Obd HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 477 of 1681

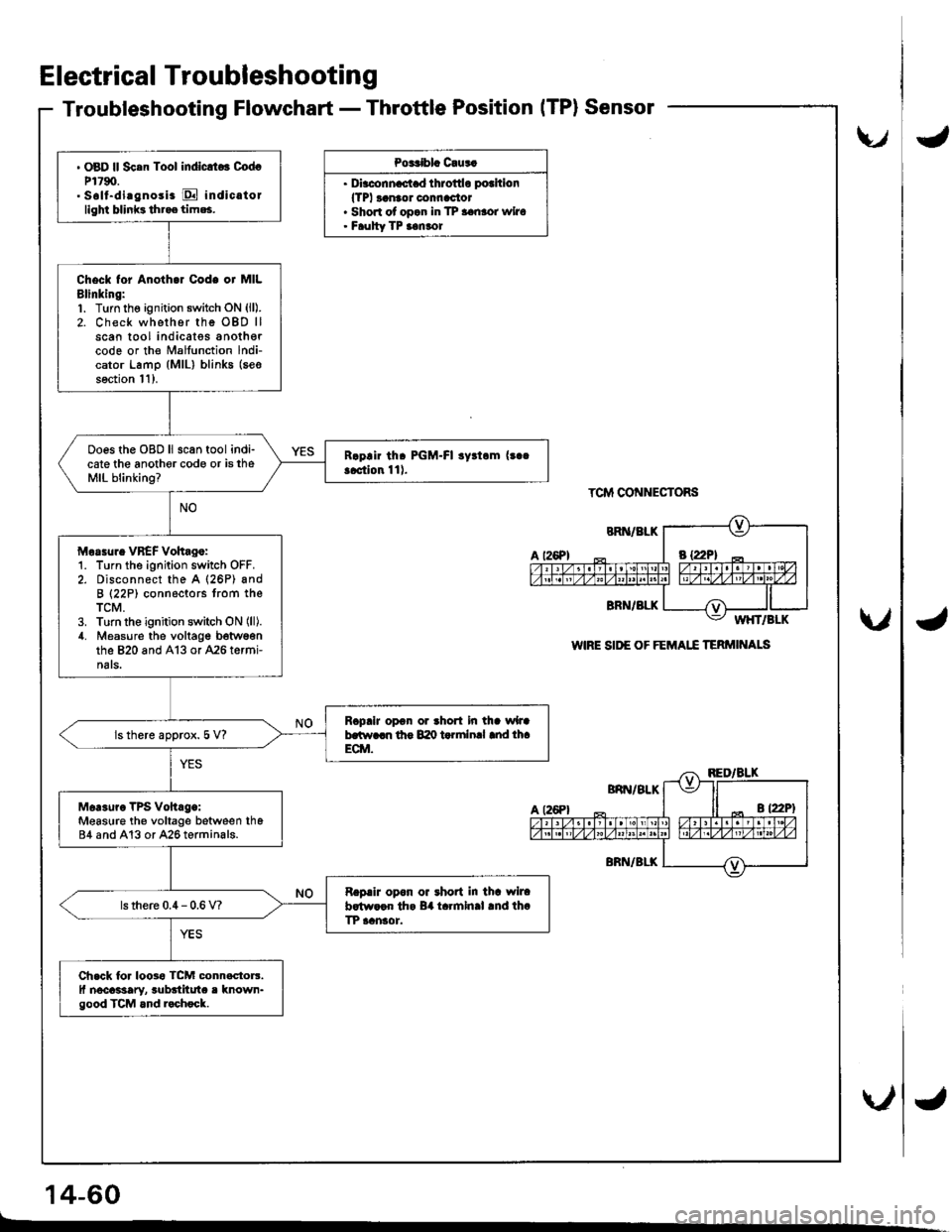

Electrical Troubleshooting

Troubleshooting Flowchart - Throttle PositionITP}Sensor

Po3Cblc C!us.

. Dirc.nn.c.t d throttlo pothion

lTPl ranaor connac'tor. Shon of opan in TP aanror wiro. Faulty TP ianror

TCM CONNECTORS

WIRE SII'E OF FEMAI.I TERMI'TALS

' OBD ll Sc.n Tool indlclto3 CodcP1790.. Soll-di.gnosi. E indic.tollighi blinks tht.e tim*,

Check tor Anoth.r Code or MILBlinking:1. Turn the ignition switch oN (ll).

2. Check whether rhe OBD llscan tool indicatss anothercode or the Malfunction lndi-cator Lamp (MlL) blinks (seo

soction l1).

Ooes the OBD ll scan tool indi-cate the anothor code or is theMIL blinking?

Morrur. VBEF Vohag.:1. Turn the ignition switch OFF.2. Disconnect the A (26P) andB (22P) connectors trom theTCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage b6twsonthe 820 and A13 or 426 termi-nats.

RcpaiJ opon or thort in tha wlJab.tt r..n lho 840 t rlnlnal md lh.ECM.ls there approx. 5 V?

Mer3uro TPs vohrg.:Measure th€ voltage between th684 and A13 or A26 terminals.

Rapair opon oa rhoat in thr wlrab.tw.cn th. B4 t.rmln.l .nd th.TP aansor.ls there 0.4 - 0.6 V?

Ch.ck lor loosa TcM connactorr.ll nocassary, rubditut. r known-good TCM and r.chock.

