key HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 93 of 1681

\-

L

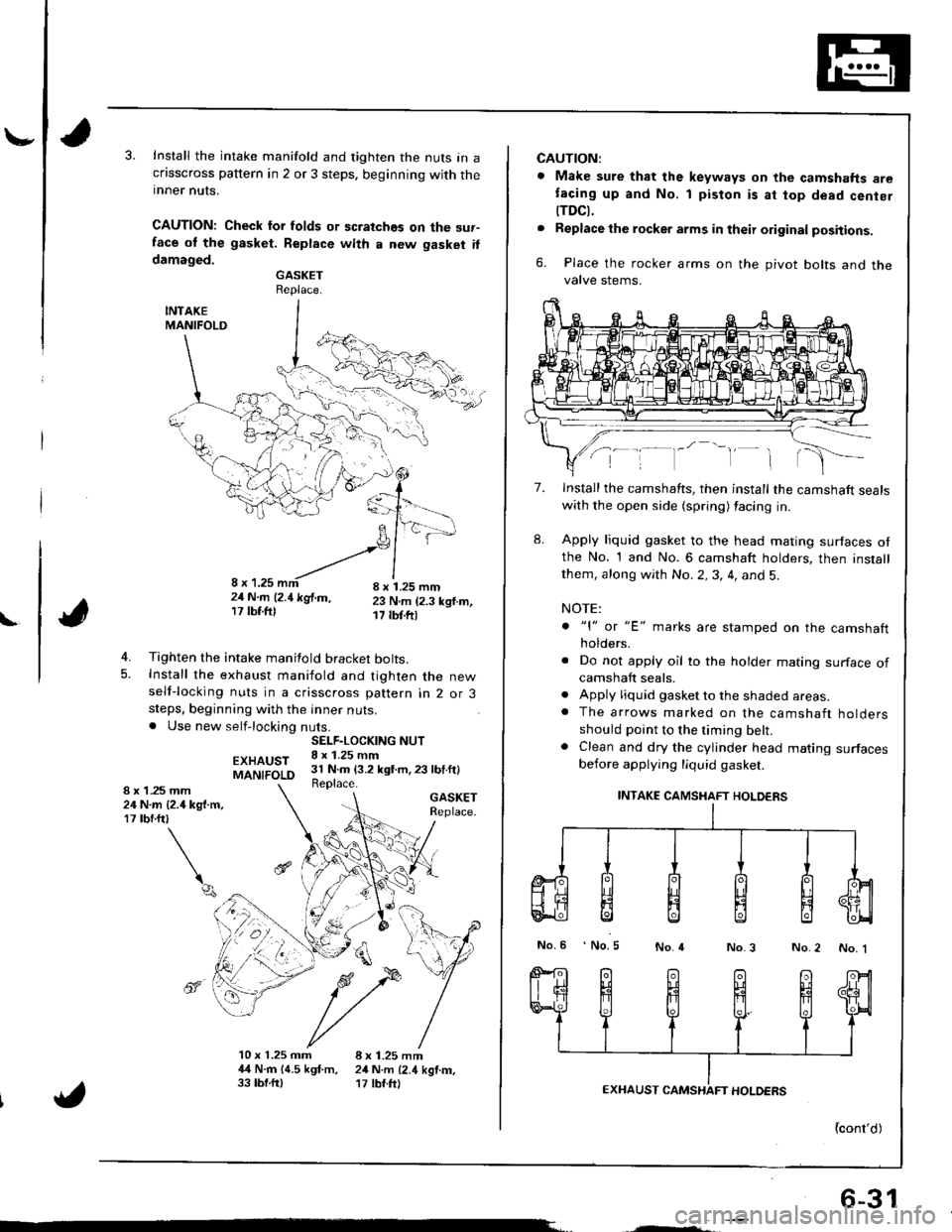

Install the intake manifold and tighten the nuts in acflsscross pattern in 2 or 3 steps. beginning with theinner nuts.

CAUTION: Check lor folds or scratches on the sur-face ol the gasket. Replace with a new gasket ildamaged.GASKETReplace.

INTAKEMANIFOLD

4. Tighten the intake manifold bracket bolts.5. Install the exhaust maniiold and tighten the newself-locking nuts in a crisscross pattern in 2 or 3steps, beginning with the inner nuts.. Use new self-locking nuts.

EXHAUSTMANIFOLD

GASKETReplace.

4

10 x 1.25 mm 8 x 1.25 mm4,{ N.rn 14.5 kgf.m, 24 N.m {2.4 kgtm,33 tbf.ftl '17 tbf.ft)

SELF.LOCKING NUT8 x 1.25 mm31 N.m (3.2 kgt m,23 lbf.ft)Replace.1 .25 mmN.m {2.4 kg{.m,rbrftt

\q

8x2417

",', r, ^-'-"-!,1,,,';-21N.m l2.1kglm, 23 N.m (2.3 ksf.m,17lbf.ftl 17 tbf.ftr

6-31

CAUTION:

. Make sure that the keyways on the camshafts aretacing up and No. 1 piston is at top dead cenier

tTDCt.. Replacethe rocker arms in their original positions.

6. Place the rocker arms on the pivot bolts and thevalve stems.

7.

8.

Install the camshafts, then install the camshaft sealswith the open side (spring) facing in.

