rocker HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 19 of 1413

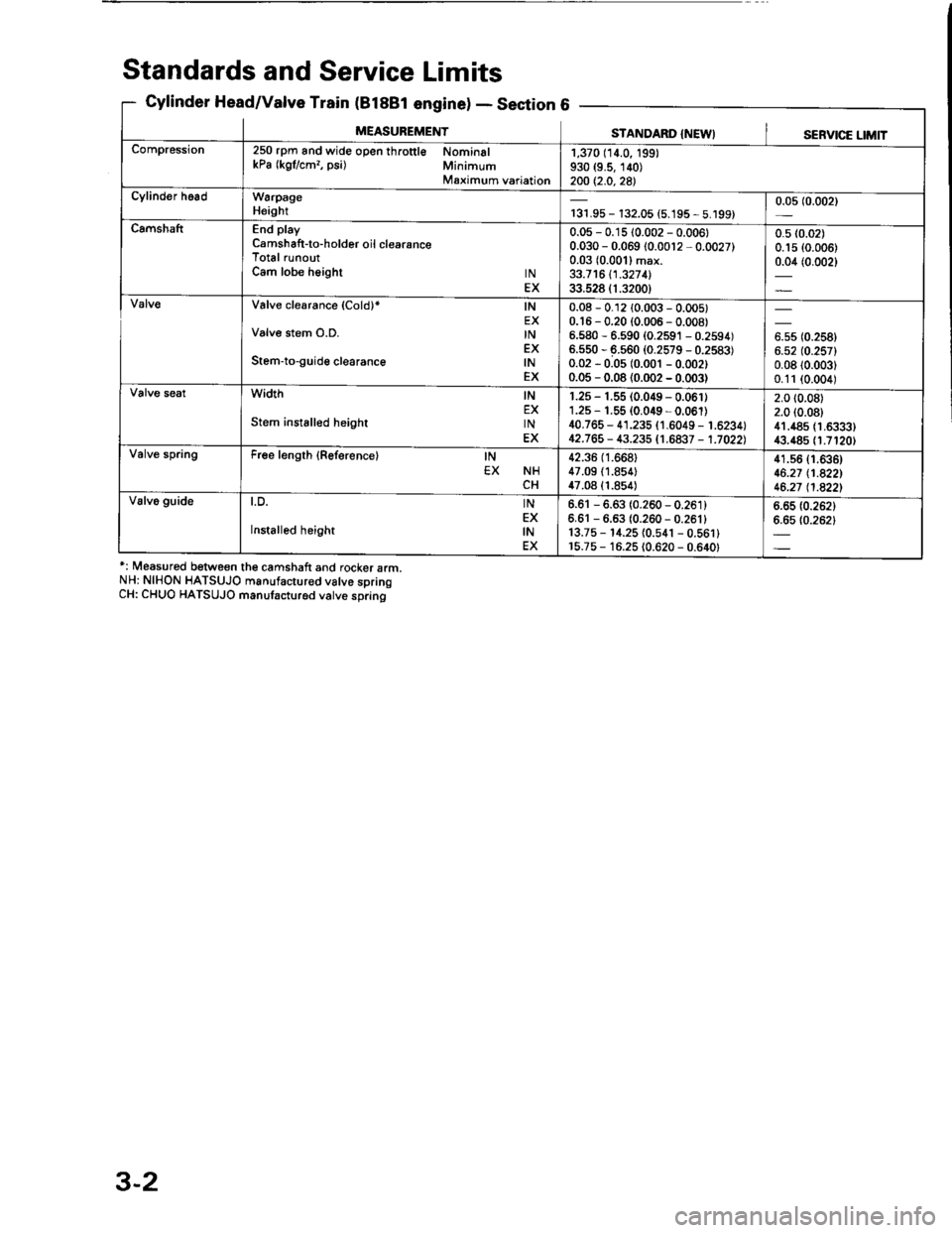

Standards and Service Limits

Cylinder Head/Valve Train (B188t enginelSecti6

*: Measured between the camshaft and rocker arm.

NH: NIHON HATSUJO manufactur€d valve spring

CH: CHUO HATSUJO manufacturod valve sDrino

- Declron

MEASUREMENTSTANDARD {NEWI '

SERVICE LIMIT

Compression250 rpm and wide open th.ottl€ Nominal

kPa (kgflcm?, psi) Minimum

Maximum variation

1,370 (14.0, 199)

930 (9.5, 140)

200 t2.0,2a)

Cylinder h.adW6rpage

Heightr31.95- 132.05 (5.195 - 5.199)

0.05 (0.002)

CamshaftEnd play

Camshaft-to-holder oil clearance

Total runout

Cam lobe height tN

EX

0.05 - 0.15 (0.002 - 0.0061

0.030 - 0.069 10.0012 - 0.0027)

0.03 (0.001) max.

33.7 16 11 .327 1l

33.528 (1.3200)

0.5 (0.02)

0.1s {0.006)

0.04 (0.002)

Valve clearance (Cold)* lN

EX

Valve stem O.D. tN

EX

Stem-to-guide clearance lN

EX

0.08 - 0.12 {0.003 - 0.005)

0.'r 6 - 0.20 (0.006 - 0.008)

6.580 - 6.590 (0.2591 - 0.2594)

6.550 - 6.s60 (0.2579 - 0.2583)

0.02 - 0.0s (0.001 - 0.002)

0.05 - 0.08 (0.002 - 0.003)

6.s5 (0.258)

6.52 (0.257)

0.0810.003)

0.11 (0.004)

width tN

EX

Stem instslled height tN

EX

r.25 - 1.55 (0.049 - 0.061)

1.25 - 1.55 {0.049 - 0.061)

40.765 - 41.235 (1.6049 - 1.6234)

12.763 - 43.235 t1,6a37 - 1.7022)

2.0 t0.08)

2.0 (0.08)

41.485 (1.6333)

43.485 (1.7120)

Valve springFree length {Reference} lN

EX NH

CH

42.36 (1.668)

47.09 {1.854}

47.08 (1.854)

41.s6 {1.636)

46.27 tl.A22l

46.21 l1.a22l

Valv6 guideLu. lN

EX

Installed height lN

6.61 - 6.63 (0.260 - 0.261)

6.61 - 6.6s (0.260- 0.261)

