ground HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1123 of 1681

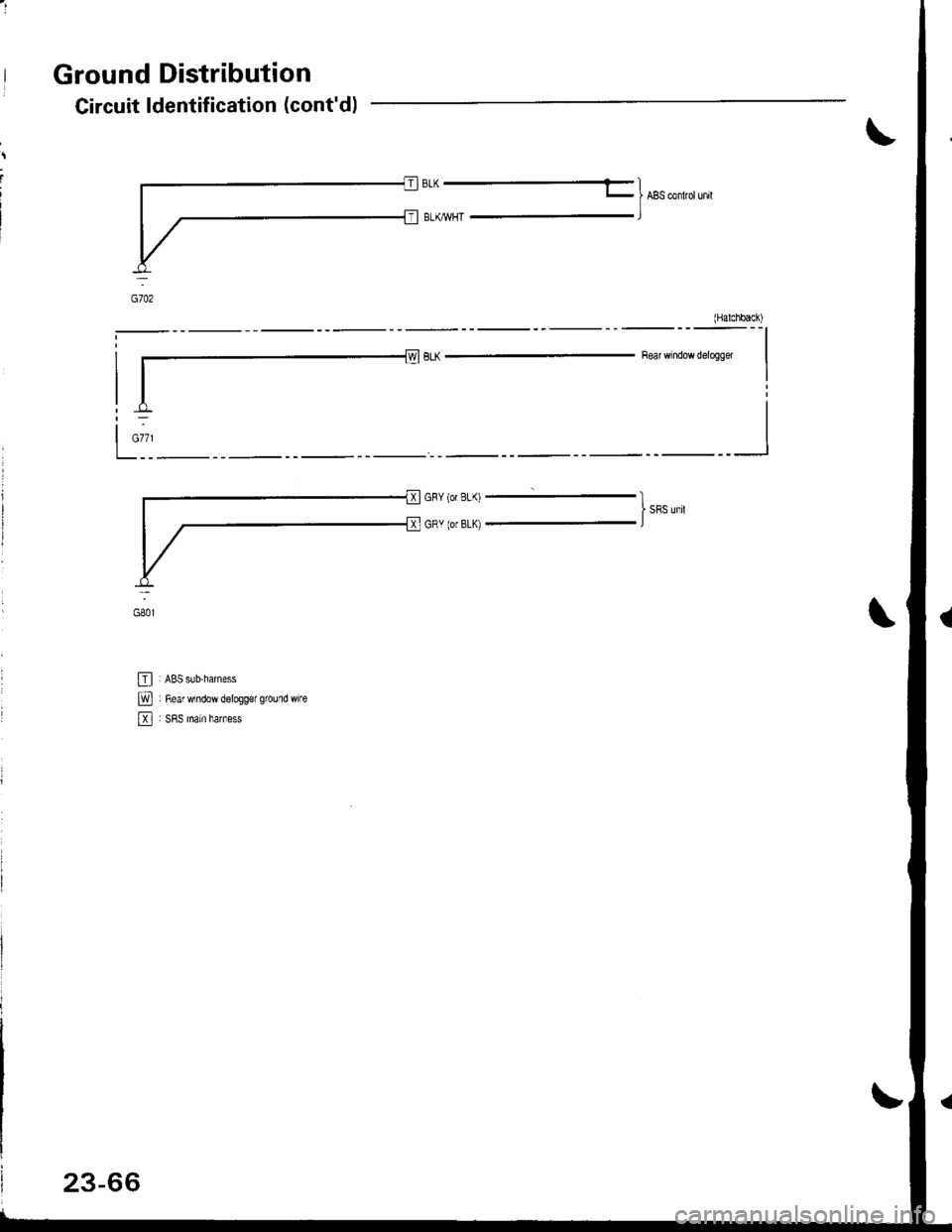

Ground Distribution

Circuit ldentification (cont'd)

