Valve cover HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 450 of 1681

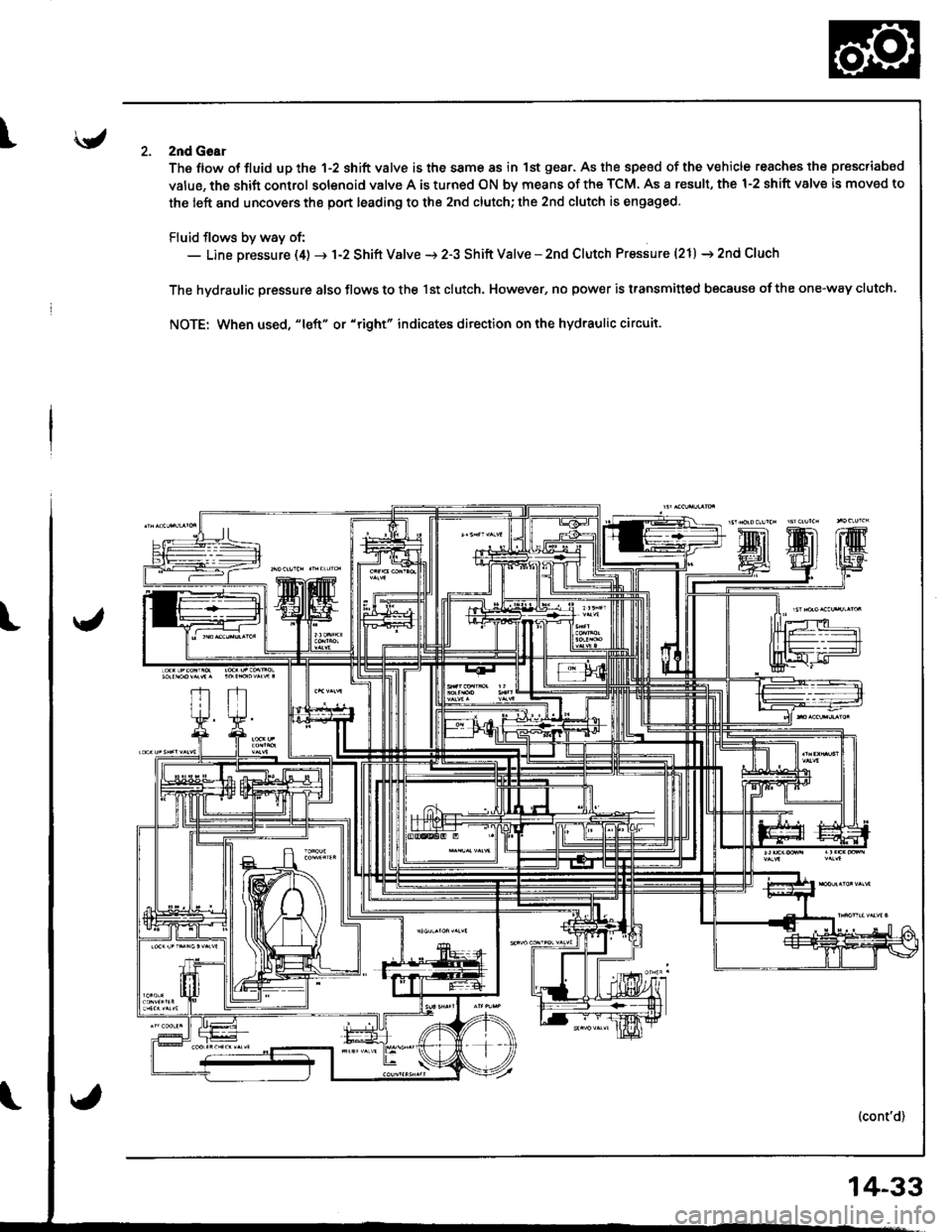

Iznd Goar

The ftow ot fluid up the 1-2 shift valve is the same 8s in 1st gear. As the speed of the vehicle reaches the prescriabed

value, the shift control solenoid valve A is turned ON by means of the TCM. As a result, the 1-2 shift valve is moved to

the left and uncovers the port leading to the 2nd clutch; the 2nd clutch is engaged.

Fluid flows by way of:- Line pressure (4) -r 1-2 Shift Valve i 2-3 Shift Valve - znd Clutch Pressure (21) i 2nd Cluch

The hydraulic pressure also flows to the lst clutch. However, no pow€r is transmitted because ofthe one-way clutch.

NOTE: When used, "Ieft" or "right" indicates ditection on the hydraulic circuit.

