lock HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 597 of 1681

Adjustment

NOTE: Before adjusting the throttle controlcable, make

sure:

a Throttle cable lree play is correct (see section 11).a ldle speed is correct (see section 11).a To warm up the engine to normal operating tempera-

ture {the cooling fan comes on)

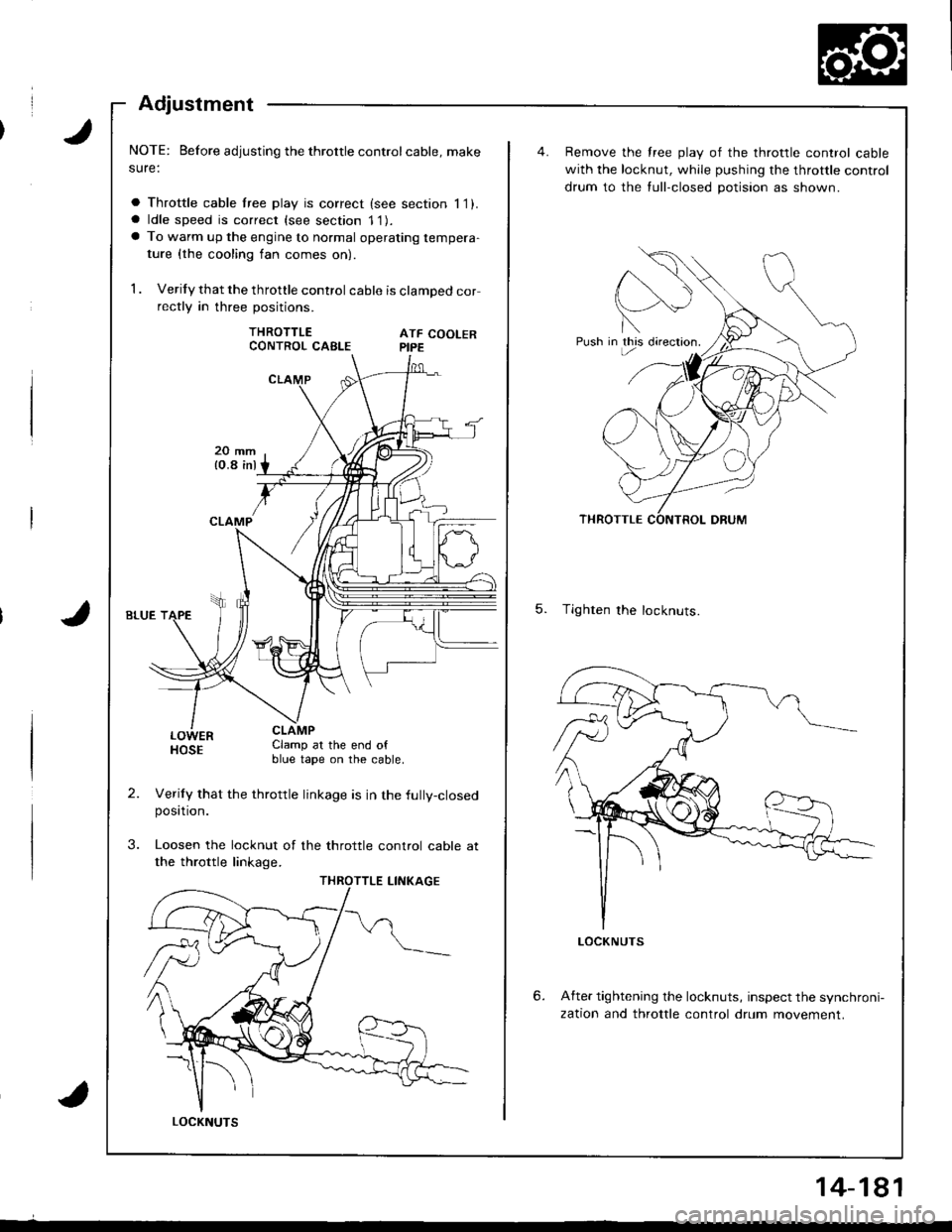

1 . Verify that the throttle control cable is clamped correctly in three positions.

THROTTLEATF COOLERPIPE

LOWERHOSEClamp at the end ofblue tape on the cable.

Verily that the throttle linkage is in the fully-closedposttron.

Loosen the locknut of the throttle control cable at

the throttle linkage.

CONTROL CABLE

LOCKNUTS

14-181

Push in this directron.

Remove the free play of the throttle control cable

with the locknut, while pushing the throttle control

drum to the tull-closed potision as shown.

5. Tighten the locknuts.

6.After tightening the locknuts, inspect the synchroni-

zation and throttle control drum movement.

Page 602 of 1681

Differential (81881 engine)

Backlash Inspection

Place differential assembly on V-blocks and install

both axles.

N4easure the backlash ot both pinion gears

Standa.d (Newl: O.O5-0.15 mm (O.OO2-0.006 in)

3. It the backlash is not within the standard, replace

the differential carrier.

Final Driven Gear RePlacement

1. Remove the bolts in a crisscross pattern ln several

steps, then remove the linal driven gear trom the

differential carrier.

NOTE: The final driven gear bolts have left-hand

tnreaos.

10 x 1.0 mm101 N'm 110.3 kgf'm, 74.5 lbf'fll

Left-hand threads

FINAL DRIVEN GEAR

OIFFERENTIALCARRIER

Install the final driven gear by tightening the bolts

in a crissc.oss pattern in several steps.

OIAL INDICATOR

Charnfer on inside diameter ottinal driven gear faces carrier.