BLK-lr- | A8S controlunrt

8LK,ryHT - J

i ,., *n

out

E ABssub'hamess

B : Rear wlndow delogger ground wire

I : sRs main hamess

23-66

Page 1126 of 1681

1

I

PowerRelays

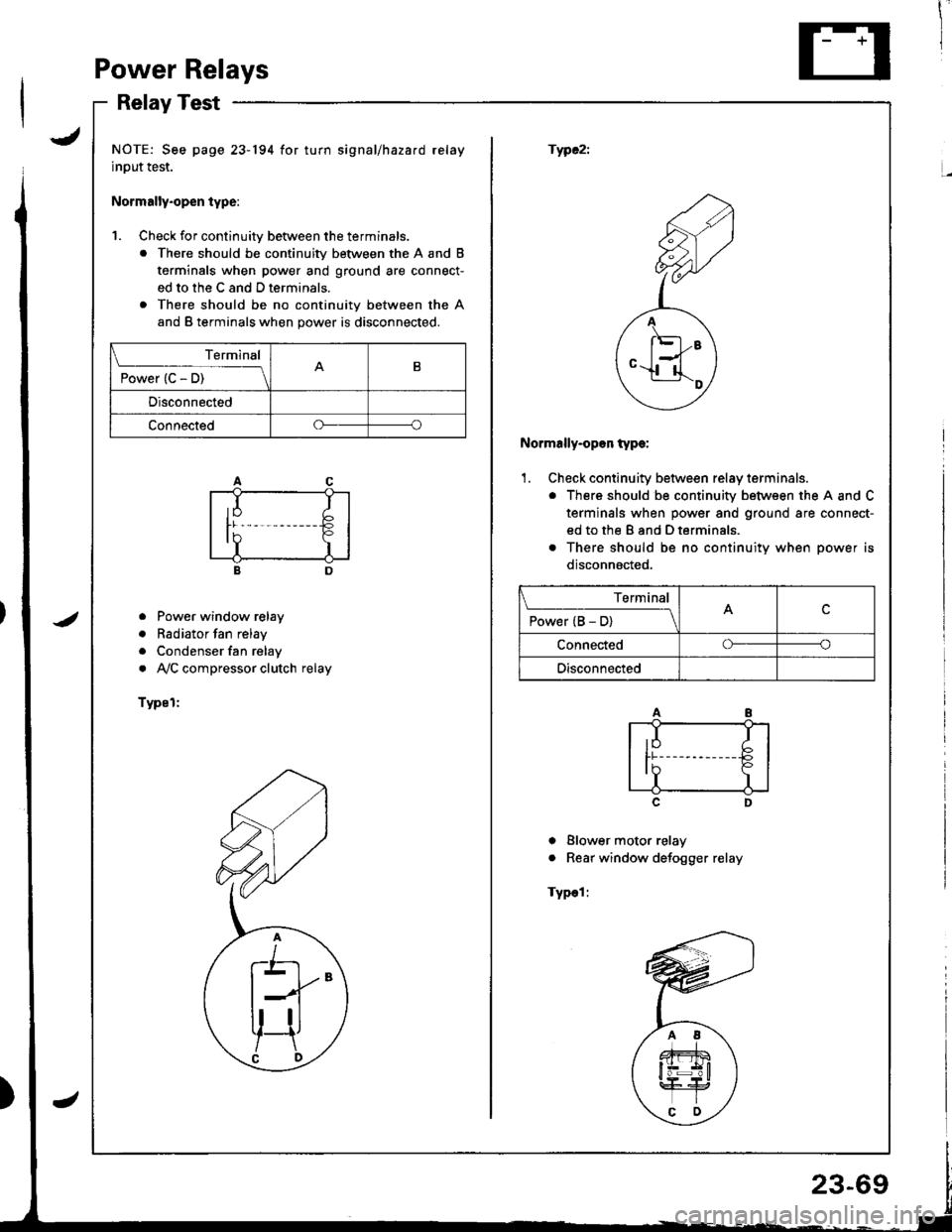

RelayTest

JNOTE: See page 23-194 for turn signal/hazard relay

input test.

Normally.open type:

fWC2i

1. Check for continuitv between the terminals.

. There should be continuity between the A and B

terminals when power and ground are connect-

ed to the C and D terminals.

. There should be no continuity between the A

and B terminals when power is disconnected.

<2

F;Z

,,A

/ l'El--E \

ey

Normally-opon type:

'1. Check continuity between relay terminals.

. There should be continuity between the A and C

terminals when power and ground are connect-

ed to the B and D terminals.

o There should be no continuitv when oower is

disconnacted,

o Power window relay

. Radiator fan relay

. Condenser fan relay

. AVC compressor clutch relay

Typel:

c

I Blower motor relay

. Rear window defogger relay

Typel:

Terminal

P";(c5t--__\B

Disconnected

Connectedoo

Terminal

P"*"r(B5-lc

Connectedoo

Disconnected

Page 1134 of 1681

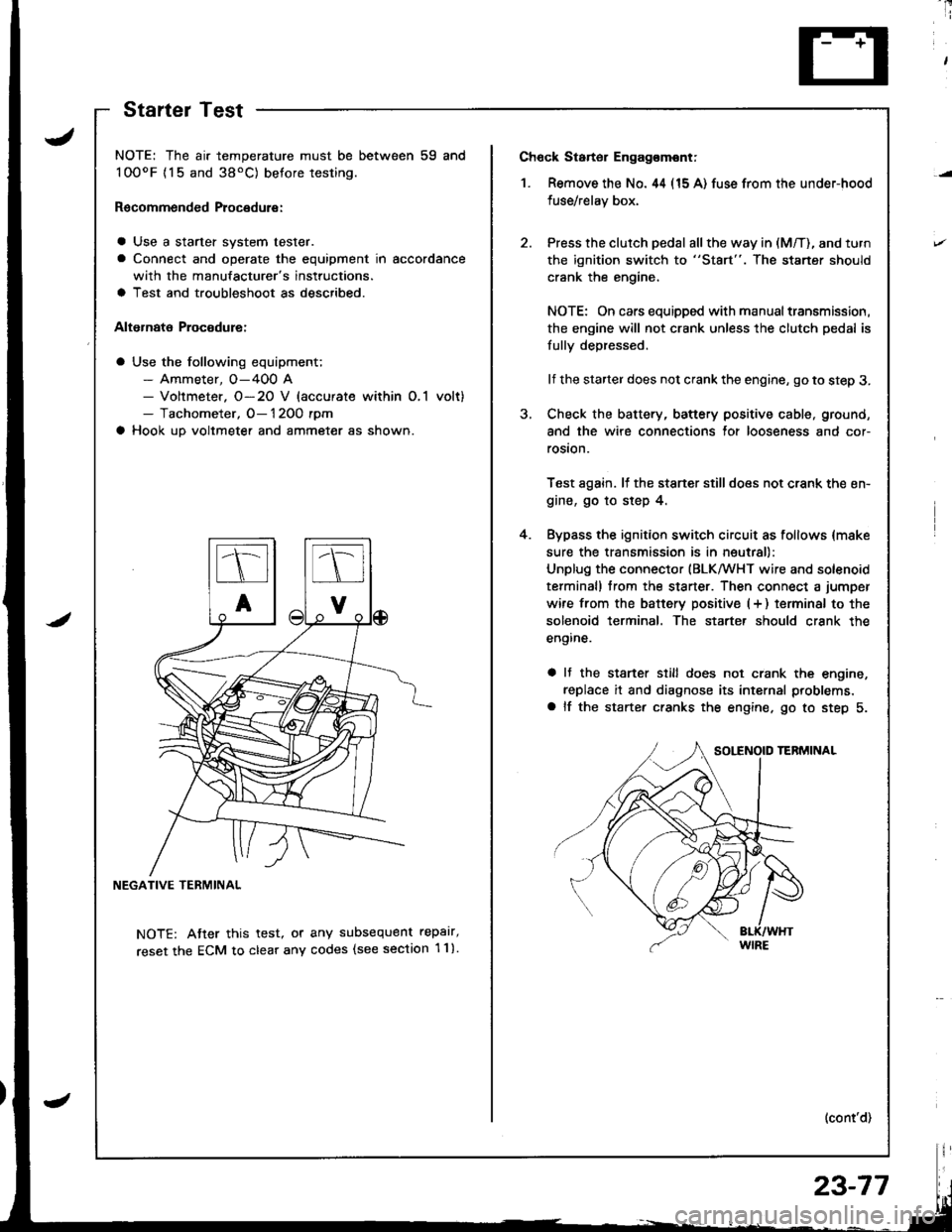

Ch6ck Starter Engag€mont;

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

Press the clutch pedal all the way in (M/T), and turn

the ignition switch to "St8rt". The staner should

crank the engine,

NOTE: On cars equipped with manual transmission,

the engine will not crank unless the clutch pedal is

fully depressed.

lf the starter does not crank the engine, go to step 3.