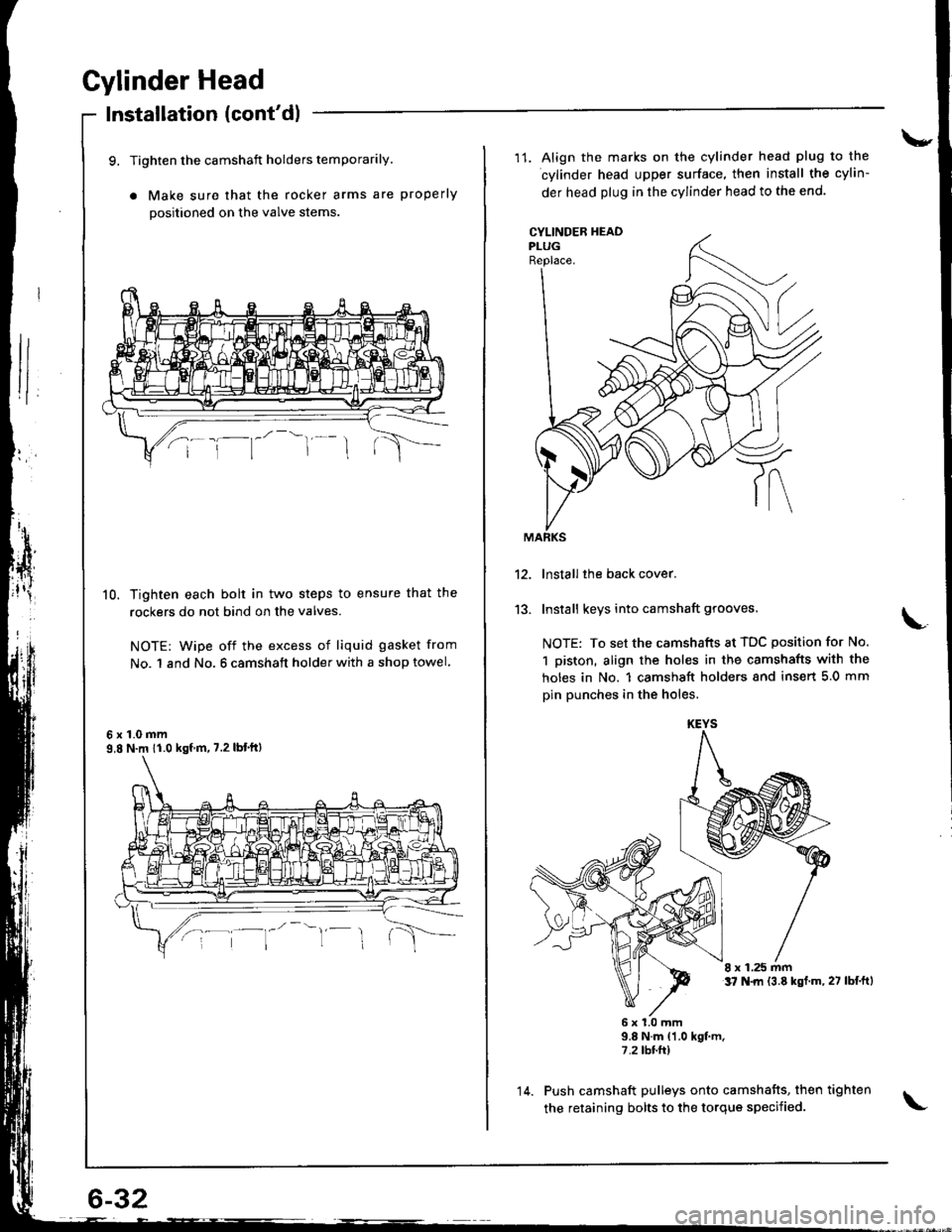

Apply liquid gasket to the head mating surfaces otthe No. 1 and No. 6 camshaft holders, then installthem, along with No.2,3, 4, and 5.

NOTE:

. "l" or "E' marks are stamped on the camshaftholders.

. Do not apply oil to the holder mating surface ofcamshaft seals.. Apply liquid gasket to the shaded areas.. The arrows marked on the camshaft holdersshould point to the timing belt.. Clean and dry the cylinder head mating surfacesbefore applying liquid gasket.

INTAKE CAMSHAFT HOLDERS

No.6 No.5No.4No.3 No.2 No. 1

{cont'd)

Page 94 of 1681

Cylinder Head

Installation (cont'dl

9, Tighten the camshaft holders temporarily.

a Make sure that the rocker arms are properly

positioned on the valve stems

10. Tighten each bolt in two steps to ensure that the

rockers do not bind on the valves.

NOTE: wipe off the excess of liquid gasket from

No. 1 and No. 6 camshaft holder with a shop towel

6x1.0mm9,8 N.m 11.0 kgf m, 7.2 lbt'ftl

\-

11. Align the marks on the cylinder head plug to the

cylinder head upper surface, then install the cylin-

der head plug in the cylinder head to the end.

CYLINDEB HEADPLUGReplace.

13.

lnstall the back cover.

Install keys into camshaft grooves.

NOTE: To set the camshafts at TDC position for No.

1 piston, align the holes in the camshafts with the

holes in No. 1 camshsft holders snd insert 5.0 mm

pin punches in the holes.

8 x 1.25 mmt7 N.|rl {3.8 kst.m,27 lbf.ftl

6x1.0mm9.8 N.m {1.0 kgt m.7.2 tbr.ft)

Push camshaft pulleys onto camshafts, then tighten

the retaining bolts to the torque specified.

KEYS

14.