14-33

Page 451 of 1681

Description

Hydraulic Flow (cont'dl

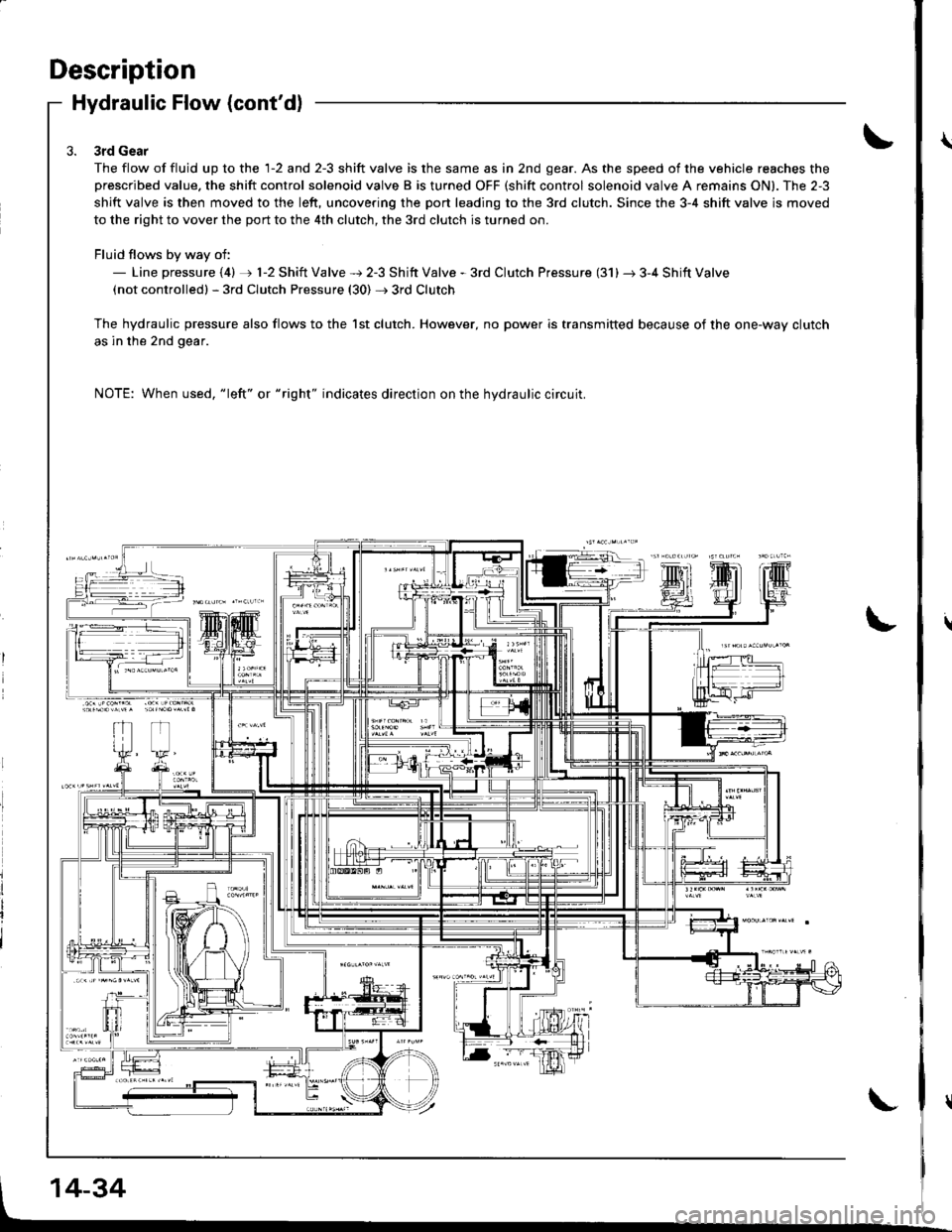

3rd Gear

The flow of fluid up to the 1-2 and 2-3 shift valve is the same as in 2nd gear. As the speed of the vehicle reaches theprescribed value. the shift control solenoid valve B is turned OFF (shift control solenoid valve A remains ON). The 2-3

shift valve is then moved to the left, uncovering the port leading to the 3rd clutch. Since the 3-4 shift valve is moved

to the right to vover the port to the 4th clutch, the 3rd clutch is turned on.

Fluid flows by way of:- Line pressure (4) rj) 1-2 Shift Valve + 2-3 Shift Valve - 3rd Clutch Pressure (31) r 3-4 Shift Valve(not controlledl - 3rd Clutch Pressure (30) + 3rd Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-way clutch

as in the 2nd gear.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit.

14-34

Page 452 of 1681

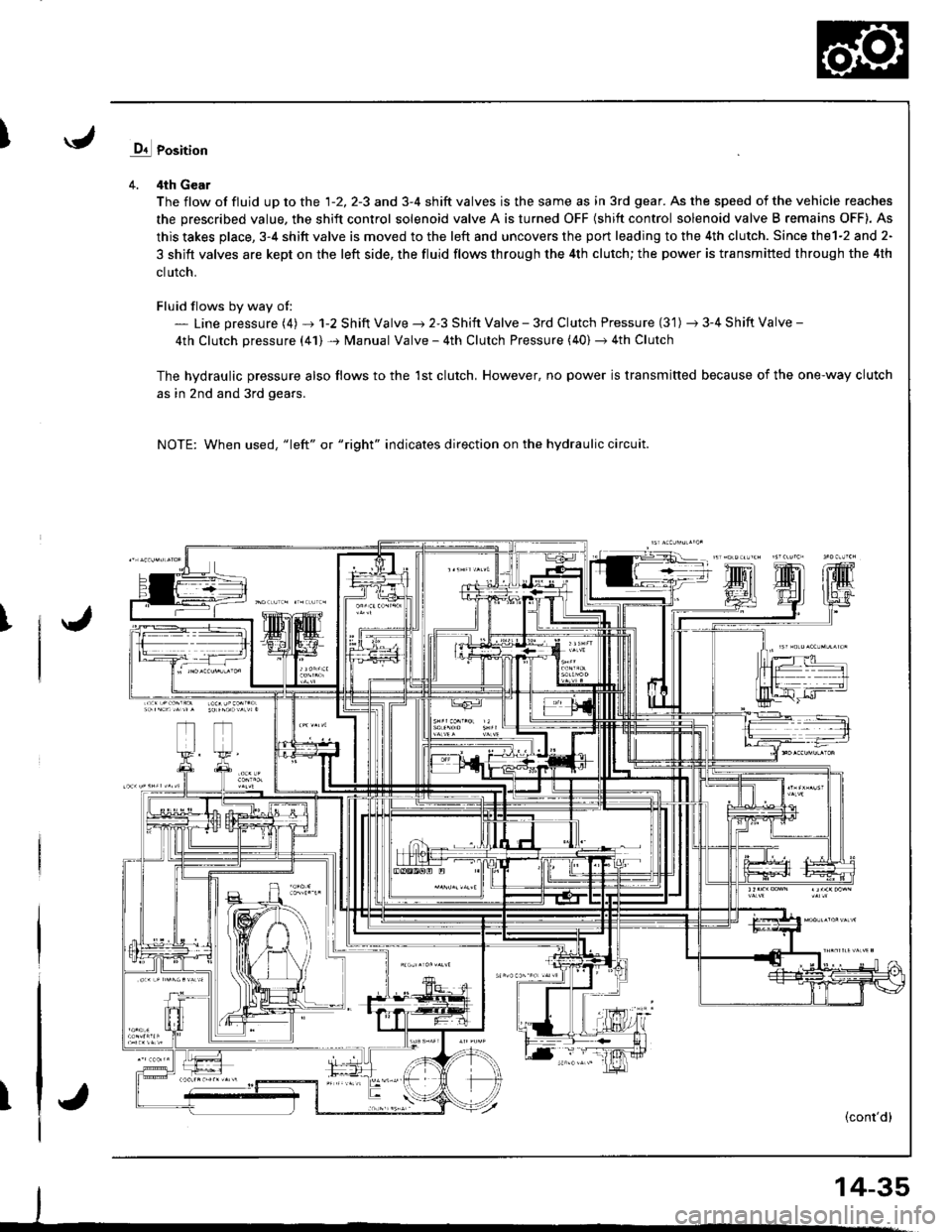

Iq1 Position

4. 4th Gear

The flow of fluid up to the 1-2, 2-3 and 3-4 shift valves is the same as in 3rd gear. As the speed of the vehicle reaches

the prescribed value, the shift control solenoid valve A is turned OFF (shift control solenoid valve B remains OFF). As

this takes place, 3-4 shitt valve is moved to the left and uncovers the port leading to the 4th clutch. Since thel-2 and 2-

3 shift valves are kept on the left side, the fluid flows through the 4th clutch; the power is transmitted through the 4th

clutch.

