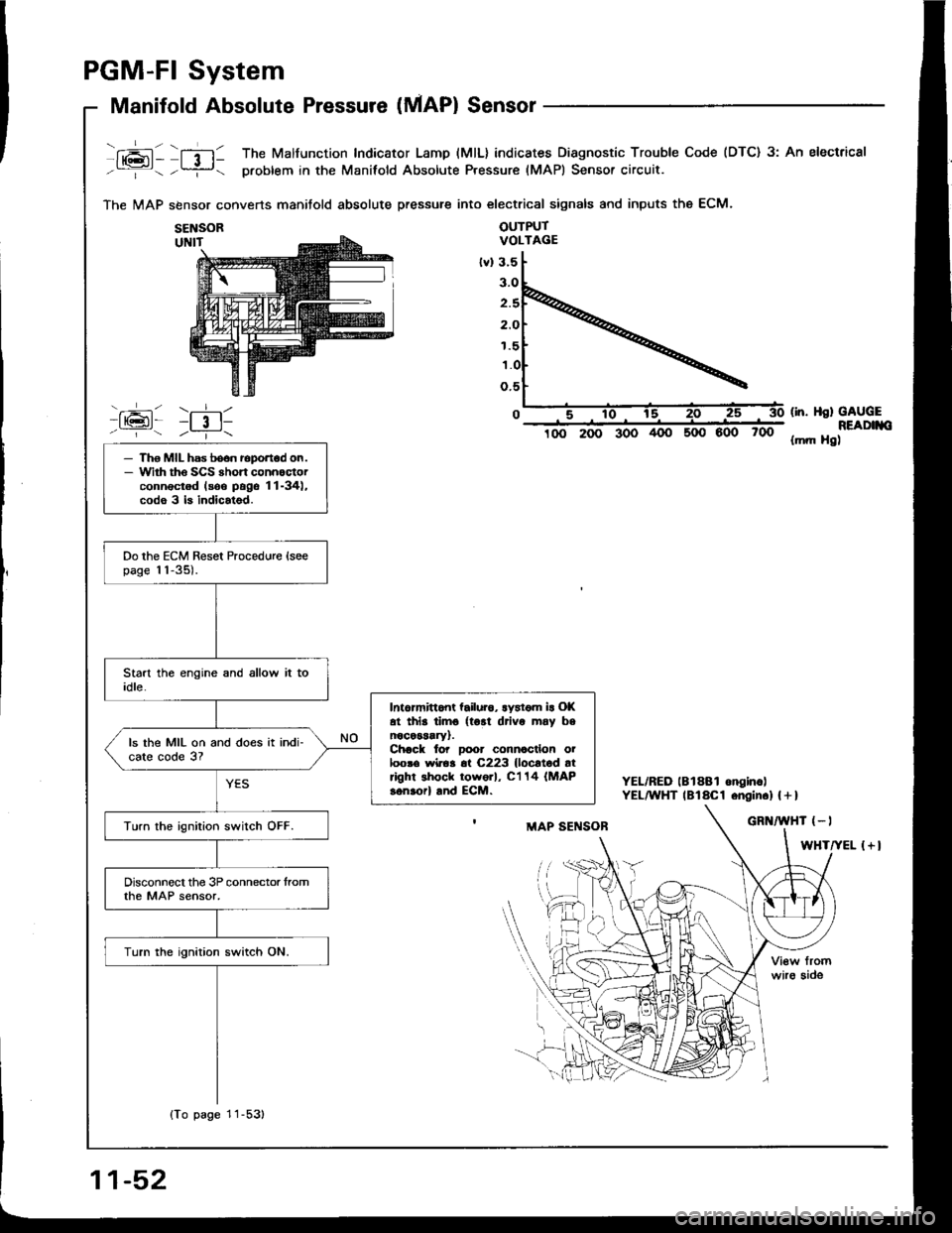

Manifold Absolute Pressure (MAP) Sensor

fxai - lfil1 The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 3: An electrical

-:- -?- problem in the Manifold Absolute Pressure (MAPI Sensor circuit.

The MAP sbnsor converts manitold absolute pressure into electrical signals and inputs the ECM.

OUTPUTVOLTAGE

600 700

(in. Hsl GAUGEREADIIIO{mft Hg)

YEL/RED lBlSBl onginc)YEL^YHT lBlaCl .ngin.l | + I

{+l

SENSOR

1.5

- Tho MIL has boon roportod on.- Wirh tho SCS rhort connoctorconnectod lsoo pags 11-34),codo 3 b indicatsd.

Do the ECM Reset Procedure {soepage 11-35).

