service HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1523 of 1681

Headlights (cont'd)

- How the Circuit Works

Low Beam OperationRefer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

With the headlight switch in HEAD and the dimmer

switch in LO, current flows through the headlight

switch, fuse 21 , tuse 22, and the low beam

filaments to ground, and the low beams come on.

tligh Beam Operation

With the headlight switch in HEAD and the dimmer

switch in Hl, current flows through the headlight

switch, dimmer/passing switch, fuses 4, 5, 21, and

22, and the low and high beam filaments to ground,

and the low and high beams come on.

Current also tlows through the high beam indicator

light to ground. The high beam indicator comes on

to remind the driver that the high beams are on.

Flash operation

The flash feature works with the headlight switch in

OFF, PARK, or HEAD (low beams). When you

move the flash-to-pass switch to ON, current flows

through the switch, fuses 4 and 5, and the high

beam filaments to ground, and the high beams

flash. The high beam indicator also flashes during

the flash oDeration. The flash function has no effect

it the high beams are already on.

Daytime Running Lights Day Operation

When you turn the ignition to ON (ll) with the

parking brake released, the daytime running lights

control unit supplies battery voltage at the

WHT/RED wire. This voltage is applied to the high

beam headlights through the daytime running lights

resistor. Each high beam headlight receives less

than battery voltage causing them to come on al

reduced brightness.

lf the parking brake is set, a ground signal is applied

to the daytime running lights control unit at the

RED/GRN wire. It the parking brake is set when you

first turn the ignition switch to ON (ll), the high beam

headlights will remain off until you release the

parking brake. Once the high beam headlights are

in day mode, setting the parking brake will not

cause the headlights to turn off . When low or high

beam operation is requested, baftery voltage trom

the headlight switch is applied to the daytime

running light control unit via the RED/vVHT wire.

The daytime running light control unit then

discontinues the daytime running light mode.

1 10-10

Page 1540 of 1681

Power Windows (conrd)

- How the Circuit Works

CAUTION: You could iniure your arms, hands,

or fingers if you unintentionally switch the

driver's window to "automatic down,' while

working in that door with the power on. Discon-

nect the window switch connector or the battery

when working in the driver's door.

System Description

The operation of the power windows is controlled by

the main switch in the power window masler switch.

When the main switch is in OFF, only the driver's

door window can be opened or closed. With the main

switch ON, all windows can be opened or closed

either by switches in the master panel, or switches in

the doors. The driver's window switch also has an

automatic down mode which is tumed on by pushing

the switch down to its second position.

The power windows are driven by reversible motors.

Each motor is protected by a built-in circuit breaker.

lf the window switch is held on too long (with the

window obstructed, or after the window is fully up or

down), the circuit breaker opens the circuit. The

circuit breaker resels automaticallV as it cools.

Driver's Window

With the ignition switch in ON (tt), vottage isprovided to the coil ol the power window relay

through fuse 24. The contacts of the power window

relay close, and voltage is applied to the driver's

switch. When you push the power window master

switch to Uq voltage is applied to the driver's power

window motor. (The motor's ground path is backthrough the power window master switch.) The

driver's window motor then drives the window uo.

When you push the switch to DOWN, voltage ls

applied in the opposite direction and the motor

drives the window down.

Automatic Down (Driver's Window)

With the ignition switch in ON (tl), vottage is applied

to the coil of the power window relay. The contacts

of the power window relay close and voltage is

applied to the power window master switch. When

you push the driver's switch to the AUTO DOWN

position, voltage is applied through the drivels

switch to the driver's window motor. The control unit

receives pulses at the pulser input while the motor

is running. When the window is fully down, the

motor stops, and pulses are no longer generated by

the pulser. This is sensed by the control unit at thepulsBr input, and voltage is no longer applied to the

driver's window motor.

Passenger Windows

With the ignition switch in ON (tt), vottage is apptied

to the coil of the power window relay through fuse

24. The contacts of the power window relay then

close, applying voltage to the individual window

switches and the power window master switch. With

the master panel main switch ON, the passenger

windows can be operated from the individual

window switches or from the master Danel switches.

