air condition HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 788 of 1681

Troubleshooting Precautions

Kickback

L The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

Pump Motol

1. The pump motor operates when the ABS is functioning.

2. The ABS control unit checks the pump motor operation during initial diagnosis and when the vehicle is started. You

mav hear the motor operate at this time, but it is normal

Brake Fluid Replacement/Air Bleeding'1. Brake fluid replacement and air bleeding procedures are the same as vehicles without ABS. To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowcharts procedures assume that the cause of the problem is still present and the ABS indica-

tor is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Find out when the ABS indjcator came on. such as during initial diagnosis. during ABS control, after ABS control,

when vehicle speed was at a certain speed, etc.

3, When the ABS indicator does not come on during the test-drive, but troubleshooting is performed based on the DTC,

check for loose connectors, poor contact at the terminals, etc. before you start troubleshooting'

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustrations show the female terminals with a single outline and the male terminals with a double outline.

Page 995 of 1681

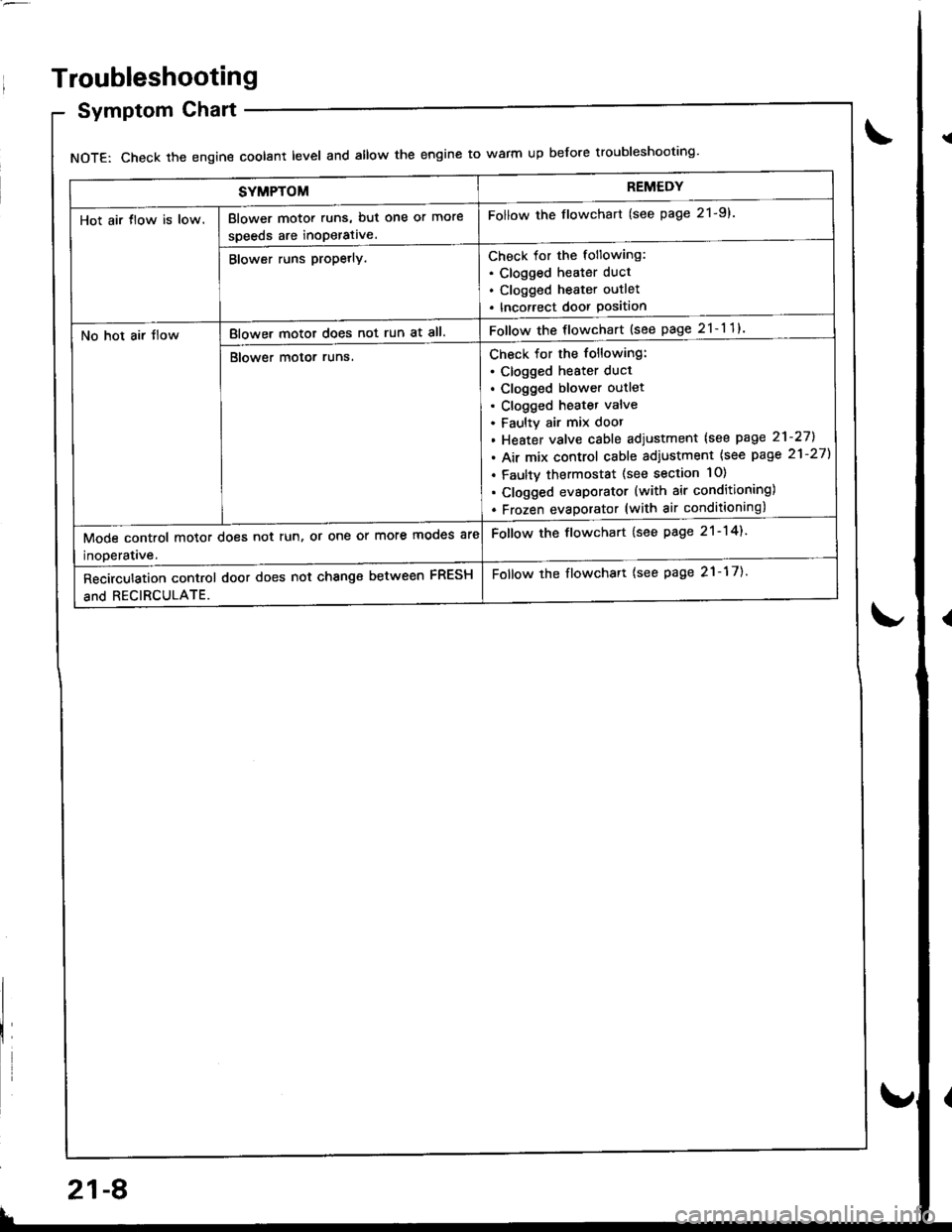

SYMPTOMREMEDY

Hot air tlow is low.Blower motor runs, but one or more

speeds are inoperative.