Check the battery, battery positive cable, ground,

and the wire connections for looseness and cor-

rosion.

Test again. lf the stsner stilldoes not crank the en-

gine, go to step 4.

Bypass the ignition switch circuit as follows {make

sure the transmission is in neutral)

Unplug the connector (BLKMHT wire and solenoid

terminal) trom the staner. Then connect a jumper

wire from the batterv positive (+ ) terminal to the

solenoid terminal. The starter should crank the

engine.

a It the stsrter still does not crank the engine,

replace it and diagnose its internal problems,

a lf the starter cranks the engine. go to step 5.

(cont'd)

4.

NOTE: The air temperature must be between 59 and

100oF {15 and 38'C) betore testing.

Recommended Procedure:

a Use a starter system tester.

a Connect and operate the equipment in accordance

with the manufacturer's instructions.

a Test and troubleshoot as described.

Alternate Procodure:

a Use the following equipment;- Ammeter, O-400 A- Voltmeter. O-20 V (accurate within O,1 volt)- Tachometer, O- 1 2OO rpm

a Hook up voltmeter and ammeter as shown.

NEGATIVE TERMINAL

NOTE: Atter this test, or any subsequent repalr,

reset the ECM to clear any codes (see section 1 1).

StartelTest

23-77

Page 1142 of 1681

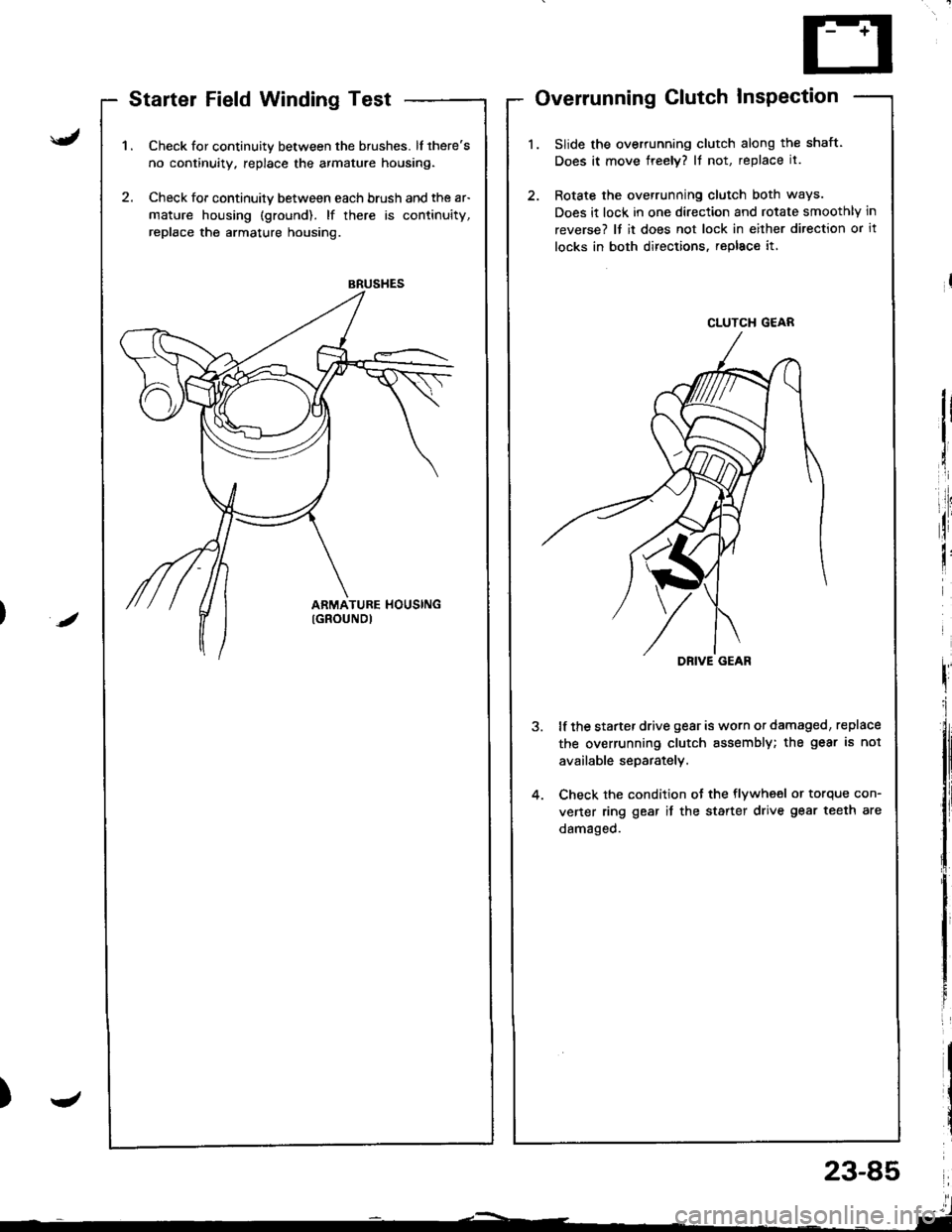

BRUSHES

Startel Field Winding Test

Check for continuity between the brushes. lf there's

no continuity. replace the armature housing.

Check for continuily between each brush and the ar-

mature housing (ground). lf there is continuity,

replace the armature housing.

Overrunning Clutch InsPection

Slide the overrunning clutch along the shaft.

Does it move freely? It not, replace it.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? It it does not lock in either direction or it

locks in both directions, repl8c€ it,

lf the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not

available separately.

Check the condition ot the flywheel or torque con-

vener ring gear it the starter drive gear teeth are

damaged.