When you push the front passenger's window

switch to UR voltage is applied to the front

passenger's window motor. (The motor is grounded

through the contacts in the front passenger's window

switch and the power window master switch.) The

wndow moves up as long as you hold the switch in

lhe UP position. lf you push the switch to DOWN,

voltage is applied in the opposite direction io the

front passenger's window motor, and the window

moves down as long as you hold the switch in the

DOWN position. The window switches in the other

doors operate similarly.

When you push the front passenger's switch in the

master panel to UP, voltage is applied through the

front passengeas window switch contacts to the

front passenger's window motor (The motor is

grounded through the contacts in the front

passenger's window switch and the power window

master switch.) The window moves up as long asyou hold the switch in the UP position. lf you push

the switch to DOWN, voltage is applied in the

opposite direction to the front passenger's window

motor, and the window moves down as long as you

hold the switch in the DOWN position. The otherpassenger window switches in the master panel

operate similarly.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

120-6

Page 1542 of 1681

- How The Circuit Wo

With the ignition switch ON (ll), voltage is applied

through fuse 24 to the coil of the moonroof relay.

The moonroof relay energizes and voltage is

applied from fuse 49 through the closed contacts of

the moonroof relay to the moonroof switch.

Open Operation

When you push the moonroof switch to the OPEN

position, voltage is applied to the moonroof motor.

The moonroot motor is grounded through the

CLOSE contacts of the moonroof switch, and the

motor runs to open the moonroof

Close Operation

When you push moonroof switch to the CLOSE

position, voltage is applied to the moonroof motor.

The moontoof motor is grounded through the OPEN

contacts of the moonroof switch, and the motor runs

to close the moonroof.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

122-1

Page 1548 of 1681

- How the Circuit Works

The immobilizer system is designed to prevent the

car f rom being started without the owner's ignition

key. lf an attempt is made to start the car without

the correct key, the immobilizer system will disable

the car's fuel supply.

The immobilizer system consists of the ignition key,

immobilizer receiver unit, immobilizer indicator

light, PGM-FI main relay, fuel pump, and the PCM

or ECM.

With the ignition switch in ON (ll) or START (lll), the

immobilizer receiver unit and the PCM or ECM

receive an "ignition on" signal through fuse 44 and

the PGM-FI main relay. The PCM or ECM then

sends power to the ignition key transponder through

the immobilizer receiver unit. The transponder then

sends a coded signal back to the PCM or ECM

through the receiver unit. lf the signal is correct, the

PCM or ECM will energize the car's fuel supply

system by grounding the PGM-FI main relay. The

immobilizer indicator light flashes a code to indicate

that the correct key has been inserted. lf the

ignition key signal is not correct, the PCM or ECM

will not energize the car's fuel supply system by not

grounding the PGM-Fl main relay. The immobilizer

indicator light then flashes a code to indicate that an

incorrect key has been inserted.

Refer to the Service Manual (Section 23,

Body Electrical) for specific tests and

troubleshooting procedures.

132-1

Page 1558 of 1681

lnterlock System

- How the Circuit Works

Key Interlock

Battery voltage is supplied at all times through f use

33 to the key interlock switch. When the key is in

the ignition, battery voltage is supplied to the key

intedock solenoid and the key interlock circuit in the

interlock control unit. When the A/T gear position

switch is in PABK, ground is provided to the key

interlock circuit. This removes ground from the

interlock solenoid, the solenoid is deenergized, and

the key can be removed from the ignition.

Shift Position Interlock

Battery voltage is supplied at all times lrom fuse 52

to the brake switch. With the ignition in ON (ll) or

START (lll), battery voltage is supplied through luse

25 to the shift lock solenoid. When you push the

brake pedal, battery voltage is applied through the

GRN/VVHT wire to the transmission ('98-�99 models)

or powertrain ('00 model) control module (TCM or

PCM). lf, at the same time, you do not push the

accelerator pedal, a low voltage signal is sent

through the RED/BLK wire to the TCM or PCM. The

TCM or PCM then applies voltage through the

WHT/RED wire to the shift lock circuit in the

interlock control unit. lf the A,/T gear position switch

is in the PARK position, the shift lock circuit

provides ground to the shift lock solenoid. The

solenoid is then energized, and the shift lever can

be moved from the PARK Dosition.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

138-2

Page 1561 of 1681

Power Mirrors

- How the Gircuit Works

The two outside mirrors are controlled by the power

minor switch. Each mirror has two reversible

motors: one motor moves the mirror uo and down

and the other motor moves the mirror left and right.