13.75 - 14.25 {0.541 - 0.561}

r5.75 - 16.25 10.620 - 0.640)

6.65 (0.262)

6.6510.2621

3-2

Page 76 of 1413

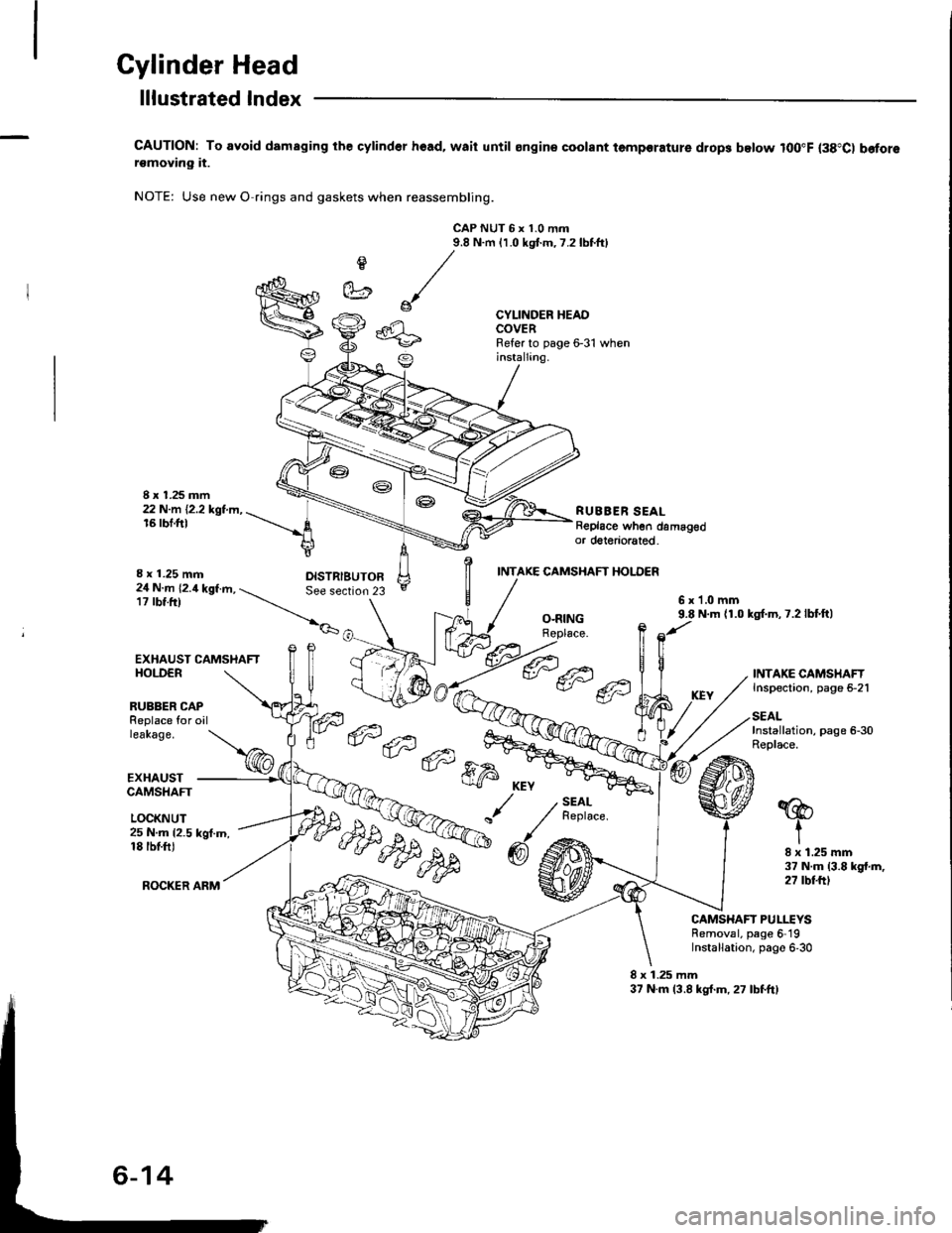

Cylinder Head

I x 1.25 mm22 N.m 12.2 kgt.m,16 rbf.ft)

lllustrated lndex

CAUTION: To avoid damaging the cylind6r hoad, waii until ongin€ coolant temporature drop3 below lOO"F (38"C) b€forersmoving it.

NOTE: Use new O rings and gaskets when reassembling.

CAP NUT 6 x 1.0 mtn9.8 N.m 11.0 kgtm,7.2lbtftl

e

et

CYLINDER HEADCOVERRefer to page 6-31 wheninstallang.

RUBBER SEALReplace when damagedor doteriorated.

I x 1.25 mm

EXHAUST CAMSHAFTHOI.DER

INTAKE CAMSHAFT HOI.DER

24 N.m 12.4 kgf.m, -. See section17 rbt.tr) --_r,_

__.|._6x1.0mm9.8 N.m {1.0 kgl.m,7.2lbf.ft)O-RINGRoplace.

RUBBER CAPReplace for oilleakage.

EXHAUSTCAMSHAFT

LOCKNUT

INTAKE CAMSHAFTInspection, page 5-21

SEALInstallation, page 6-30Replace.- 6tal --,

ffi;r

KEY

/./

"