t26Pl

U

\./

\"/

14-60

.d

{

4

Page 478 of 1681

IJ

v

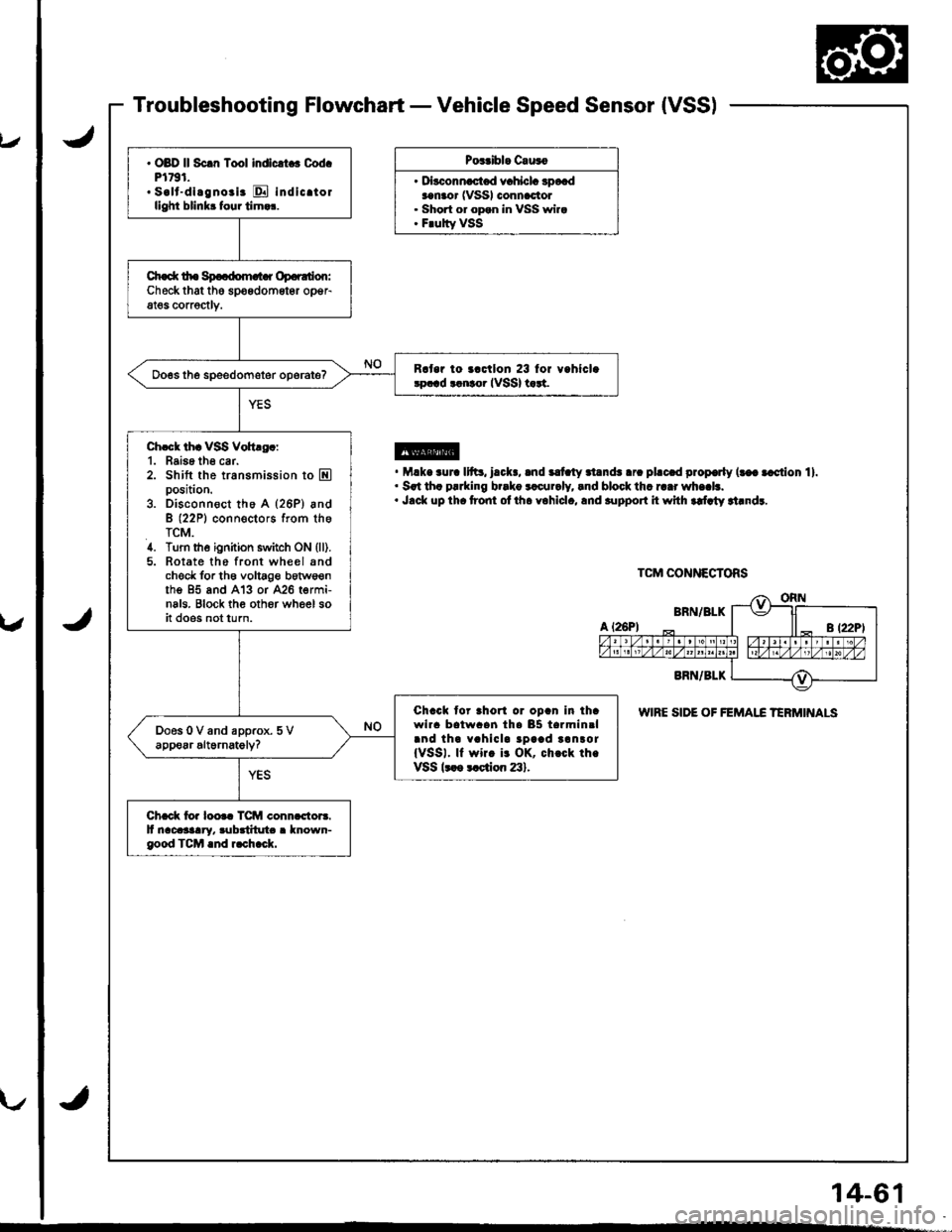

Troubleshooting Flowchart - Vehicle Speed Sensor {VSS)

Pos.ibl. C.u3o

. D|""."-"t"d .r"hl"L 3p*daanaor (VSSI connactol. Short or opan in VSS wira. F.ulty VSS

@. M.k. .ur. 11ft3, l.cl(., .nd ilt ty .l.nds .r. pl.c.d prop€rly (t€a .cction 11.. Srt th. p!.king b..ko rlcur.ly, lnd block thr r..r wh..b.. J.ck up th. t?ont ol ih. yohlcl., lnd .upport it whh rdlty rt.ndr.

WIRE SIDE OF FEMAI.C TERMINALS

. OBD ll Sc.n Tool indlcrt . Cod.Pl791.. s.lt-dl.gno.i. E indicrtorllghi blinkr four tirn.r.

Ch.d( tho Sp..dom.t r Op.r.don:Checkthat the spoedometgr opeFat€s corrsctlv.

R.t.r io ..ctlon 23 lor v.hlcl.!p.!d tlnto. IVSSI t rt.

Ch.ck thr VSS Voh.g.:1. Baise th6 car.2. Shift the transmission to Eposition.

3. Disconn€ct tho A (26P) andB (22P1 conn€ctors from theTCM.4. Turn the ignition switch ON (ll).

5. Rotate the front wheel sndcheck for th6 voltage botws€nthe 95 and A'13 or 426 termi-nals. Block th€ oth6r wheel soit does not turn.

Chack tor ahorl or opan in ihawlra batwaan tha 85 tarmin.land tha vahicla tpaad tanror{VSSI. ll wirc i! OK, ch.ck th.VSSk ot ction 23).

Chack io. loo.c TCM conn.ctors.It nacasaary. rubditut . known-good TCM .nd r.ch.ck.

