air condition HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 307 of 1681

ldle

Air

Gontrol System

Gonditioning Signal

\

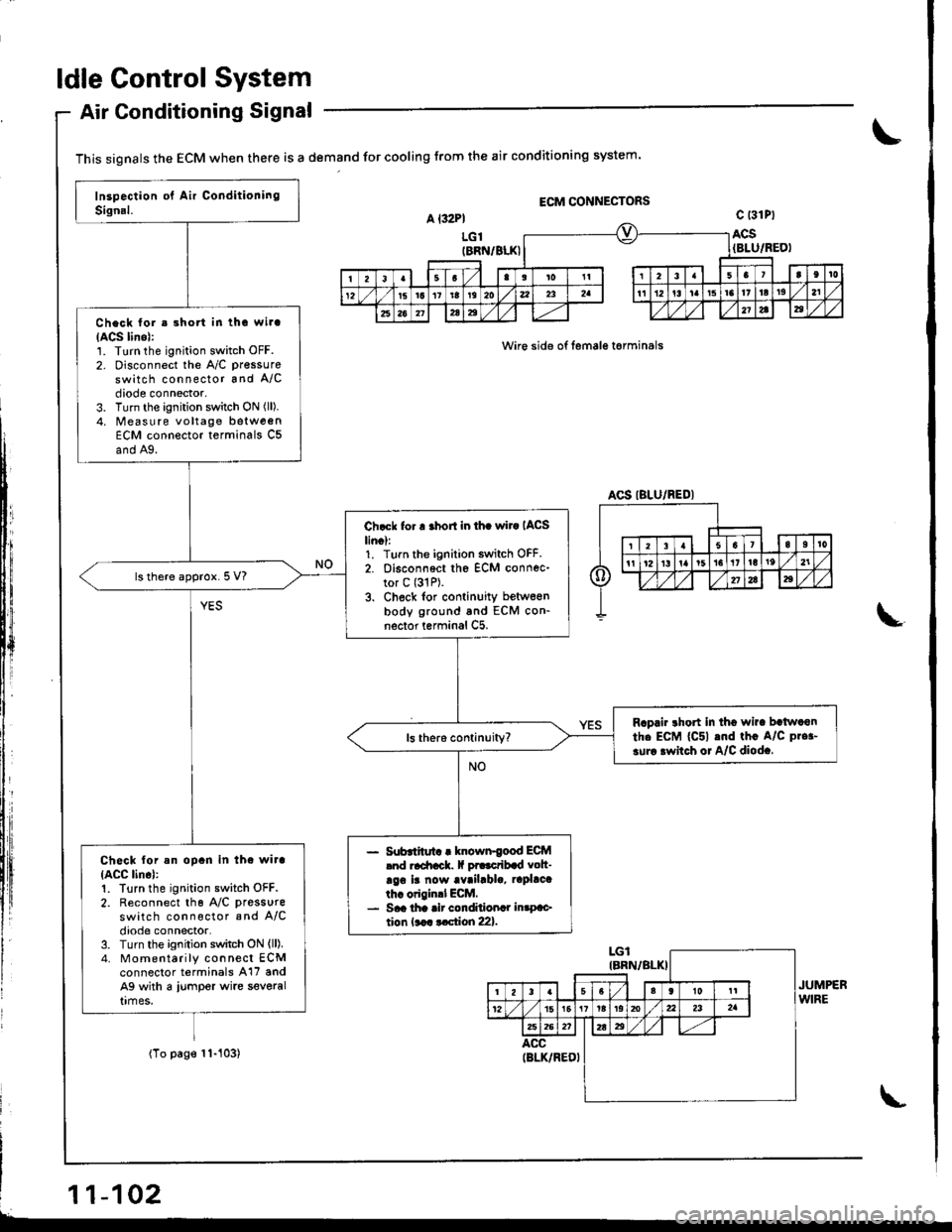

This signals the ECM when there is a demand for cooling from the air conditioning system'

ECM CONNECTORS

a l32Pl

LGl(BRN/BLKI

c t31Pt

ACSIBLU/REDI

wire side of femal€ torminals

;

L

LGI

JUMPERWIRE

ACS IBLU/REDI

Check lor.3hort in thG wira(ACS lino):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch connector and A/Cdiode connector,3. Turn the ignition switch ON (ll).

4. Measu re voltage betwo€nECM connector terminals C5and A9.

Ch.ck to.. rhorl in th. wir. IACSlincl:1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Ch6ck {or continuity betwe€n

body ground tnd ECM con-nector terminal C5.

lsthere approx.5 V?

Rapair rhort In tho wira batwaon

th. EcM {c5l and thc A/c pre.-

sur. rwitch ot A/C diod.,

- Subtlilut I known{ood Ecttllnd raahack. lf prtactibad voft-

rgo ir now avaihbla, tcplacalh. originll ECM.- Saa tha air condhiond in.plction 1... r.ction 221.

Check lor an opan in th€ wi.a(ACC lin.l:'1. Turn the ignition switch OFF.2. Reconnect th6 A,/C pressure

switch connector and A/Cdiode connector.3. Turn the ignilion switch ON (ll).