@6

SEALReplace.'@

t25 N.m {2.5 kgf.m,18 tbtfiJ

ROCKER ARM

I x 1.25 mm37 N.m (3.8 kgt.m,27 rbtftt

CAMSHAFT PULLEYSRemoval, page 6 19Installation, page 6,30

8 x 1.25 mm37 N.m 13.8 kg{.m,27 lbfftl

Page 82 of 1413

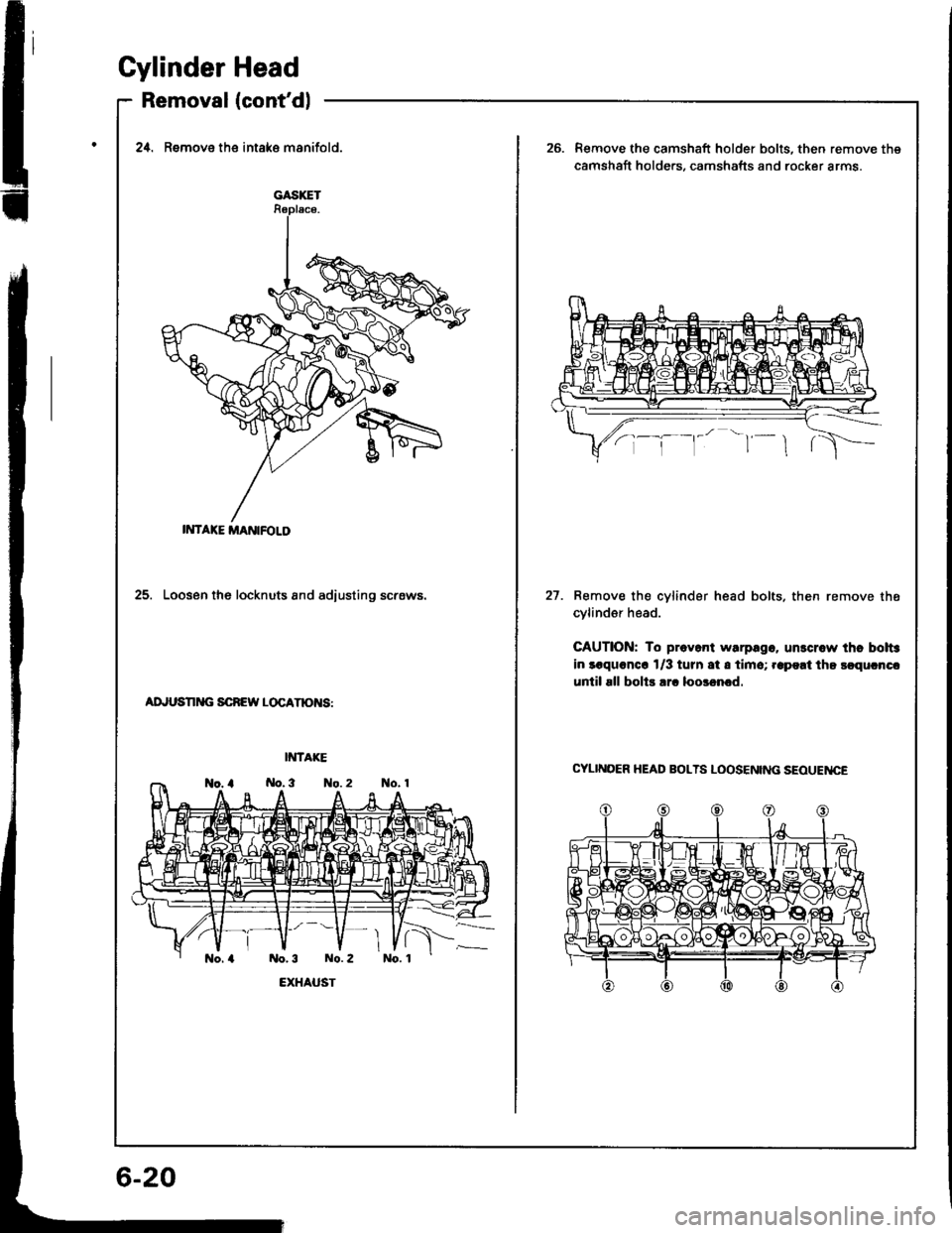

Cylinder

Removal

Head

(cont'dl

GASXET

IMTAXE MANIFOLD

2,0. Remove the intake msnifold.Remove the camshaft holder bolts, then remove the

camshaft holde.s. camshafts and rocker arms.

25. Loosen the locknuts and adiusting screws.27. Remove the cylinder head bolts. then remove the

cvlindsr head.

CAUTION: To preyant warpago. unlcr.w thc bolt3

in laquoncc 1/3 turn at I tim6; .apeat the $qurnca

until sll boltr arc loosrncd.

ADJUSNNG SCNEW LOCATN)NS:

CYLINOER HEAD BOLTS LOOSENING SEOUENCE

Page 83 of 1413

!

1.

2.