Intormittont tailuro, lystom ir Ol(at thls timo {tort drivo may bsnocessary).Chack to? Door connocllon oiloosa wiroa 6t C223 {locltod atright shock tow6rl, C'l 14 (MAP

sonaorl and ECM.

ls the MIL on and does it indi-cate code 3?

Turn the ignition switch OFF.

Disconnect the 3P connector tromthe MAP sensor,

Turn the ignition switch ON.

{To page 11-53)

11-52

Page 256 of 1413

PGM-FI System

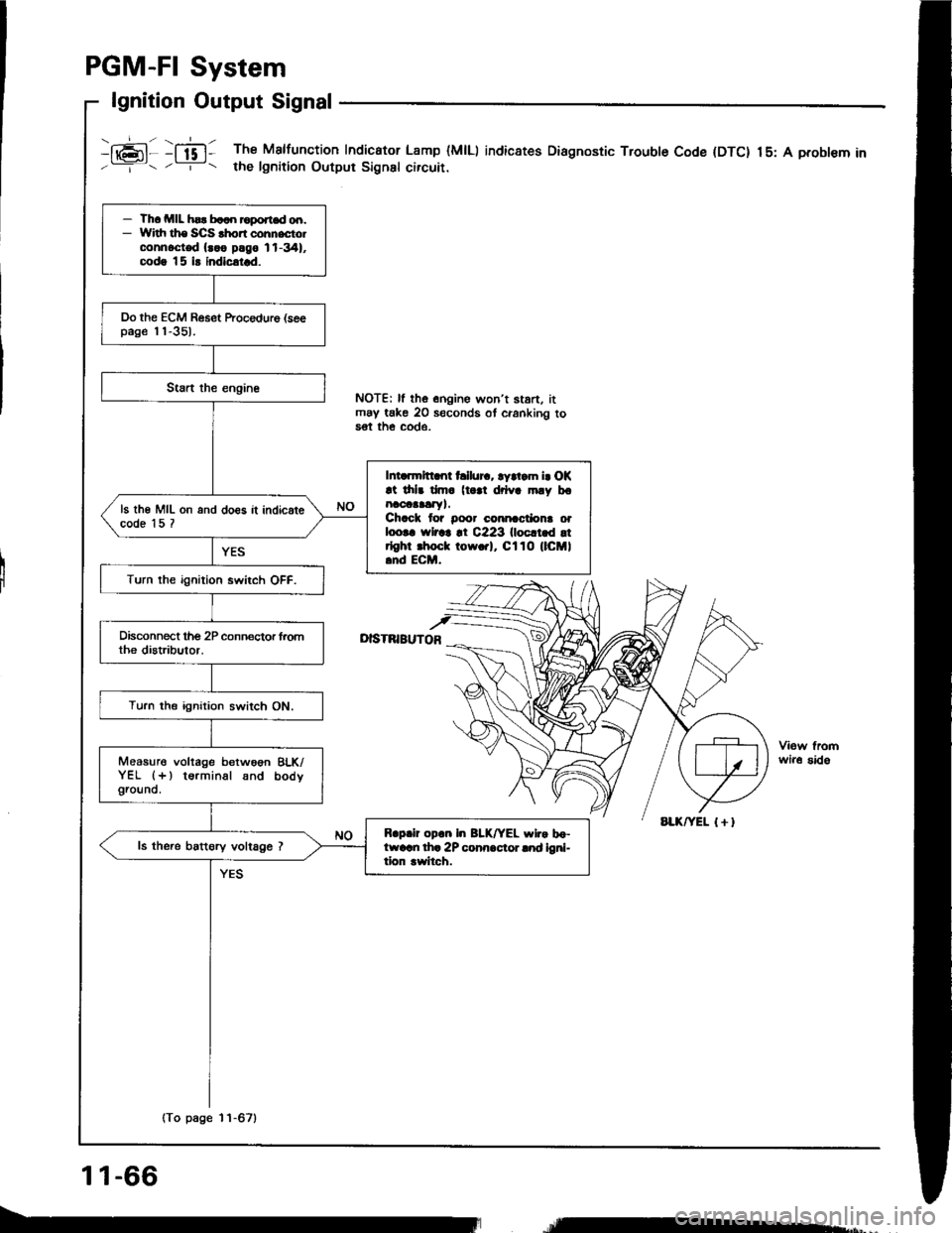

lgnition Output Signal

i16;11 :ffi1 The Malfunction Indicator Lamp (MlLl indic8tes Diagnostic Trouble Code (DTC) 15: A probl€m in'--=-- . -r- t the lgnition Output Signsl circuir.

I

NOTE| ll the onoine won't stan. itmay take 20 seconds ot cranking to5€t th€ COde.