TCM CONNECTORS

14-61

Page 481 of 1681

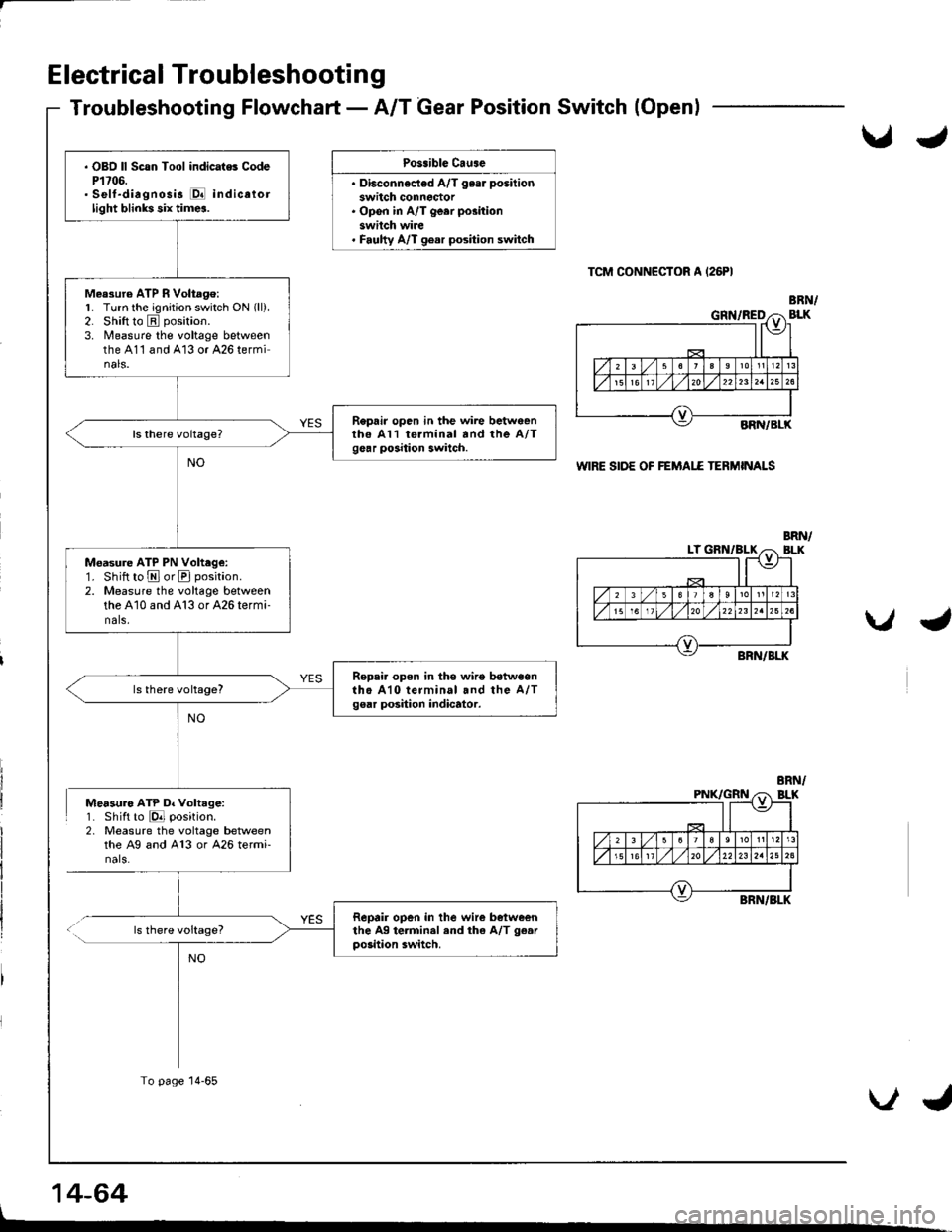

Electrical Troubleshooting

Troubleshooting Flowchart - A/T Gear Position Switch(Openl

Po3.ible Cause

. Di"""."."i"d A/T ,"". p""iti

switch connoctor. Open in A/T ge.r position

switch wire. Faulty A/T gear position switch

TCM CONN€CTOR A (26PI

WIRE SIDE OF FEMAI.E TERMINALS

Measuro ATP D. Voltage:1. Shift to E position.2, Measure the voltage betweenthe Ag and A13 or 426 termi-nals.

ls there voltage?

14-64

BRN/BLK

NO

. OBD ll Scsn Tool indicate. CodeP1706.. Self-diagnosis E indicatorlight blinks six times.

Measuro ATP R Voltago:1. Turn the ignition switch ON (ll).

2. Shift to E position.

3. Nleasure the voltage betweenthe 411 and 413 or 426 terminals.

Repair open in the wire bctweanthe A11 te.minal and the A/Tgear position switch.

Moasure ATP PN Volt.ge:1. Shift to E or E position.

2. Measure the voltage betweenthe 410 and A13 or 426 termi-nals.

Ropai. open in the wirs betweentho A10 terminal snd the A/Tgear position indicator.

Repair open in the wire betweenthe Ag terminal end the A/T g€arpo3ition switch.

To page 14-65

VJ

Page 483 of 1681

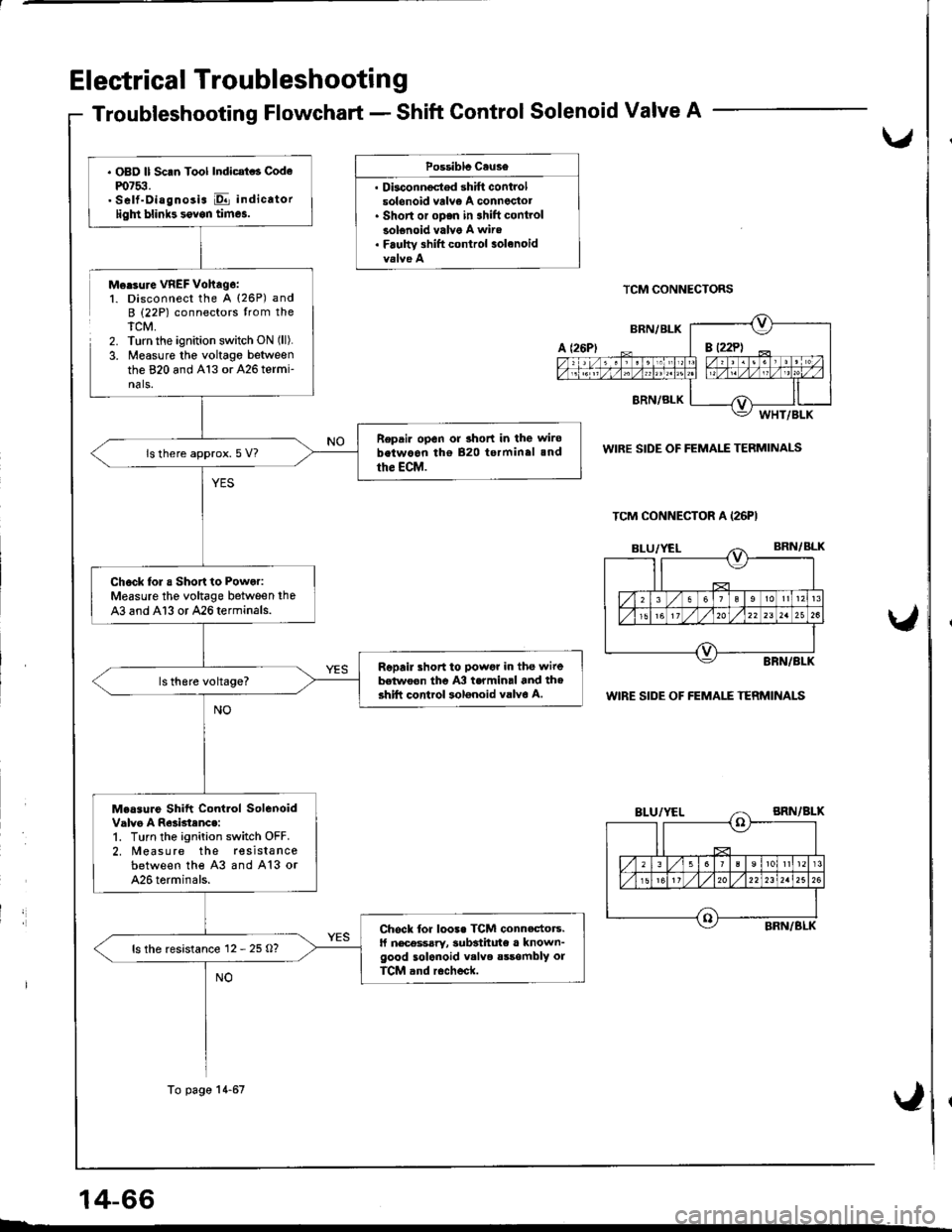

Electrical Troubleshootin g

Troubleshooting Flowchart - Shift Gontrol Solenoid Valve A

,

Possiblc Cause

. Dbconnoctod shift controlsolonoid vrlv€ A conneclot. Short or oDen in 3hift controlsolenoid valve A wire. Faulw 3hift control solanoid

Morsure VREF Vohag6:1. Disconnect the A (26P) andB (22P) connectors trom theTCM,2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe 820 and A13 or 426 termi-nals.