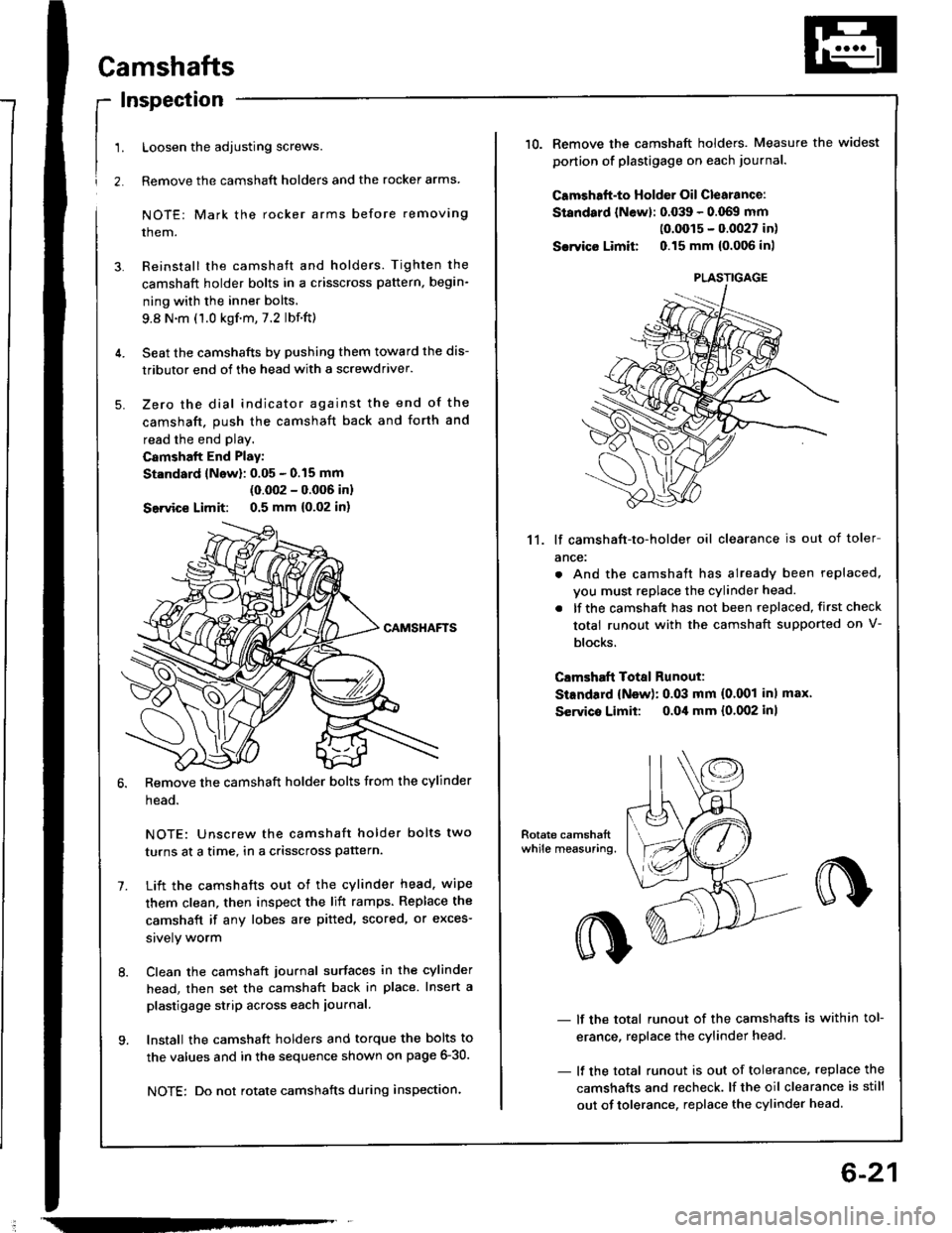

Camshafts

Inspection

Loosen the adjusting screws.

Remove the camshaft holders and the rocker arms

NOTE: Mark the rocker arms before removing

them.

Reinstall the camshaft and holders. Tighten the

camshaft holder bolts in a crisscross pattern, begin-

ning with the inner bolts.

9.8 N.m (1.0 kgf.m,7.2 lbf.ft)

Seat the camshafts by pushing them toward the dis-

tributor end of the head with a screwdriver.

Zero the dial indicator against the end of the

camshaft. push the camshaft back and forth and

read the end play.

Camshalt End Play:

St.ndard lNow): 0.05 - 0.15 mm

(0.002 - 0.006 inl

Seivice Limit: 0.5 mm {0,02 in)

Remove the camshaft holder bolts from the cylinder

head.

NOTE: Unscrew the camshaft holder bolts two

turns at a time, in a crisscross pattern.

Lift the camshafts out ot the cylinder head. wipe

them clean, then inspect the lift ramps. Replace the

camshaft if any lobes are pitted, scored, or exces-

srvely worm

Clean the camshaft journal surfaces in the cylinder

head, then set the camshaft back in place. Insert a

plastigage strip across each iournal.

Install the camshaft holders and torque the bolts to

the values and in the sequence shown on page 6-30.

NOTE: Do not rotate camshafts during inspection.

-

6-21

10.Remove the camshaft holders. Measure the widest

ponion of plastigage on each journa..

Camshaft-to Holder Oil Clearance:

Standard lNewl: 0.039 - 0.069 mm(0.0015 - 0.0027 in)

Sarvico Limit 0.15 mm {0.006 inl

11. lf camshaft-to-holder oil clearance is out of toler

ance:

. And the camshaft has already been replaced,

vou must replace the cylinder head.

. lf the camshaft has not been replaced, first check

total runout with the camshaft supported on V-

blocks.

Clmshaft Total Runout:

StEndard {New): 0.03 mm (0.001 inl max'

Servico Limit: o.Oil mm {0.002 inl

- lf the total runout of the camshafts is within tol-

erance, replace the cylinder head.

- lf the total runout is out of tolerance, replace the

camshafts and recheck. lf the oil clearance is still

out of tolerance. replace the cylinder head.