Page 157 of 1681

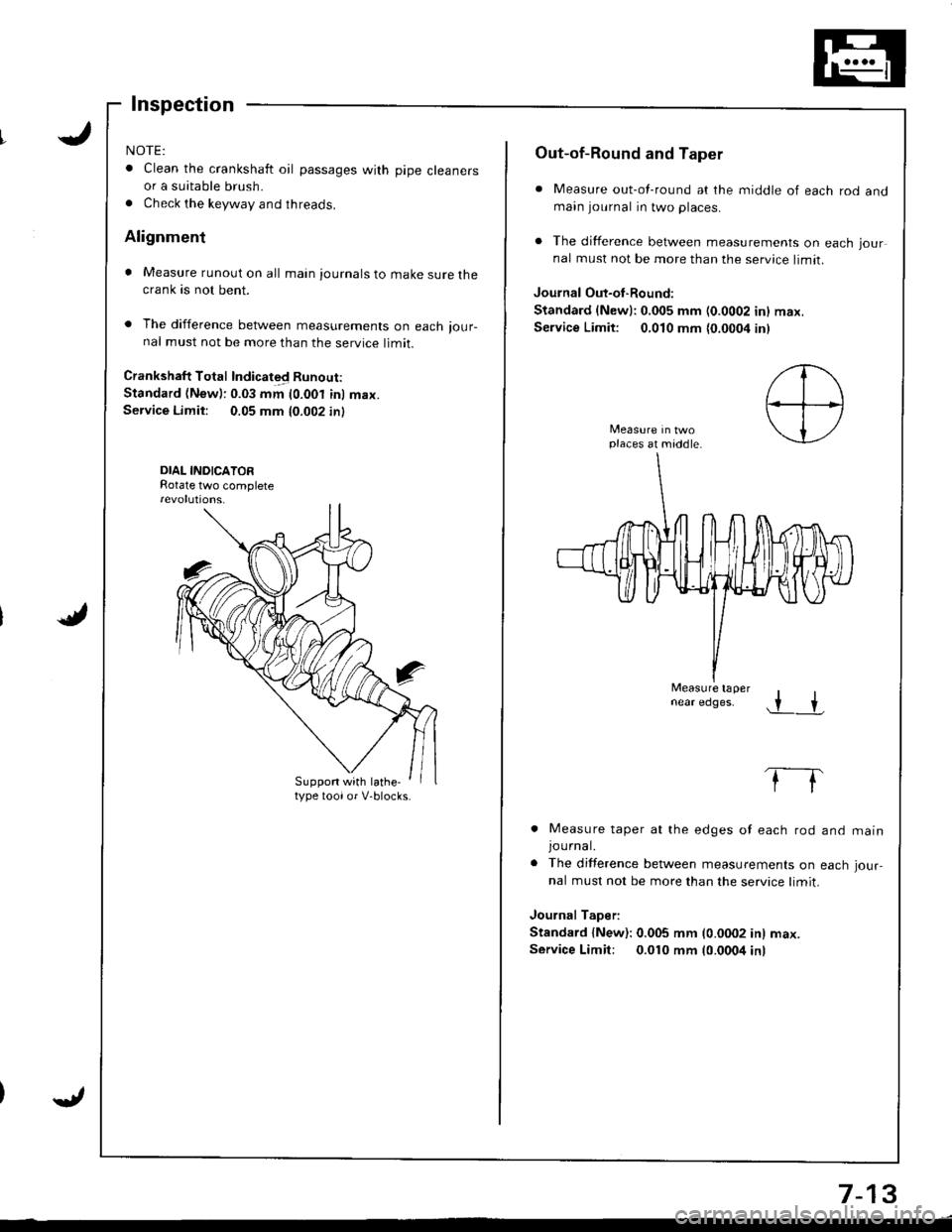

NOTE:

. Clean the crankshaft oil passages with pipe cleanersor a suitable brush.

. Check the keyway and threads.

Alignment

. Measure runout on all main journals to make sure thecrank as not bent.

. The difference between measurements on each ,our-nal must not be more than the service limit.

Crankshaft Total Indicated Runout:

Standard (New): 0.03 mm (0.001 inl max.Service Limit: 0.05 mm 10.002 in)

DIAL INDICATORRotate two complete

Suppon with lathe-type toolor V-blocks.

Out-of-Round and Taper

. Measure out-of-round at the middle of each rod andmain journal in two places.

. The difference between measurements on each jour

nal must not be more than the service limit.

Journal Out-oI-Round:

Standard {Newl:0,005 mm (0.0002 inl max.

Service Limit: 0,010 mm {0.0004 inl

places at middle.

Measure tapernear edges..r +

. Measure taper at the edges of each rod

JOUrnal.. The difference between measurements on

nal must not be more than the service limit.

Journal Taper:

Standard {New): 0.005 mm (0.0002 in) max.

Service Limit: 0.010 mm 10.0004 inr

and matn

each Jour-

7-13

Page 592 of 1681

Adiustment

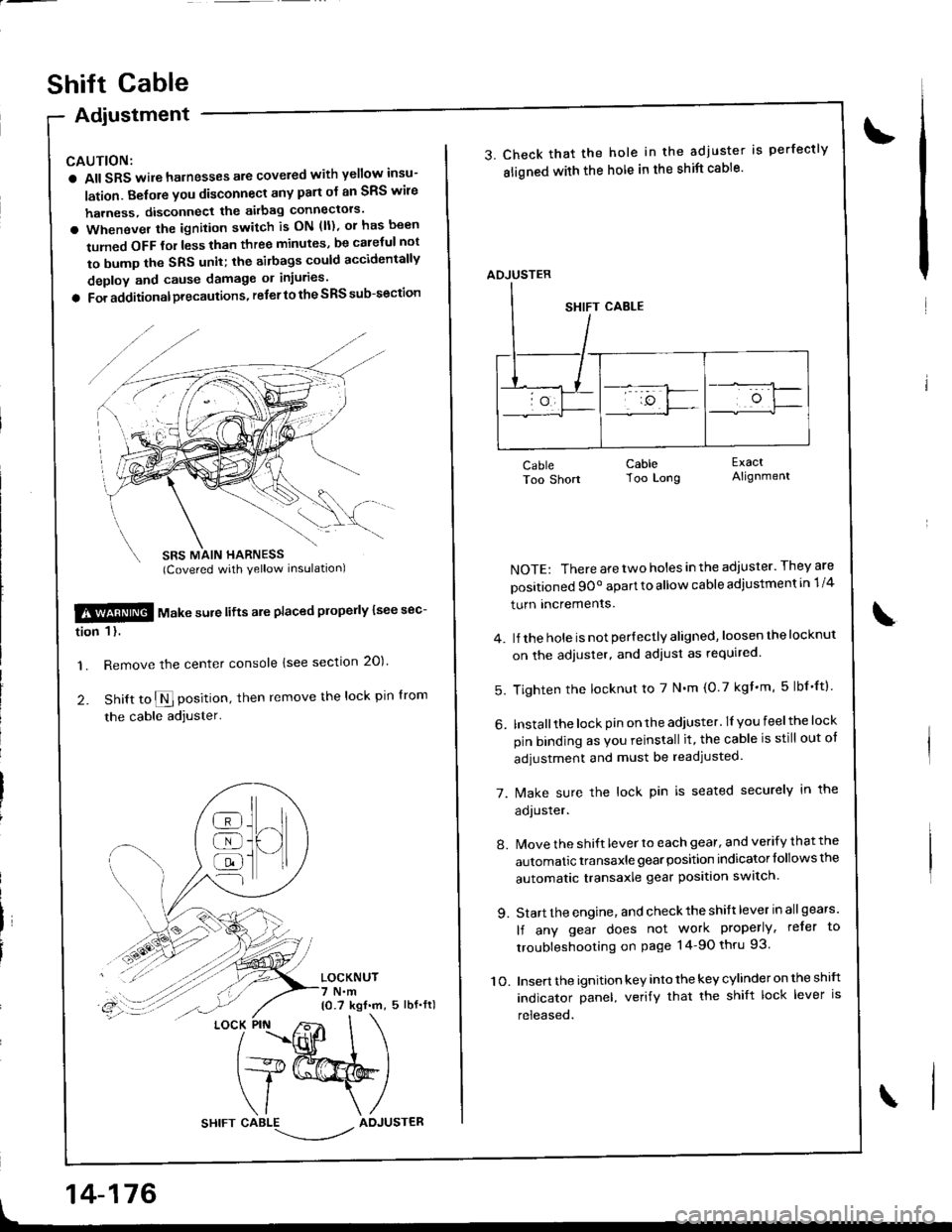

CAUTION:

a All SRS wile harnesses are covered with yellow insu-

lation. Belore you disconnect any part ol an SRS wire

harness, disconnect the akbag connectors'

a Whenever the ignition switch is ON (ll), or has been

tumed OFF tol less than three minutes, be caletul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries'

a For additionalprecautions, referto the SRS sub-section

SBS MAIN HARNESS(Covered with yellow inslrlationl

$!@ rtl"t . "ure lifts are placed plope y lsee sec-

tion 1 l.