D|STNIBUTOB

wir6 sido

- Th. MIL hsr b..n roport.d od.- Widr ths SCS .hon cohnecto.connoct€d {..o plgo 11-341,codg |5 i! indicatrd.

Do the ECM Reset ftocedure (seepage 'l'l-351.

Intarmltt nt hllur.. ryltam i. OK!t drlr dm. (t |l drlva mly bonaoaaalry).Chack tor Door cmnactiona orloo|. rYlrar !t C223 llocltld !trlghr .hoct tow.rl, Cl10 (lCMl.nd ECM.

ls th€ MIL on and do€s it indicatecode 15 ?

Turn the ignition swirch OFF.

Turn the ignition switch ON.

Measure voltage betwoon BLK/YEL (+) terminal snd bodygrouno.

R.p.ir op.n In BLK/YEL wlr. bo-ftvarn th. 2P conn.cior lnd ioni-tion rwitch.

ls the.e battory voltage ?

(To page 11-67)

11-66

re*,

Page 260 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With HONDA INTEGRA 1994 4.G Workshop Manual PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With](/img/13/6067/w960_6067-259.png)

PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With lho SCS lhon connectolconnoctod {ree pago 11-34}, cod.20 is indicatod.

Do the ECM B6set Procedurs {seepage 1 'l-35).

Start engine and keep engin€speed at idle.Turn on headlights.

lntennlna tlllure, lyrtom lt Ol(!t irl. dm. (lgtt driv. mly [email protected] for Door connactlona oaloota wiro. rt C218 IELD, lndEctrt.

Ooes the MIL indicato code 20?

Romove the undgr-hood fusg/relay box and remove the tus6/relav box lowet cover.

Turn lhe ignition switch ON.

Measure voltage betw€on BLK/YEL (+l terminal and BLK (-)terminal.

Msasuro voltag€ b€tweon BLK/Y€L {+) terminal snd bodvground.ls there bartory voltagel

Rcpir oo.n in BLK wir.batwaan lha 3P connrc-tor lnd G2Ol {loc.t.dtroit ot angh|. comprn-m.r dghl .ld.l,

B.p.lr op.n in BLKrYEL wlrr b.-tw..n o.24ACG (ALn flcl115A: Bl88l .ngln!, 20 A:818C1cnginol fu!. In thr und.r{..htu.o/r.lly bor lnd tho 3P con-rcclo?.

View tromwire side

BLK (-)

(To page 11-7'l)