PLASTIGAGE

Page 91 of 1413

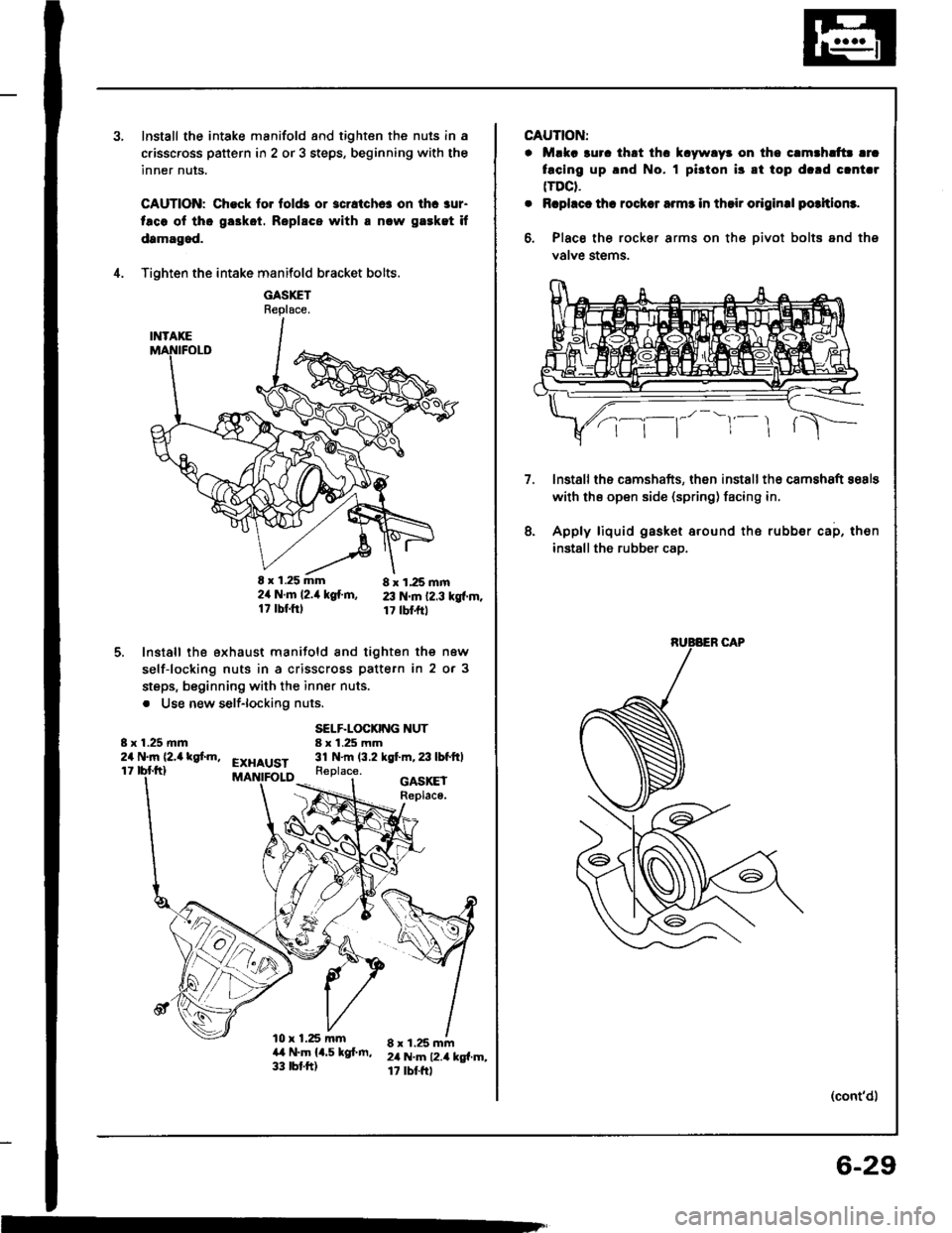

Install the intake manifold and tighten the nuls in a

c.isscross pattern in 2 or 3 steps, beginning with the

inner nuts.

CAUTION: Check to. fold3 or 3cratchc! on ihc aur-

taco ol tho ga3kot. Roplscs with a nlw gaeket if

damagod.

Tighten the intake manifold bracket bolts.

GASXETReplace.

E x 1.25 mm 8 x 1,25 mm2ir N.m l2.it kg{.m, 23 N.m 12.3 kgf.m.17 tbf.ftl 17 tbl.frt

Install the exhaust manifold and tighten the new

self-locking nuts in a crisscross pattern in 2 or 3

steps, beginning with the inner nuts.

. Use new self-lockiflg nuts.

4.

5.

8 x 1.25 mm24 N.m (2,a kgf.m,

SELF.LOCKING NUT8 x 1.25 mm31 N.m (3.2 kgt m,23lbfftlEXHAUST11Replace.

l0 x 1.25 mma,t N.m 14.5 kgf.m,33 tbt.ft)

GASKEIReplace.

8 x 1.25 mm2il N.m 12.4 kg{.m,17 rbtftl

m

CAUTION:

. Mlka 3uro thrt thc k.ywlyr on tho c.mthlttr lrc

facing up .nd No. I pi3ton i3 8t top d.rd clnt.r(TDCt.

. Rcphct th! rocksr armr in thsir o.iginal potltlom.

6, Place the rocker arms on the oivot bolts and ths

valve stems.

lnstallths camshafts, then installth€ camshaft sosls

with ths open side (spring) facing in.

Apply liquid gasket around the rubber cap, then

installthe rubber cao.

7.

8.

(cont'd)

6-29

Page 92 of 1413

Cylinder Head

Installation (cont'dl

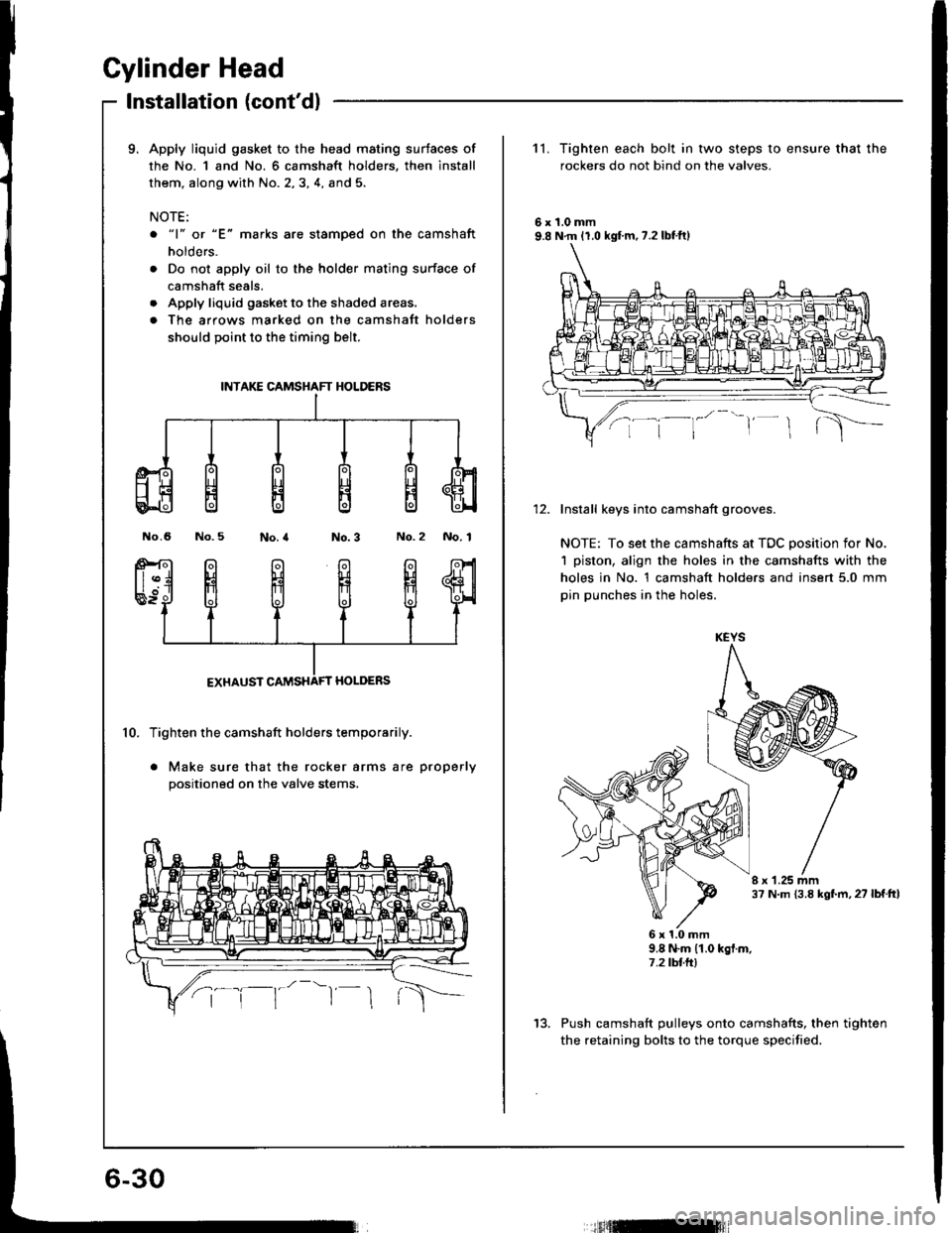

9. Apply liquid gasket to the head mating surtaces of

the No. 1 and No. 6 camshaft holders, then install

them, along with No. 2,3, 4, and 5.