Fluid flows by way of:- Line pressure (4) + 1-2 Shift Valve ) 2-3 Shift Valve - 3rd Clutch Pressure (3'1) -t 3-4 Shift Valve -

4th Clutch pressure (41) + Manual Valve - 4th Clutch Pressure (40) + 4th Clutch

The hvdraulic pressure also flows to the 1st clutch, However, no power is transmitted because of the one-way clutch

as in 2nd and 3rd gears.

NOTE: When used, "1eft" or "right" indicates direction on the hydraulic circuit.

I

T(cont'd)

14-35

Page 456 of 1681

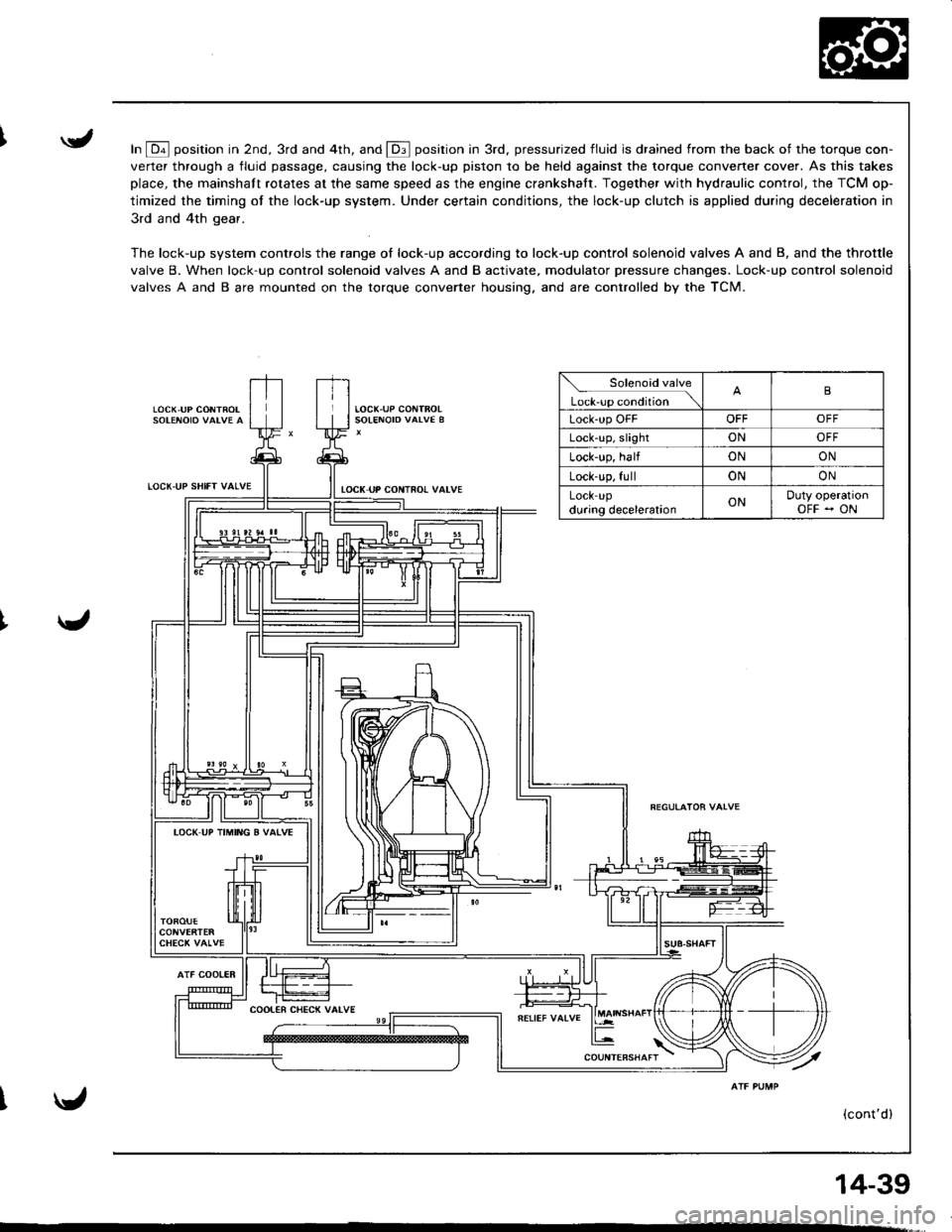

In E position in 2nd, 3rd and 4th, and E position in 3rd, pressurized fluid is drained from rhe back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes

place, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM op-

timized the timing of the lock-up system. Under certain conditions, the lock-up clutch is applied during deceleration in

3rd and 4th gear.

The lock-up system controls the range of lock-up according to lock-up control solenoid valves A and B, and the throttle

valve B. When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid

valves A and B are mounted on the torque converter housing. and are controlled by the TCM.

LOCK,UP CONTROL

LOCT.UP SHIfT VALVE

AlF COOIER

tocK uP coNTno! valvE

Solenoid valve

L*r""r "o.Jtio" \B

Lock'up OFFOFFOFF

Lock-up, slightONOFF

Lock-up, halfONON

Lock-up, fullONON

LOCK-Updu.ing decelerationONDuty operationOFF - ON

IOCK UP TIMING B VATVE

(cont'd)