Follow the flowchart (see page 21-9).

Blower runs propetly.Check for the following:. Clogged heater duct

. Clogged heater outlet

. Incorrect door Position

No hot air tlowBlower motor does not run at all.Follow the flowchart {see page 21-11}

Blower motor runs.Check for the following:

. clogged heater duct

. Clogged blower outlet. Clogged heatet valve

. Faultv air mix door

. Heater valve cable adjustment lsee page 21-27].

. Air mix control cable adiustment {see page 21-27)

. Faulty thermostat (see section 10)

. Clogged evsporator (with air conditioning)

. Frozen evaDorator (with air conditioning)

Mode control motor does not run, or one or more mooes are

inoDeratave.

Follow the flowchart (see page 21-14).

Recirculation control door does not change between FRESH

and RECIRCULATE.

Follow the flowchart {see page 21-17).

Troubleshooting

Symptom Chart

NOTE: Check the engin€ coolant level and allow the engine to warm up before troubleshooting'

21-8

v

Page 1007 of 1681

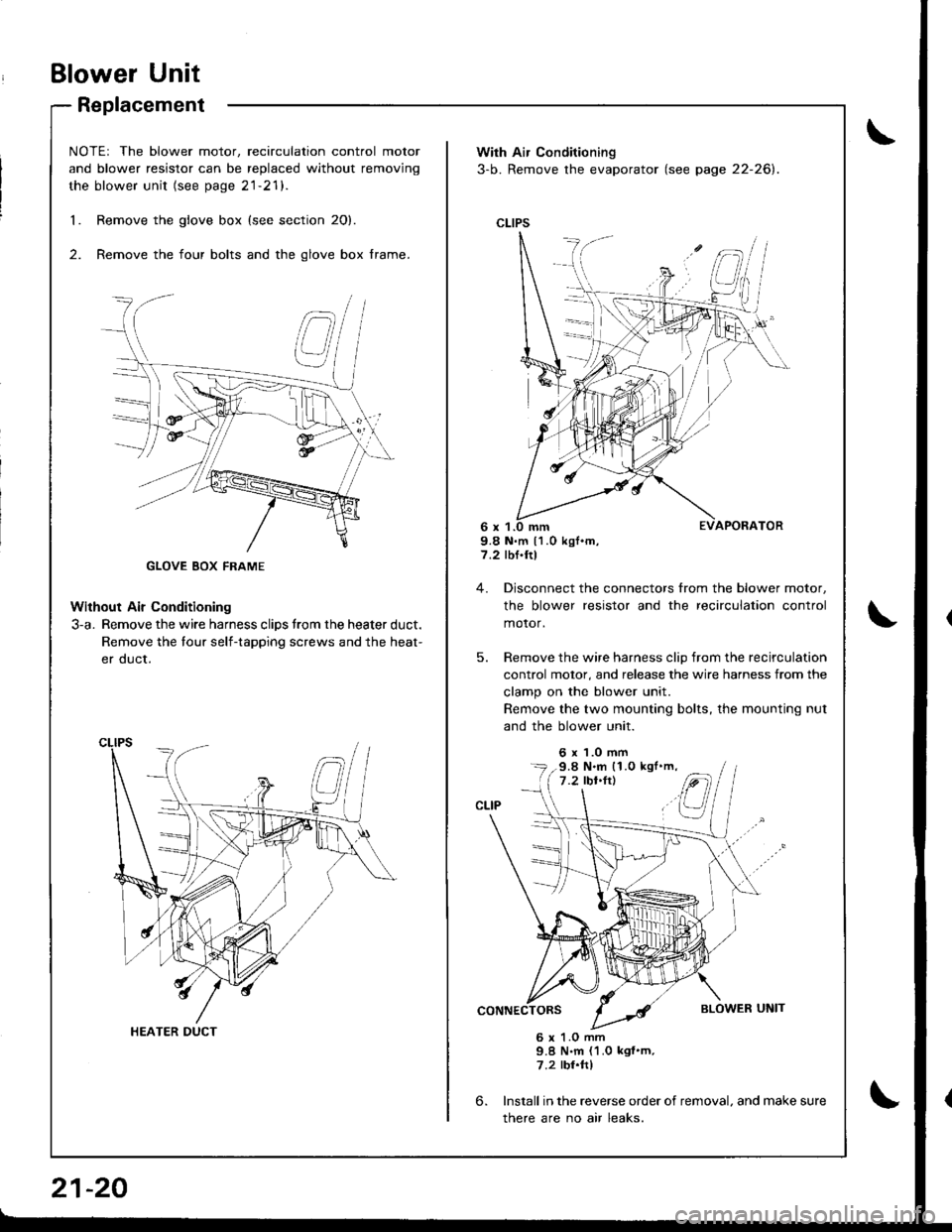

Blower Unit

Replacement

NOTEr The blower motor, recirculation control motor

and blower resistor can be replaced without removjng

the blower unit (see page 21-21).

Remove the glove box {see section 20}.

Remove the four bolts and the glove box frame.

Without Air Conditioning

3-a. Remove the wire harness clips trom the heater duct.

Remove the tour self-tapping screws and the heat-

er duct.

1.

2.

HEATER DUCT

21-20

With Air Conditioning

3-b. Remove the evaporator (see page 22-26).

CLIPS

9.8 N.m 11.0 kgf.m,7.2 rbf.ftl

4. Disconnect the connectors from the blower motor,

the blower resistor and the recirculation control

motor,

5. Remove the wire harness clip from the recirculation

control motor, and release the wire harness from the

clamp on the blower unit.

Remove the two mounting bolts, the mounting nut

and the blower unit.

6 x 1.0 mm

6.

6 x 1.O mm9.8 N.m (1.0 kgf'm,7.2 rbr.ftl

Install in the reverse order of removal. and make sure

there are no air leaks.