4. Momentarily connect ECMconnector terminals A'17 andAg wkh a iumper wire severaltimes,

(To page 11"103)

IBRN/BLKI

Ial,/l l8 I r0 I rl

12't516 11alrslzo ,/ l4l a3 | 2.

aa2621zel dt

IBLK/REDI

11-102

\

Page 308 of 1681

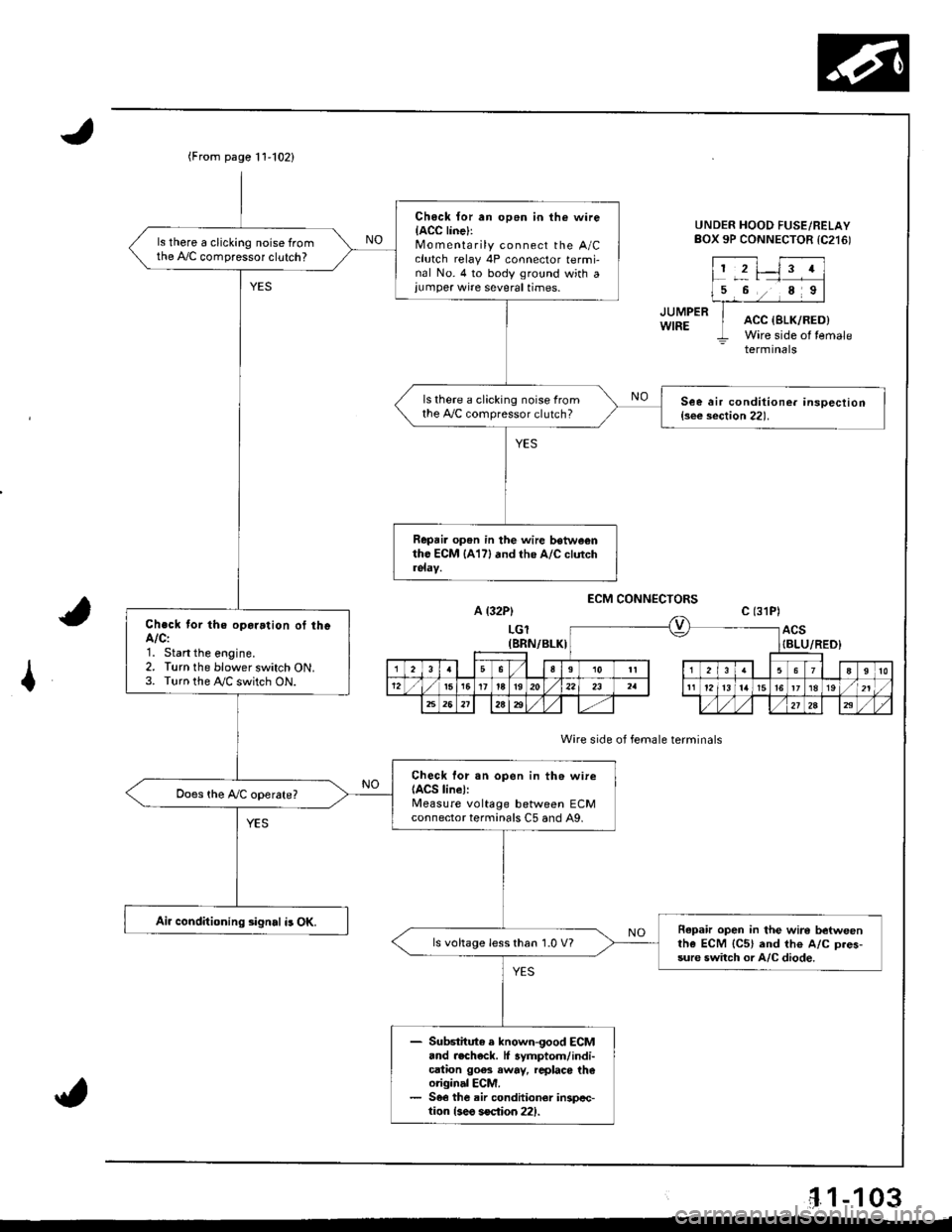

(From page t 1'102)

Ch6ck {or an op6n in the wireIACC linel:Mo m enta rily connect the A/Cclutch relay 4P connector termi-nal No. 4 to body ground with a,umper wire several times.

ls there a clicking noise fromthe A,/C compressor clutch?

ls there a clicking noise fromthe 4,./C compressor clutch?See air conditione. insoection{s€e section 22).

Repai. op6n in the wire betwe€ntho ECM lA17l and the A/C clutch

Check tor the oparation of theA/C:1. Start the eogine.2. Turn the blower switch ON.3. Turn the !y'C switch ON.

Check lor sn open in th6 wireIACS line):Measure voltage between ECMconnector terminals C5 and A9,

Air conditioning signal i3 OK.Repafu open in the wire betweenthe ECM {C5} and th€ A/C D.es-sure switch or A/C diode.

ls voltage less than 1.0 V?

- Substitute e known-good ECM.nd .echeck. lf 3ymptom/indi-cation goes away, rcplaco th€original ECM.- 56€ the air conditionor inspcc-tion {3eo soction 221.

UNDER HOOD FUSE/RELAYBOX 9P CONNECTOR tC216)

JUMPERWIREACC {SLK/RED)Wire side of temale- terminals

A {32P)

LGl(BRN/BLKI

ECM CONNECTORS

Wire side of female terminals

c (31P)