The oower mirror switch contains three switches lo

control mirror direction, and two switches to select

the left or right mirror. With the ignition in ON (ll),

battery voltage is supplied to the power mirror

switch. The mirror selector switch directs voltage

from two of the direction switches to either the left

or the right minor. Each direction switch is used for

more than one function.

Mirror Up Operation

With the power mirror switch in the up position,

switch 1 is moved to the A oosition. Switch 1

applies battery voltage to both the left and right

power mirror up/down motors. lf the mirror selector

switch is in the left position, the left up/down motor

is grounded through the mirror selector switch and

switch 2 in the B position to G501 (Sedan) or G502

(Hatchback). lf the right mirror up/down motor is

selected il is also grounded through switch 2 in the

B position.

Mirror Down Operation

With the power mirror switch in the down position,

switches 2 and 3 are moved to the A position.

Switch 2 applies battery voltage to the left or right

power mirror up/down motor as determined by the

mirror selector switch. The selected mirror motor is

grounded through switch I in the B position to G501

(Sedan) or G502 (Hatchback). When switch 2 is

moved to position A, it also applies battery voltage

to the selected mirror lefyright motor. With switch 3

in the A position, battery voltage is supplied to both

sides of the leruright motor so it does not move.

Mirror Left Operation

With the power mirror switch in the left position,

switches 1 and ? ate moved to the A oosition.

Switch 2 applies battery voltage to the left or right

power mirror lefvright motor as determined by the

mirror selector switch. The selected mirror motor is

grounded through switch 3 in the B position to G501

(Sedan) or G502 (Hatchback). When switch 2 is

moved to position A, it also applies battery voltage

to the selected mirror up/down molor. With switch 1

in the A position, battery voltage is supplied to both

sides of the uD/down motor so it does not move.

Mirror Right Operation

With the power mirror switch in the right position,

switch 3 is moved to the A position. Switch 3

applies battery voltage through the mirror selector

switch to the left or right lefvright motor. The

motor is grounded through the mirror selector

switch and switch 2 in the B oosition to G501

(Sedan) or G502 (Hatchback).