9.8 N.m (1.0 kgl'm,

Page 1021 of 1681

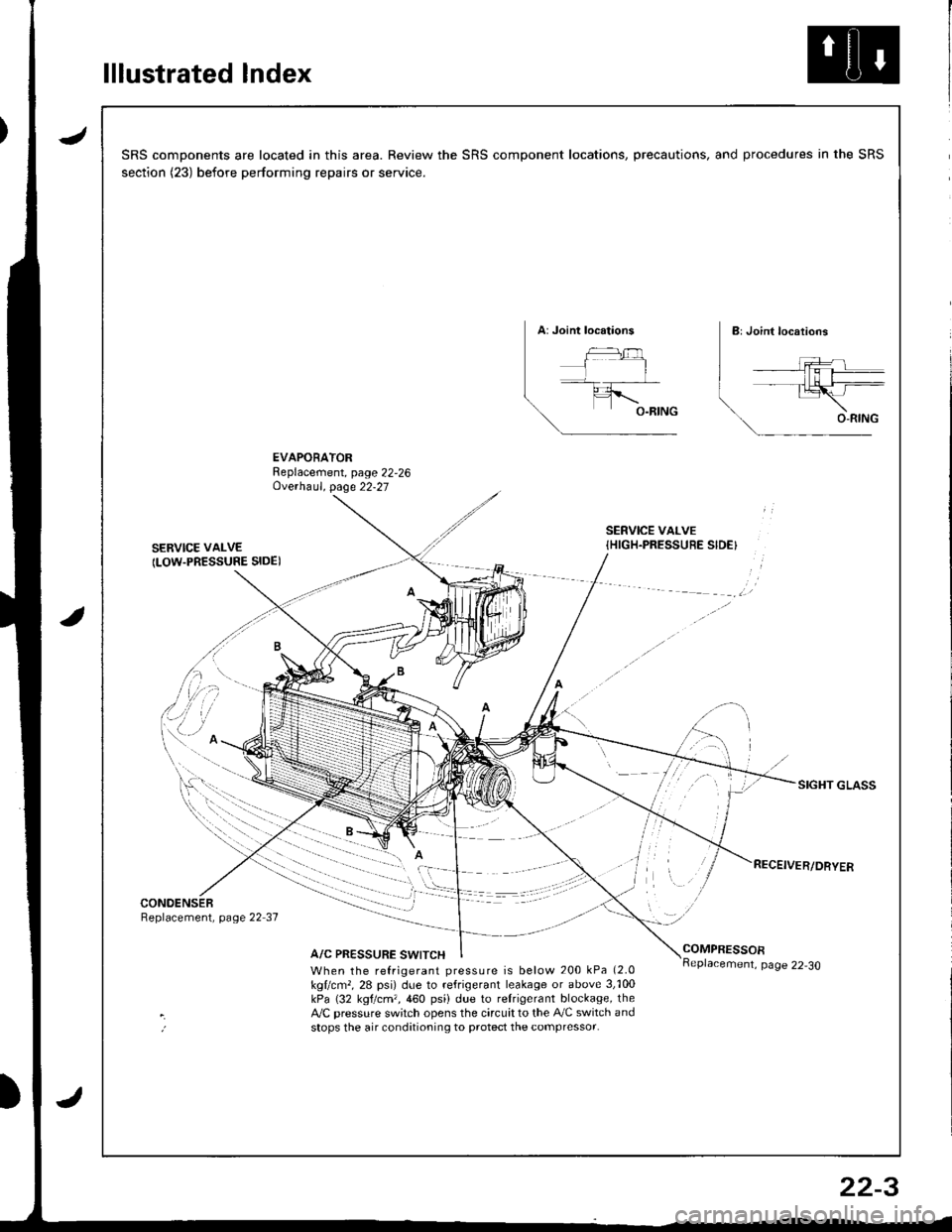

lllustrated Index

JSRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (23) before performing repairs or service.

EVAPORATORReplacement, page 22,26Ove.haul. page 22-27

SERVICE VAI-VE

ILOW.PRESSURE SIDE)

SERVICE VALVE{HIGH.PRESSUEE SIDE}

SIGHT GLASS

CONOENSERReplacement, page 22 37

A/C PRESSURE SWITCHCOMPRESSOR

When the refrigerant pressure is below 200 kPa (2.0

kgllcm,, 28 psi) due to refrigerant leakage or above 3,'100kPa (32 kgtcm,,460 psi) due to relrigerant blockage, theA,/C pressure sw;tch opens the circuit to the A,/C switch andstops the air conditioning to protect the compressor.