14-39

Page 510 of 1681

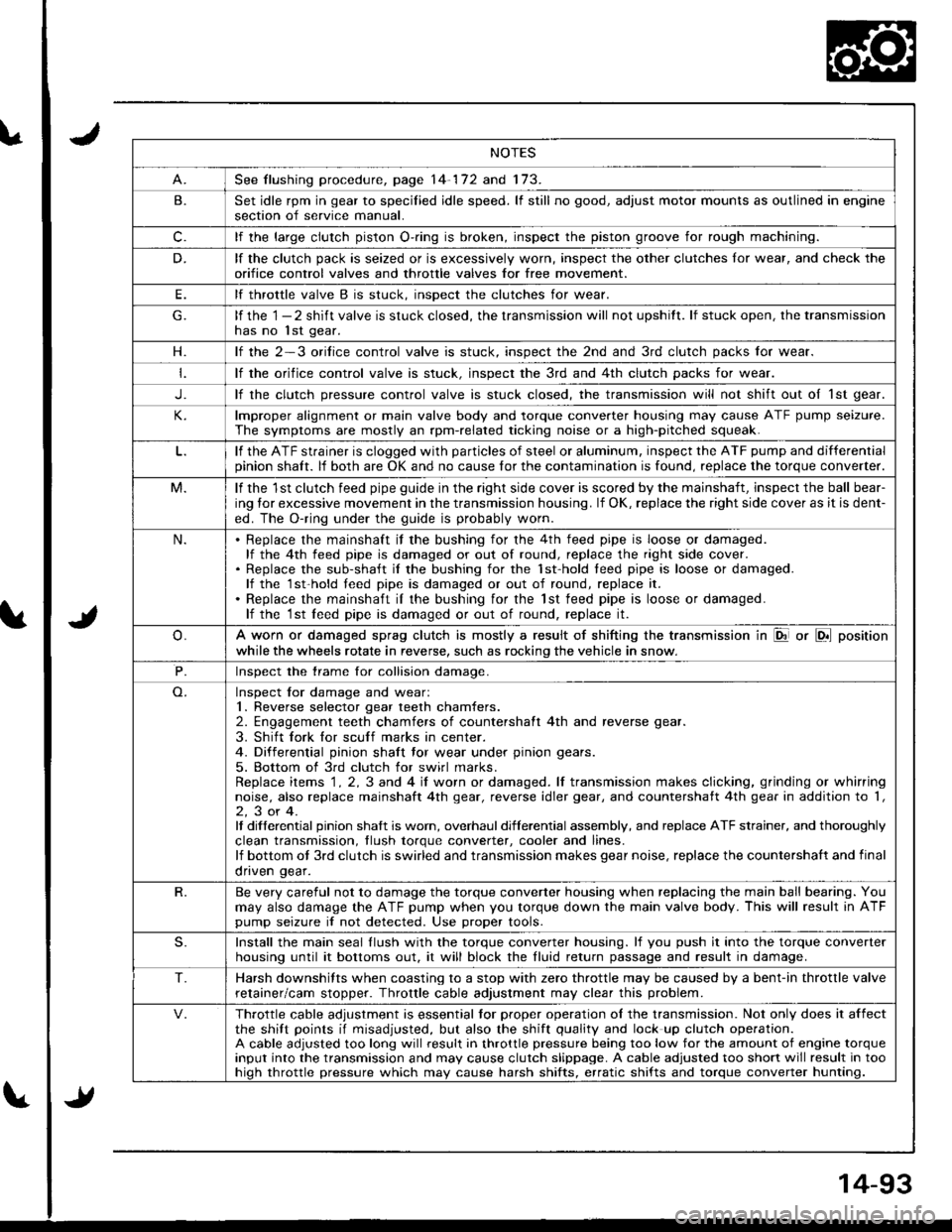

NOTES

See flushing procedure, page 14-172 and 173.

B.Set idle rpm in gear to specilied idle speed. lf still no good, adjust motor mounts as outlined in enginesection of service manual.

c.lf the large clutch piston O-.ing is broken, inspect the piston groove for rough machining.

D.lf the clutch pack is seized or is excessively worn, inspect the other clutches lor wear, and check the

orifice control valves and throttle valves for free mov€ment.

E.lf throttle valve B is stuck. insDect the clutches for wear.

lf the 1 - 2 shift valve is stuck closed, the transmission will not upshitt. lf stuck open, the transmissionhas no lst gear.

H.lf the 2-3 orilice control valve is stuck, inspect the 2nd and 3rd clutch packs for wear.

lf the orifice control valve is stuck. inspect the 3rd and 4th clutch packs for wear.

J.lf the clutch pressure control valve is stuck closed, the transmission will not shift out oI 1st gear.

lmproper alignment or main valve body and torque converter housing may cause ATF pump seizure.

The symptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

lf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

M.lf the 1st clutch feed pipe guide in the right side cover is scored by the mainshaft, inspect the ball bear-

ing lor excessive movement in the transmission housing. lf OK, replace the right side cover as it is dent-

ed. The O-ring under the guide is probably worn.

N.Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged.lf the 4th feed pipe is damaged or out of round, replace the right side cover.Replace the sub-shaft il the bushing for the 1st-hold teed pipe is loose or damaged.lf the 1st-hold teed pipe is damaged or out of round, replace it.

Replace the mainshaft iI the bushing for the lst feed pipe is loose or damaged.lf the 1st leed pipe is damaged or out of round, replace it.

A worn or damaged sprag clutch is mostly a result of shifting the transmission in El or LDll position

while the wheels rotate in reverse, such as rocking the vehicle in snow.

P.Inspect the trame for collision damage.

Inspect lor damage and wear:1. Reverse selector gear teeth chamfers.2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.4. Differential pinion shaft tor wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.Replace items 1 . 2, 3 and 4 iI worn or damaged. lf transmission makes clicking, grinding or whirringnoise, also replace mainshaft 4th gear, reverse idler gear, and countershatt 4th gear in addition to '1,

2,3or4.It differential pinion shalt is worn, overhaul differential assembly, and replace ATF strainer, and thoroughly

clean transmission, tlush torque conveder, cooler and lines.lf bottom ot 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and final

onven qear.

R.Be very careful not to damage the torque converter housing when replacing the main ball bearing. You

may also damage the ATF pump when you torque down the main valve body. This will result in ATFpump seizure if not detected. Use proper tools.

S.Install the main seal llush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out. it will block the fluid return passage and result in damage.

T.Harsh downshifts when coasting to a stop with zero throttle may be caused by a bent-in throttle valve

retainer/cam stopper. Throttle cable adjustment may clear this problem.

Throttle cable adjustment is essential tor proper operation ol the transmission. Not only does it affectthe shift points if misadjusted, but also the shift quality and lock up clutch operation.A cable adjusted too long will result in throttle pressure being too low for the amount of engine torqueinput into the transmission and may cause clutch slippage. A cable adjusted too short will result in toohiqh throttle pressure which may cause harsh shifts, erratic shifts and torque converter hunting.