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

141-2

Page 1606 of 1681

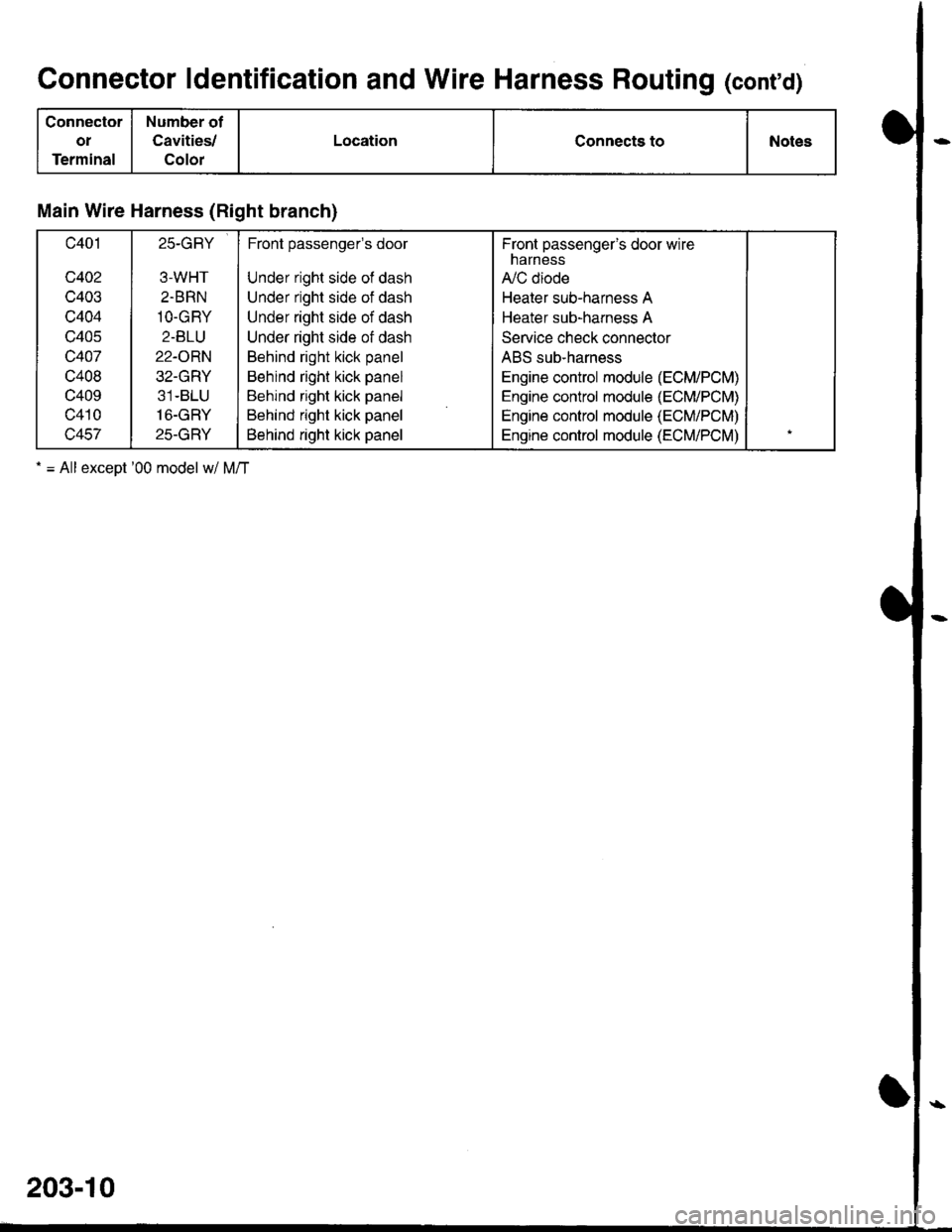

Connector ldentification and Wire Harness Routing (cont'd)

Connector

oI

Terminal

Number of

Cavities/

Color

LocationConnects toNotes

Main Wire Harness (Right branch)

c401

c402

c403

c404

c405

c407

c408

c409

c410

c457

25-GRY

3-WHT

2.BRN

1O-GRY

2-BLU

22-ORN

32-GRY

31-BLU

16-GRY

25-GRY

Front passengels door

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Behind right kick panel

Behind right kick panel

Behind right kick panel

Behind right kick panel

Behind right kick panel

Fronl passenger's door wirenarness

A,/C diode

Heater sub-harness A

Heater sub-harness A

Service check connector

ABS sub-harness

Engine control module (ECM/PCM)

Engine control module (ECM/PCM)

Engine control module (ECM/PCM)

Engine control module (ECM/PCM)