page 22-30

22-3

Page 1024 of 1681

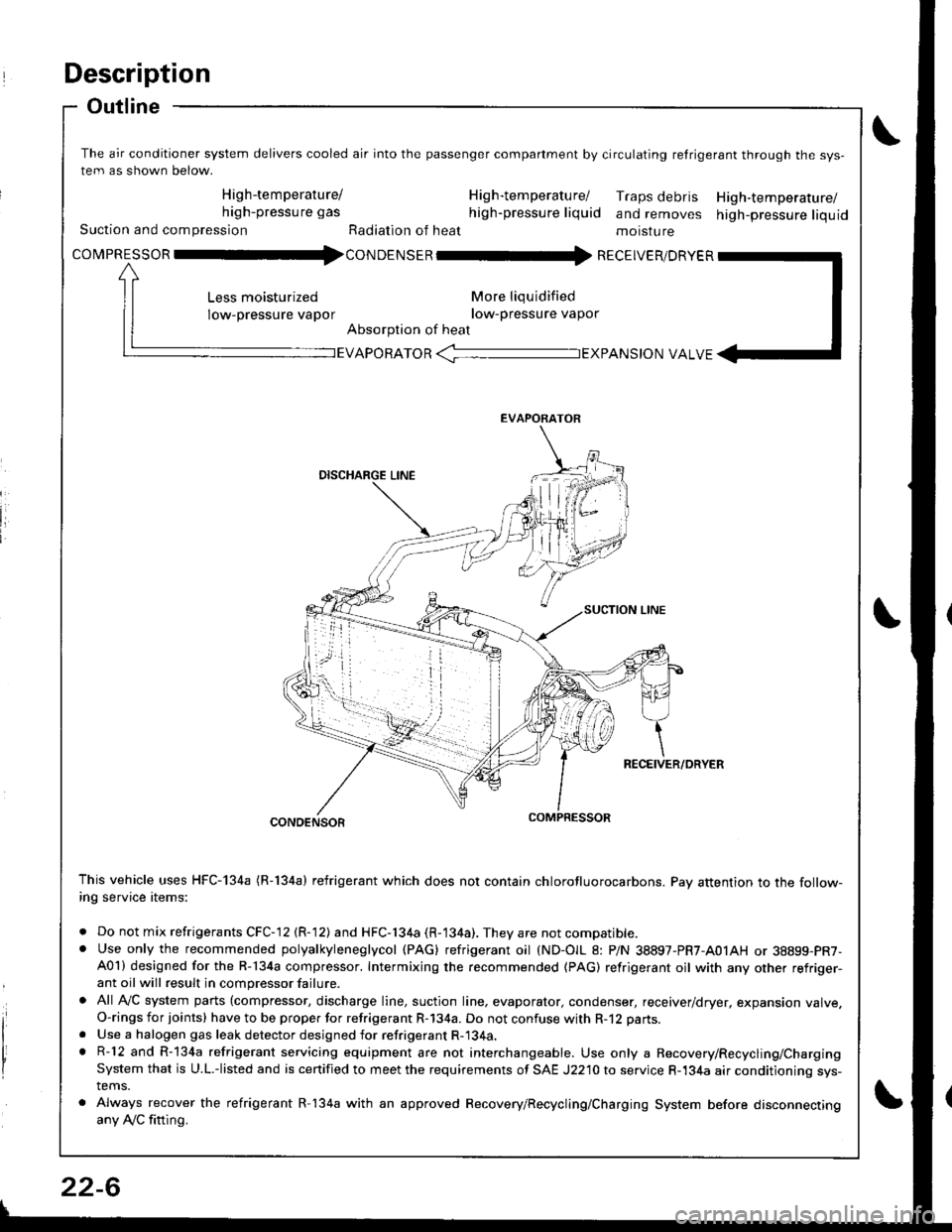

Description

Outline

The air conditioner system delivers cooled air into the passenger companment by circulating retrigerant through the sys-

tem as shown below.

High-temperature/ H ig h-tem peratu rel Traps debris High-temperature/high-pressure gas high-pressure liquid and removes high-pressure liquidSuction and compression Radiation of heat moisture

covpnEsson -tl4con oetsen -rr{ REcEIvER/DRvER

More liqu idified

low-pressure vapor

Absorption of heat

Less moisturized

low-pressure vapor

EVAPORATOR -TEXPANS|ON VALVE

EVAPORATOR

CONDENSOR

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01) designed for the R-134a compressor. Intermixing the recommended (PAG) refrigerant oil with any other refriger-ant oil will result in compressor failure.

. All AVC system parts (compressor, discharge line, suction line. evaporator, condenser, receiver/dryer, expansion valve.O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/ChargingSystem that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning sys-tems.

. Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnectingany Ay'C fitting.