'1. Remove the center console lsee section 20)'

2. Snitt to $ position, then remove the lock pin lrom

the cable adjuster'

LOCKNUT7 N.m10.7 kgf.m, 5 lbf.fl)

t

]H

@

@

@

{l

LOCK PIN

14-176

shift cable

3. Check that the hole in the adjuster is perfectly

sligned with the hole in the shift cable'

CableToo Short

NOTE: There are two holes in the adjuster. They are

positioned 9Oo apart to allow cable adiustment in 1/4

turn Incremenrs.

4. lJ the hole is not per{ectly aligned, loosen the locknut

on the adjuster, and adiust as required.

5. Tighten the locknut to 7 N'm (0.7 kgf'm, 5lbf'ftl

6. Installthe lock pin on the adiuster. lI you feelthe lock

pin binding as Vou reinstall it, the cable is still out ot

adjustment and must be readjusted.

7. [/ake sure the lock pin is seated securely in the

aoJusrer.

8. Move the shift lever to each gear, and verify that the

automatic transaxle gear position indicator follows the

automatic transaxle gear position swatch.

9. Start the engine, and check the shift lever in allgears'

lf any gear does not work properly, refer to

troubleshooting on page 14-90 thru 93.

10. Insert the ignition key into the key cylinder on the shift

indicator panel, verify that the shift lock lever is

released.

CableToo Long

ExactAlignment

\

ADJUSTER

Page 1058 of 1681

J

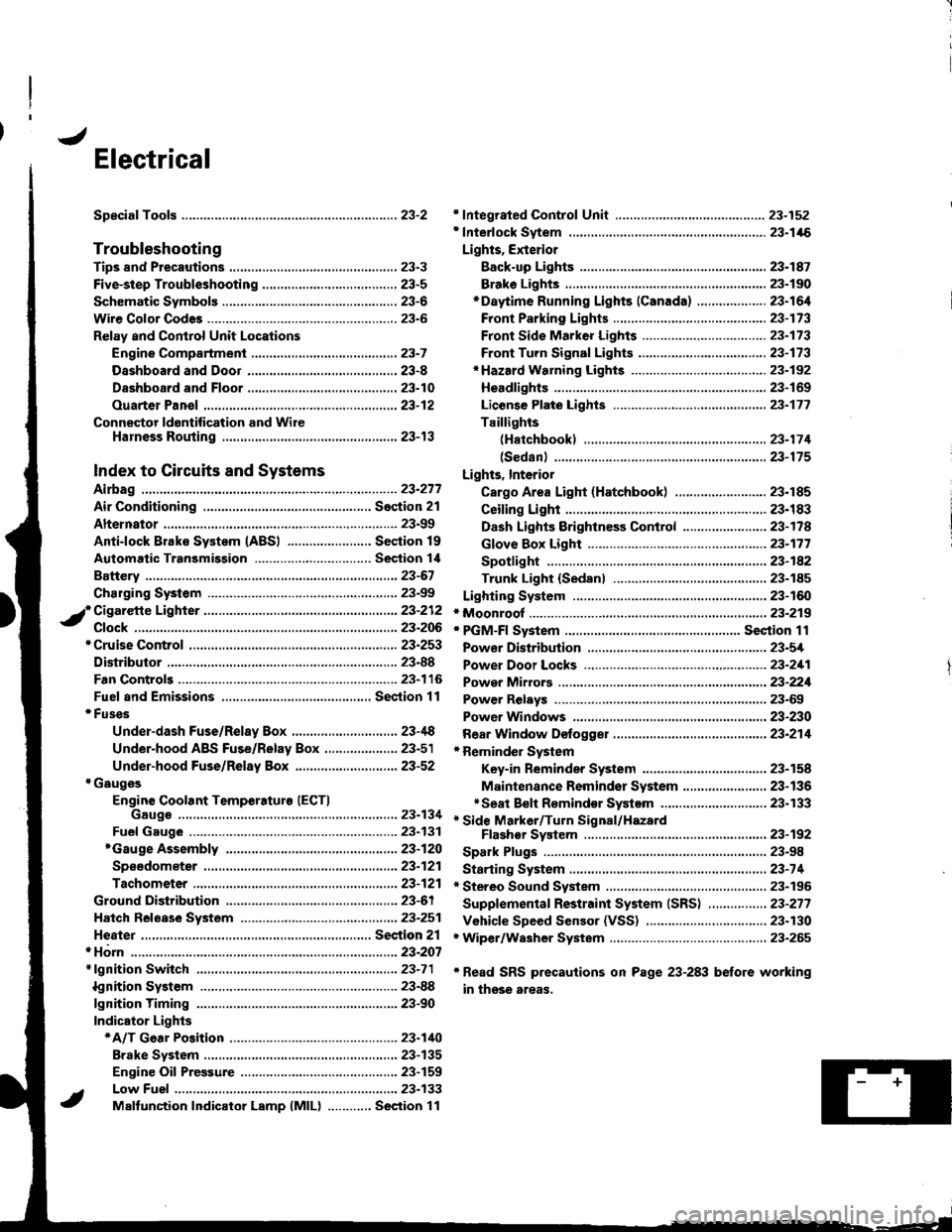

Electrical

Speciaf Toofs ..........................23-2

Troubleshooting

Tips 8nd Precautions .......................,..,.,.,.,.,......,..., 23-3

Five-step Troubleshooting ............,......,.,.,...,..,....., 23-5

Schsmatic Svmbols ...............23-6

Wire Color Code3 .. ................. 23-6

Relay and Control Unit Locations

Engine Compartment ......,.,.................,.,.,.,.,.,,,, 23-7

Dashboard and Door .........,...........,.....,.,....,.,.... 23-8

Dashboard and Floor ......................................... 23-10

Ouarter Pan€f .,,.,...,.,..,...,,,23-12

Connector ldontification and WireHarness Routing ......,.,......23-'13

Index to Circuits and Systems

Airbag

* Integrated Control Unit .....,.,.,.....23-152* Interlock Sytem .,...,.,...........,. 23.146

Lights, Exterior

Eack-up LighB ..................23.187

Brake Ligh$ ......................23-190*Daytime Running Lights (Canada) ................... 23"164

Front Parking Lights .......................................... 23-173

Front Side Marker Lights .................................. 23-173

Front Turn Signal Lights ..................-.......,...,.,. 23-173* Hazard Warning Lights ....................,........,....... 23-192

Headlights.....23-169

23-253 powerDistribution..................... 23-5/r

Air Conditioning.....,....... Soction 21

Alternator ..........,................... 23.99

iCigarette Lighter .........23-212

*Cruise Control

Distributor

'.'.,.'.'.,.'...,,,,.,''.'.,.',.'''.' 23.277

.............................. 23.88

................... 23-90lgnition Timing ......