GRn/iED I - |

BLK/YEL I + I

11-70

Page 916 of 1413

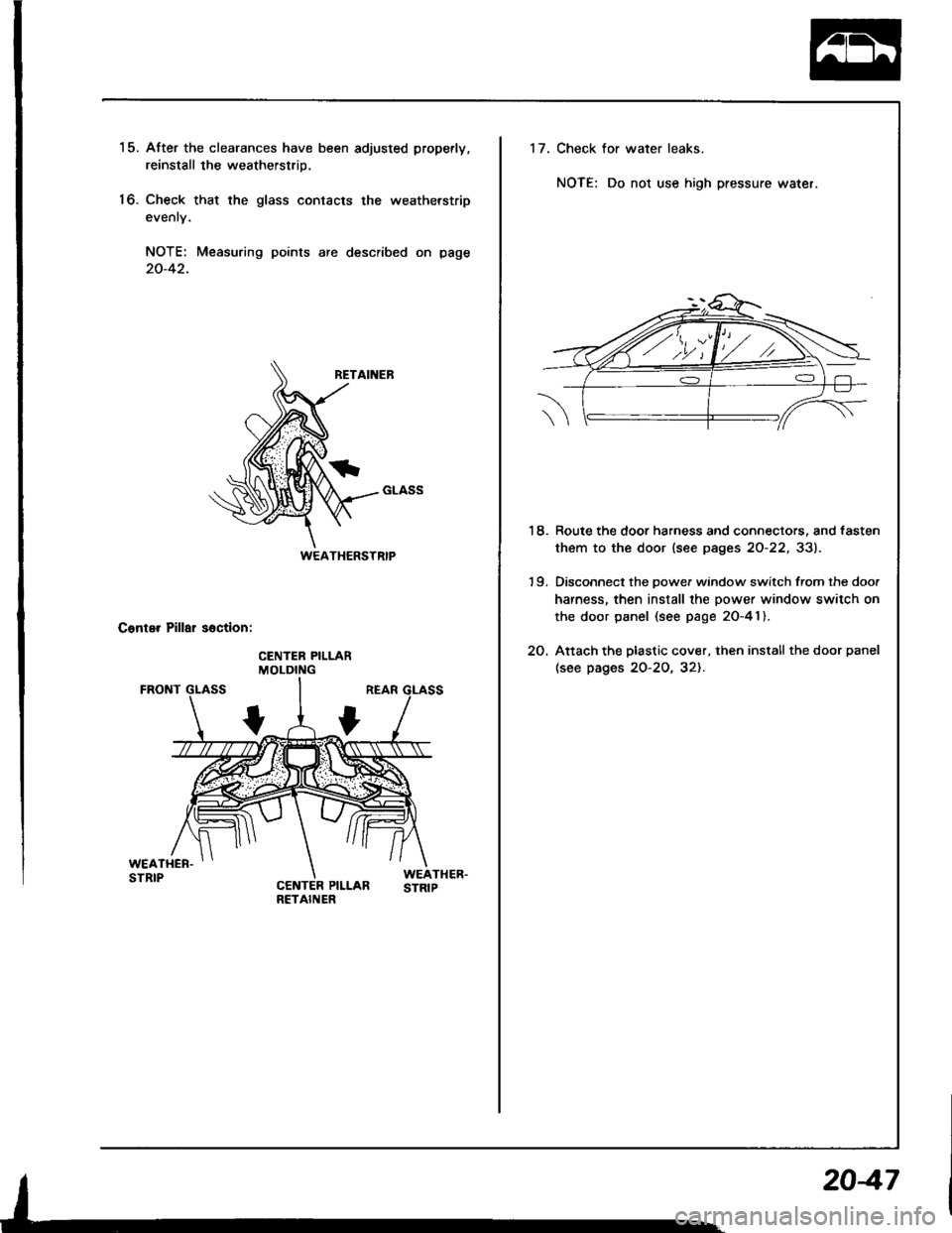

15. After the clearances have been adjusled properly.

reinstall the weatherstrip.

16. Check that the glass contacts the weatherstrip

evenly.

NOTE: Measuring points are described on page

20-42.

Conter Pillar soction:

WEATHERSTRIP

17.Check for water leaks.

NOTE; Do not use high pressure water.

18. Route the door harness and connectors, and fasten

them to the door (see pages 20-22, 331.

19. Disconnect the oowef window switch from the doo.

harness, then install the power window switch on

the door panel (see page 20-41).

2O. Attach the plastic cover, then install the door panel

(see pages 2O-2O, 321.

2047

Page 1038 of 1413

Heater

lflustrated Index ............. .........21-2

Heater Door Positions .........,..,. 21-3

Circuit Diagram ....................... 21-6

Troubleshooting

Symptom Chart ............. ......21-8

Flowcharts

Blower Motor Speed ............................... 21 -9

Bfower Motor .........,..,,,,,.. 21-11

Mode Control Moto. ............ ................... 21 -14

Recircufation Control Motor ......,...,.,,,.,.... 21 -17

Heater Control Panel Input/

Output Signals ..............21-19

Blower Unit

Repfacoment ....................... 21-20

Overhaul .......21-21

+Heater Unit

Repfacement ....................... 21-22

Overhaul .......21-24

Def roster Door Adjustment ...,............. ......,, 21 -25

Heatel Control Panel

Repfacoment ....................... 21-25

Overhaul .......21-26

Heater Valve Cable

Adjustment ...21-27

Air Mix Control Cable

Adjustment ... 21-27

Mode Control Motol

Test .............. ..................... 21-2e

Repfacement ..,..............,,,,.. 21-28

Recirculation Control Motor

Test .............. ..................... 21-29

Repfacement ....................... 21-29

Relay

Test .............. ..................... 21-30

Heater Fan Switch

Test .............. ..................... 21-30

Mode Control Switch

Test .............. ..................... 21-31

Recilculation Control Switch

Test .............. ..................... 21 -31

*: Read SRS precautions before working in this area.