. = All exceot '00 model w/ M/T

203-10

Page 1643 of 1681

\

\

Specifications

Standards and Service Limits .............. g-2

Design Specifications 3-15

Body Specifications ... 3-18

Page 1644 of 1681

I

I

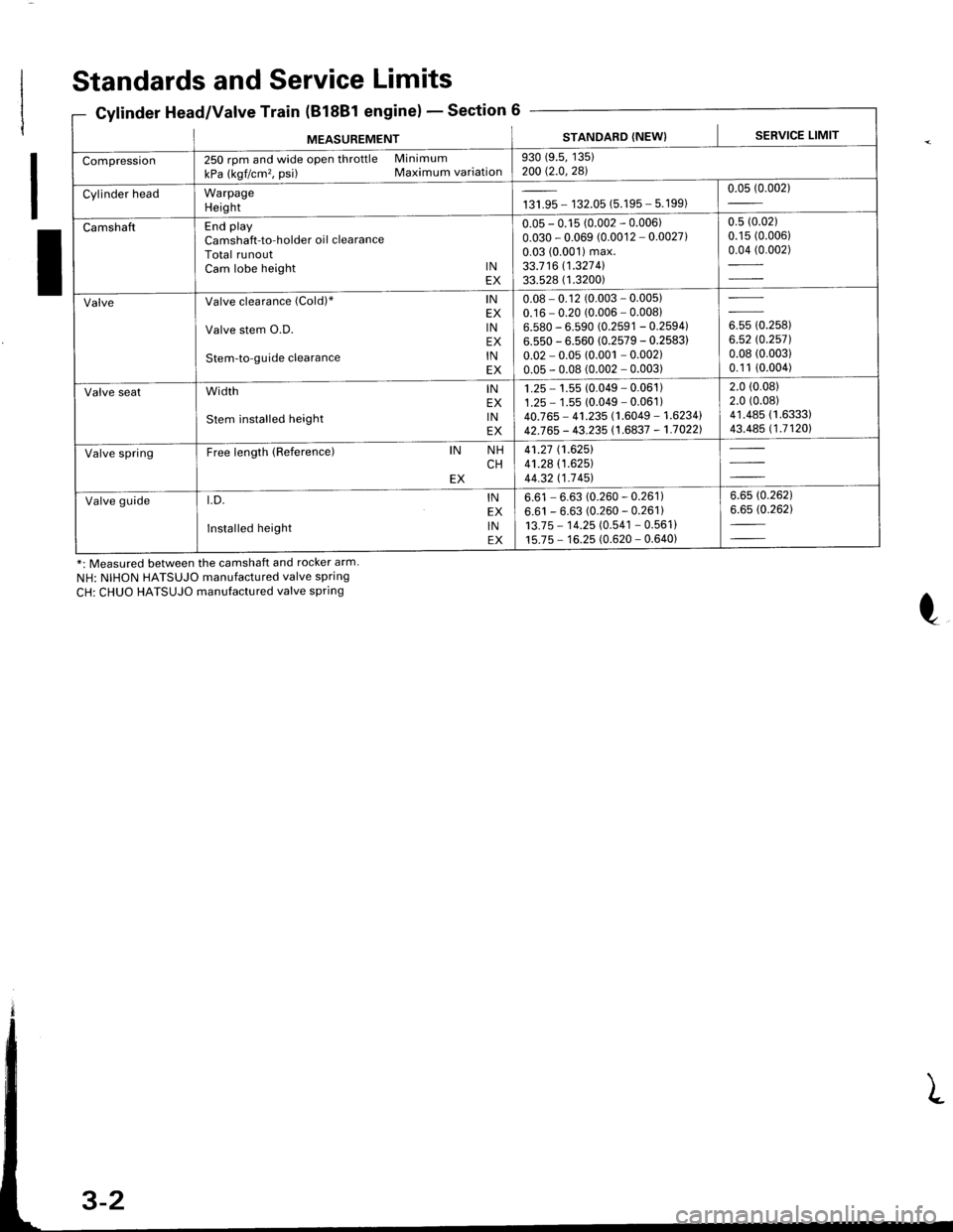

Standards and Service Limits

Cylinder Head/Valve Train (B18Bl engine)Section 6

*: Measured between the camshaft and rocker arm.

NH: NIHON HATSUJO manufactured valve spring

CH: CHUO HATSUJO manufactured valve spring

MEASUREMENTSTANDARD (NEW) I SERVICE LIMIT

Compression250 rpm and wide open throttle Minimum

kPa (kgf/cm'�, psi) Maximum variation930 (9.5, 135)200 Q.0,281

Cylinder headWarpageHeightta,|* - 132.05 (5.195 - 5.199)0.05 (0.002)

CamshaftEnd playCamshaft-to-holder oil clearanceTotal runoutCam lobe height lNEX

0.05 - 0.15 (0.002 - 0.006)0.030 - 0.069 (0.0012 - 0.0027)0.03 (0.001) max.33.7 16 11.327 4l33.528 ( 1.3200)

0.5 (0.02)

0.15 (0.006)

0.04 (0.002)

ValveValve clearance (Cold)" lNEX

Valve stem O.D. lNEX

Stem-to-guide clearance lNEX

0.08 - 0.12 (0.003 - 0.005)0.16 - 0.20 (0.006 - 0.00816.580 - 6.590 (0.2591 - 0.2594)6.550 - 6.560 (0.2579 - 0.2583)