\

15-4

Page 610 of 1681

Differential (818C1 engine)

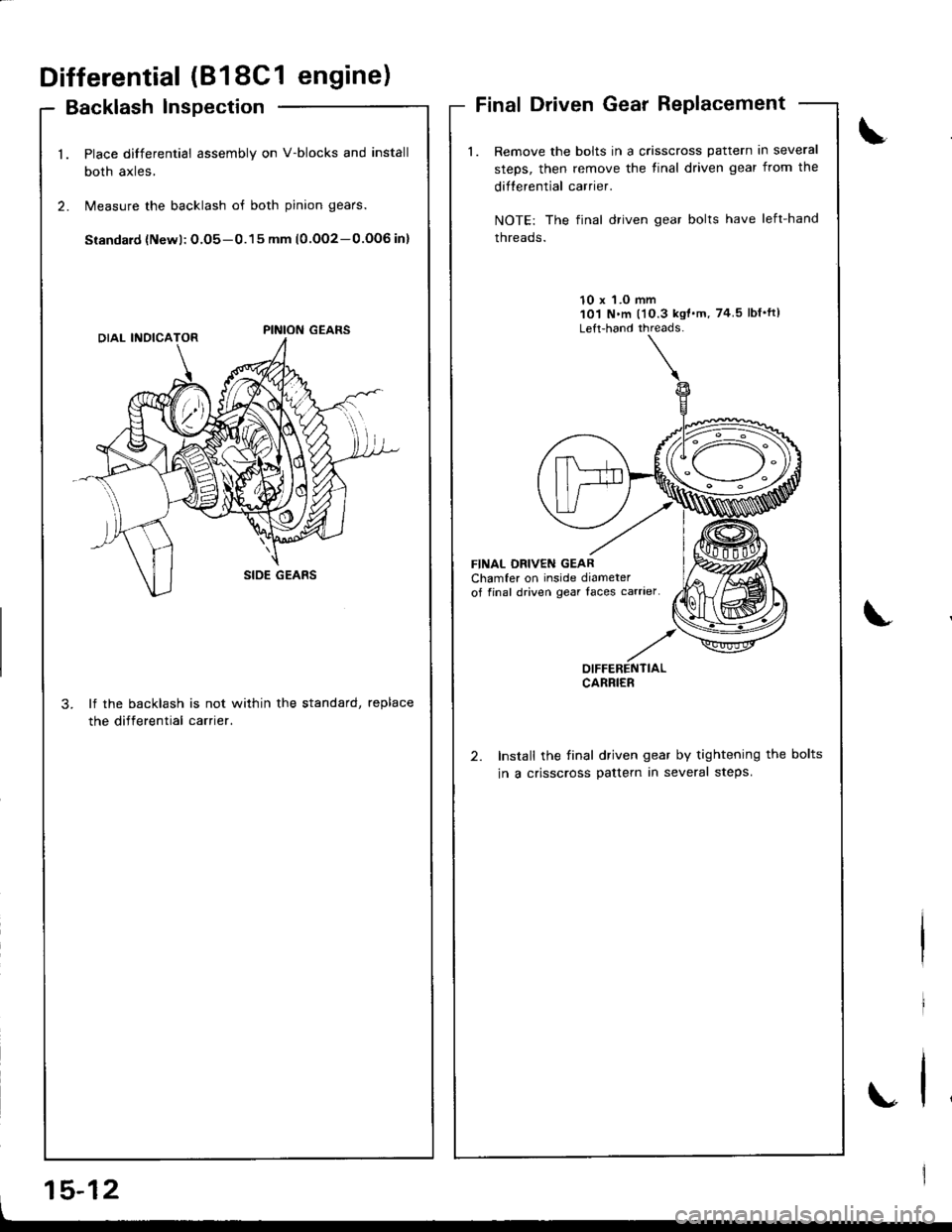

Backlash lnspection

Place differential assembly on V-blocks and install

both axles,

Measure the backlash of both pinion gears.

Siandard {Newl: O.O5-0.15 mm (0.OO2-0.OOG in}

lf the backlash is not within the standard, replace

the differential carrier.

Final Driven Gear Replacement

Remove the bolts in a crisscross pattern in several

steps, then remove the tinal driven gear from the

difterential carrier.

NOTE: The final driven gear bolts have left-hand

threads.

10 x 'l.O mm101 N.m l'10.3 kgt'm, 74 5lbf'ft)

Left-hand threads-

FINAL DBIVEN GEARChamfer on inside diameterof final driven gear Iaces carrier

Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.

\

.,

OIFFERENTIALCARRIER

I

15-12

Page 619 of 1681

Limited Slip Differential (B18C5 engine)

Description (cont'd)