Page 521 of 1681

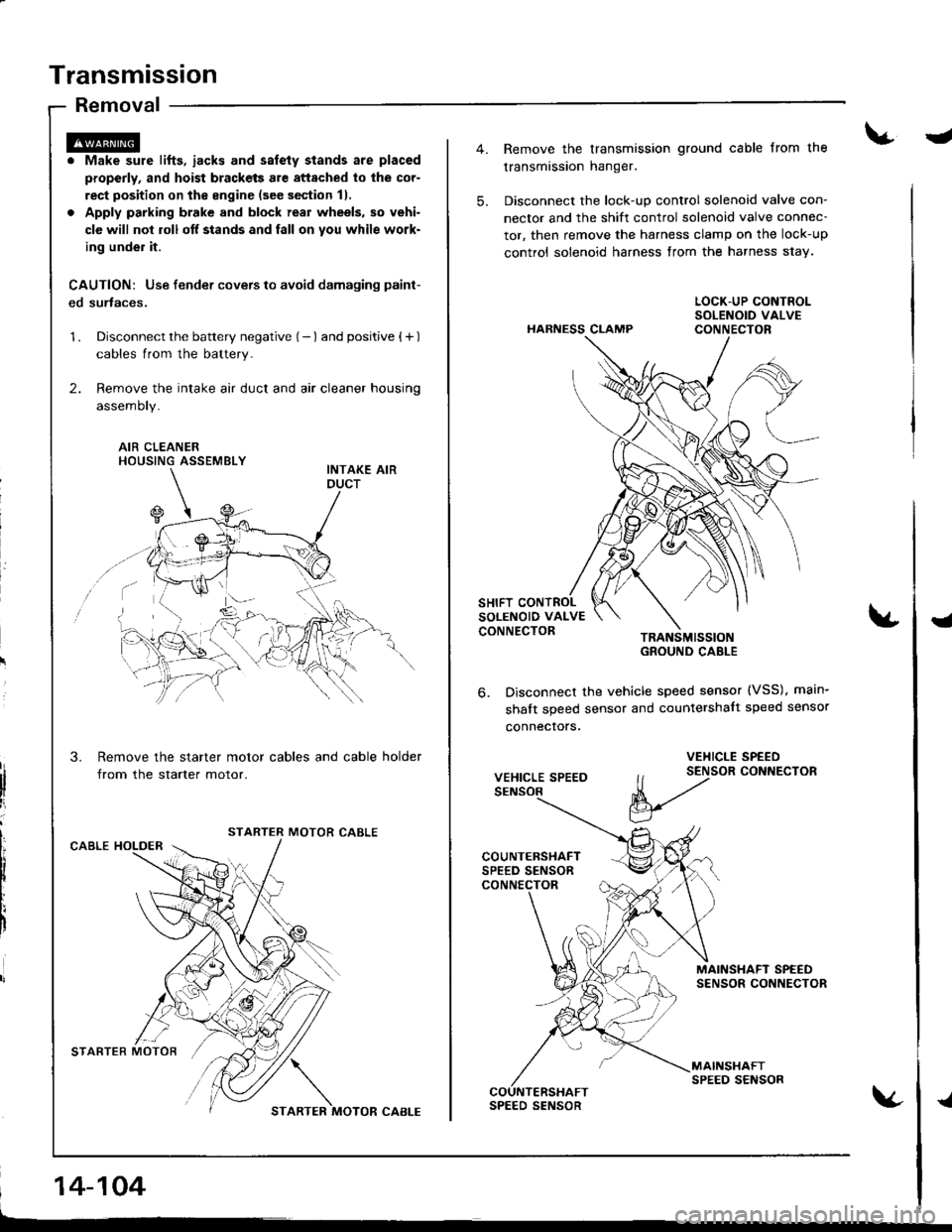

Transmission

Removal

. Make sure lifts, iacks and salety stands are placed

properly, and hoist brackets are attached to lhe cor-

rect position on the engine (see section 11.

. Apply parking brake and block real wheels, so vehi-

cle will nol roll off stands and fall on you while work-

ing under it.

CAUTION: Use fender covers to avoid damaging paint-

ed surtaces.

1 . Disconnect the battery negative (- ) and positive { + )

cables from the battery.

2. Remove the intake air duct and air cleaner housing

assemoty.

AIR CLEANERHOUSING ASSEMBLY

Remove the starter motor cables and cable holder

from the starter motor.

MOTOR CABLECABLE HOLDER

STARTER MOTOR'/,/ \

STARTER MOTOR CABI-E

14-104

-

5.

Remove the transmission ground cable from the

transmission hanger.

Disconnect the lock-up control solenoid valve con-

nector and the shift control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness s1ay.

HARNESS CLAMP

TRANSMISSIOIGROUND CABLE

Disconnect the vehicle speed sensor (VSS), main-

shalt speed sensor and countershalt speed sensor

connecrors.

{

6.