22-6

Page 1039 of 1681

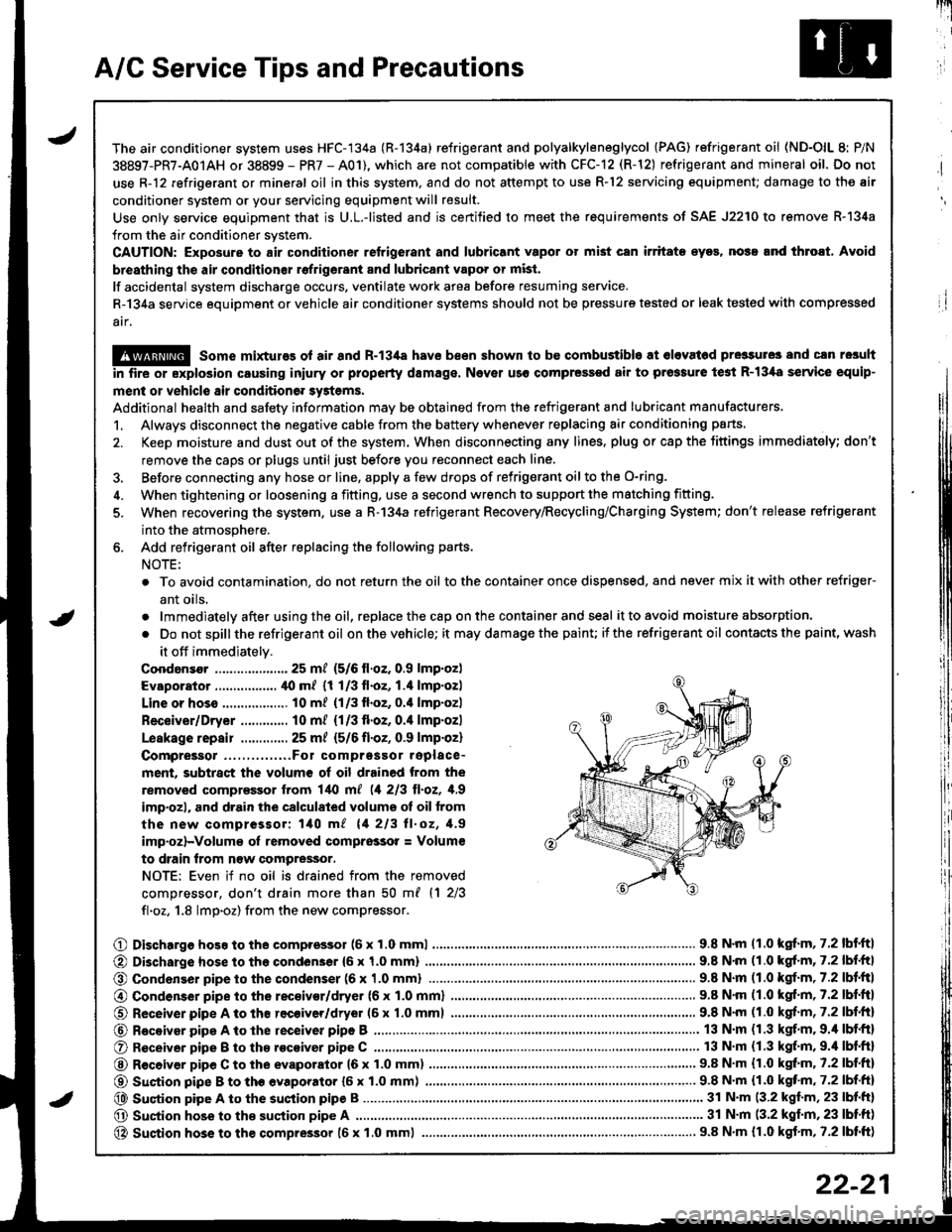

A/C Service Tips and Precautions

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol {PAG) refrigerant oil (ND-OlL 8: P/N

38897-PR7-A01AH or 38899 - PR7 - A01), which are not compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not

use R-12 refrigerant or mineral oil in this system. and do not attempt to use R-12 servicing equipment; damage to the air

conditioner system or your servicing equipment will result.

Use only service equipment that is U.L.-listed and is certified to meet the requirements of SAE J2210 to remove R-l34a

from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and lubricant vapor ot mist can irritate eyos, nose.nd throat, Avoid

breathing th€ air conditionsr rofrigerant 8nd lubricant vapo. or mist.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with comp.essed

atf,

@ some mixtures ol air and R-13i[a have been shown to be combustible at olevat6d pre3sures and cln resuh

in fire or explosion causing iniury or property damage. Nover uso compressed air to prossure te3t R-13,[8 service equip-

ment or vehicle air condition6r systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers,

1. Always disconnect the negative cable from the battery whenever replacing air conditioning parts.