/

J

CLUTCH G€AR

DRIVE GEAR

23-85

l'l- ,-----_ -'l

Page 1154 of 1681

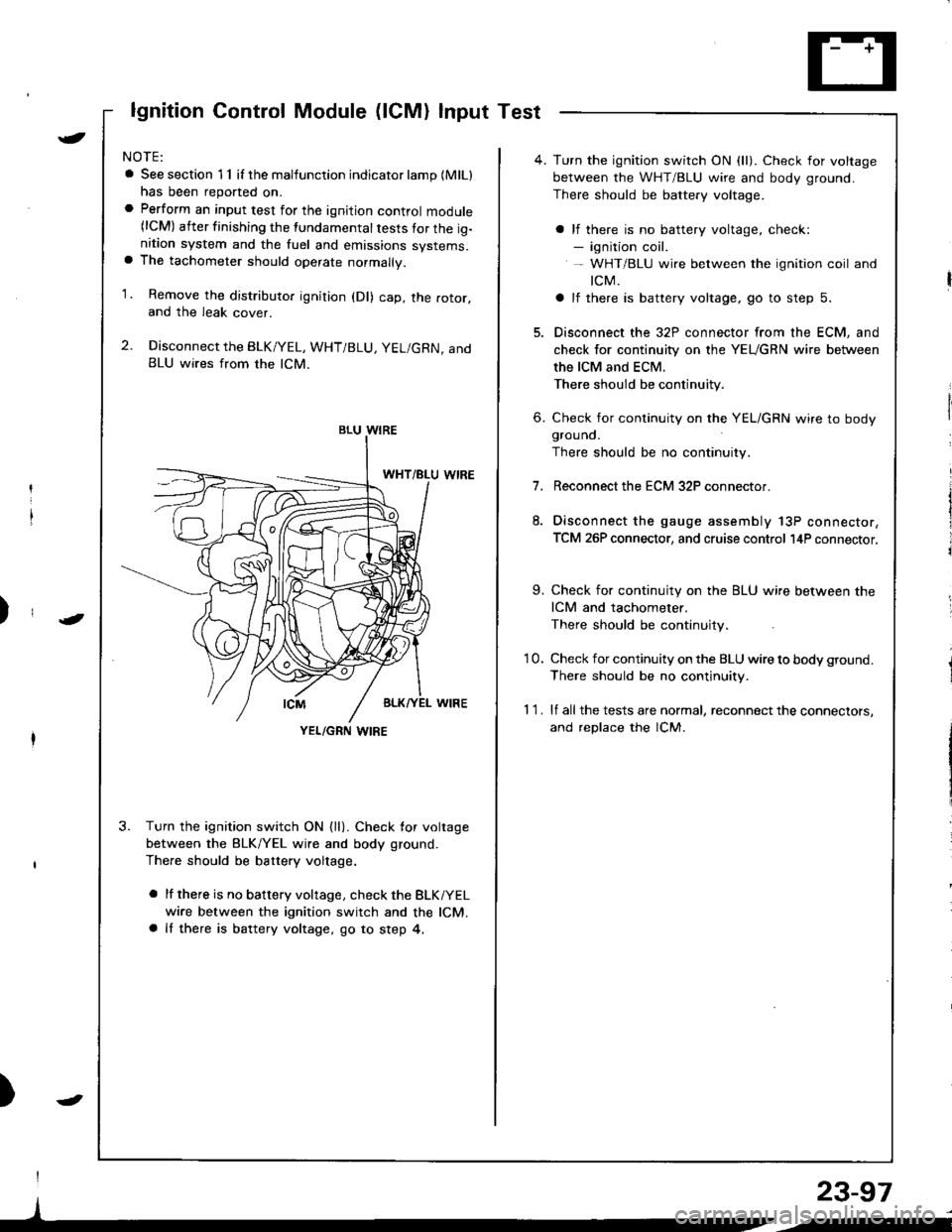

lgnition Control Module (lCM) Input Test

NOTE:

a See section 1 1 if the malfunction indicator lamp (MlLl

has been reported on.a Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the ig-nition system and the fuel and emissions systems.a The tachometer should operate normally.

1. Remove the distributo. ignition (Dl) cap, the rotor,and the leak cover.

2. Disconnect the BLK/YEL, WHT/BLU, YEL/GRN, andBLU wires from the lCM.

3. Turn the ignition switch ON {ll}. Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

a lf there is no battery voltage, check the BLKiYEL

wire between the ignition switch and the lCM.a It there is battery voltage, go to step 4,

)

I

)

BLU WIRE

YEL/GRN I,\'IRE

4. Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground.

There should be battery voltage.

a lf there is no battery voltage, check:- ignition coil.- WHT/BLU wire between the ignition coil and

tcM.

a lf there is battery voltage, go to step 5.

5. Disconnect the 32P connector from the ECM, and

check for continuity on the YEUGRN wire between

the ICM and ECM.

There should be continuity.

6. Check for continuity on the YEL/GRN wire to bodygrouno.

There should be no continuity.

7.Reconnect the ECM 32P connector.

Disconnect the gauge assembly 13P connector,

TCM 26P connector, and cruise control l4P connector.

9. Check for continuity on the BLU wire between the

ICM and tachometer.

There should be continuity.

'10. Check for continuity on the BLU wire to body ground.

There should be no continuity.

1 1 . lf all the tests are normal, reconnect the connectors,

and replace the lCM.