VEHICLE SPEED

VEHICLE SPEED

ll t2tor coNNEcroR

V

MAINSHAFT SPEEDSENSOR CONNECTOR

MAINSHAFTSPEED SENSORCOUNTERSHAFTSPEED SENSOR{

Page 530 of 1681

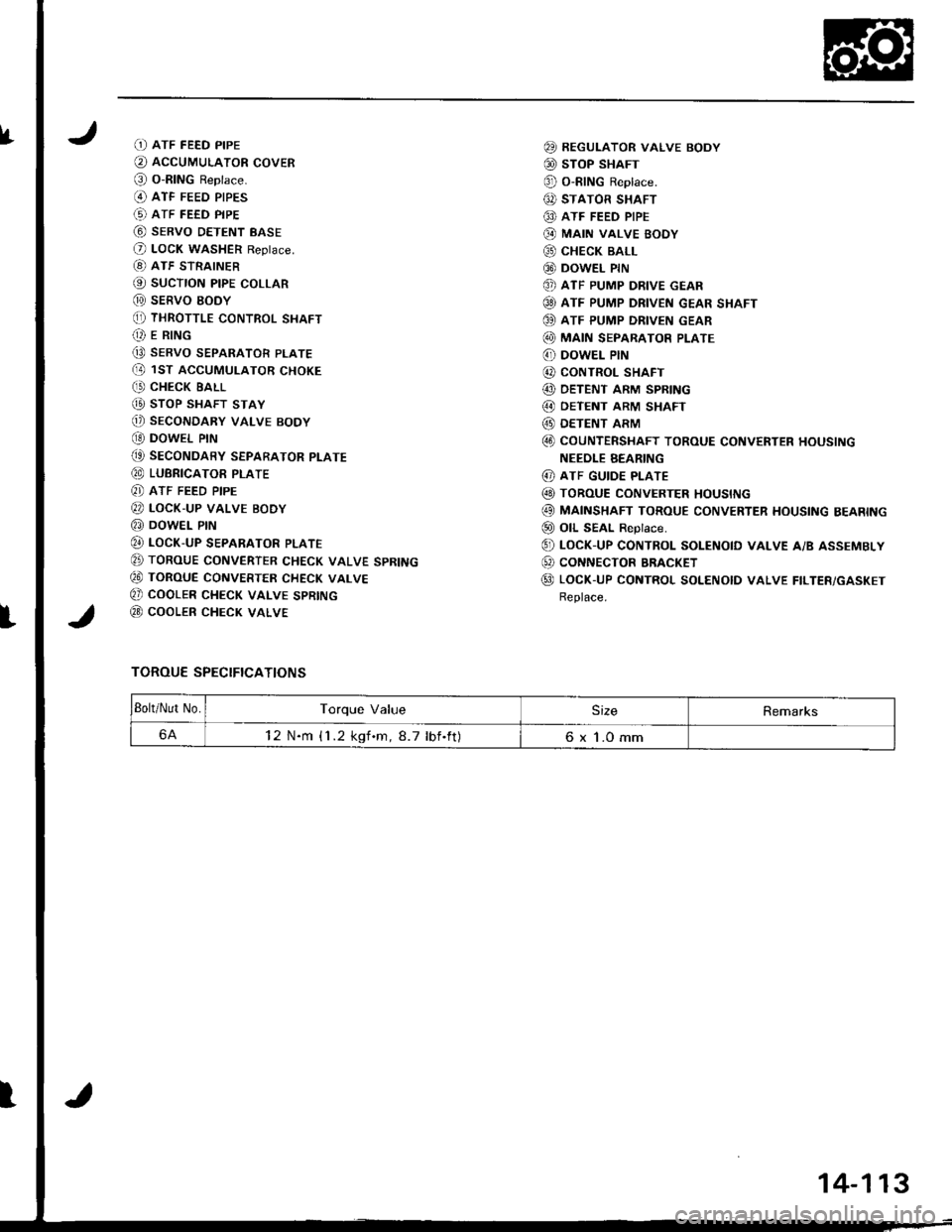

IfD ATF FEED PIPE

O AccUMULAToR covER

@ o-RING Reptace.(O ATF FEED PIPES

(!) ATF FEED PIPE

@ sERvo DETENT BASE

O LocK WASHER Reptace.

[8) ATF STRAINER

@ sucTroN ptpE coLLAR

@ sERVO EODY(, THRoTTLE coNTRoL SHAFT(t E R|NG

Q9 SERVO SEPARATOR PLATE(D 1ST ACCUMULAToR cHoKE

C' CHECK EALL

@ sToP SHAFT STAY

@) SECONDARY VALVE BODY

OO DOWEL PIN

(t SEcoNDARY SEPARAToR PLATE

@ LUBRICAToR PTATE

8] ATF FEED PIPE

@ LocK-uP vALvE BoDy

@ DowEL PrN

@ LocK-uP SEPARAToR PLATE

E TORoUE CoNVERTER cHEcK VALVE SPRING

€0 ToRouE CoNVERTER cHEcK vALvE

Q) COOLER CHECK VALVE SPRING

@ cooLER cHEcK VALVE

TOROUE SPECIFICATIONS

@ REGULAToR vALvE BoDY

@ sToP SHAFT

@ o-RING Reptace.

6, STATOR SHAFT

@ ATF FEED PIPE

@ MA|N VALVE BOOY

@ cHEcK BALL

@ DowEL PrN

@ ATF PUMP DRIVE GEAR

@ ATF PUMP DRIVEN GEAR SHAFT

OO ATF PUMP DRIVEN GEAR

@ MA|N SEPARAToR PLATE

6' DowEL PIN

@ CONTROL SHAFT

@ DETENT ARM SPRING

@ OETENT ARM SHAFT

@ DETENT ARM

@ coUNTERSHAFT ToRoUE coNVERTER HoUSING

NEEOLE BEARING

@ ATF GUIDE PLATE

@ ToRouE coNvERTER HoustNG

@ MAINSHAFT ToRoUE coNvERTER HousING BEARING

@ oll SEAL ReDtace.

@ LocK-up coNTRoL soLENotD vALvE A/B ASSEMBLy

@ coNNEcToR BRACKET

@ LocK-UP coNTRoL SoLENoID vALvE FILTER/GASKET

Replace.