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMALE TERMINALS

14-66

TCM CONNECTOR A (26PI

. OBD ll Scan Tool Indicat . Codem7$.. Self-Diagnosis E indicatorligln blinb sovon times.

Repair open or 3hort in the wirobetwoon tho 820 terminal 3nd

the ECM.ls there approx. 5 V?

Chock lol a Short to Power:Measure the voltage between the

43 and Al3 or 426terminals.

Repail short to powgr in the wirebelwoon the A3 termin.l and th6shift control solonoid valvo A.

Measure Shift Contlol SolenoidValvo A R63btenc.:1. Turn the ignition switch OFF.2. Measure the resista ncebetween the 43 and A13 or426 torminals.

Chock for loo3. TCM connectors.ll nec€ssary, 3ubsthute a known-good solenoid v.lve sssombly orTCM and r6check.

ls the resistance 12 - 25 O?

To page 14-67

Page 485 of 1681

Electrical Troubleshootin g

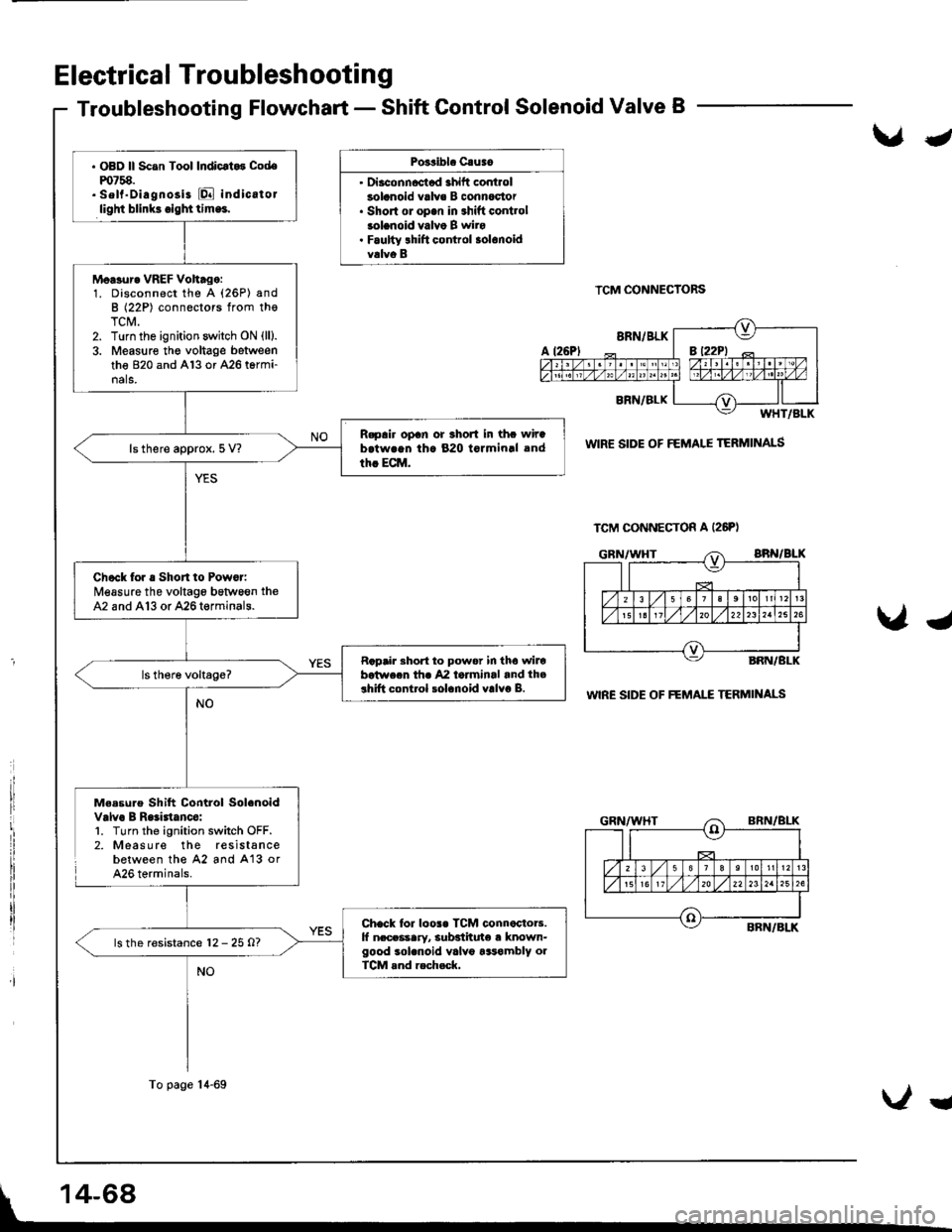

Troubleshooting Flowchart - Shift Control Solenoid Valve B

Po3sibl. Cauao

' Diaconncctad ahift controlsolanoid valve B connoc'tor. Short ol op.n in shift contlolsolanoid valvo B wiro. Faulty lhift control solonoidvalvo B

TCM CONNECTORS

WIR€ SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMAI."E TERMII{ALS

Me.sure Shift Control Solenoidvalvo B Raliatanco:l. Turn the ignition switch OFF.2. Measure the resistancebetween the 42 and A'13 orA26 terminals.

J

Ug

TCM CONNECTON A (26PI

. OBD ll Scan Tool Indicrt.3 Codem758.. sell"Diagnosi3 [Q indicatorlight blink3.igl|ttlm.!.

Moasur. VREF Voh.go:1. Disconnect the A (26P) andB (22P) connectors from thoTCM.2. Turn the ignition switch ON (lll.

3. Measure the voltage betweenthe 820 and Al3 or A26 termi-nals.

R.pair opan or 3hort in thc wirab.twrqn th. 820 tormin.l and

th. ECM.ls there approx. 5 V?

Check for . Short to Powor:Measure the voltage bstween theA2 and A13 or 426termin8ls.

Rapair Bhort to power in tho wilobotwecn thr 42 laiminal and th.3hift control solanoid valvo B.