23-97

/i

Page 1160 of 1681

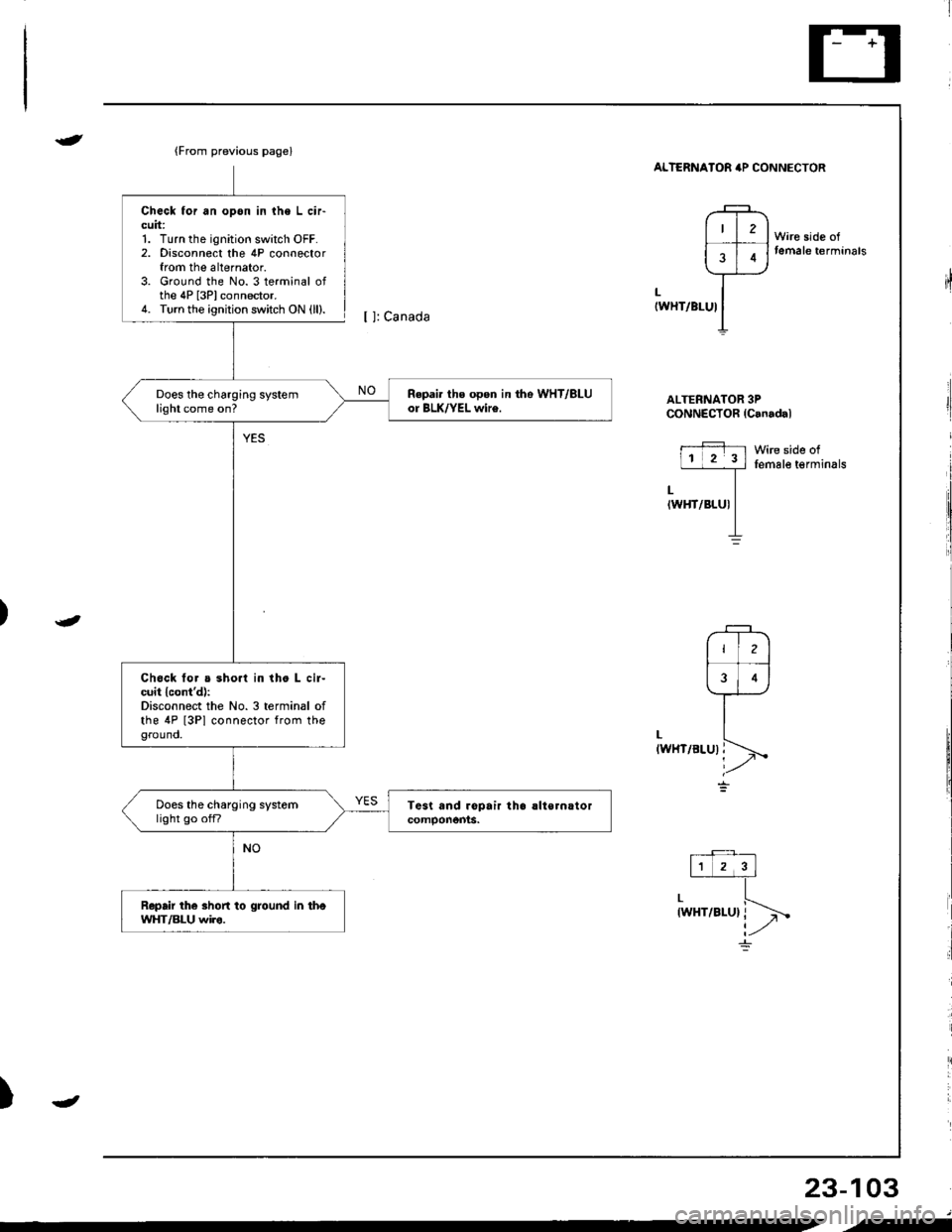

{From previous page}

Repai. ths open in tho WHT/ALUor BLK/YEL wir€.Does the charging systemlight come on?

Chock tor a sho.l in the L cir-cuit lcont'd):Disconnect the No.3 terminal ofthe 4P [3Pl connector from theground.

Does the charging systemlight go offi

Repair the shon to ground in thoWHT/BLU wiro.

{

t

Check for an opon in lhe L cir-cuit:1. Turn the ignition switch OFF.2. Disconnect the 4P connectorfrom the alternator.3. Ground the No. 3 terminal ofthe 4P [3Plconnector.4. Turn the ignition switch ON (ll).

ALTERNATOB irP CONNECTOR

ALTERNATOR 3PCONNECTOR {Canadal

11 2 3l

,l

iin"vr.rr\

Wire side oftemale t€rminals

[ ]: Canada

LIWHT/BLUI

LIWHT/BLU)

Wire side offemale terminals

)