Page 1062 of 1413

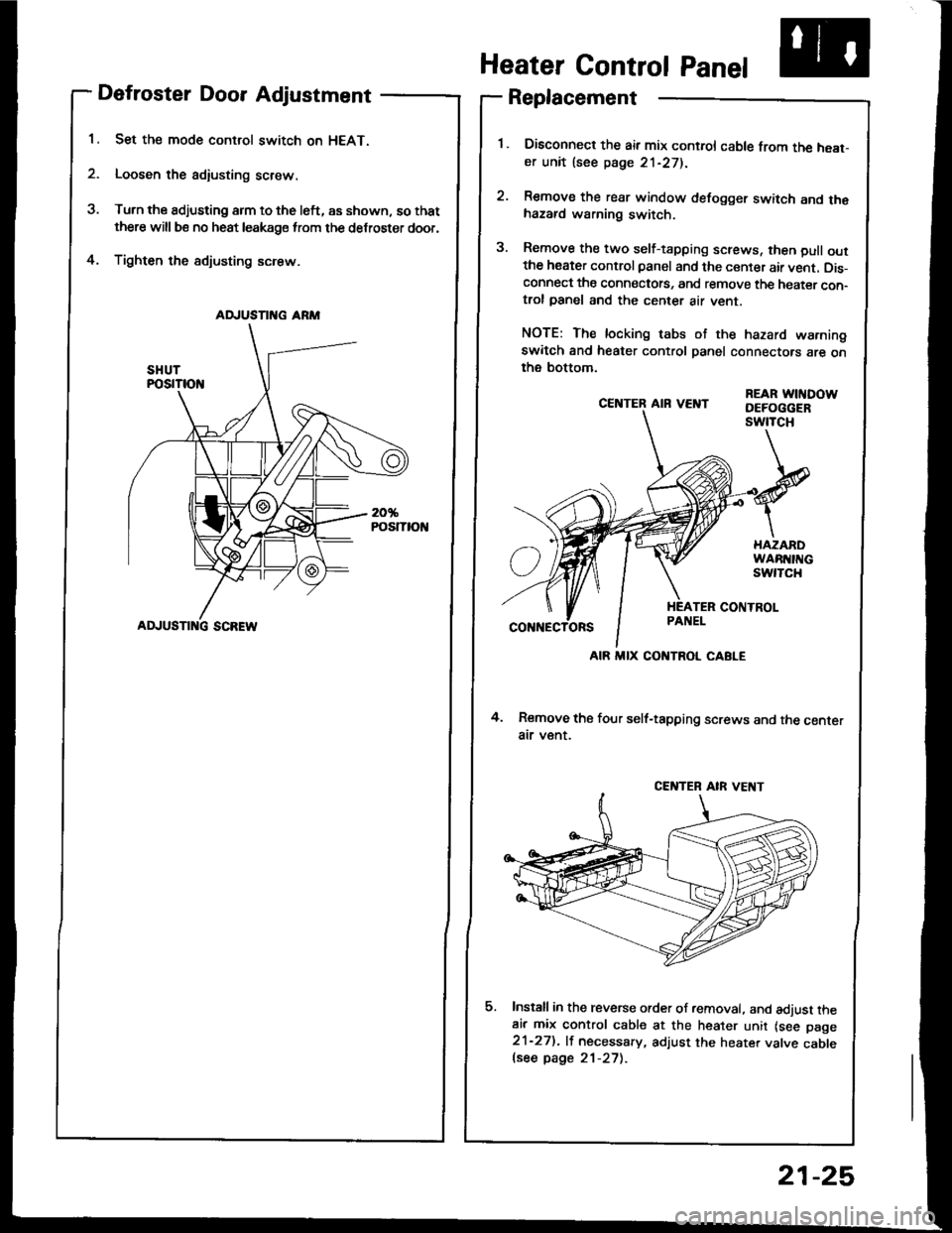

Defroster Door Adjustment

Set the mode control switch on HEAT.

Loosen the adiusting screw.

Turn the adjusting arm to the left, as shown, so that

there will be no heat leakage from the defroster door,

Tighten the sdjusting screw.4.

CE]TTER AIR VEI{T

4. Remove the four self-tapping screws and the centerair v€nt.

Install in the reverse order of removal. and adjust theair mix control cable at the heater unit lsee page21-27). lf necessary, adjust the heater valve cablelsee page 21-27).

REAR WITIDOWDEFOGGERswtTcH

Heater Control Panel

Replacement

Disconned the air mix control cable from the heat-er unit lsee page 21-271.

Remove the rear window defogger switch and thehazard warning switch.

Remove the two self-tapping screws, then pull outthe heater control panel and the center air vent. Dis-connect the connectots, and remove the heater con-trol panel and the center air vent.

NOTE: The locking tabs of the hazard warningswitch and heater control panel connectors are onthe bottom.