Indicator Lights

Key-in Reminder System

Maintenance Reminder System*Seat Belt R€mindor System .,...........................* Side Marker/Turn Signal/HazardFlashcr Svstem .................23-192

Spark Plugs ............................23-98

Starting System .....................23-74* Stereo Sound System ...,......,..........,...,......,.,.,.,..,., 23-196

Supplemental Restraint System (SRS) ................ 23-277

Vshicle Speed Sensor (VSS) ................................. 23.130r Wiper/Washer System .........................................., 23-265

*Read SRS precautions on Psge 23-283 before working

in those areas,

23-154

23.136

23"133

Page 1062 of 1681

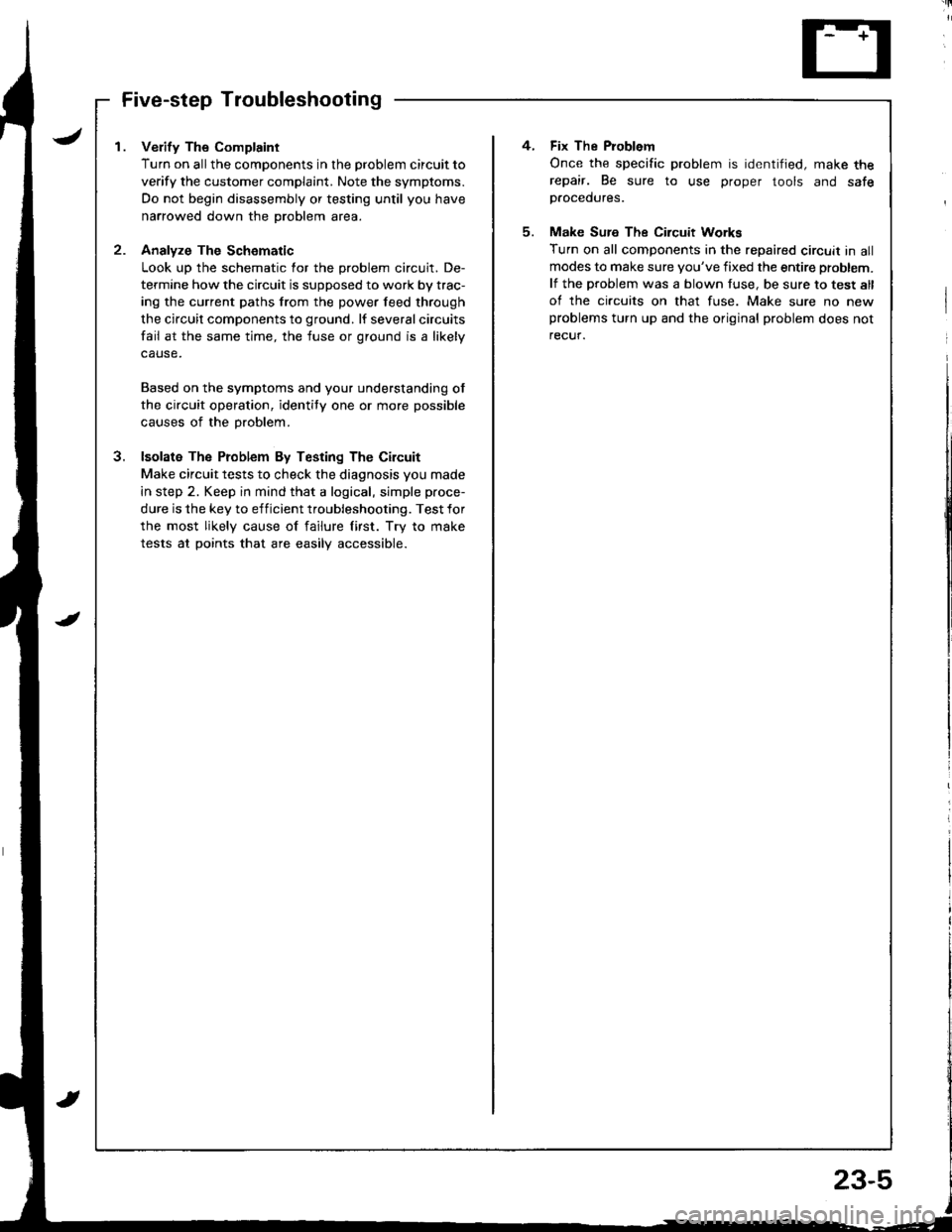

I . Verify The Complaint

Turn on allthe components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

2- Analyze The Schomatic

Look up the schematic for the problem circuit. De-

termine how the circuit is supposed to work by trac-

ing the current paths from the power feed through

the circuit components to ground. lf several circuits

fail at the same time, the fuse or ground is a likely

Based on the symptoms and your understanding ot

the circuit operation, identity one or more possible

causes of the problem.

3. lsolata The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep in mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure lirst. Try to make

tests at points that are easilV accessible.

4. Fix The Problem

Once the specific problem is identified, make therepair. Be sure to use proper tools and safep.ocedures.

5. Make Sure The Circuit Workg

Turn on all components in the repaired circuit in allmodes to make sure you've fixed the entire problem.

lf the problem was a blown fuse, be sure to test all

of the circuits on that fuse. Make sure no newproblems turn up and the original problem does not

recuf.