23-103

4

--

Page 1161 of 1681

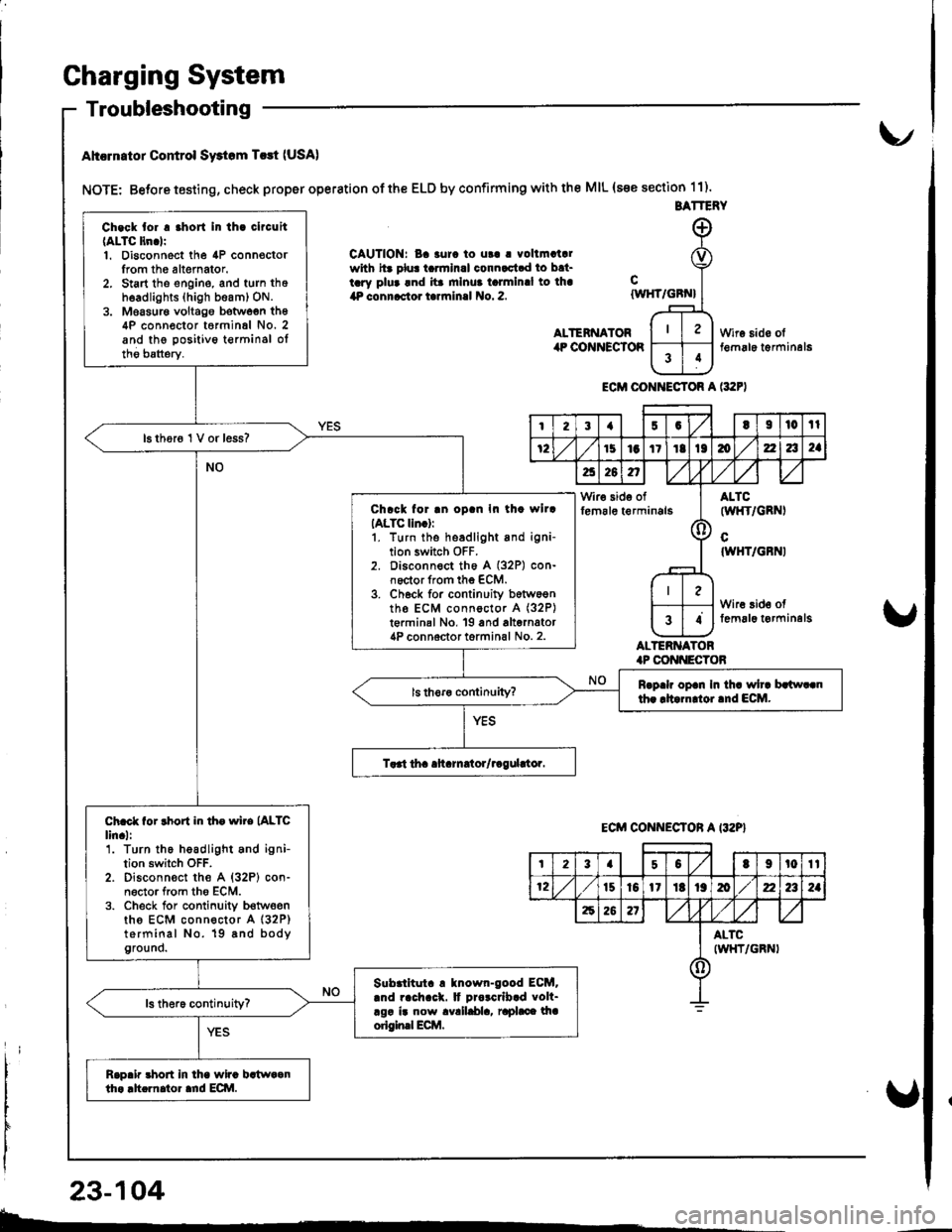

Gharging System

Troubleshooting

Ahcrn.tor Control Swtom T.rt (USA)

NOTE: Betore testing, check proper operation of the ELD by confirming with the MIL (s€e section 11).

CAUTION: Ba 3urc to ut! | vollmatalwith hr plu! tarmlnal connactad to bat-tary plua and ita mlnua talmlnal to lha4P connactor tarrninal No. 2.

ALTENNATORilP COiINECTOR

cIWHT/GBN}

ALTERNATOR.P CONI{ECTOB

Wire sido olt€m6le t€rminal6

ECM CONI{ECTOR A l:t2F)

BATTERY

Ch.ck tor . .hort In th. clrcuit(ALTC ltn.lr1. Disconnect the 4P connoctorIrom th6 altemator.2. Start tho engine, and turn thoh6adlights (high beam) ON.3. Moasur€ voltago botwoen th64P conn€ctor t6rminal No. 2and the positivo t€rminsl oltho batterv.

16 thor6 1 V or less?

Chrck for .n oD.n In th. wllrIALTC lln.):1. turn the headlight and igni-tion switch OFF.2. Disconnect th6 A (32P) con-noctor from the ECM.3. Ch6ck for continuity b6tw6entho ECM connoctor A (32P)

t€rminal No, 19 and alternator4P connoctor torminal No. 2.

Rrp.h op.n In th. wh. brlw..nth. rltarn oi.nd ECM.

Ch.ct for rhort in th. wire (ALTC

lin.l:'1. Turn the headlight and ignition switch OFF.2. Disconn€ct the A {32P} con-n6ctor from tho ECM.3. Check for conlinuity b€twoenths ECM connector A (32P)

terminal No. 19 8nd bodyground.

Slbrlltut. ! tnown-good ECM..nd rach.ck. It Drorcrlb.d volt-rgr ir now avalldla, raphce lhaorigin.l Ecilt.

Rap.ir 3hort in lha wira bstwaanth. .h.rnator ard ECI\|.

I23{5GtI|l0tl

72151aItIt136zla2a

a26n,/,V

Wir€ side offem6le t€rminals(l

ALTC(wl{T/GRNI

cIWHT/GBNI

Wire 3id€ offemal6 t€rminelg34

ECM CONNECTON A I32P}

t23a50t9t0tt

12t510l1Itt9mz2a2a

62621

ALTCIWHT/GRNI()

23-104

b-.

Page 1162 of 1681

{

t

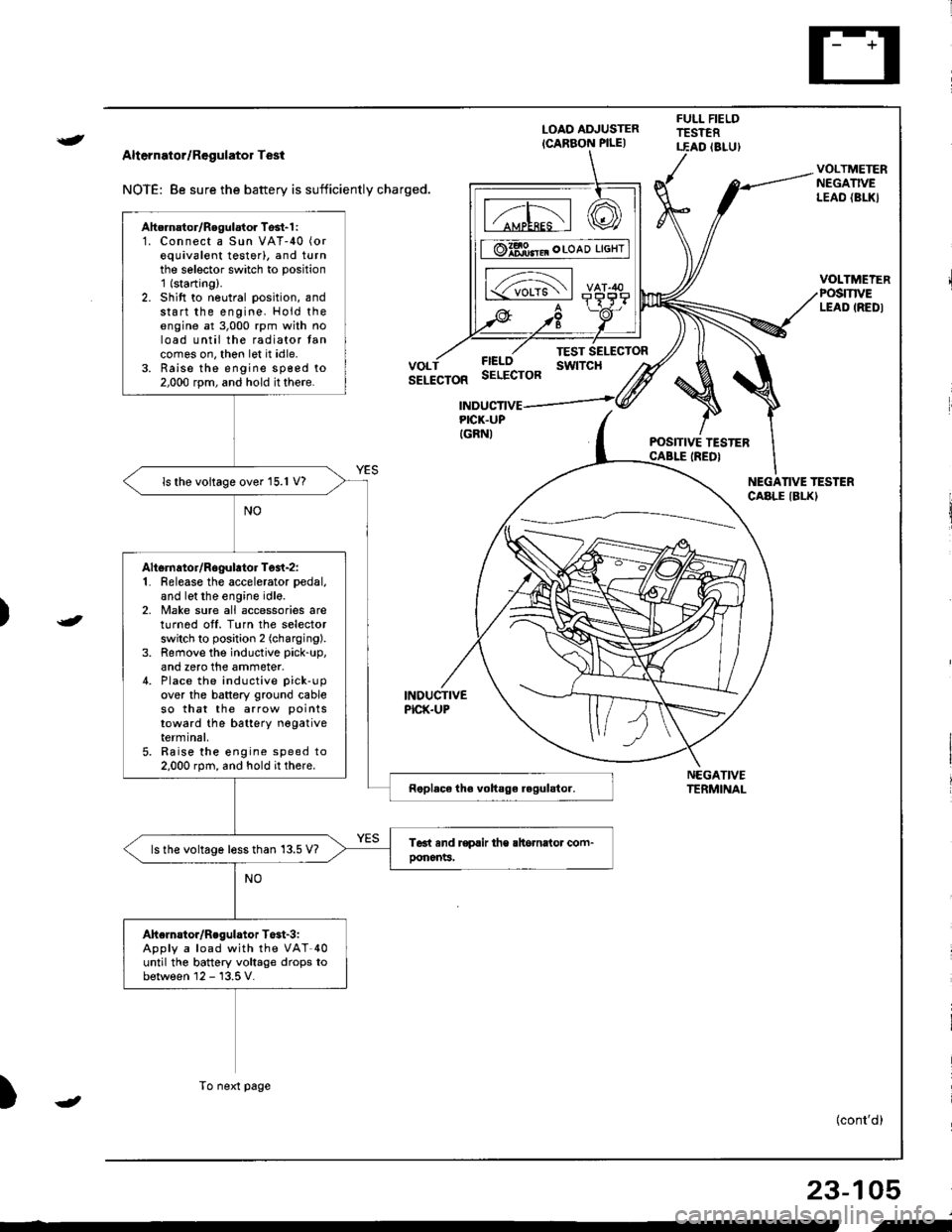

Alternator/Regulator Test

NOTE: 8e sure the battery is sufficiently charged.