AD.'USTII{G ARM

ADJUSTI G SCREW

AIR MIX CONTROL CABLE

CENTEB AIR VE T

21-25

Page 1092 of 1413

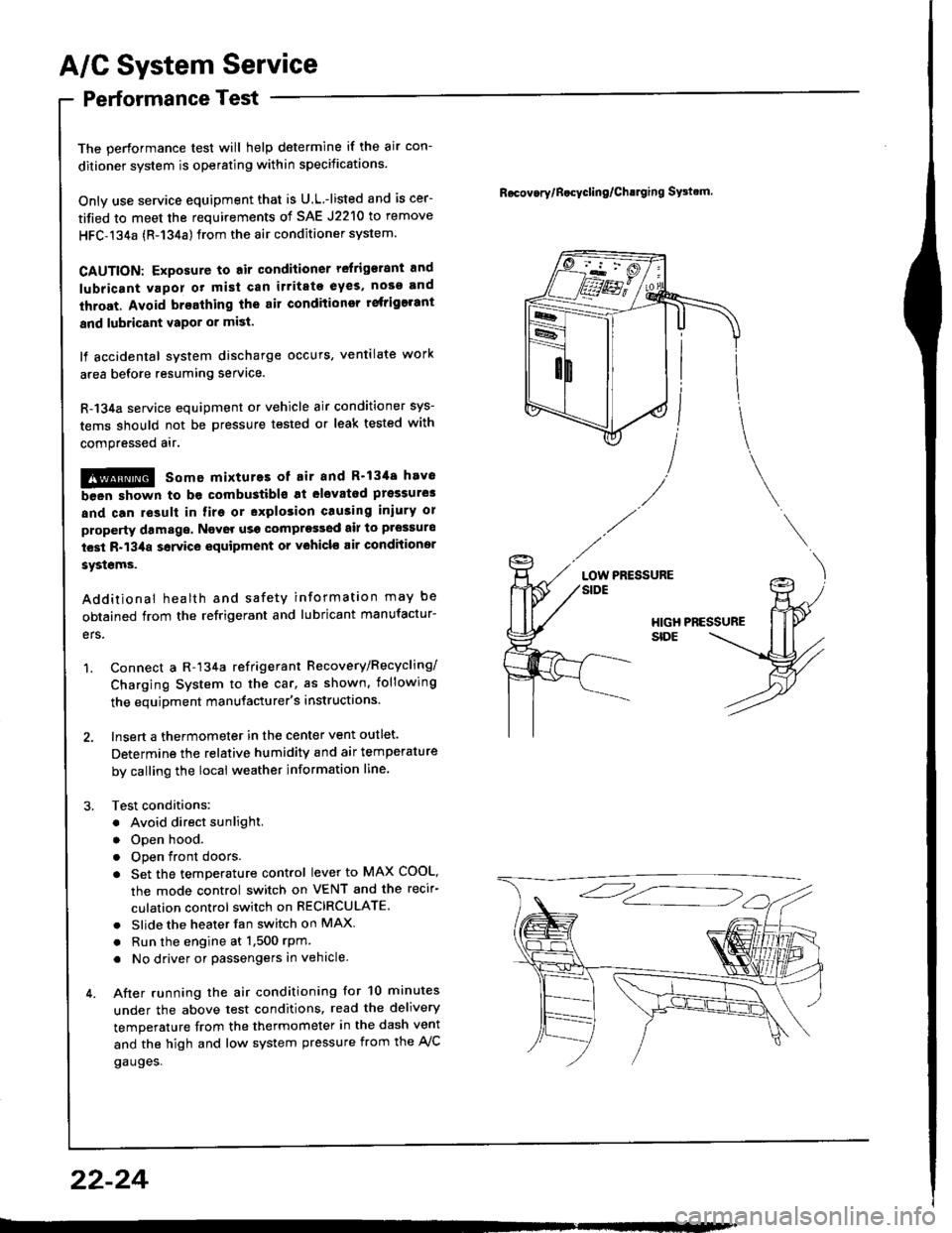

A/G System Service

Performance Test

The performance test will help determine if the air con-

ditioner system is operating within specitications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a {R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner relrig€rant and

lubricant vapor ot mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner rstrigerant

and lubricant vapor or mi3t.

It accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comPressed atr.

!@ some mixtures ot air and R'1344 hrv6

been shown to be combustibls at elovatod prsssurel

and can result in firg or explosion causing iniury 01

property damage. Ngvor usg compregsed ail to prossuro

t€st R-134a ssrvice equipment or vohicl€ air conditioner

syst€ms.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the car, as shown, iollowing

the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air temperature

by calling the local weather information line,

3. Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open front doors

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.

. Slide the heater fan switch on MAX

. Run the engine at 1,500 rPm

. No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions. read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A,/C

gauges.

Rocov.rylB.cycling/Ch!lging SFtrm.