NOTE:

o "1" or "E" marks are stamoed on the camshaft

holders.

. Do not apply oil to the holder mating surface of

camshaft seals.

. Apply liquid gasket to the shaded areas.

. The arrows marked on the camshatt holders

should point to the timing belt.

No.6 No.5No.2 No. 1

10. Tighten the camshaft holders temporarily.

. Make sure that the rocker arms are properly

positioned on the valve stems.

INTAKE CAMSHAFT HOLDERS

11. Tighten each bolt in two steps to ensure that the

rockers do not bind on the valves.

6r1.0mm9.8 N.m 11.0 kgf.m,7.2lbtft)

Install keys into camshaft grooves.

NOTE: To set the camshafts at TDC position for No.

1 piston, align the holes in the camshafts with the

holes in No. 1 camshaft holders and insert 5.0 mm

pin punches in the holes.

I r 1.25 mm37 N.m {3.8 kgf.m, 27 lbf.ttl

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbtft)

Push camshaft pulleys onto camshafts, then tighten

the retaining bolts to the torque specified.

KEYS

13.

tfitml

Page 95 of 1413

Cylinder Head/Valve Train

818C1 engine

Special Tools ............. 6-34

wEc

Troubleshooting Flowchart

WEC Solenoid Valve ................... 6-36

VTEC Pressure Switch ................. 6-38

VTEC Solenoid Valve Inspection .... 6-41

Rocker Arms

Manual Inspection .....,................. 6-42

Inspection Using Special

Tools ....................................,.....,.. 6-/|i|

Valve Glearance

Adiustment ............ 6-44

Timing Belt

lllustrated 1ndex ............................... 6-46

Inspection .............. 6-48

Tension Adiustment ........................ 6-48

Removal ................. 6-4{l

lnstallation ............. 6-51

Crankshaft Pulley Bolt

Replacement .........6-47

Cylinder Head

lllustrated Index ............................... 6-53

Removal .................6-55

Warpage ................6-74

lnstallation ............. 6-75

Rocker Arms

Removal ................. 6-60

Location ................. 6-61

lnspection .............. 6-62