LOAO ADJUSTER

ICARBON PILE)

FULL FIELDTESTERT.EAD (8LU)

POSITIVE TESTERCABLE IREDI

NEGATIVETERMINAL

VOLTMETERNEGATIVELEAO {BL|(}

VOLTMEIERPOSmVELEAD IREDI

FIELOSELECTOR

TEST SELECTORswtTcHVOLTSELECTOR

INDUCTIVEPICK.UP

INDUCTIVEPICK.UPIGRNI

NEGANVE TESTERCABLE IBLKI

)

)

{cont'd)

23-105

Ahernator/Regulator Tosl-1 :1. Connect a Sun VAT-40 (or

equivalent testerl, and turnthe selector switch to position'1 (starting).

2. Shift to neutral position, andstart the engine. Hold theengine at 3,000 rpm with noload until the radiator tancomes on, thon let it idle.3. Raise the engine sp€ed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

Altsrnator/Rogulator Test-z:1. Release the accelerator pedal,

and let the engine idle.2, Make sure all accessories areturnod off. Turn the selectorswitch to position 2 (charging).

3. Remove the inductive pick-up,

and zero the ammeter.4. Place the inductive pick-up

over the battery ground cableso that the arrow points

toward the batterY negativeterminal,5. Raise the engine speed to2.000 rpm, and hold it there.

ls the voltage less than 13.5 V?

Ahelnstor/Regulator T$t-3iApply a load with the VAT-40until the battery voltage drops tobetween 12 - 13.5 V.

To next page

-

i-

Page 1163 of 1681

From previol.rs page

The charging swtem is OK.lsthe amperage 70 A or more?

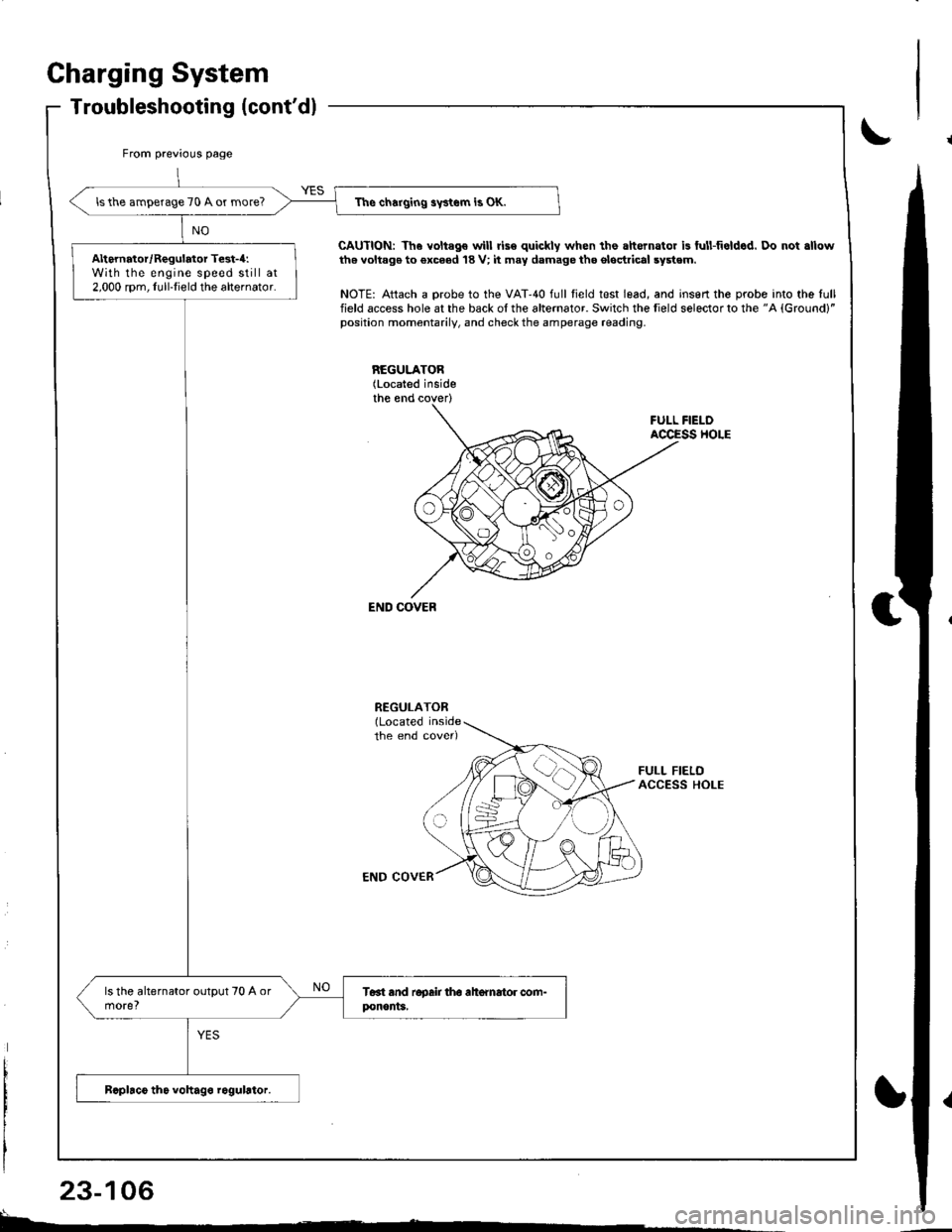

Alternator/Regulator Test-4:With the engine speed still at2,000 rpm, Iull-Iield the alternator.