Page 1085 of 1681

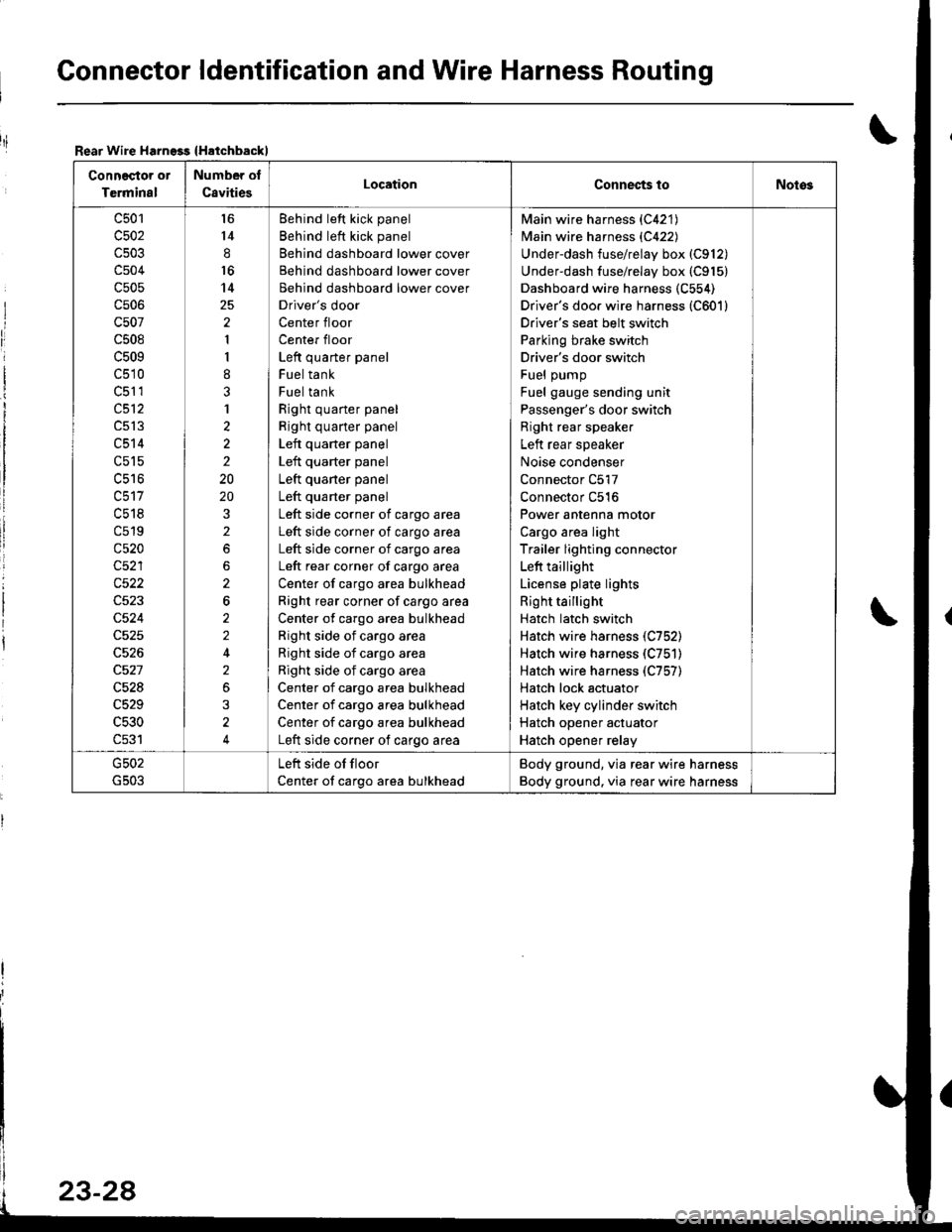

Gonnector ldentification and Wire Harness Routing

Rear Wire Harngss {Hatchbackl

Connector or

Terminal

Number of

C8vitiesLocationConnec{s toNotos

c501

c502

c504

c505

cs06

c507

c508

c509

c510

c51 1

c512

c513

c514

c515

uc to

c518

c519

c520

c522

c524

c528

c529

c530

c531

l6

14

8

16

14

2

1

I

8

3

1

2

2

2

20

20

2

2

6

2

2

2

3

4

Behind left kick panel

Behind left kick panel

Behind dashboard lower cover

Behind dashboard lower cover

Behind dashboard lower cover

Driver's door

Center floor

Center floor

Left quarter panel

Fuel tank

Fuel tank

Right quarter panel

Right quarter panel

Left quarter panel

Left quarter panel

Left quaner panel

Left quarter panel

Left side corner of cargo area

Left side corner of cargo area

Left side corner of cargo area

Left rear corner of cargo area

Center of cargo area bulkhead

Right rear corner of cargo area

Center of cargo area bulkhead

Right side of cargo area

Right side of cargo area

Right side of cargo area

Center of cargo area bulkhead

Center of cargo area bulkhead

Center of cargo area bulkhead

Left side corner of cargo area

Main wire harness {C421)

Main wire harness {C422)

Underdash fuse/relay box (C912)

Underdash fuse/relay box (C915)

Dashboard wire harness (C554)

Driver's doo. wire harness (C601)

Driver's seat belt switch

Parking brake switch

Driver's door switch

Fuel pump

Fuel gauge sending unit

Passenger's door switch

Right rear speaker

Left rear speaker

Noise condenser

Connector C517

Connector C516

Power antenna motor

Cargo area light

Trailer lighting connector

Left taillight

License plate lights

Right taillight

Hatch latch switch

Hatch wire harness (C752)

Hatch wire harness (C751)

Hatch wire harness (C757)