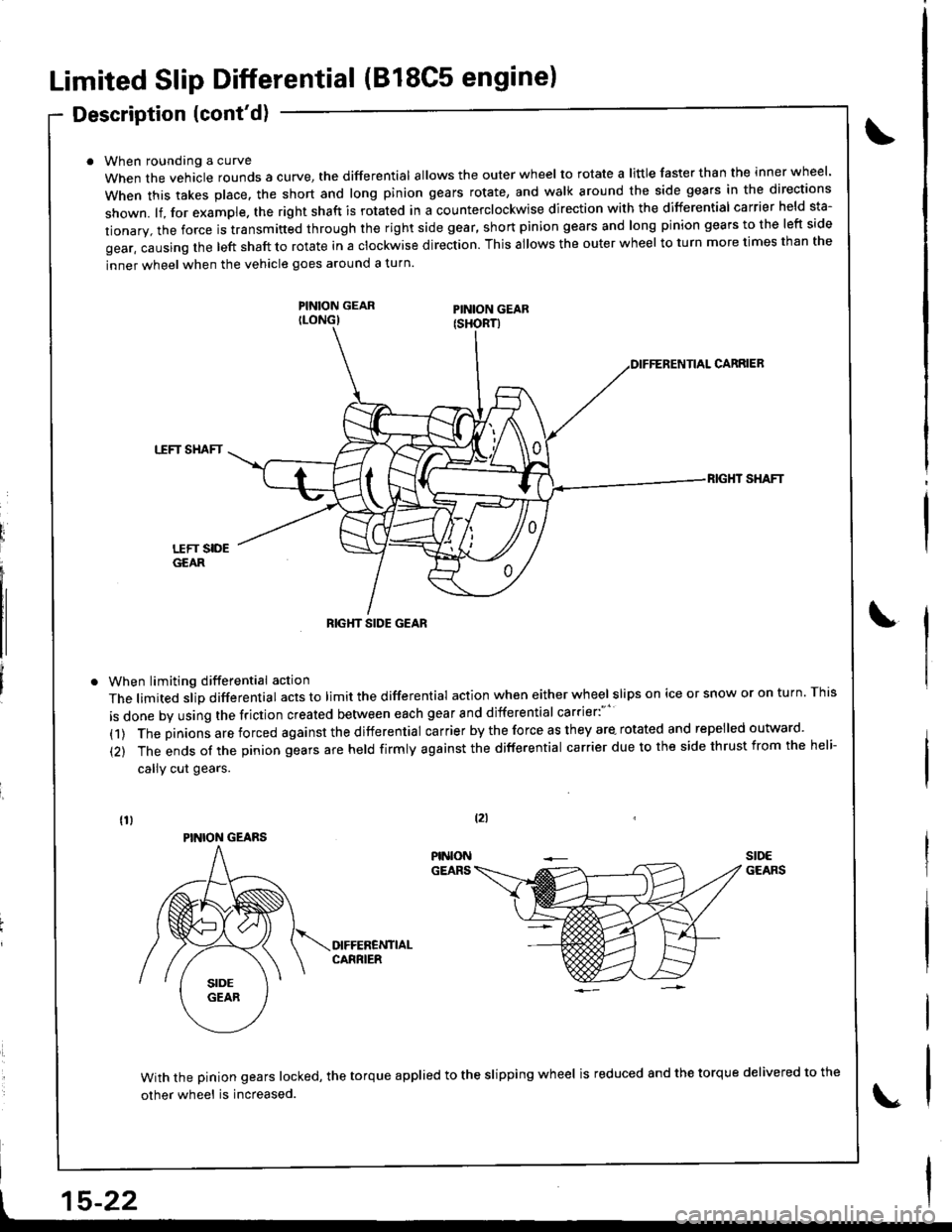

When roundang a curve

When the vehacle rounds a curye, tne differential allows the outer wheel to rotate a little faster than the inner wheel.

when this takes p|ace. the short and |ong pinion gears rotate, and wa|k around the side gears in the directions

shown. lf, for example. the right shaft is rotated in a counterclockwise direction with the differential carrier held sta-

tionary, the force is transmitted through the right side gear, short pinion gears and long pinion gears to the left side

gear, causing the left shaft to rotate in a clockwise direction. This allows the outer wheel to turn more times than the

inner wheel when the vehicle goes around a turn.

PINION GEARILONG)

When limiting differential action

The limited slip differential acts to limit the differential action when either wheel slips on ice or snow or on turn. This

is done by using the friction created between each gear and differential carrier:"''

(1) The pinions are forced against the differential carrier by the force as they are- rotated and repelled outward.

(2) The ends of the pinion gears are held firmly against the differential carrier due to the side thrust from the heli-

callY cut gears.

CARRIEB

TTFT SHAFT

RIG}IT SHAFT

With the pinion gears locked, the torque applied to the slipping wheel is reduced 8nd the torque delivered to the

other wheel is increased.

tzl

t15-22

RIGHT SIDE GEAR

PINION GEARS

Page 620 of 1681

Operational Check

Set the parking brake and block the rear wheels.

Raise the front of the vehicle, and support it with

safety stands in the proper locations (see section 1).

With the engine off, shift the transmission into lstgear,

Rotate either front wheel bv hand and check that

the other wheel rotates in the opposite direction.

lf the opposite tront wheel does not rotste, or if voucannot spin the front wheels at all, the limited slip

differential is faulty and should be roplaced.