0.02 - 0.05 (0.001 - 0.002)0.05 - 0.08 (0.002 - 0.003)

ouu to.rutt6.52 rc.2571.0.08 (0.003)

0.1 1 (0.004)

Valve seatwidth lNEX

stem installed height lNEX

1 .25 - 1.55 (0.049 - 0.061 )1.25 - 1 .55 (0.049 - 0.061 )40.765 - 41.235 (1.6049 - 1.6234142J65 - 43.235 (1.6837 - 1.70221

2.0 (0.08)

2.0 (0.08)

41.485 (1.6333)

43.485 (1.71201

Valve springFree length (Reference)IN NHCHEX

41.27 (1.6251

41.28 (1.625)

44.32 t1-7 451

Valve guidet.D. lNEX

Installed height lNEX

6.61 - 6.63 (0.260 - 0.261)6.61 - 6.63 (0.260 - 0.261)13.7 5 - 1 4.25 (0.541 - 0.561 )15.75 - 16.25 (0.620 - 0.640)

6.6s (0.262)

6.65 (0.262)

Page 1645 of 1681

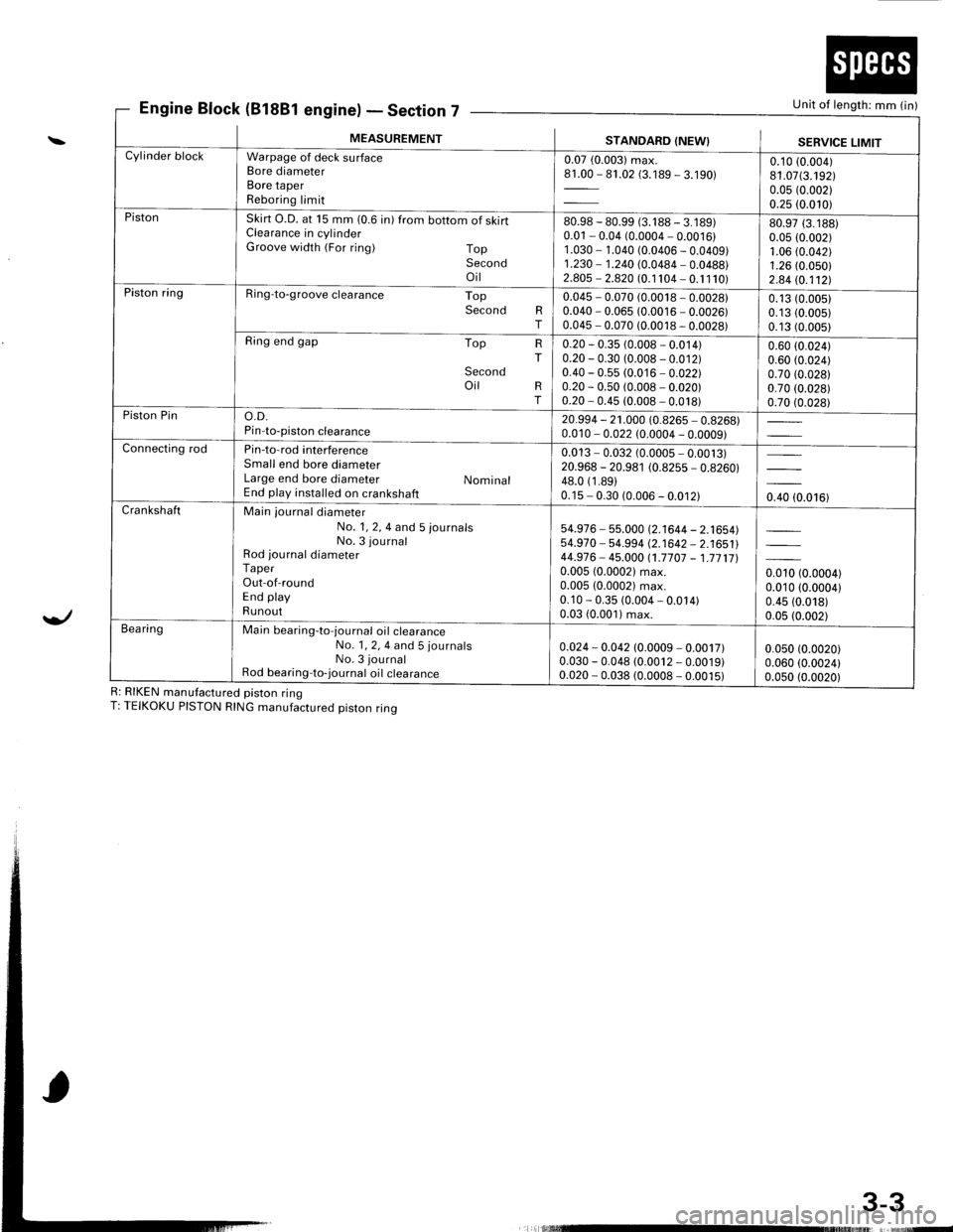

Engine Block (81881 engine)Section 7Unit of length: mm (in)

3-3

\

Yl

R: RIKEN manufactured piston ringT: TEIKOKU PISTON RING manufactured piston ring

E' - Declror

MEASUREMENTSTANDARD (NEW}SERVICE LIMITCylinder blockWarpage of deck surfaceBore diameterBore taperReboring limit

0.07 (0.003) max.81.00 - 81.02 (3.189 - 3.190)0.10 (0.004)

81.07(3.192)0.05 (0.002)

0.25 (0.010)PistonSkirt O.D. at 15 mm (0.6 in) from bottom of skirtClearance in cylinderGroove width (For ring) TopSecondoil

80.98 - 80.99 (3. 1 88 - 3. 1 89)0.01 - 0.04 (0.0004 - 0.0016)1 .030 - 1.040 (0.0406 - 0.0409)1.230 - 1.240 (0.0484 - 0.0488)2.805 - 2.820 (0.1 104 - 0. 1 1 10)

80.97 (3.188)

0.05 (0.002)1.06 (0.042)

1.26 (0.050)