ACS{BLU/RED}

I

'1.1-103

Page 316 of 1681

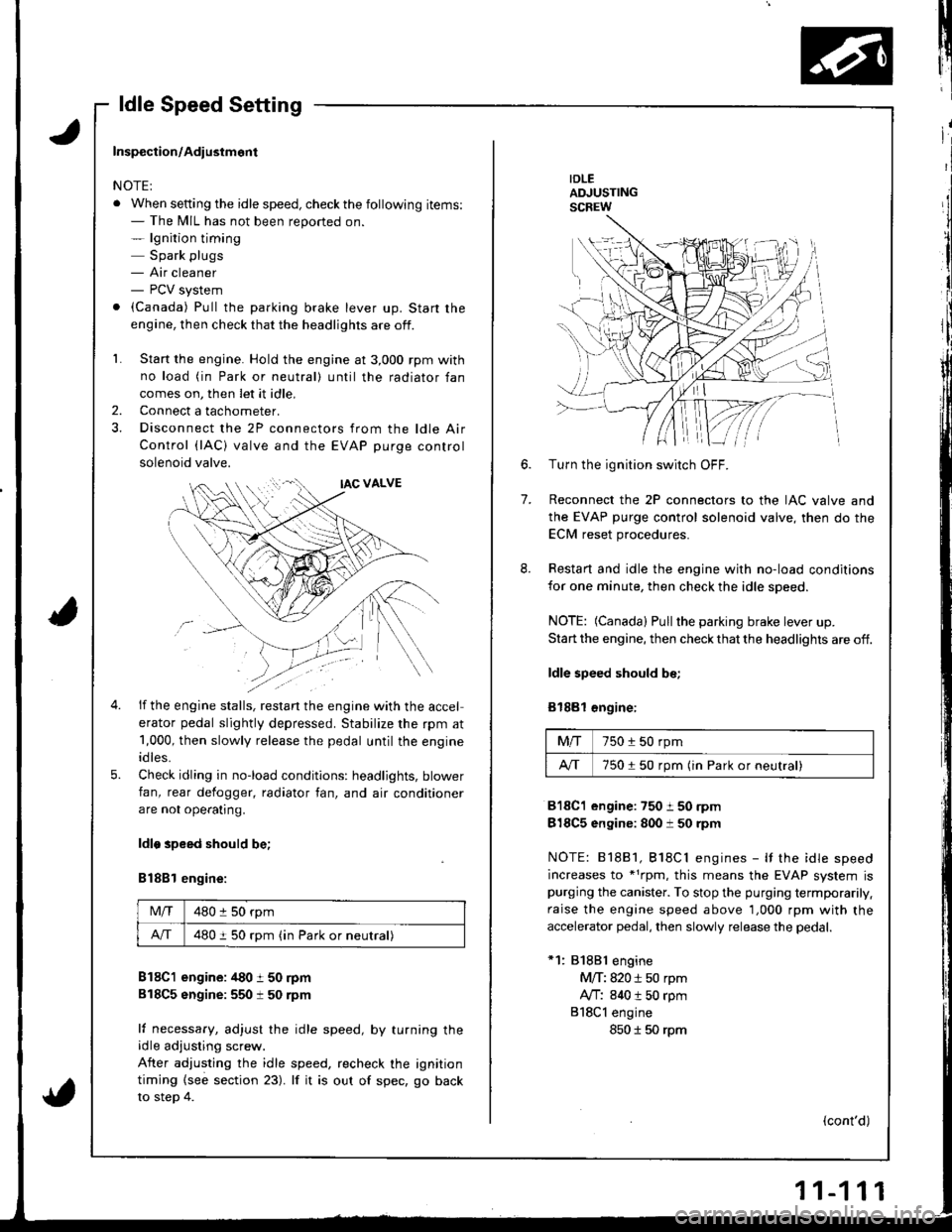

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 317 of 1681

ldle Control System

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 334 of 1681

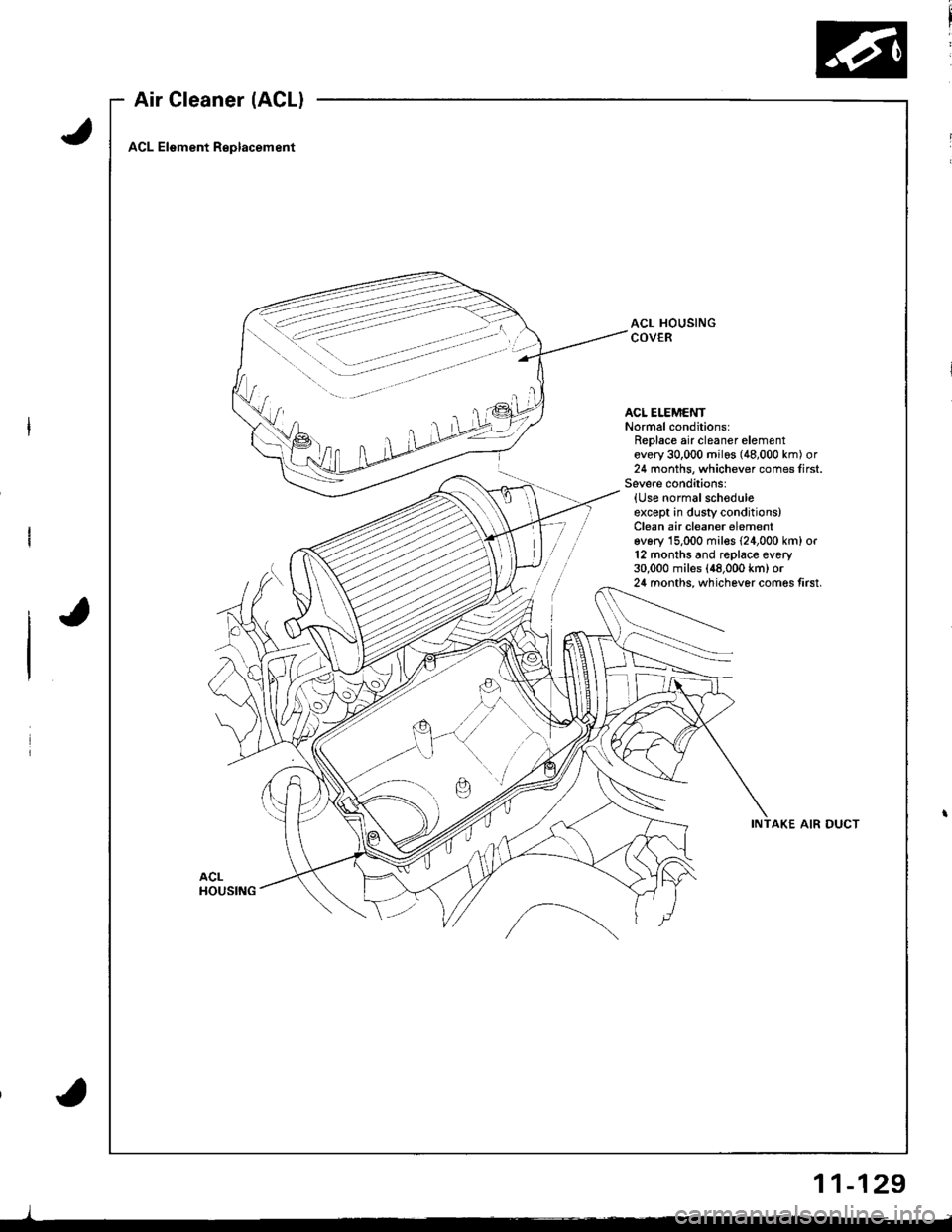

Air Cleaner (ACLI

ACL Element Replacement

ACL HOUSINGCOVER

ACL ELEMENTNormal conditions:Replace air cleaner elementevery 30,000 milos (48,000 km) or24 months, whichever comes first.Severe cond;tions:{Use normalschoduleexcept in dusty conditions)Clean air cleaner elementev6ry 15,000 mil€s {24,000 km} or12 months and replace every30,000 miles (48,000 km) or24 months, whichever comes tirst.

INTAKE AIR DUCT

)