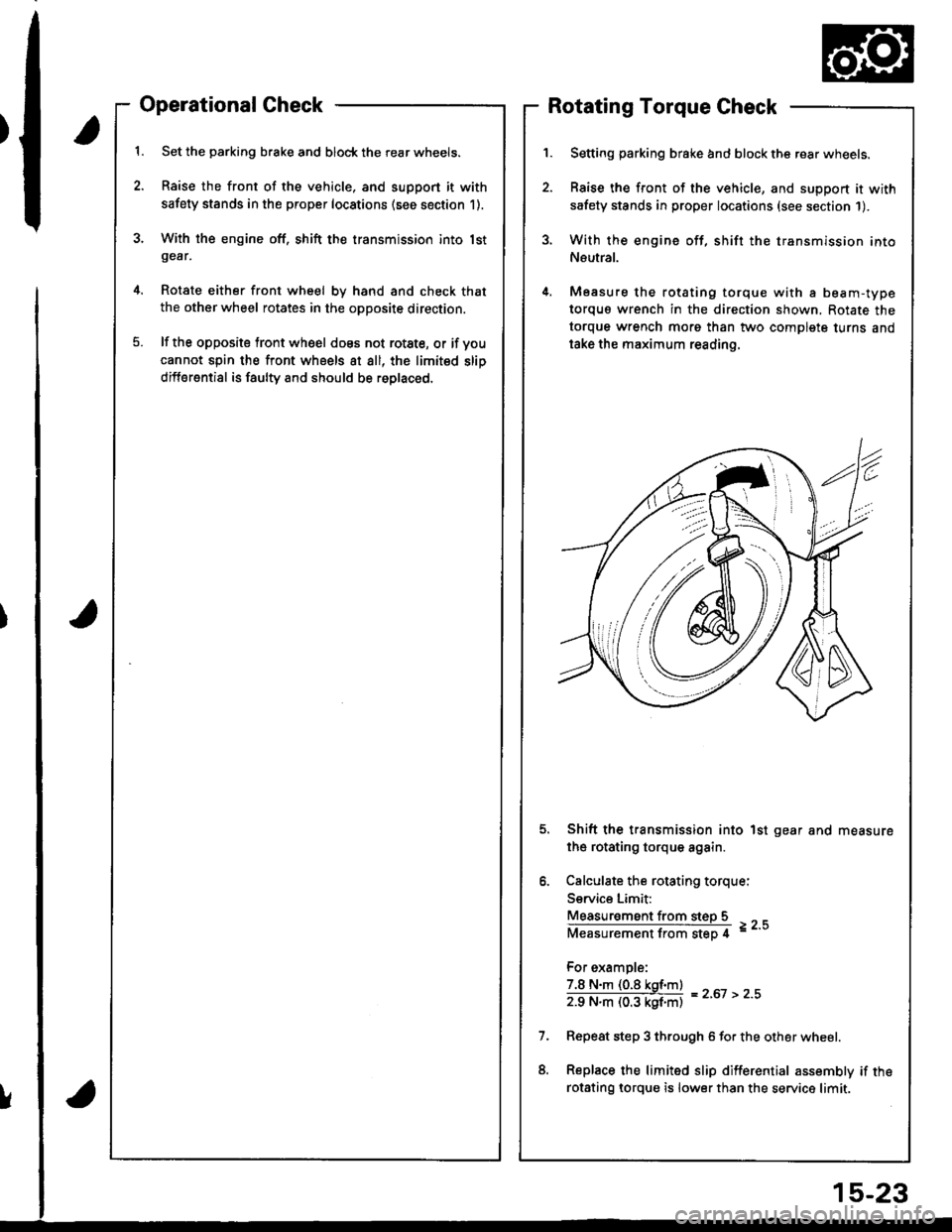

Rotating Torque Check

Setting parking brake and block the rear wheels.

Raise the front of the vehicle, and support it with

safety stands in proper locations (see section 1).

With the engine off, shift the transmission into

Neutral.

Measure the rotating torque with a beam-type

torquo wrench in the direction shown, Rotate the

torque wrench morg than two complete turns and

take the maximum reading.

Shift the transmission into 1st gear and measure

the rotating torque again.

Calculate the rotating torque:

Service Limit:

Measur€ment from steD 5

Measurementfrom step 4 =--

For example:

7.8 N.m (0.8 kgf.m)

zg N"ll (03 kgf'ntl = z'ot > z''

Repeat step 3 through 6 for the other wheel.

Replace the limited slip differential assembly if the

rotsting lorque is lower than the service limit.

!