Bolt/Nut No.Torque ValueSizeRemarks

6A12 N.m {1 .2 kgf.m,8.7 lbf.ft)6 x 1.0 mm

I

14-113

Page 535 of 1681

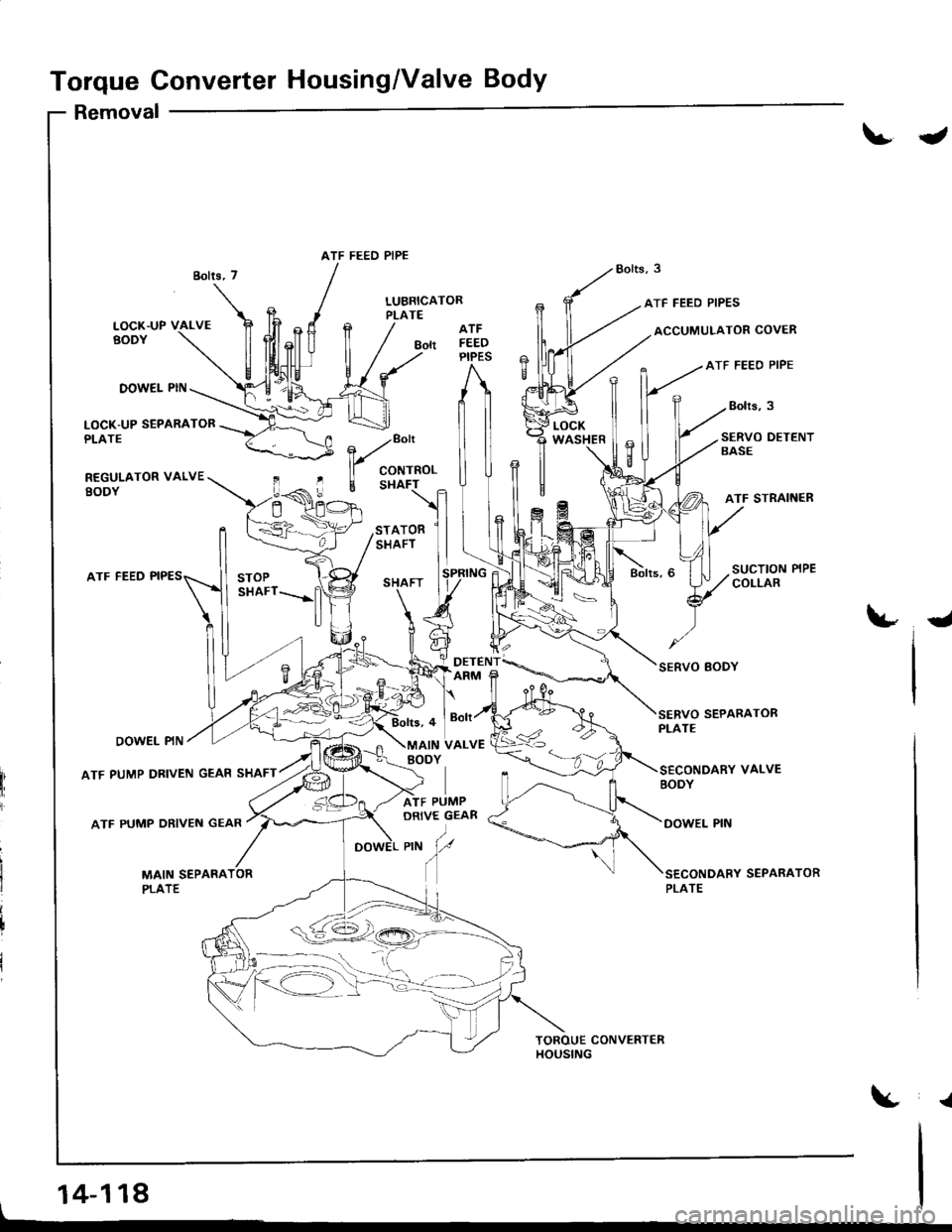

Torque Converter Housing/Valve Body

Removal

t

LUBRICATORPLATEATF FEED PIPES

ACCUMULATOR COVER

ATF FEEO PIPE

Bolrs,3

ATF

Bott FEEDPIPES

DOW€I- PIN

LOCK-UP SEPARATORPLATE

REGULATOR VALVEEODY

SERVO DETENTSASE

ATF STRAINER

LOCKWASHER

ATF FEED

DOWEL PIN

ATF PUMP DRIVEN GEAR SHAFT

ATF PUMP ORIVEN GEAR

-

SEPARATOR

.a

ATF FEED PIPE

, ./"o"

ll coNrRoL

E Sl{AF-r

ATOR

PLATE

_ro-rr!_

Page 536 of 1681

I

l"

I

J

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.

a Blow out all passages.

a When removing the valve body replace the lollowing:. O-rings. Lock washers

1 . Remove the ATF feed pipes from the servo body, ser-vo detent base, accumulator cover, lock-up valve

body and main valve body.

2. Remove the three bolts securing the ATF strainer

and servo detent base, then remove the strainer

and detent base.

3. Remove the three bolts securing the accumulator

cover, then remove the accumulator cover.

4. Remove the six bolts securing the servo body. then

remove the servo body and separator plate.

5. Remove the one bolt securing the secondary valvebody, then remove lhe secondary valve body andseparator plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remov€ th€ lubricator

plate. Iock-up valve body, and separator plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body.

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

housrng.

1O. Remove the detent arm and detent arm shatt from

the main valve body.

1 'l . Remove the four bolts securing the main valve body,

then remove the main valve body.

'I2. Remove the ATF pump driven gear shatt, then re-

move the ATF pump gears.

13. Remove the main separator plate with two dowel

pins.