2.84 (0.112!.Piston ringRing-to-groove clearance TopSecond RT

0.045 - 0.070 (0.0018 - 0.0028)0.040 - 0.065 (0.0016 - 0.0026)0.045 - 0.070 (0.0018 - 0.0028)

0.13 (0.0051

0.13 (0.005)

0.13 (0.005)

Ring end gap Top

Secondoil

HT

RT

0.20 - 0.35 (0.008 - 0.014)0.20 - 0.30 (0.008 - 0.012)0.40 - 0.55 (0.016 - 0.022)0.20 - 0.50 (0.008 - 0.020)0.20 - 0.45 (0.008 - 0.018)

0.60 (0.024)

0.60 (0.024)

0.70 (0.028)

0.70 (0.028)

0.70 (0.028)Piston Pino.D.Pin-to-piston clearance20.994 - 21.000 (0.8265 - 0.8268)0.010 - 0.022 (0.0004 - 0.0009)Connecting rodPin-to-rod interferenceSmall end bore diameterLarge end bore diameter NominalEnd play installed on crankshaft

0.013 - 0.032 (0.0005 - 0.0013)20.968 - 20.981 (0.8255 - 0.8260)48.0 (1 .89)0.15 - 0.30 (0.006 - 0.012)0.40 (0.016)CrankshaftMain journal diameterNo. 1, 2, 4 and 5 journalsNo. 3 journalRod journal diameterTaperOut-of-roundEnd playRunout

54.976 - 55.000 (2.1644 - 2.1654)54.970 - 54-994 (2.1642 - 2.1651144.976- 45.000 (1.7707 - 1.771710.005 (0.00021 max.0.005 (0.0002) max.0.10 - 0.35 (0.004 - 0.014)0.03 (0.001) max.

0.010 (0.0004)0.010 (0.0004)

0.45 (0.018)

0.05 (0.002)Bea ringMain bearing-to-journal oil crearanceNo. 1, 2, 4 and 5 journalsNo. 3 journalRod bearing-to-journal oil crearance

0.024 - 0.042 (0.0009 - 0.0017)0.030 - 0.048 (0.0012 - 0.0019)0.020 - 0.038 (0.0008 - 0.0015)

0.050 (0.0020)

0.060 (0.0024)0.0s0 (0.0020)

L rlllllllllrltruE