11-129

Page 343 of 1681

t"iI

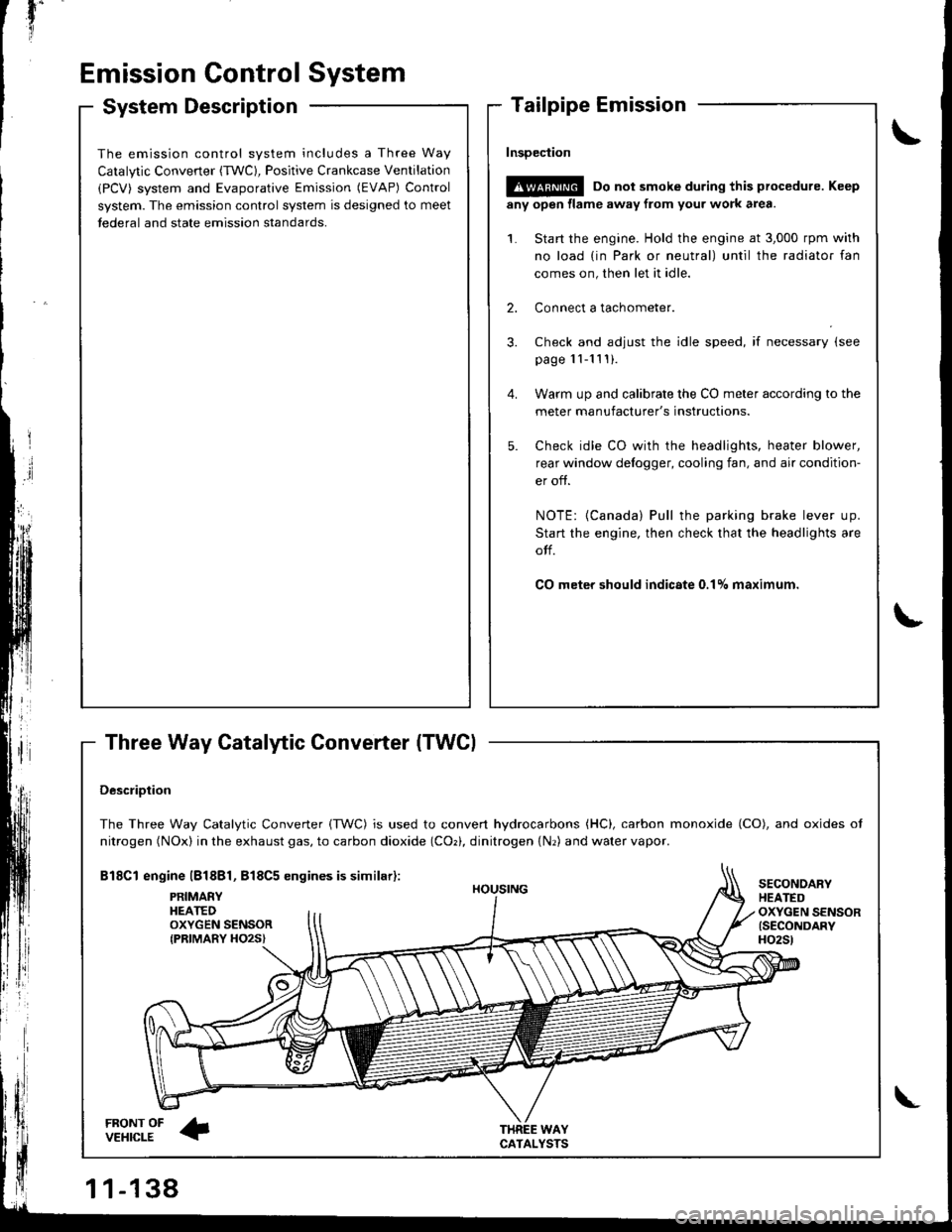

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 418 of 1681

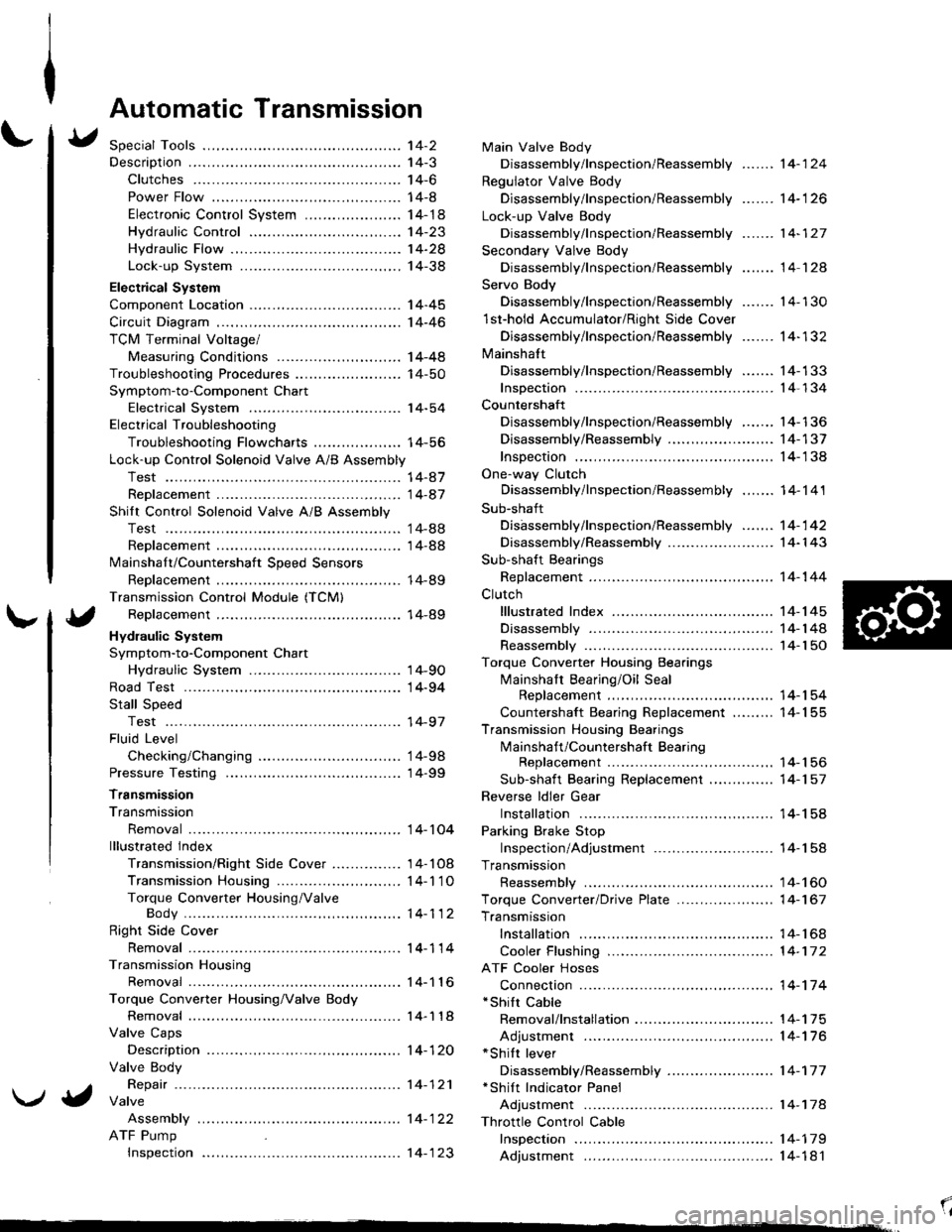

Automatic Transmission

Special Tools ................ '14-2

Descraption .................... 14-3

Clutches ............ ...... 14-6

Power Flow ..,........... 14-8

Electronic Control System ..................... 1 4-1 8

Hydraulic Control ...... 14-23

Hydraulic Flow .........- 14-28

Lock-up System ........ 14-38

Electrical System

Component Location -................................ 1 4-45

Circuit Diagram ............. 14-46

TCM Terminal Voltage/

Measuring Conditions ......,.................... 1 4-48

Troubleshooting Procedures .. . ... ........ ...... ... 14-50

Symptom-to-Component Chart

Electrical System ...... 14-54

Electrical Troubleshooting

Troubleshooting Flowcharts .......... ... ...,.. 14-56

Lock-up Control Solenoid Valve A/B Assembly

Test .................. ...... 14-A7

Replacement ............. 14-a7

Shilt Control Solenoid Valve A/B Assembly

Test .................. ...... '14-88

Replacement .,..,........ 14-88

lvlainshaf t/Countershaft Speed Sensors

Replacement ....-......,. 14-89

Transmission Control Module (TCM)

Replacement ............. 14-89

Hydraulic System

Symptom-to-Component Chart

Hydraulic System ...... 14-90

Road Test ,................... 14-94

Stall Speed

Test .................. ...... 14-97

Fluid Level

Checking/Changing .... 14-98

Pressure Testing ........... 14-99

Transmission

Transmission

Removal ............. ...... 14-10�4

lllustrated lndex

Transmission/Right Side Cover ............... 1 4-1 08

Transmission Housin9 ................,..,....... 1 4-1'1 O

Torque Converter Housing/ValveBody .................. .. 14-112

Right Side Cover

Removal ............. ...... 14-114

Transmission Housing

Removal ............. ...... 14-1 l6

Torque Converter Housing/Valve Body

Removal ............. ...... l4-1 18

Valve Caps

Description ...........-... 14-120

Valve Body

Repair ................ ...... 14-12'l

Valve

Assembly

ATF Pump

Inspeclton

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly

Secondary Valve Body

Disassembly/lnspection/Reassembly

Servo Body

....... 14-124

....... 14-126

....... 14-127

....... 14 124

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection/Reassembly .......