Chack lor loos. TCM connactoB.lf n.ceasary, subsiituto a known-good sol.noid valv6 tasambly olTCM rnd rech.ck.

ls the resistance 12 - 25 O?

To page 14-69

Ug

Page 487 of 1681

Electrical Troubleshootin g

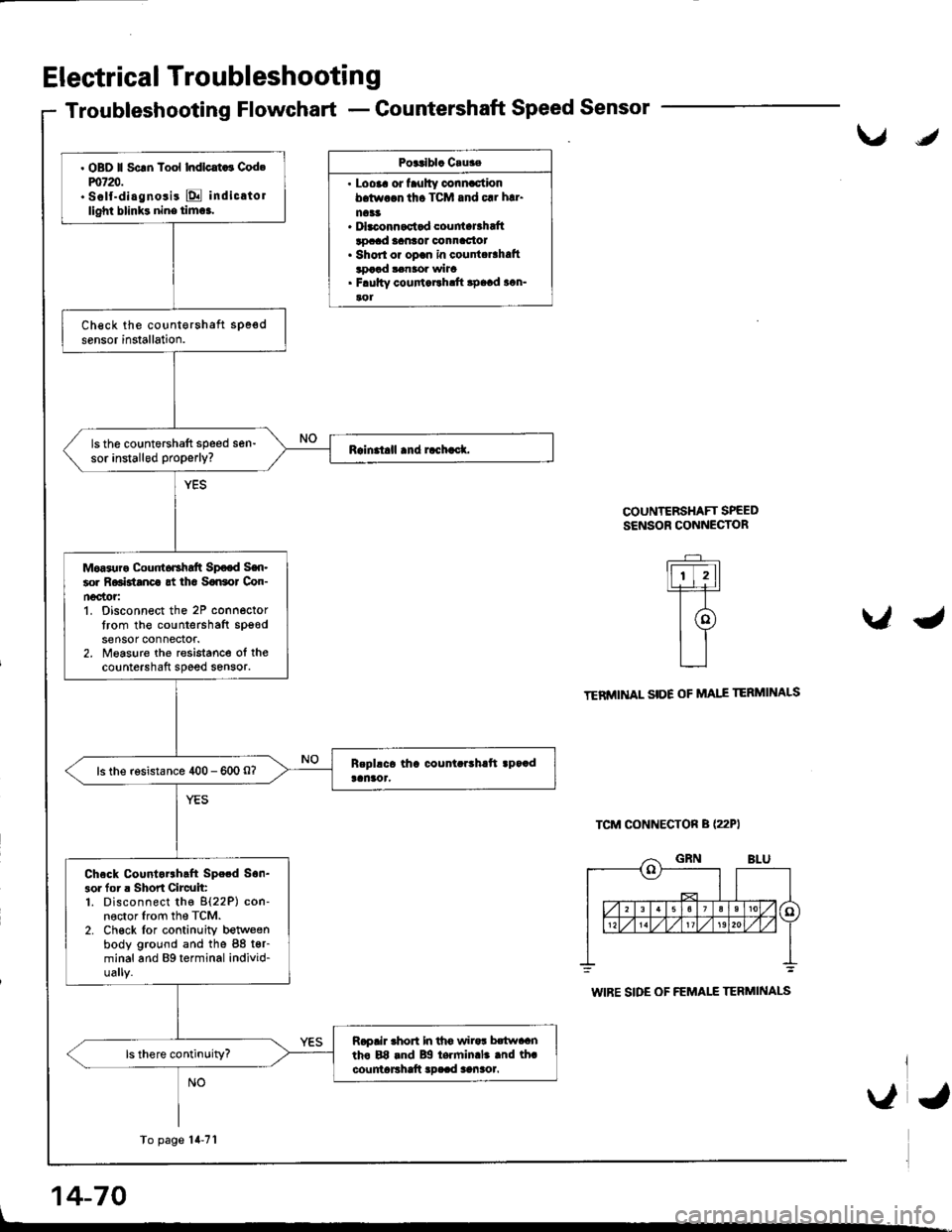

Troubleshooting Flowchart - Countershaft Speed Sensor

Posalbla Cruae

. Loora or faulty connactionb.tw.$ tho TCM and 61 h!1.

na33. Dbconnactad couniaBhaftlocad lantot oonnac{ot. Shorl or opan in counta6hatttDaad $naor wha. F.ultv coufiaEh.ft apaad acn-aol

COUNTERSHAFT SPEEDSENSOR CONNECTOR

\IJ

U\lO

.-_

lfr-trtlL+l-r-T-

t@tl

L__l

TENMINAL SIDE OF MAIE

TCM CONNECTON B (22PI

TERMINALS

L

14-70

WIBE SIDE OF FEMALE TERMINALS

. OBD ll Scrn Tool Indlcat ! Cod.m720.. Self-diagnosis E indicatollighl blinks nine tim6.

ls the countershaft speed sen-sor installed properly?

Moas{ra Cour 6Ghaft Sp€od Sen-60r R6Btanca gt iha SaGol Con-n€c'tor:1. Disconnect the 2P connectortrom the countershafl spgodsensor connectof.2. Measure the resistance ol thecountershaft speed sensor.

ls the rosistance 400 - 600 O?

Check Countorrhcft Spe.d Son-3ol for r Shon Circuit:1. Disconnect the 8{22P) con-nector lrom the TCM.2. Ch€ck lor continuity betweenbody ground and the 88 t€r-minal and Bg terminal individ-ually.

Rapair rhon In th6 wiro! hwaantho E8 rnd Bg te.min.l. .nd th.countaFhaft !D..d aanaol.