15-23

Page 627 of 1681

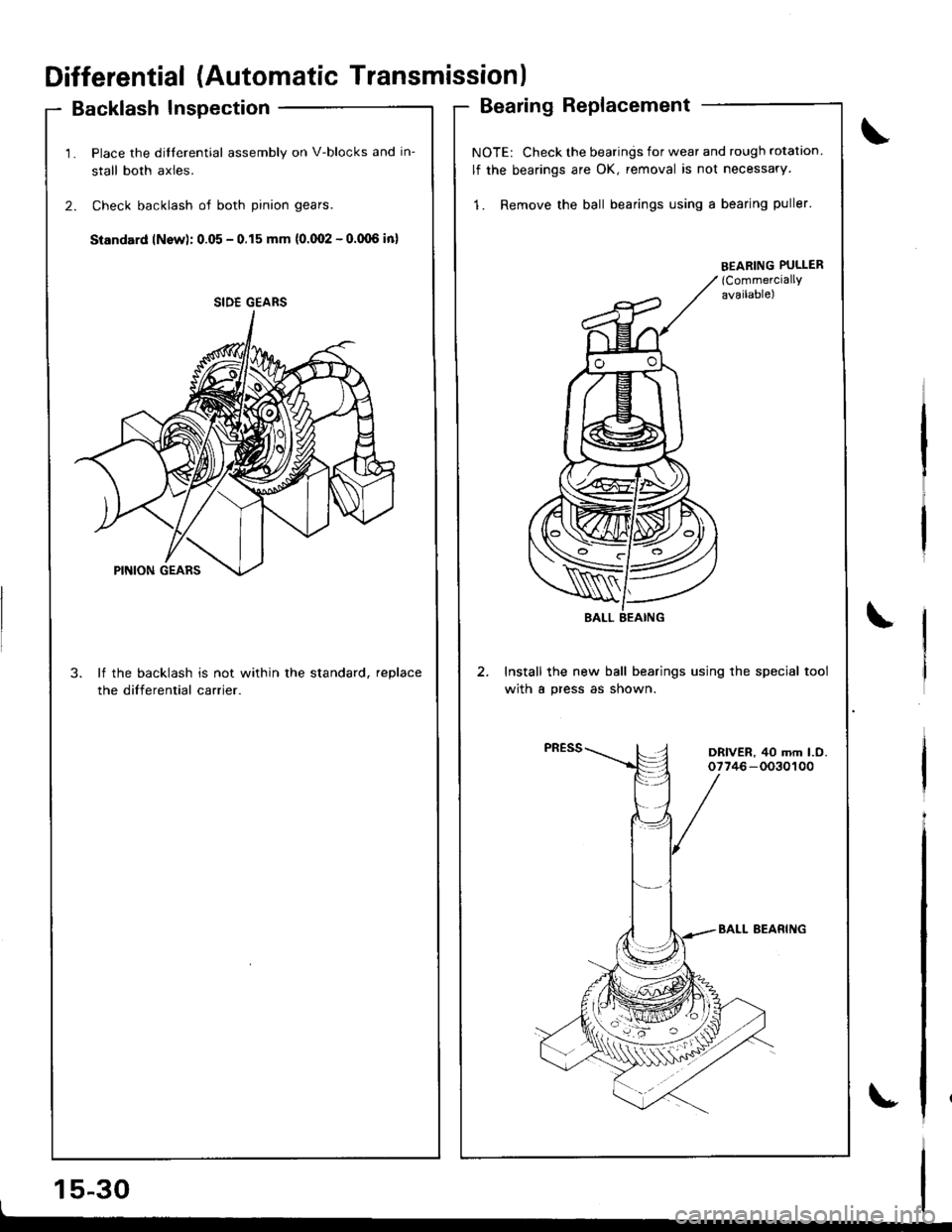

Differential (Automatic Transmissionl

Backlash Inspection

1. Place the dilferential assembly on V-blocks and in-

stall both axles.

2. Check backlash of both pinion gears.

Standard lNsw): 0.05 - 0.15 mm {0.(Xt2 - o.(Xl6 in)

3. lf the backlash is not within the standard, reDlace

the differential carrier.

15-30I

Bearing Replacement

NOTE: Check the bearings for wear and rough rotation

lf the bearings are OK, removal is not necessary.

1. Remove the ball bearings using a bearing puller'

Install the new ball bearings using the special tool

with a press as shown.

SIDE GEARS

EEABING PULLER(CommerciallY

available)

\

DRIVER, 40 mm l.O.07746-0030100

Page 634 of 1681

t

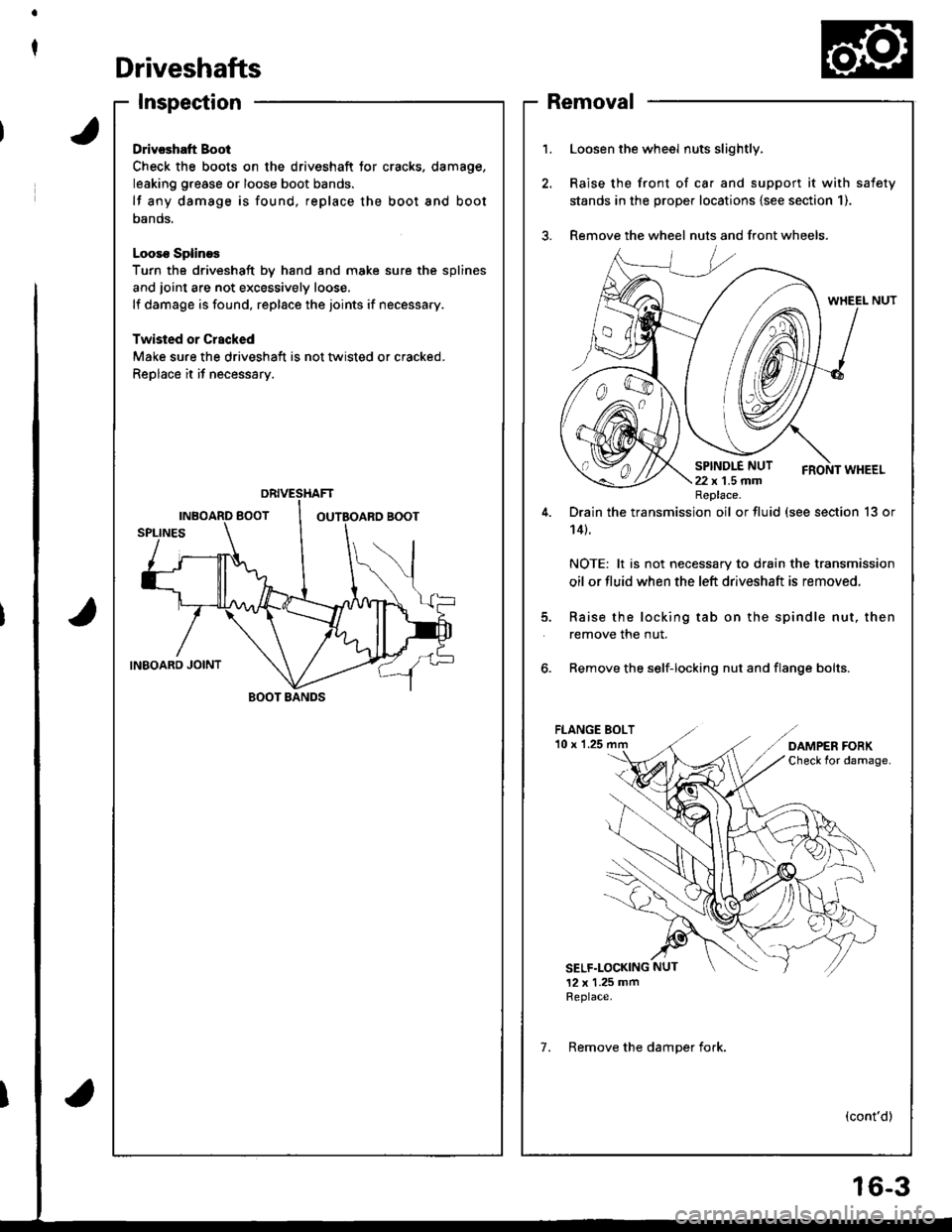

Driveshafts

Inspection

Drivcshatt Boot

Check the boots on the driveshaft tor cracks. damage,

leaking grease or loose boot bands.

lf any damage is found, replace the boot and boot

oanos.