PRESSURELOW

22-24

Page 1107 of 1413

Electrical

Special Tools

Troubleshooting

Tips and Precautions ................................ 23-3Five-stop Tloubleshooting ..............,...-..-... Z3-sSchematic Symbols ................................_. 23-6wire Color Cod€s ..................................... 23-6Relay and Control Unit Locations

Engine Compartment .........,............ ... --. 23-7Dsshboard and Door ..,,......................... 23-gDashboard and Floor ............................. 23-t OOuaner Panel .....-.....23-12Connector ldentification and WireHarness Routing ........ 23-i 3

Index to Circuits and Systems

Airbag ............... ...-..-... 2g-26sAir Conditioning ....,.. Section 2lAltelnator ......_.............. 23-99Anti-lock Brake Systsm (ABS) Section 19Automatic Transmission Section 14Battery .............. .......... 23-66Chafging System ........... 23-98rCigalstte Lighter .....................-...-......-..-.. Z3-2O4Cfock ................. ..........23-197rcruise Controf .......--..-... 23-242Distributor .................... 23-87Fan Controls ................. 23-1ogFuel and Emissions ... Section 1i*Fuses

Under-dash Fuse/Relay Box ................... 23-48Undor-hood ABS Fuse/Retay Box ............ 23-51Under-hood Fuse/Relay Box,.................. 23-52rGauges

Engine Coolant Temperature {ECT)Gauge ................ ..23-126Fuef cauge ............... 2g-123'Gauge Assembly ....--.23-113Speedometer .....-...,,. 23-114Tachometer .....,.....-.. 23-114Ground Distribution ........ 23-60Heater ,,,........,.... ..... Section 2lrHorn ................. ........... 23-199*fgnition Switch ............. 23-70fgnition Syst6m .......-..-.. 23-A7lgnition Timing .............. 23-89Indicator Lights"A/T Gear Position .............. ................... 23-1 32B1ak6 System ...,..,..-.23-127Engine Oil Pressura .............................. _ 23-1 51Low Fuel ............ ......23-125Malfunction Indicator Lamp {MlL} ...,,. Section I l

tfnteglated Control Unit ...29-144*lnterlock System ...................................... 23-1 3gLights, Exteriol

Back-up Lights ........... 23-179Brake Lights .............. 23-t8ltDaytime Running Lights {Csnada} ........... 23-156Front Palking Lights ............................. 23-1 65Flont Side Marker Lights ....................... 23-165Front Turn Signal Lights ........................ 23-1 65*Hazard Warning Lights .........................- 2g-1A4Headlights ................. 23-t6tLicense Plate Lights .............................. 23-1 69Taillights(Harchback) .......... 23-166

{Sedan) .............. .. 23-167Lights. Inteliol

Cargo Area Light {Hatchback) ...... -.. -.. -... 23-177Ceifing Light ........-..-.23-175

Dash Lights Blightness Controt .............. 23-t70Glove Box Lighr ................................... 23-1 69Spotfighr ............ ....-.23-174Trunk Light (Sedanl ............... .............. - 23.-177*Lighting Sysrem .......-.-... 23-152:Moonroof ,,.,.......,..,,,,,.-.23-211PGM-FI Systom ........ S€crion 11Power Distribution .,.-..--..23-54Power Door Locks .............,,..................... 23-233Power Mirors ..,..,....-...- 23-216Power Relays ...........,..... 23-68Power Windows ............ 29-222*Rear Window Defogger ........,... ..........,..... - 23-20,6Reminder Systems

Key-in Remindel System ....,.............,.... 23-1 50Lights-on Reminder System ................... 23-l 5f*Maintenance Reminder system ..,,.... -.. - -. 23-.1 2gSeat Belt Reminder System ..................- 23-125*Side Markel/Turn Signal/Hazard

Ffasher System .,..,..-.23.-1A4Spark Pfugs .........-...-..... 23-97Starting System ....,,.....-. 23-73*Stereo Sound System ...,.......................,,.. 23-l gg

Supplemental Restraint System {SRS} ......... 23-265Vehicfe Speed Sensor {VSS) .............--..-.... 23-122*Wiper/Washer Systom ...............--.........-..- Zg-254

rRead SRS pi€cautions on Page 23-271 betore workingin these areas.