To page'14-71

\,a,

Page 489 of 1681

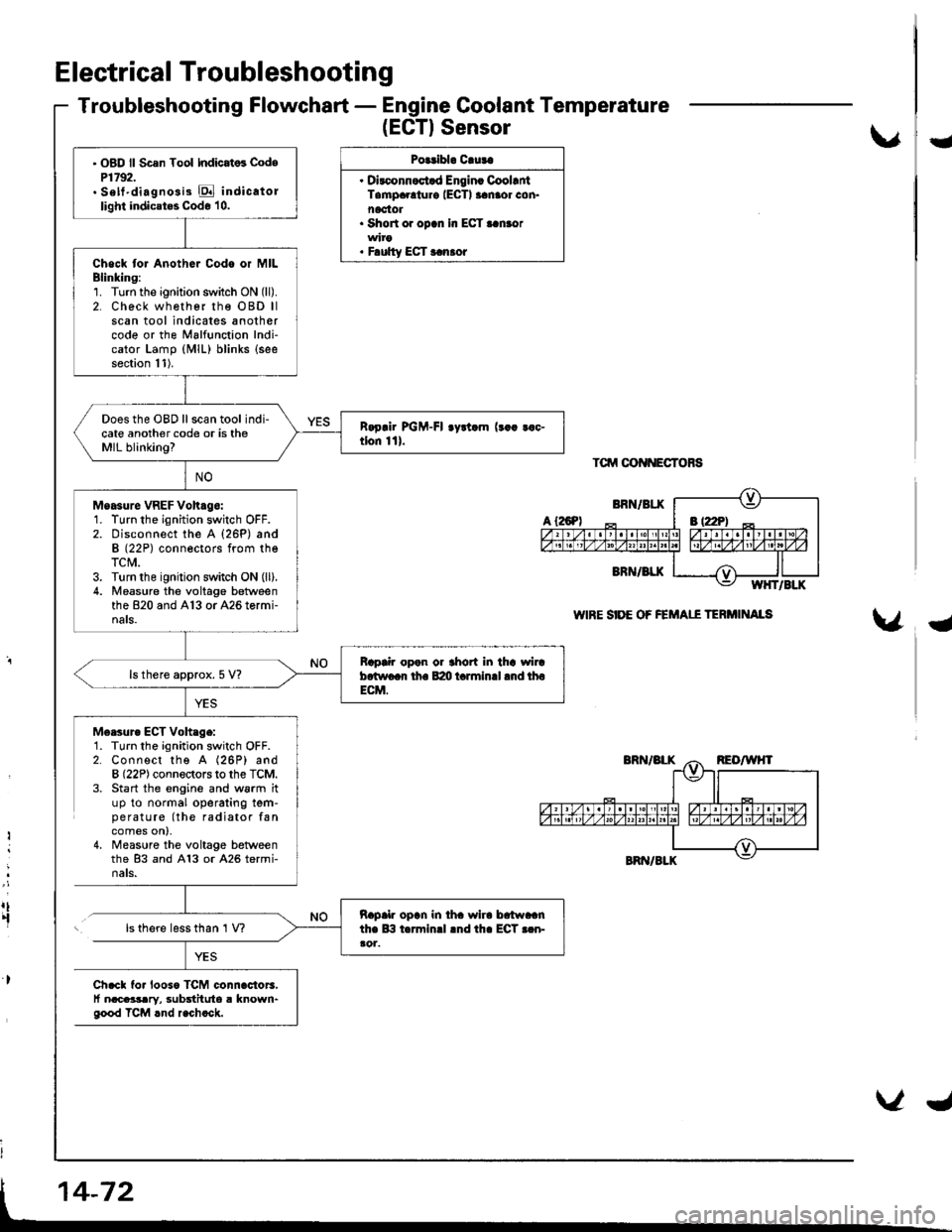

Electrical Troubleshooting

Troubleshooting Flowchart - Engine Coolant Temperature

(EGTISensor

Polribl. Cluta

. Dirconnoct.d Engin. CoollntTampaolur€ IECTI aanaor con.noctot. Short or opcn In ECT..n.or

. F.ulty ECT r.n.or

Tctrrt oot{NEcToRs

WIRE SIDE OF FEMAII TERi'IINAIS

U

{

M6esur. ECT Voh.ge:1. Turn the ignition switch OFF.2. Connect the A (26P) andB (22P) connectors to the TCM.3. Start the engine and w6rm ituP to normal operating tem-pe ratu re (the radiator fancomes on),4, Measure the voltage betweenthe 83 and A13 or A26 termi-nats.

Ii

:

rt.fls there less than 1 V?

Ch.cl fo. looso TCM connac{or3,t nacaasary, substituto a known"good TCM rnd r.chock.

' OBD ll Scsn Tool Indicat6 CodeP1792.. Sett'diagno3i3 E indicatollight indicates Code 10.

Chock tor Anothor Codo or MILBlinking:1. Turn the ignition switch ON (ll).

2. Check wh€ther rhe OBD llscan tool indicates anothercode or the Malfunction Indi-cator Lamp (MlL) blinks (see

section 11).

Does the OBD ll scan tool indi-cate another code or is theMIL blinking?

Moasure VREF Voh.go:1. Turn the ignition switch OFF.2. Disconnect the A {26P) andB (22P) conneotors from theTCM.3. Turn the ignition switch ON (ll).

4. Measu.e the voltage betweenthe 820 and A13 or A26 tormi-nals.

Bap|ir open or thort in tha wircb.two.r th. B:m t.rminll .nd thoECM.

ls there approx. 5 V?

napalr opln in iha wlra brtwaanthe lB t.rminrl lnd th. ECT r.n-ao1.