Mainsha{t

14-130

14-132

Disassembly/lnspection/Reassembly ....... 14-133

Inspection ................. 14-134

Countershaft

Disassembly/lnspection/Reassembly,..,.., l4-136

Disassembly/Reassembly ..,...,..,.........,,.. 1 4-1 37

Inspection ......,...,..,... 14-138

One-way Clutch

Disassembly/lnspection/Reassembly ....,.. 14-141

Sub-shaft

Disassembly/lnspection/Reassembly ...,,..'14-142

Disassembly/Reassembly ....................... 1 4- l 43

Sub-shaft Bearings

Replacement ,..,,.,,..,.. 14-144

Clutch

lllustrated Index ................................... I 4-1 45

Disassembly ............. 14-144

Reassembly .............. 14-150

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Replacement ......... 14-154

Countershaft Bearing Replacement ......... 1 4- 1 55

Transmission Housing Bearings

Mainshaft/Countershaft BearingReplacement ......,.. 14-'156

Sub-shaft Bearing Replacement .,............ 1 4-1 57

Reverse ldler Gear

Installation .........-..... 14-158

Parking Brake Stop

Inspection/Adjustment .......................... 1 4-1 58

Transmission

Reassembly .............. 14-160

Torque Converler/Drive Plate ..............,.,,.,, 1 4-1 67

Transmission

Installation ............... 14-168

Cooler Flushing ......... 14-172

ATF Cooler Hoses

Connection ,..,,,....,,.,, '14-'174

*shift cable

Removal/lnstallation . . .. .... ... .... ... .... .. . ... .. 14-'l75

Adjustment ,..,...,,,,.,, 14-'116*Shilt lever

Disassembly/Reassembly ....................... 1 4-'17 7'Shift Indicator Panel

Adjustment .............. 14-178

\l

)g

Page 466 of 1681

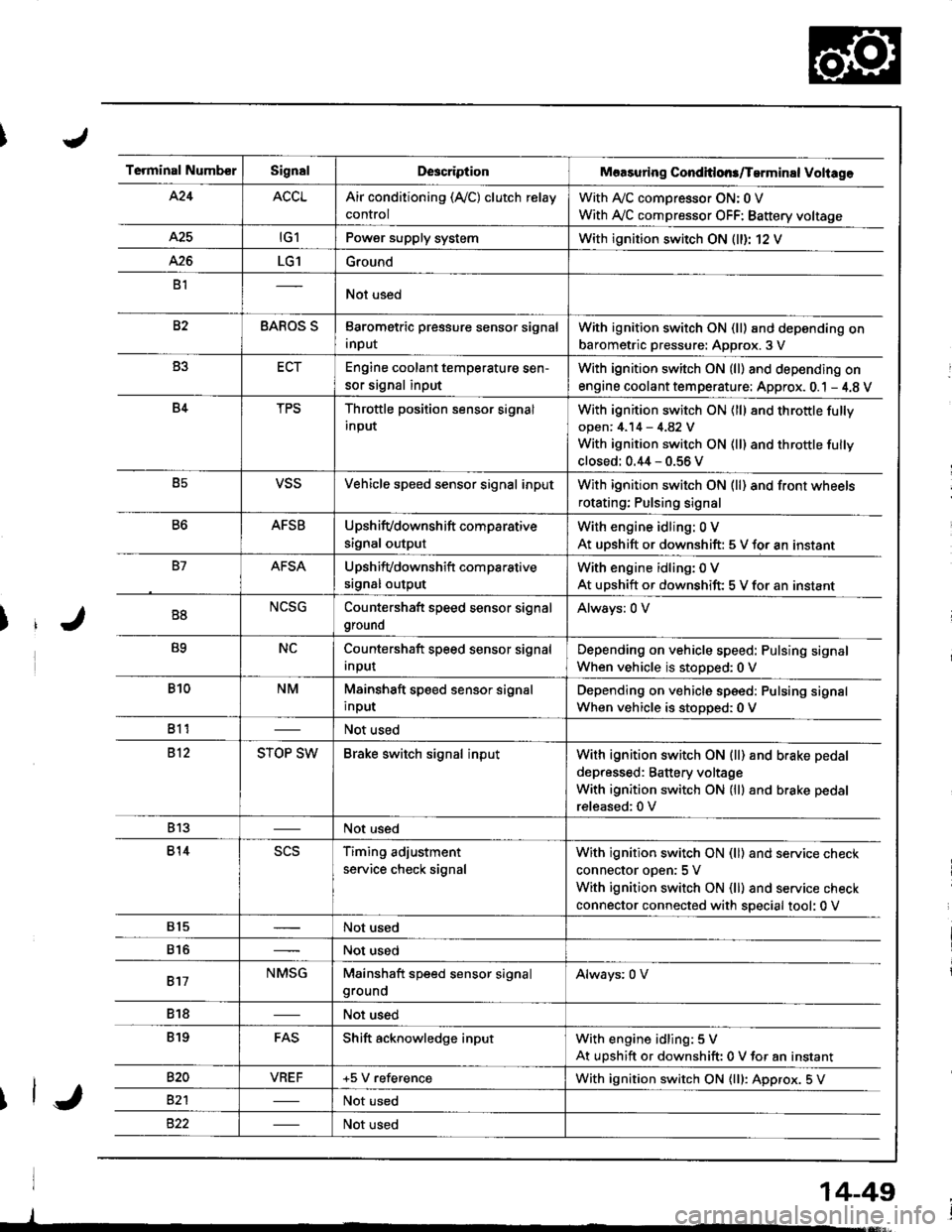

Terminal NumberSignalDescriptionMaasuring Conditlons/Tarminal Voliage

424ACCLAir conditioning (Ay'C) clutch relay

control

With A,/C comDressor ON: 0 V

With Ay'C compressor OFF: Battery voltage

A25tG1Power supply systemWith ignition switch ON (ll)r 12 V

426LG1Ground

B1Not used

82BAROS SBarometric pressure sensor signal

input

With ignition switch ON (ll) and depending on

barometric pressure: Approx. 3 V

B3ECTEngine coolant temperature sen-

sor signal input

With ignition switch ON (ll) and depending on

engine coolant tem perature: Approx. 0.1 - 4.8 V

B4TPSThrottle position sensor signal

input

With ignition switch ON (ll) 8nd throttle fully

open: 4.14 - 4.82 V

With ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

B5VSSVehicle speed sensor signal inputWith ignition switch ON (ll) and front wheels