Hatch lock actuator

Hatch key cylinder switch

Hatch opener actuator

Hatch opener relay

Left side of floor

Center of cargo area bulkhead

Body ground, via rear wire harness

Body ground. via rear wire harness

riI

Page 1091 of 1681

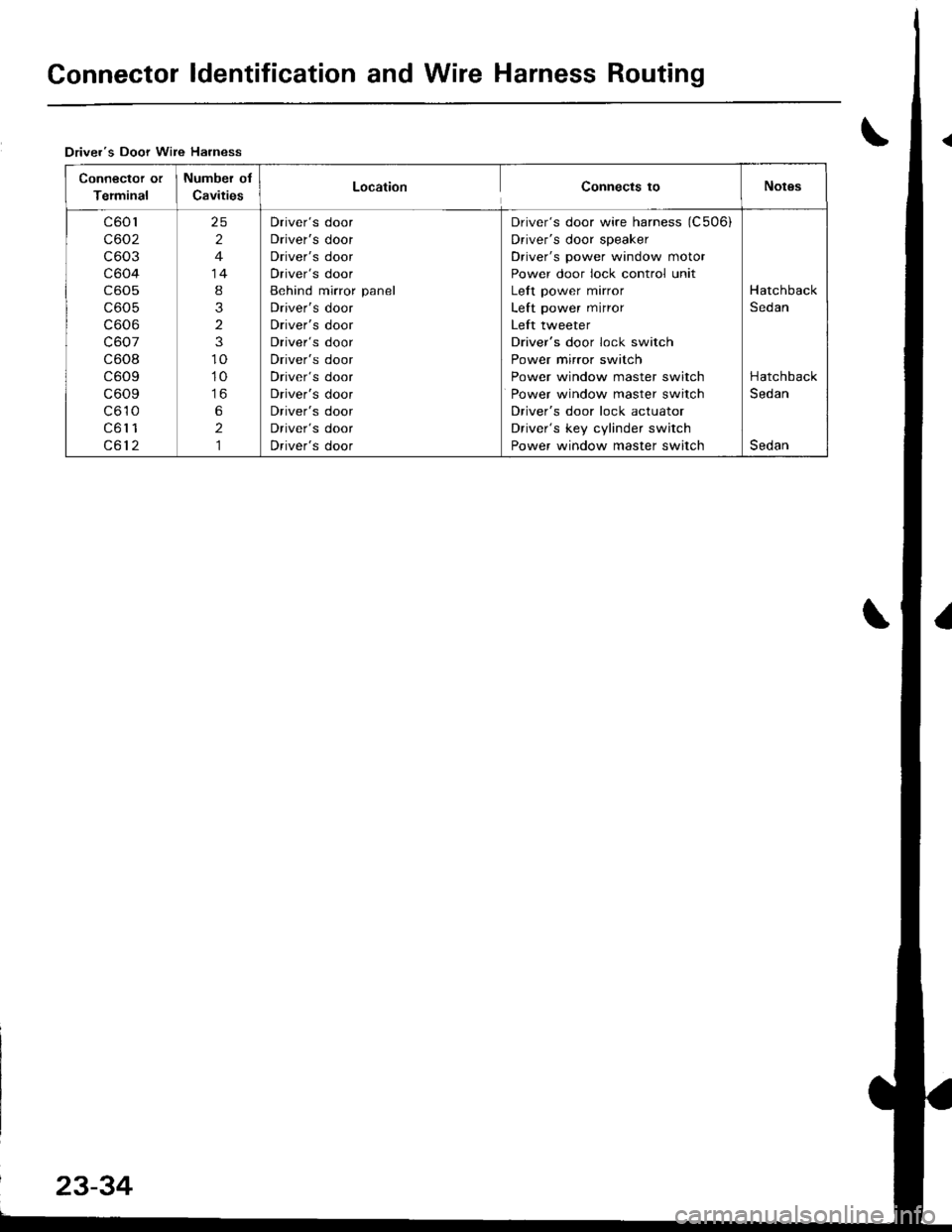

Connector ldentification and Wire Harness Routing

Driver's Door Wire Harness

Connector or

Terminal

Number of

CavitiesLocationConnects toNotgs

c601

c602

c603

c604

c605

c605

c606

c607

c608

c609

c609

c610

c61 1

c612

25

2

4

14

8

3

2

3

10

10

to

6

2,]