Arm-to-Shaft G|earance .................. 6-63

Installation ............. 5-64

Camshafts

Inspection .............. 6-65

Valve Guides

Valve Movement .............................. 6-70

Replacement .........6-71

Reaming ................. 6-72

Valve Seals

Reconditioning ......6-73

Valves. Valve Springs and Valve Seals

Removal ................. 6-67

lnstallation Sequence ..........,.......,... 6-69

Valve lnstallation ............................. 6-70

Page 103 of 1413

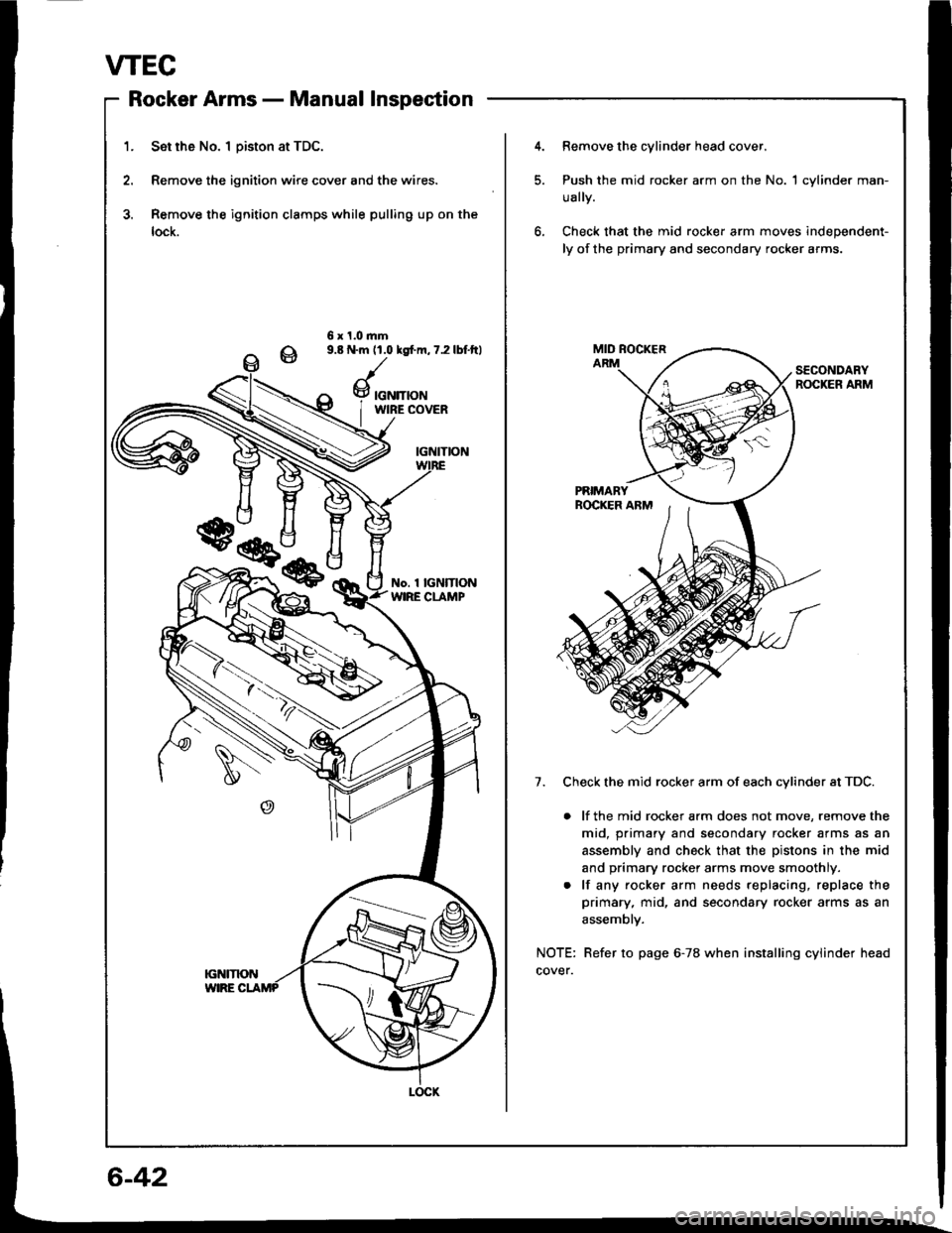

VTEC

Rocker Armsnlrungf rtrrrri' - rYrorrtrcr rrrDPEUtrl,rl

1. Set rh6 No. I Diston at TDC.

2. Remove the ignition wire cover and the wires.

3. Remove the ignition clamps while pulling up on the

lock.

4.Remove the cylinder head cover.

Push the mid rocker arm on the No. 1 cylinder man-

ually.

Check that the mid rocker arm moves independent-

ly of the primary and secondary rocker arms.

6 x 1.0.nm9.8 N.m 11.0 lgfm, 7.2 lbf.ftl

SECONDARYROCKER ARM

7. Check the mid rocker arm of each cvlinder at TDC.

. lf the mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

. lf any rocker arm needs replacing, replace the

primary, mid, and secondary rocker arms as an

assemblv.

NOTE: Refer to page 6-78 when installing cylinder head

cover.

w

Page 104 of 1413

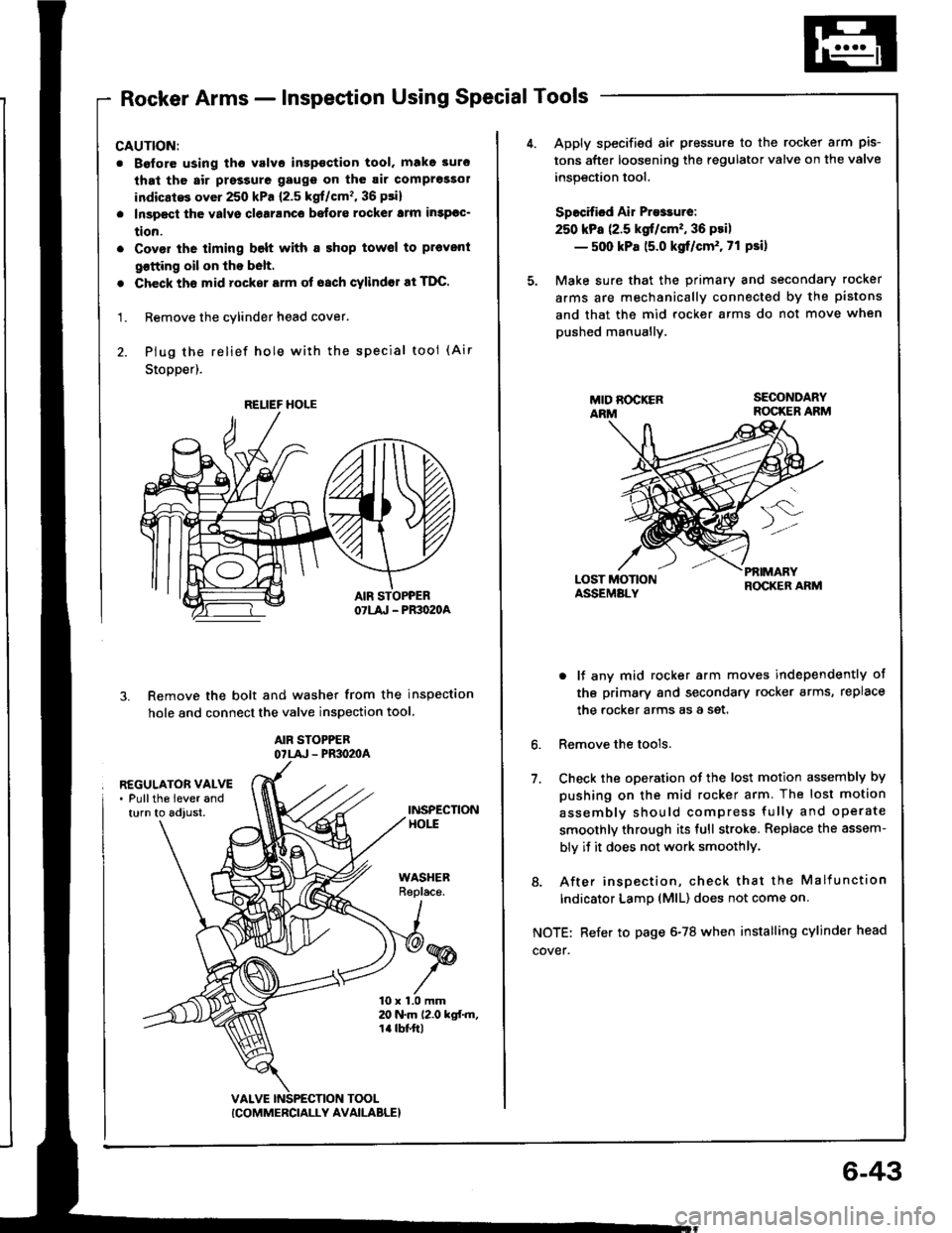

Rocker Arms - Inspection Using Special Tools

CAUTION:

. Boforo using tho valvo inspoction tool. make 3uro

that th6 air prsssure gaugs on th6 air comprossol

indicatG over 250 kPa {2.5 kgf/cm'�, 36 psi}

. Inspect the valvs clearanco befors rockel lrm insPoc-

tion.

. Covor the timing belt with a shop towsl to pl€vent

qotting oil on lhe b6lt.

. Check ths mid rocker srm of oach cylindor at TDC.

1. Remove the cylinder head cover.

2. Plug the relief hole wiih the special tool (Air

Stopper).

Remove the bolt and washer from the inspection

hole and connect the valve inspection tool

AIR STOPPEBOTLA' - PR3O2OA

3.