Page 490 of 1681

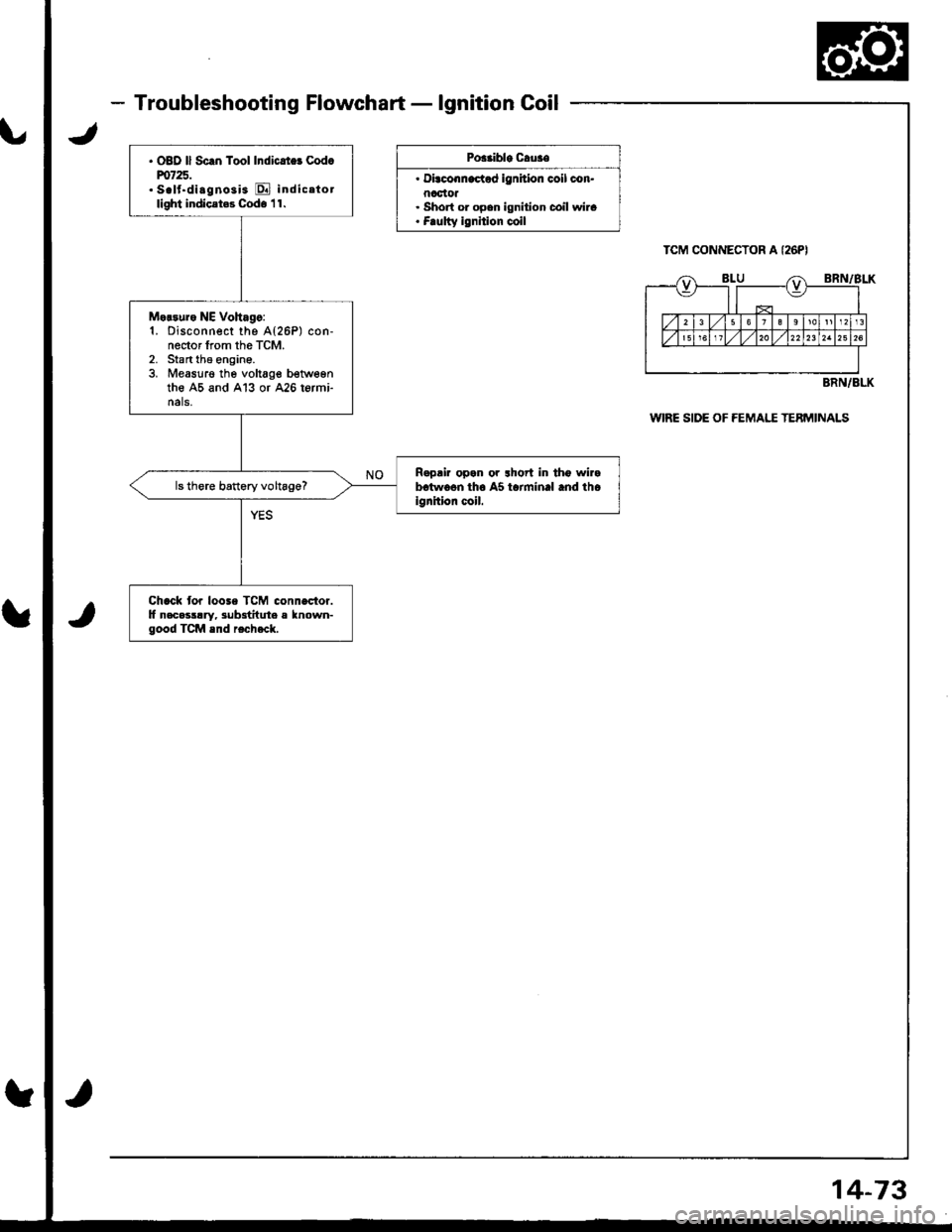

. OBD ll Sc.n Tool Indicrt$ cod.m725.. S.lf.di.gnosi3 E indicetotlight indicet$ Cod. 'l 1.

Motsure NE Vohago:1. Disconnect the A{26P) con-nector from the TcM.2. Stan tha €ngine.3. Measurg the voltage betwegnthe A5 and Al3 or 426 termi-nals.

Rapair opan or lhort in tho wirabctwo6n tho AS tarminal and tholgnhion coil.ls there banery voltage?

Chack tor loose TCM connector.lf necasllry, 3ub3titule a known-good TCM snd recheck.

- Troubleshooting Flowchart - lgnition Coil

JU

Poaaible Cau3€

' Di.conn€c{od ignition coil con.nactot. Short or opcn ignition coil wira. Frulty ignition coil

WIRE SIDE OF FEMAI,T TEBMINALS

tt

tt

BRN/BLK

14-73

Page 491 of 1681

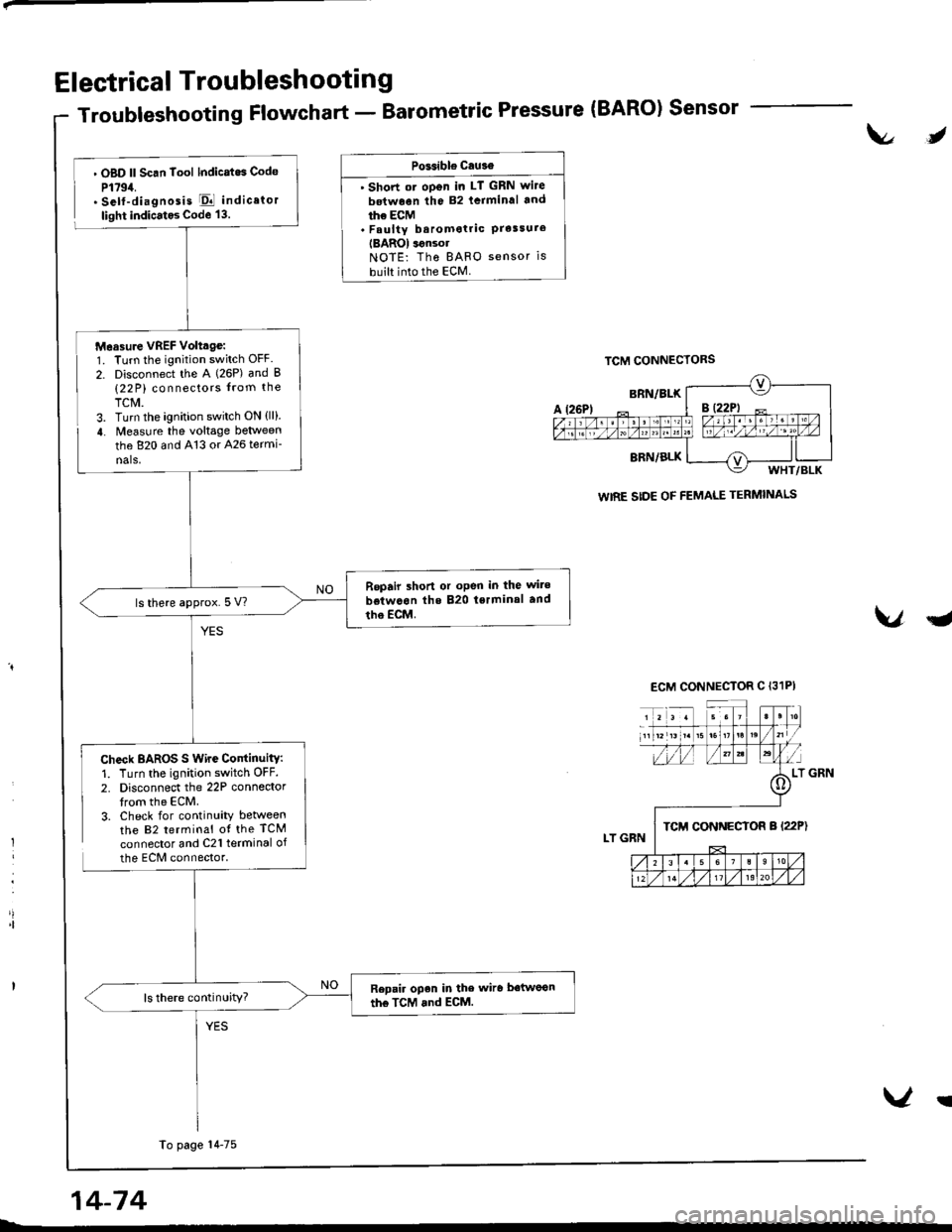

Electrical Troubleshooting

Troubleshooting Flowchart - Barometric Pressure (BARO) Sensor

t\l,

l

'|

. OBD ll Scan Tool lndicatos Code

P1794.. Self-diagnosis El indicator

light indicatos Code 13.