Driver's door

Driver's door

Driver's door

Driver's door

Behind mirror panel

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door

Driver's door wire harness (C506i

Driver's door speaker

Driver's power window motor

Power door lock control unit

Left power mirror

Left power mirror

Left tweeter

Driver's door lock switch

Power mirror switch

Power window master switch

Power window master switch

Driver's door lock actuator

Driver's key cylinder switch

Power window master switch

Hatchback

Sedan

Hatchback

Sedan

Sedan

Page 1093 of 1681

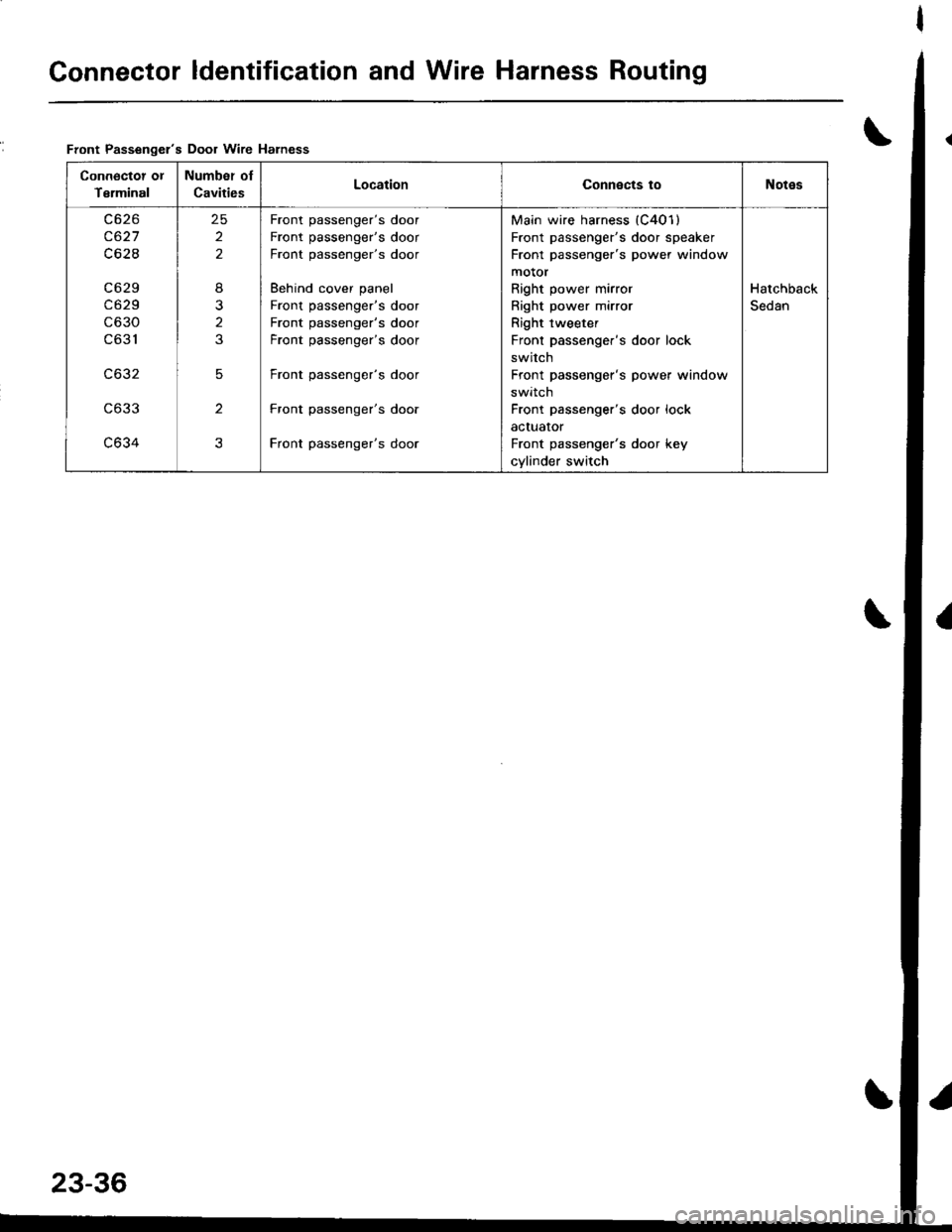

Connector ldentification and Wire Harness Routing

\Front Passengel's Door wire Harness

Connoctot ot

Terminal

Number oI

CavitiesLocationConnects toNotes

c627

c62I

c6 29

c629

c630

c631

c632

c633

c634

25

2

2

8

2

3

5

2

3

Front passenger's door

Front passenger's door

Front passenger's door

Behind cover panel

Front passenger's door

Front passenger's door

Front passenger's door

Front passenger's door

Front passenger's door

Front passenger's door

Main wire harness (C401)

Front passenger's door speaker

Front passenger's power window

motor

Right power mirror

Right power mirror

Right tweeter

Front passenger's door lock

switch

Front passenger's power window

swrrcn

Front passenger's door lock

actuator

Front passenger's door key

cylinder switch

Hatchback

Sedan

Page 1106 of 1681

T

I

1

J)

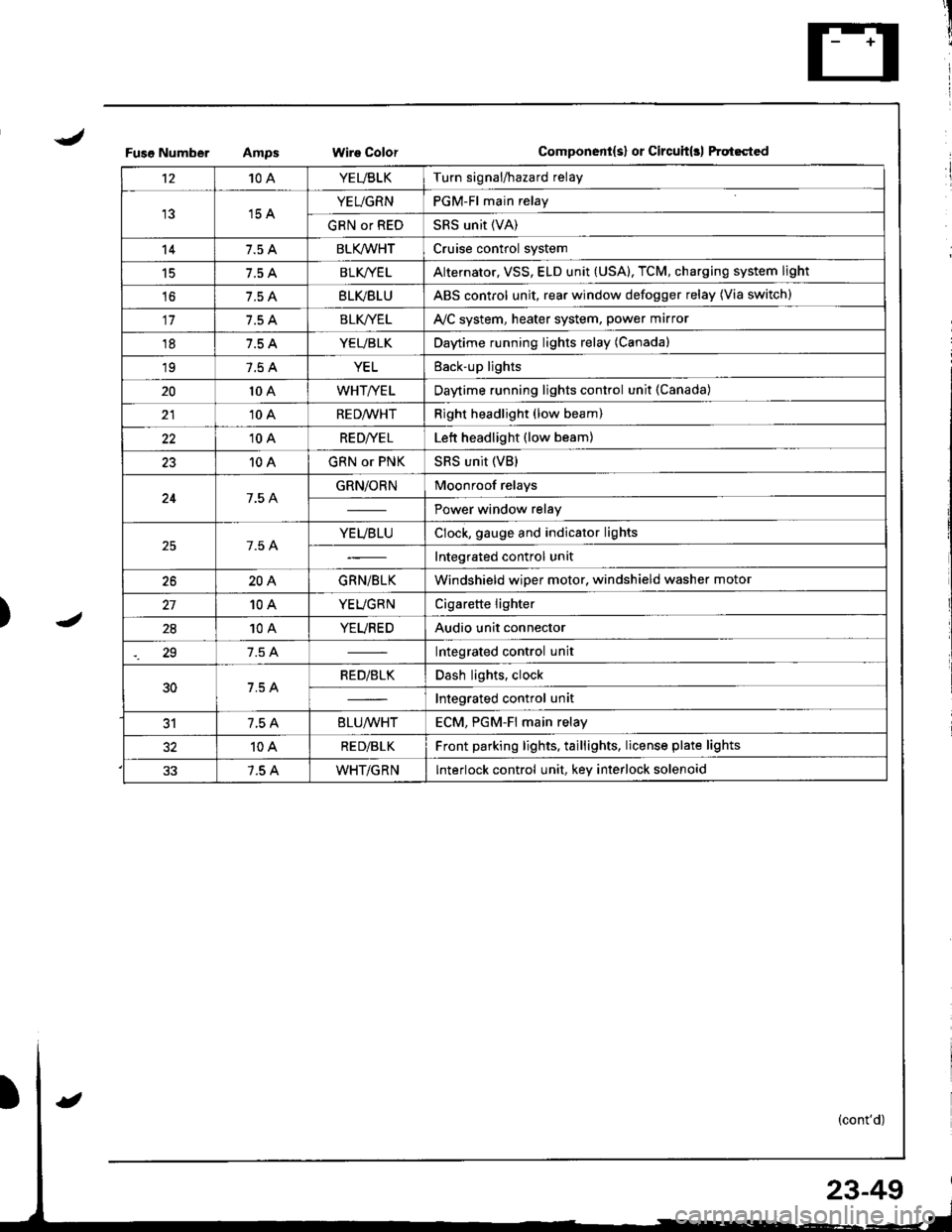

Fuso NumberWire ColorComponent{s} or Circuit(rl ftqt6cted

't210AYEUBLKTurn signal/hazard relay

15 AYEUGRNPGM-Fl main relay

GRN or REDSRS unit (VA)

147.5 ABLK/WHTCruise control system

15BLK/YE LAlternator, VSS, ELD unit (USA), TCM, charging system light

't67.5 ABLVBLUABS control unit, rear window defogger relay (Via switch)

117.5 ABLK//ELAVC system, heater system, power marror

187.5 AYEUBLKDaytime running lights relay (Canada)

197.5 AYELEack-up lights

2010 AWHT/YELDaytime running lights control unit (Canada)

2110 ARED/WHTRight headlight (low beam)

2210 ARE D|YE LLett headlight (low beam)

2310 AGRN or PNKSRS unit (VB)

247.5 AGRN/ORNMoonroof relays

Power window relay

7.5 AYEUBLUClock, gauge and indicator lights

Integrated control unit

2620AGRN/BLKWindshield wiper motor, windshield washer motor

10AYEUGRNCigarette lighter

2810AYEUREDAudio unit connector

29Integrated control unit

30RED/BLKDash lights, clock

Integrated control unit

317.5 A8LU/WHTECM. PGM-Fl main relav

10ARE D/BLKFront parking lights, taillights, license plate lights

7.5 AWHT/GRNInterlock control unit, key interlock solenoid

23-49