REGULATOR VALVE. Pullths lever andturn to adjust.INSPECTIONHOtt

WASHERReplace.

10 x 1.0 mm20 N.m 12.0 kgf.m,1a tbt'ft|

TOOL

RELIEF HOLE

ICOMMERCIALLY AVAILABLE}

6-43

Apply specified air pressure to the rocker arm pis-

tons after loosening the regulator valve on the valve

inspection tool.

Specified Air Presrure:

250 kPa (2.5 kgt/cm'�, 36 psi)

- 500 kPa 15.0 kgf/cm'. 71 Psi)

Make sure that the primary and secondary rocker

arms are mechanically connected by the pistons

and that the mid rocker arms do not move when

pushed manuallv.

LOST MOTIONASSEMALY

PfiIMARYROCKER ARM

6.

7.

o lf any mid rocker arm moves independently of

tho primary and secondary rocker arms, replace

the rocker arms as a set.

Remove the tools.

Check the oDeration of the lost motion assembly by

pushing on the mid rocker arm. The lost motion

assemblv should compress fully and operate

smoothly through its full stroke. Replace the assem-

bly if it does not work smoothlY.

8. After insoection, check that the Malfunction

Indicator LamD (MlL) does not come on

NOTE: Refer to page 6-78 when installing cylinder head

cover.

Page 115 of 1413

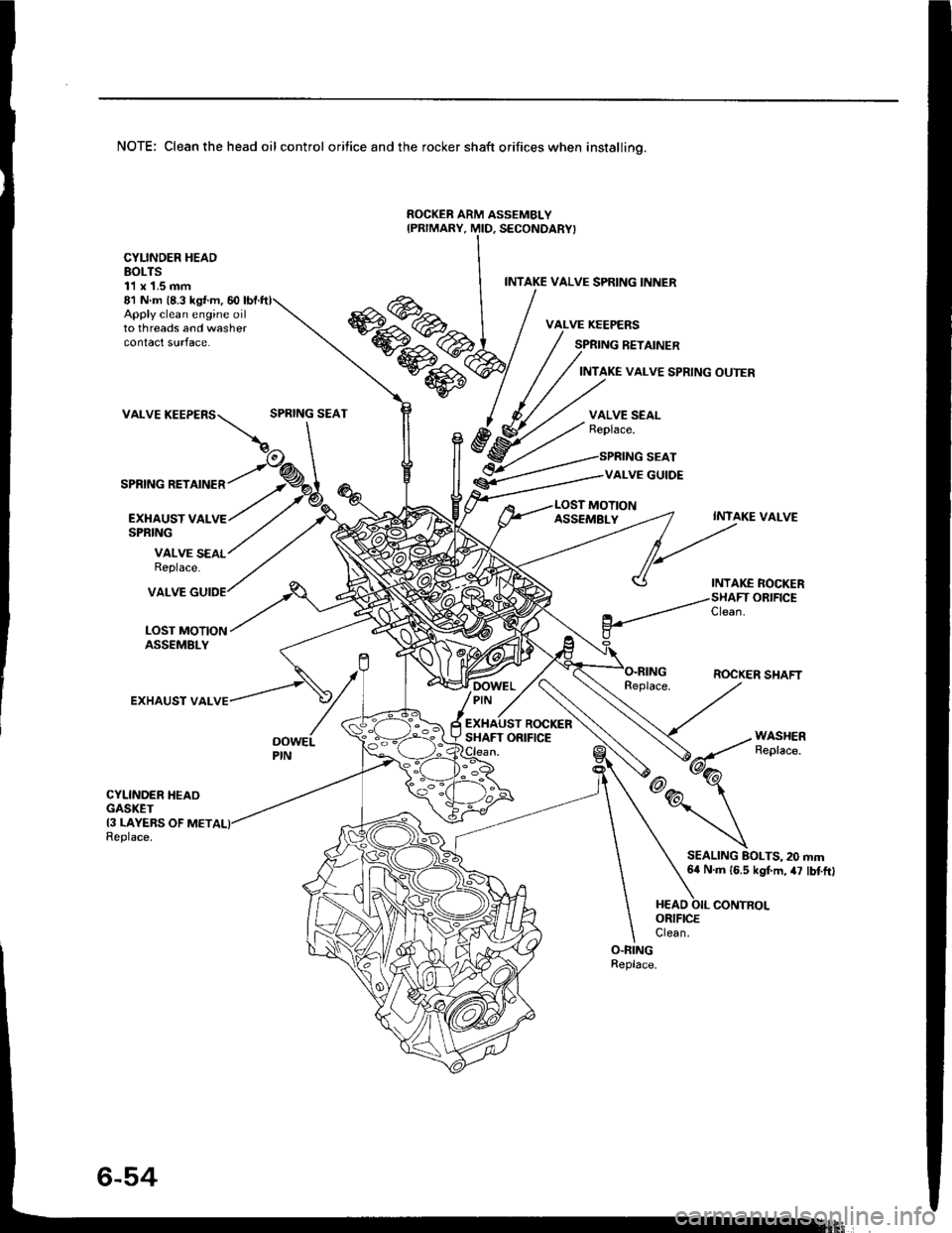

NOTE: Clean the head oil control orifice and the rocker shaft orifices when installino.

ROCKEB ARM ASSEMBLY

Apply clean engine oilto threads and washercontact surface.

81 N m (8.3 ks{ m, 60

VALVE

SPRING RETAINER

CYLINDER HEADBOLTS11 x 1.5 mm

EXI{AUST VALSPRING

INTAKE VALVE SPRING INNER

SPRING RETAINER

INTAKE VALVE SPRING OUTER

SPRING SEATVALVE SEALReplace.

SPRING SEAT

VALVE GUIDE

MOTION

VALVE SEALReplace.

ASSEMBLYINTAKE VALVE

INTAKE ROCKERORIFICE

LOST MOTIONASSEMBLY

VALVE

EXHAUST VAL

Clean.

ROCKER SHAFTDOWELPIN -,

ROCKERSHAFT ORIFICEOOWELPIN

CYLINDER HEAOGASKET13 LAYEBS OF METReplace.

SEALING BOLTS, 20 mm64 N.m 16.5 kgf.m, 47 lbtftl