rotating; Pulsing signal

B6AFSBUpshifvdownshift comparative

signal output

With engine idling: 0 V

At uDshift or downshift: 5 V for an instant

B7AFSAUpshifvdownshift com parative

srgnal output

With engine idling: 0 V

At upshift or downshift: 5 V for an instant

B8NCSGCountershaft speed sensor signal

ground

Always: 0 V

B9NCCountershaft speed sensor signal

Input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped:0 V

B10NMMainshaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stoDoed: 0 V

811Not used

812STOP SWBrake switch signal inputWith ignition switch ON {ll) and b.ake pedal

depressed: Battery voltage

With ignition switch ON (lll and brake pedal

released:0 V

813Not used

814scsTiming adjustment

service check signal

With ignition switch ON (ll) and service check

connector oDen:5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

815Not used

816Not used

817NMSGMainshaft speed sensor signalgroundAlways: 0 V

818Not used

819FASShift acknowledge inputWith engine idling: 5 V

At upshift or downshift: 0 V for an instant

820VBEF+5 V referenceWith ignition switch ON {lll: Approx. 5 V

82'lNot used

Not used

14-49

Page 536 of 1681

I

l"

I

J

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.

a Blow out all passages.

a When removing the valve body replace the lollowing:. O-rings. Lock washers

1 . Remove the ATF feed pipes from the servo body, ser-vo detent base, accumulator cover, lock-up valve

body and main valve body.

2. Remove the three bolts securing the ATF strainer

and servo detent base, then remove the strainer

and detent base.

3. Remove the three bolts securing the accumulator

cover, then remove the accumulator cover.

4. Remove the six bolts securing the servo body. then

remove the servo body and separator plate.

5. Remove the one bolt securing the secondary valvebody, then remove lhe secondary valve body andseparator plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remov€ th€ lubricator

plate. Iock-up valve body, and separator plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body.

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

housrng.

1O. Remove the detent arm and detent arm shatt from

the main valve body.

1 'l . Remove the four bolts securing the main valve body,

then remove the main valve body.

'I2. Remove the ATF pump driven gear shatt, then re-

move the ATF pump gears.

13. Remove the main separator plate with two dowel

pins.

15.