Check BAROS S Wire ContinuitY:1. Turn the ignition switch OFF.

2. Disconnect the 22P connedortrom the ECM.3. Check for continuity betweenthe 82 terminal ot the TCM

connector and C21 terminal of

the ECM connector.

PGsible cau3€

' Short ot oDen in LT GRN wite

betwoen the 82 lcrminal and

ihe ECM. Faulty baromotric PrelsureIBAROI ignsolNOTE: Tho BAFO sensor is

built into the ECM.

VqJ

WIRE SIDE OF FEMALE TERMINALS

Measure VREF Volttge:1. Turn the ignition switch OFF.

2. Disconnect the A (26P) and B(22 P) connectors from the

TCM.3. Turn the ignition switch ON {ll}.

4. Measure the voltage between

the 820 and 413 or 426 termi-

nals,

Repair shon or oPen in the wite

betwcon the 820 tsrminal and

tho EcM.ls there approx.5 V?

Repair open in the wiro betwoon

the TcM and ECM.ls there continuity?

To page 14-75

14-74

V!

Page 493 of 1681

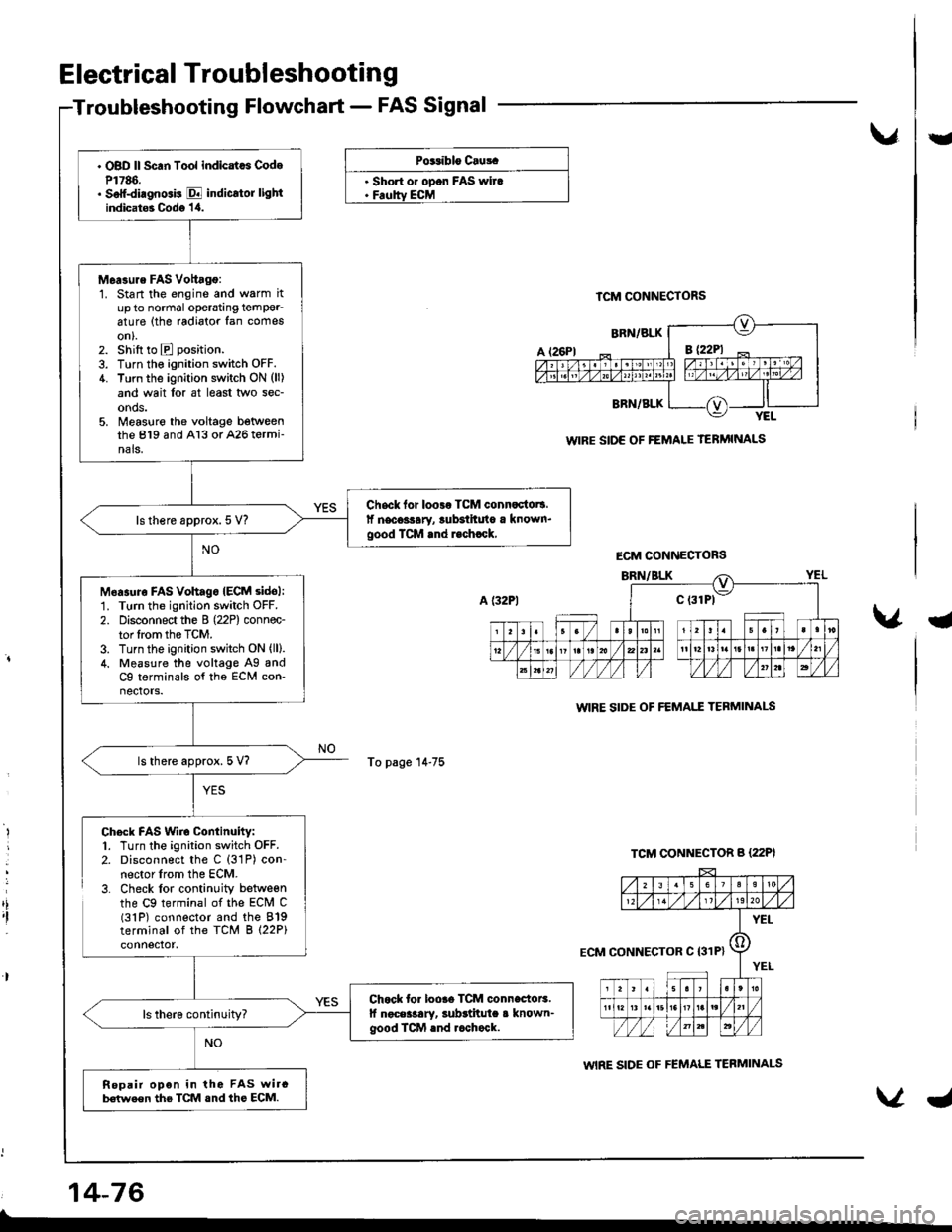

. OBD ll Scan Tool indicatcs CodeP1786.. Soff-diagnGis E indicrtor lightindicat6 Codo '1,0.

M6a3ure FAS Vottago:1. Start the engine and warm itup to normal operatang temPer_6ture (the radiator fan comeson).2. shift to E position.

3. Turn the ignition switch OFF.4. Turn the ignition switch ON (ll)

and wait lor at least two sec-onds.5. Measlre the voltage betweenthe 819 and A13 or A26 termi-nals.

Chsck for loo3r TCM connactot!.lf necoslary, lubsihuto a known.good TCM rnd r.chrck,ls there approx. 5 V?

M6asuro FAs vohagoIECM sidol:1. Turn the ignition switch OFF.

2. Disconnect the B (22P) connec-tor lrom the TCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage Ag andC9 terminals of tho ECM con-nectors.

ls there approx. 5 V?

Chock for loore TCM connectoE.lf noceilary, subrtitula a known-good ICM rnd rcchock.

Repair opon in the FAS wircb€(we€n the TCM snd ths ECM.

Electrical Troubleshooting

Troubleshooting Flowchart - FAS Signal

vU

PG.iblo Cru!.

. Short o. opon FAS wira. Feoltv ECM

To page 14-75

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMAI.T TEBMINAI-S

WIRE SIDE OF FEMALE TERMINALS

a

,i,I

Chock FAS Wiro Continuity:1. Turn the ignition switch OFF.2. Disconnect the C (31P) con-nector lrom the ECM.3. Check lor continuity betweenthe C9 terminal of the ECM C(31P) connector and the 819terminal of the TCM B (22P)

14-76

ECM CONNECTORS

ECM CONNECTOR C I31P}