Looso SplineE

Turn the driveshaft by hand and moke sure the splines

and joint are not excessively loose.

lf damage is found, replace the joints if necessary.

Twisled or Crscked

Make sure the driveshaft is not tlvisted or cracked.

Replace it if necessary.

BOOT BANDS

1.Loosen the wheel nuts slightly,

Raise the front of ca. and support it with safety

stands in the prope. locations {see section 1).

Remove the wheel nuts and front wheels.

5.

Drain the transmission oil or fluid (see section 13 or

14t.

NOTE: lt is not necessary to drain the transmission

oil or fluid when the left driveshaft is removed.

Raise the locking tab on the spindle nut, then

remove the nut.

6. Remove the self-locking nut and flange bolts.

FLANGE BOLT'10 x 1.25

SELF.LOCKING NUT

12 x 1.25 mmReplace.

(cont'd)

Replace.

7. Remove the damoer fork.

Removal

6-3

Page 645 of 1681

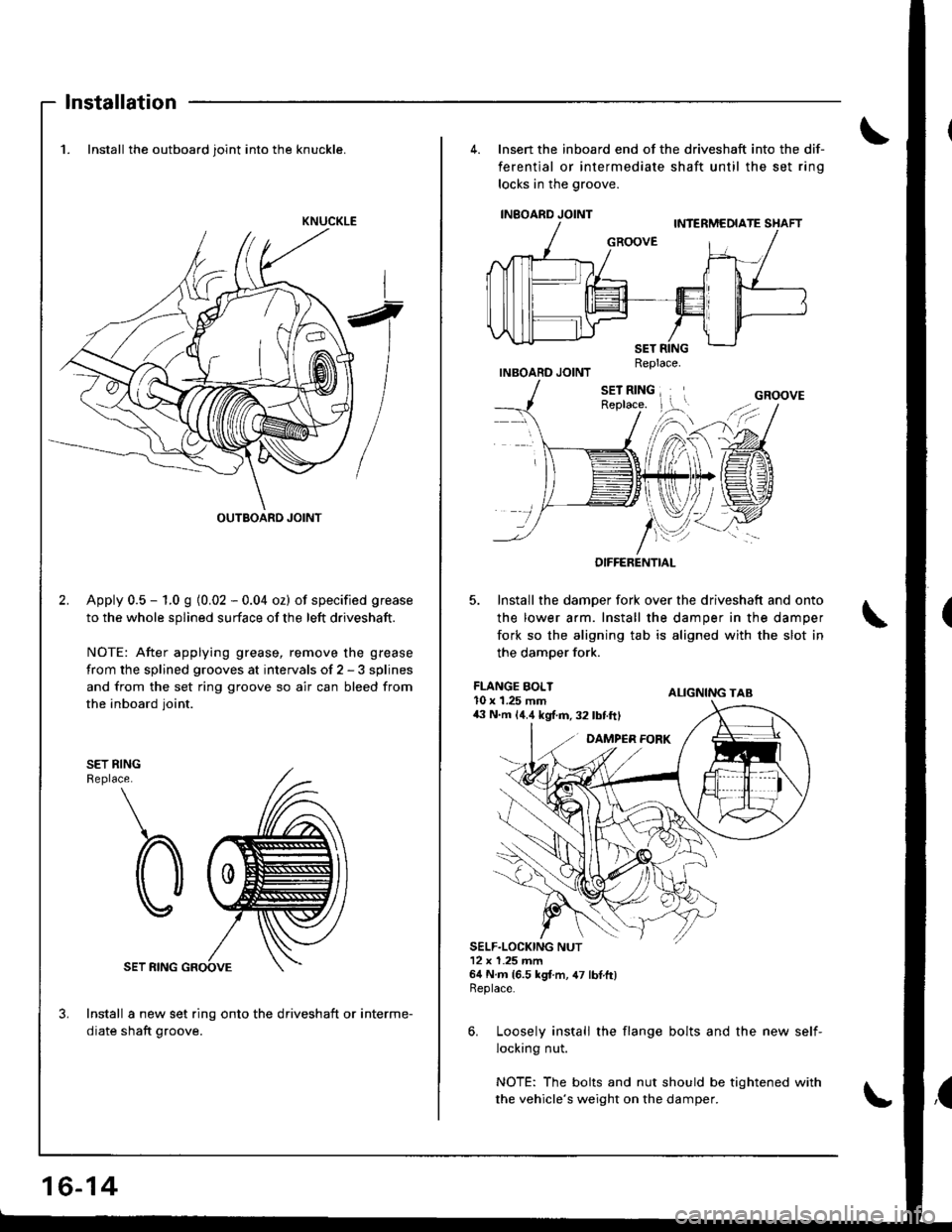

Installation

1. Install the outboard joint into the knuckle.

Apply 0.5 - 1.0 g {0.02 - 0.04 oz) of specified grease

to the whole splined surface of the left driveshaft.

NOTE: After applying grease, remove the grease

from the splined grooves at intervals of 2 - 3 splines

and from the set ring groove so air can bleed from

the inboard ioint.