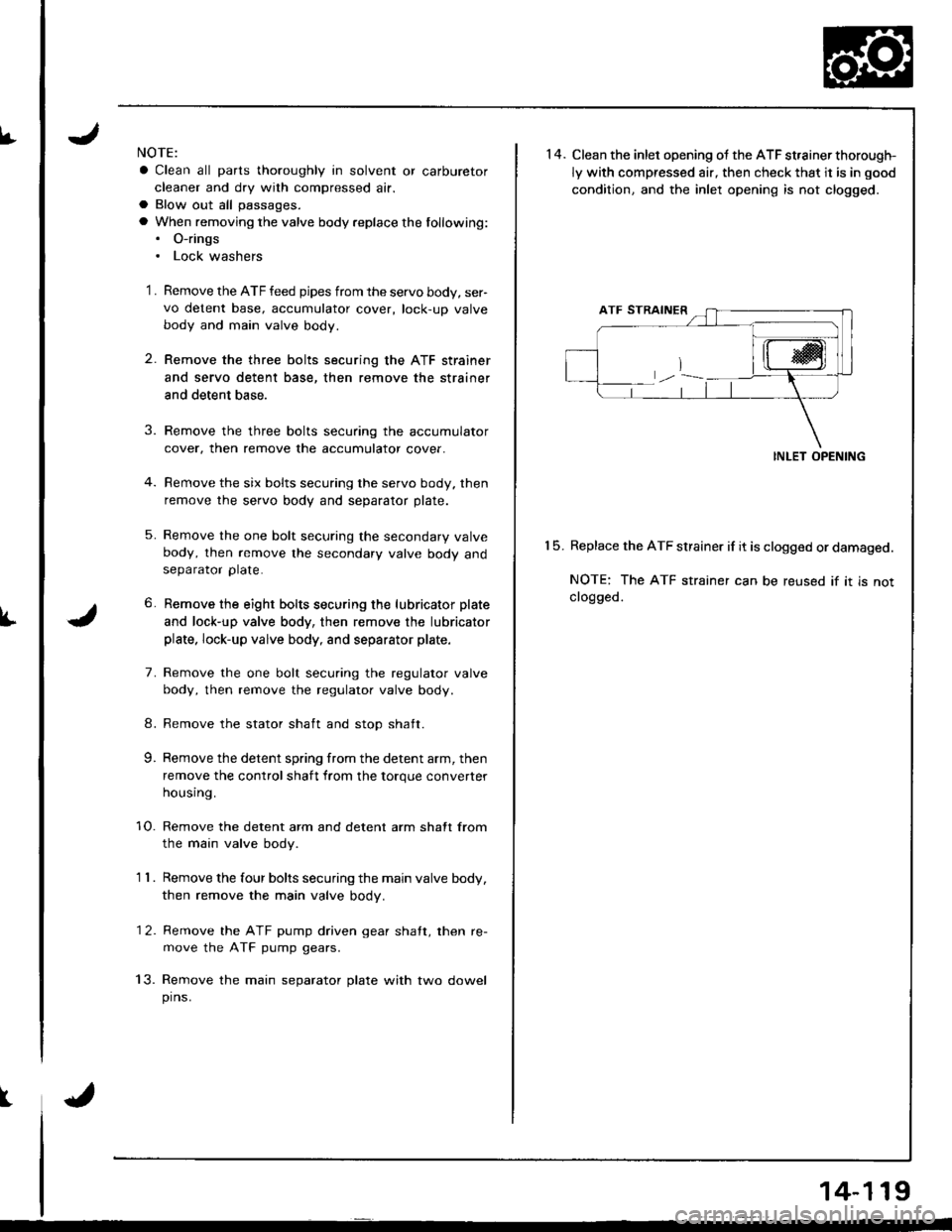

14. Clean the inlet opening ot the ATF st,ainer thorough-

ly with compressed air, then check that it is in good

condition. and the inlet opening is not clogged.

INLET OPENING

Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclogged.

14-119

Page 671 of 1681

Inspection and Adjustment

Pump Pressure Check

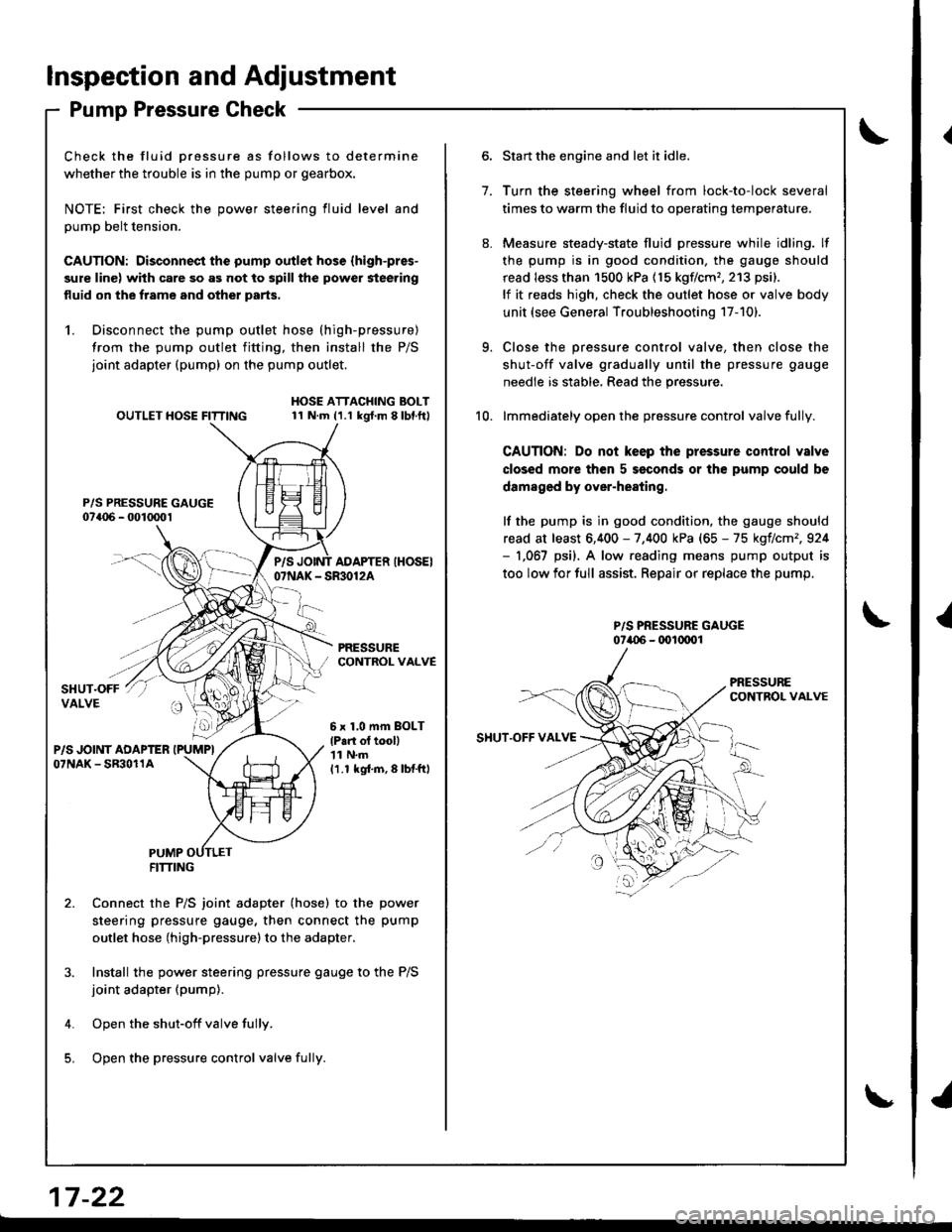

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I