-+

Page 1134 of 1413

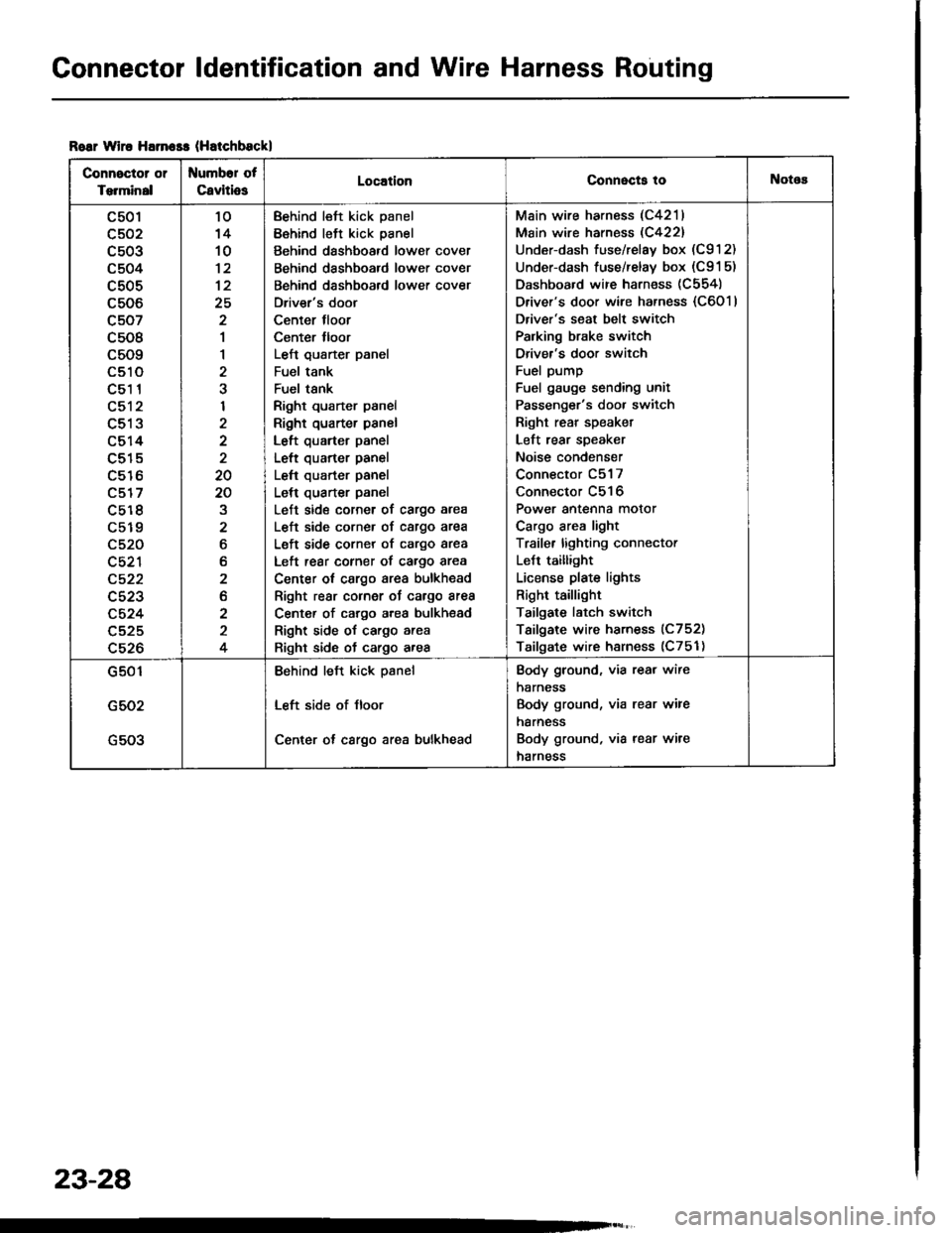

Connector ldentification and Wire Harness Routing

Roar wiro Harn$s (Hatchbsckl

Connector or

Torminal

Numbor of

CavitiosLocationConnecta tollotos

c501

c502

c503

c504

c505

c506

c507

c508

c509

LStt

c51 1

c512

c513

c514

c515

c516

c517

c5r 8

c519

c520

c521

c522

c523

c524

c525

c526

10'14

10

12

25

2

1

1

2

I

2

20

20

2

6

b

2

2

2

4

Behind left kick panel

Behind left kick panel

Behind dashboard lower cover

Behind dashboard lower cover

Behind dashboard lower cover

Driver's door

Center tloor

Center lloor

Left qusrter panel

Fuel tank

Fuel tsnk

Right quarter panel

Right quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left side corner of cargo area

L€ft side corner of cargo area

Left side corner of cargo area

Left rear corner of cargo area

Center ot cargo area bulkhead

Right rear cornor oJ cargo area

Center of cargo area bulkhsad

Right side of cargo area

Right side of cargo area

Main wire harness (C4211

Main wire harness (C422)

Under-dash fuse/relay box (C912)

Under-dash fuse/relay box (C91 5)

Dashboard wire harness (C554)

Driver's door wire harness {C6011

Driver's seat belt switch

Palking brake switch

Driver's door switch

Fuel pump

Fuel gauge sending unit

Passenger's door switch

Right rear speaket

Left rear speaker

Noise condenser

Connector C517

Connector C516

Power antenna motor

Cargo area light

Traile. lighting connector

LeJt taillight

License plate lights

Right taillight

Tailgate latch switch

Tailgate wire harness (C752)

Tailgate wire harness (C751)

G501

G502

G503

Behind left kick psnel

Left side of Jloor

Center ot cargo area bulkhead

Body ground, via rear wire

harness

Body ground, via rear wire

harness

Body ground, via rear wire

harness

23-28