SET RINGReplace.

SET RING

Install a new set ring onto the driveshaft or interme-

diate shaft groove.

KNUCKLE

OUTBOARD JOINT

16-14

4. lnsen the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set rino

locks in the groove.

INEOARD JOINT

INBOARD JOINTReplace.

lnstall the damoer fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damoer fork.

ALIGNING TAB

6. Loosely install the flange bolts and the new self-

locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

GROOVE

OIFFERENTIAL

FLANGE BOLT10 x 1.25 mm43 N.m {4.4 kgf.m,32lbtftl

Page 646 of 1681

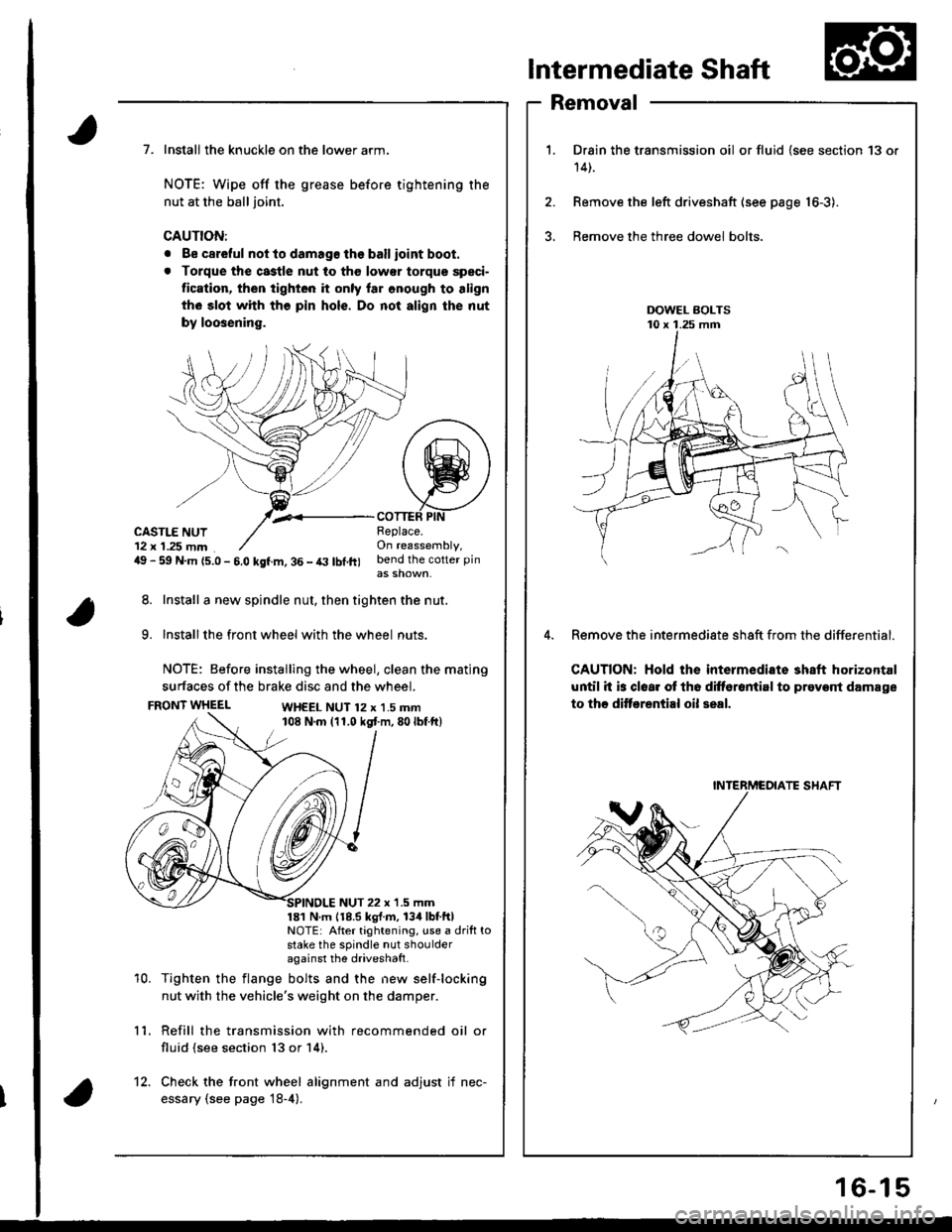

Intermediate Shaft

Removal

Drain the transmission oil or fluid {see section 13 or

14t.

Remove the left driveshaft (see page 16-3).

Bemove the three dowel bolts.

Remove the intermediate sh8ft from the differential.

CAUTION: Hold the intermediate shaft horizontal

until it is clear ot th6 difforantirl to prevont damage

to thc ditf€rential oil seal.

7. Install the knuckle on the lower arm.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. Be careful not to damago the ballioint boot.

. Torque the castle nut to tho low€r torque speci-

tication, then tighten it only lar onough to align

th6 slot whh tho pin hols. Do not align the nut

by loosening.

,.<__coTTEF PtNCASTLE NUT12 x 1.25 mm49 - 59 N.m {5.0 - 5.0 kgf.m, 36 - t3 lbl.ft)

Beplace.On reassembly,bend the cotter pin

8. Install a new spindle nut, then tighten the nut.

9. Installthe front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWH€EL NUT 12 x 1.5 mm108 N.m (11.0 kgt m,80lbf ft)

10.

NUT 22 x '1.5 mm181 N m 118.5 kgl.m, 134lbtftlNOTE: After tightening, use a drift tostake the spindle nut shoulderagainst the driveshatt.

Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

11.

12. Check the front wheel alignment and adjust if nec-

essary (see page 18-4).

INTERMCOIATE SHAFT

16-15

Page 651 of 1681

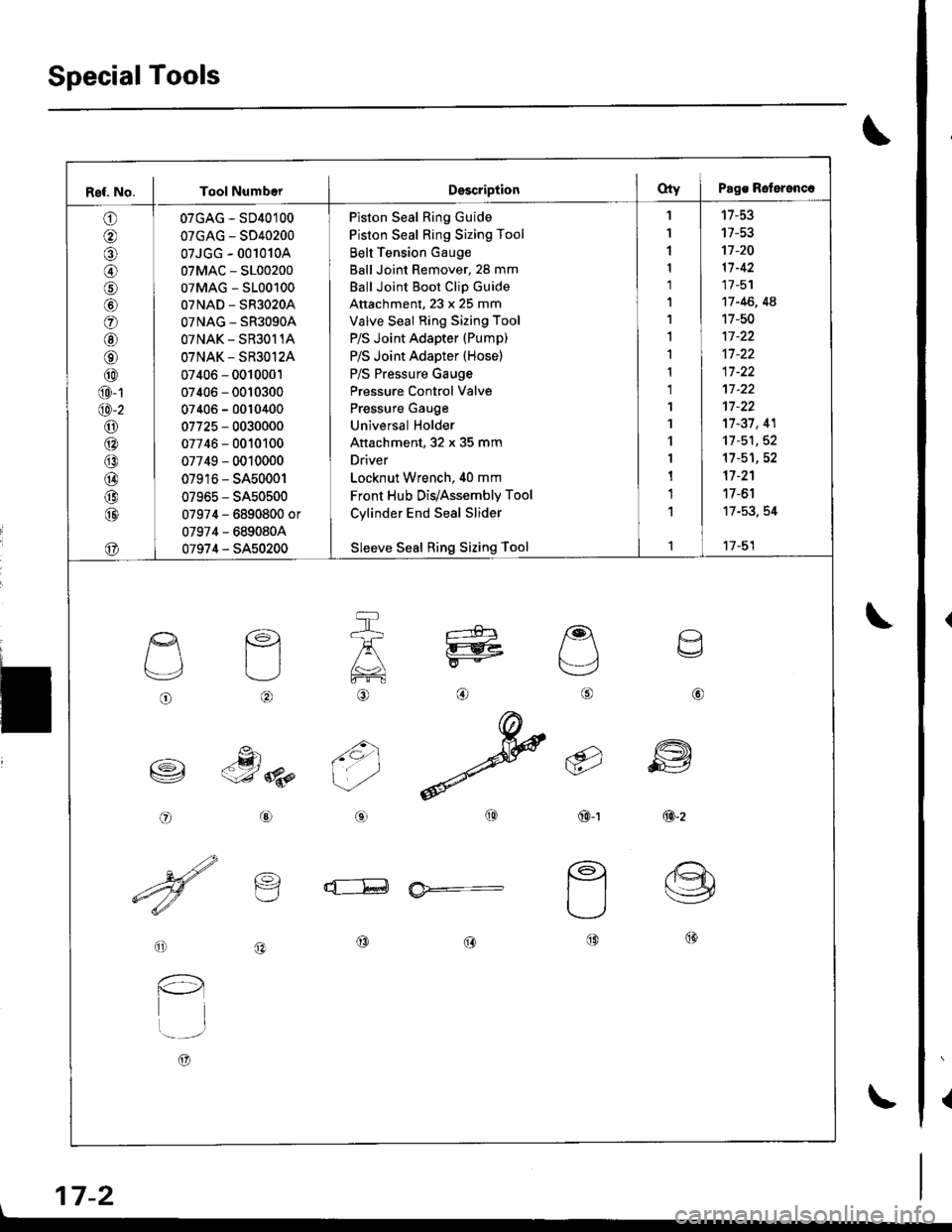

SpecialTools

{

\

\

17-2

Ref. No. I Tool NumberDsscriptionOty I Pags Reterenc.

o

@

@

o

@

@

@

@

@

@-1

@-2

o6:^

@

@

@

@

@

07GAG - SD40100

07GAG - SD40200

07JGG - 001010A

07MAC - S100200

07MAG - S100100

07NAD - SR3020A

OTNAG _ SR3OgOA

OTNAK - SR3O11A

OTNAK - SR3O12A

07406 - 0010001

07406 - 0010300

07406 - 0010400

07725 - 0030000

07746 - 0010100

07749 - 0010000

07916 - SA50001

07965 - SA50500

07974 - 6890800 or

07974 - 6890804

07974 - SA50200

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover, 28 mm

Ball Joint Boot Clip Guide

Attachment, 23 x 25 mm

Valve Seal Ring Sizing Tool

P/S Joint Adapter (Pump)

P/S Joint Adapter (Hose)

P/S Pressure Gauge

Pressure Control Valve

Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Driver

Locknut Wrench. 40 mm

Front Hub Dis/Assembly Tool

Cylinder End Seal Slider

Sleeve Seal Ring Sizing Tool

'I

1

1

1

1'|

1,l

I

1

1

1'I

'l

1

1

1

1

1

't7-53

17-53't]-20

11-42

17 -51

17 -46, 4A

17-50

17-37, 41

11-51,52't1-51,52

17 -2'�1

17 -6'l

17-53. 54

17-51

o

L'4,

o

€)

-g)c-J 8p

@

@

6i

(9')\E/'

@-t

a

6

ffi

@-z

d--E ia*=-

o

l-l

t..-_-.r

A)

@@@

\