Charging System

Troubleshooting (cont'dl

CAUTION: Th6 voltago will rise quickly when the ahernator is ful!fieldcd. Do not .llowth6 voltag€ to €xc6ed 18 V; it may damage tho ol6drical system.

NOTE: Attach a probe to the VAT'40 full field test lead, and insert the probe into the lullfield access hole at the back of the alternator. Switch the field selector to the "A {Ground}"position momentarily, and check the amperage reading.

REGULATOB(Located inside

FULL FIELOACCESS HOLE

END COVEB

END COVER

FULL FIELDACCESS HOLE

L^

23-106

Page 1164 of 1681

Alternator Replacement

)

t

-

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number before

- disconnecting the battery.

- removing the No. 47 (7.5 A) fuse from the under-hood

fuse/relay box.

removing the radio.

After service, reconnect power to the radio and turn it on.

When the word "CODE" is displayed, enter the cus

tomer's s-digit code to restore radio operation.

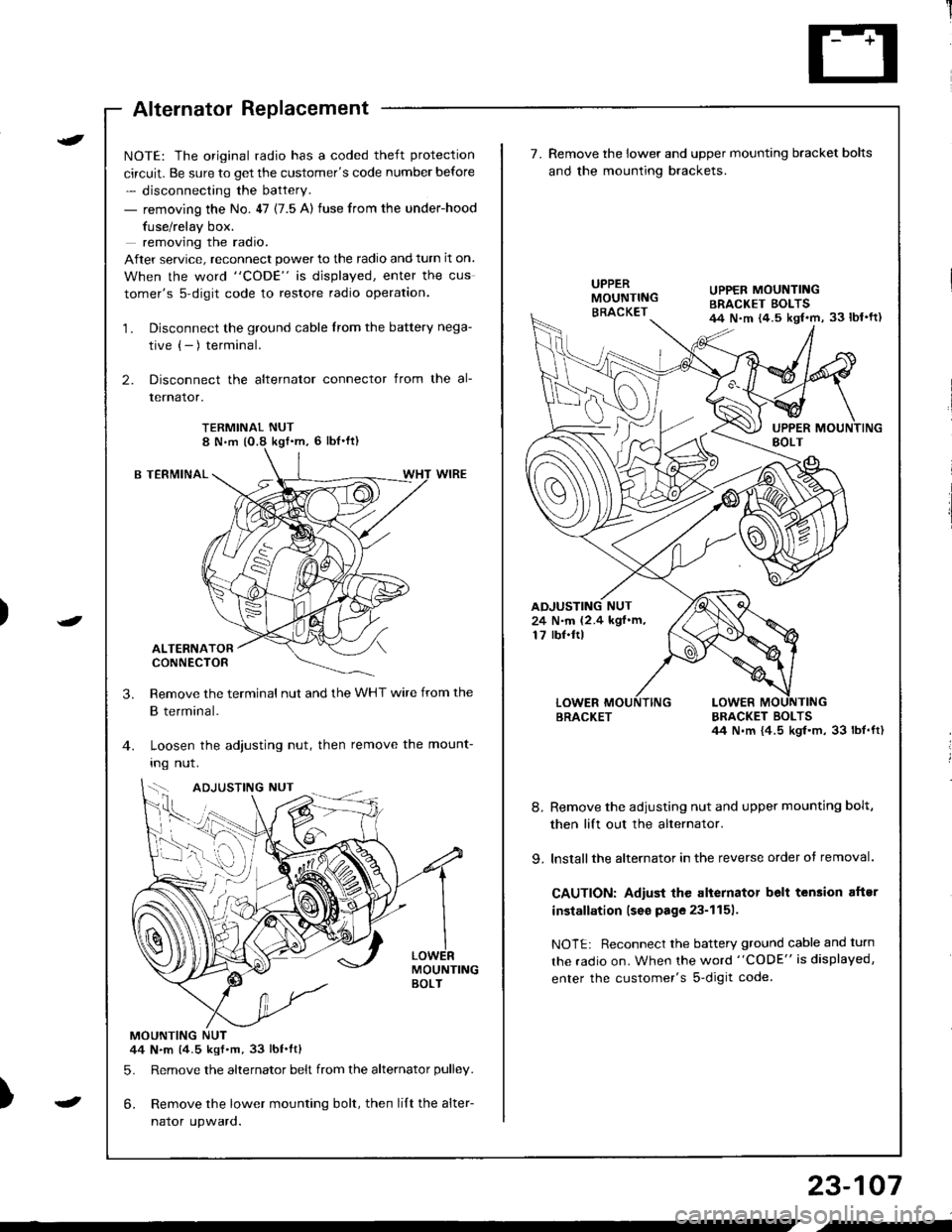

1. Disconnect the ground cable from the battery nega-

tive (- ) terminal.

2. Disconnect the alternator connector from the al-

lernalor,

TERMINAL NUT8 N,m (O.8 kgf'm, 6 lbl'ft)

B TERMINAL

ALTERNATORCONNECTOR

Remove the terminal nut and the WHT wire from the

B terminal.

Loosen the adjusting nut, then remove the mount-

Ing nut.

MOUNTINGBOLT

MOUNTING NUT44 N.m (4.5 kgf.m.33 lbt.ftl

5. Remove the alternator belt from the alternator pulley.

6. Remove the lower mounting bolt, then lilt the alter-

naror upwaro.

3.

{--,

7.Remove the lower and upper mounting bracket bolts

and the mounting brackets.

BRACKET BOLTSil4 N.m {4.5 kgl.m, 33 lbt.ft)

8. Remove the adiusting nut and upper mounting bolt,

then lift out the alternator.

9. lnstallthe alternator in the reverse order of removal.

CAUTION: Adiust the alternator belt tension aftsr

installation lseo page 23-1151.

NOTE: Reconnect the battery ground cable and turn

the radio on. When the word "CODE" is displayed,

enter the customer's s-digit code.

BRACKET

UPPER MOUNTINGBRACKET EOLTS44 N.m {4.5 kgl.m, 33 lbl'ft)

24 N.m (2.4 kgf.m,17 rbf.ftl

b-h..K

) I

23-107

-

,-