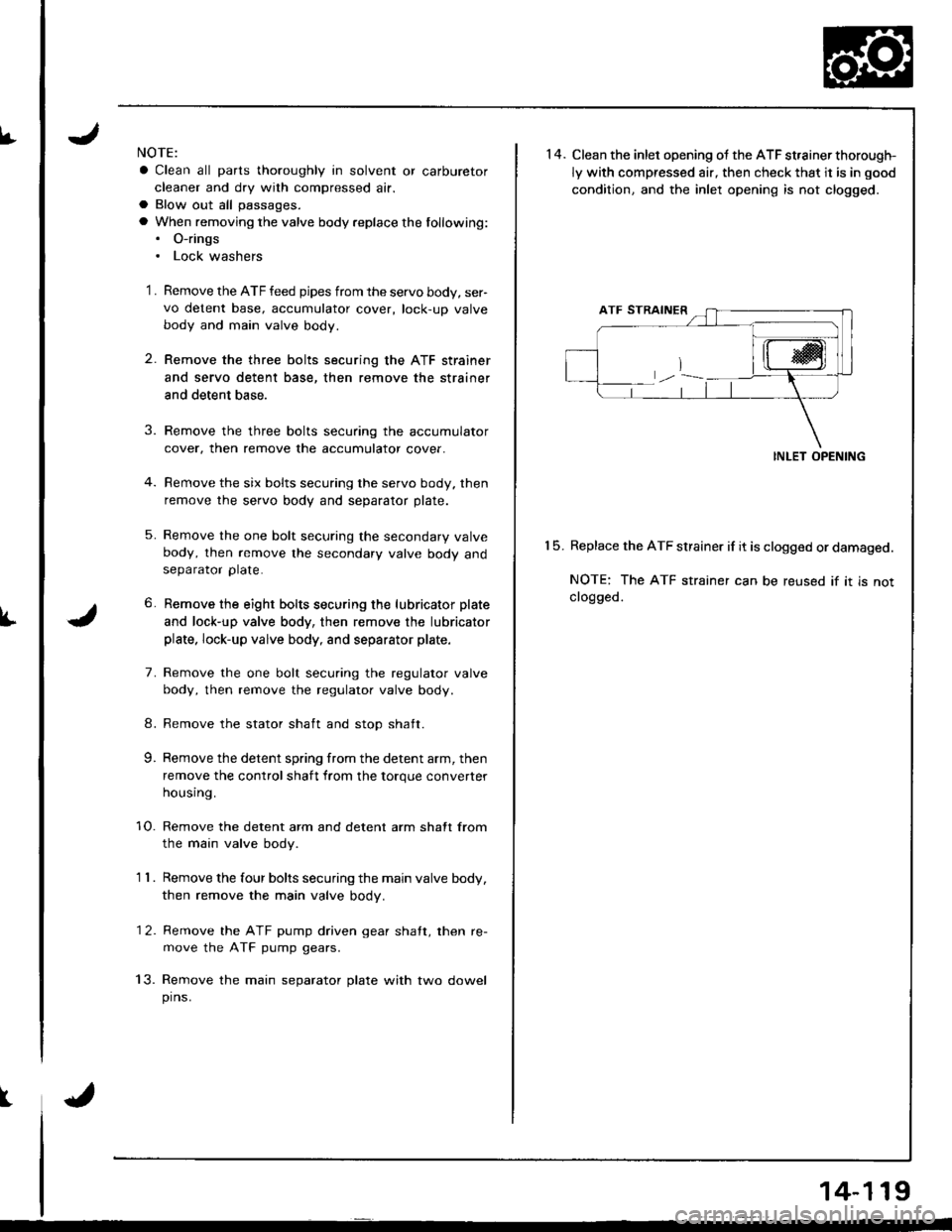

15.

14. Clean the inlet opening ot the ATF st,ainer thorough-

ly with compressed air, then check that it is in good

condition. and the inlet opening is not clogged.

INLET OPENING

Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclogged.

14-119

Page 576 of 1681

Transmission

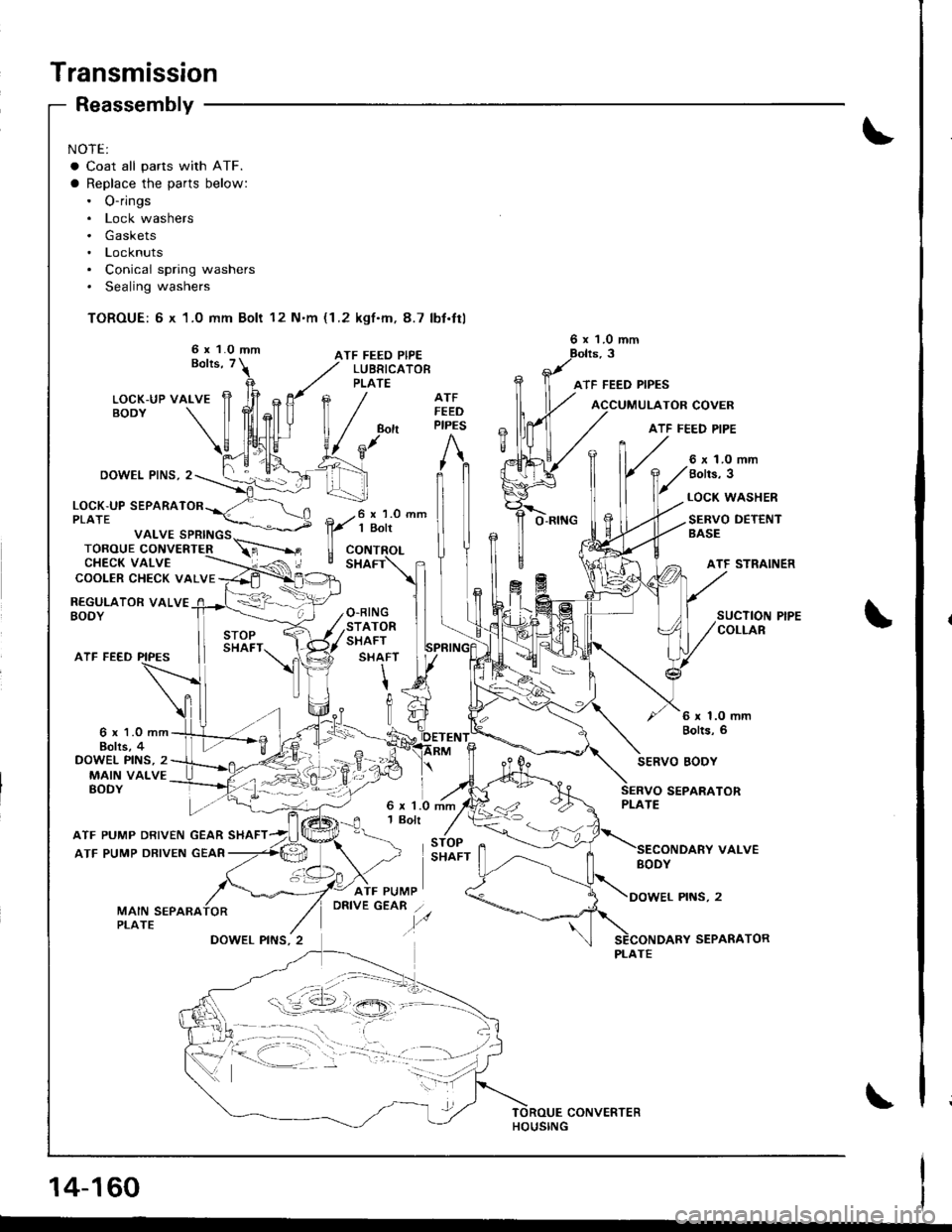

NOTE:

a Coat all parts with ATF.

a Replace the parts below:. O-rings. Lock washers. Gaskets. Locknuts. Conical spring washers. Sealing washers

TOROUE: 6 x 1.0 mm Bolt 12 N'm (1.2 kgf.m, 8.7 lbt.ttl

6 x 1.0 mmATF FEED PIPEBolts, T

Reassembly

DOWEL PINS, 2

ATF FEED

LUBRICATOBPLATE

6 x 1.0 mm

ATF FEED PIPES

O.RINGSTATORSHAFT

SHAFT

\tIt]U

ATFFEEDPIPES

STOPSHAFT

6 x 1.0 mmBolts, 6

TOR COVER

ATF FEED PIPE

VALVE SPRINGSTOROUE CONVERTERCHECK VALVECOOLER CHECK VALVE

LOCK-UP SEPARATPLATE

REGULATOR VALVEBODY

6 x 1.0 mm8olls, 3

LOCK WASHER

SERVO DETENTBASE

ATF STRAINER

SUCTION PIPECOLLAR

6 x 1.0 mmBohs, 4DOWEL PINS, 2MAIN VALVEBODY

SERVO EODY

SEPARATOR

VALVE

PINS,2

SEPARATOR

6 x 1.0 mm1 Bolt

ATF PUMP DRIVEN GEAR SHAFT

ATF PUMP DRIVEN GEAR

GEAR /.

.,,o

{--==,.-,,..;;,,, :_ :,_11,

PLATE

14-160

CONVERTER