2. Keep moisture and dust out of the system. When disconnecting any lines. plug or cap the Jittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring,

4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.

5. When recovering the system. use a R-134a refrigerant Recovery/Recycling/Charging System; don't release refrigerant

into the atmosphere.

6. Add refrigerant oil after replacing the following parts.

NOTE:

. To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refriger-

ant oils.

.lmmediatelyafterusingtheoil,replacethecaponthecontainerandseal it to avoid moisture absorption.

. Do notspillthe refrigerant oil onthevehicle; it maydamagethe painu itthe refrigerant oil contacts the paint, wash

it off immediately.

Coodansor ..-.-.-............. 25 mt (5/6 ll.oz. 0.9 lmp.oz)

Evaporator ................. ,[0 m/ (1 1/3 fl.oz, 1.4 lmp.ozl

Line or hoss .................. 10 m? {1/3fl.oz, 0.'l lmp.ozl

Receiver/Dryer ............. 10 m/ (1/3 fl.oz, 0.4 lmp.ozl

Leskage repair .............25 m/ {5/6 fl.oZ, 0.9 lmp.oz)

Compreigor .....,......,..Fo1 comprgssor replace-

ment, subtract the volum€ of oil drained from the

removed comprassor lrom l/t{l m[ (1 213 ll.oz, 1,9

imp'ozl, and drain the calculated volume ot oil from

the new compressor: 140 m/ 11 213 ll.oz, 1.9

imp.oz)-Volum€ oI removed comprsssor = Volum€

to drain trom n€w compressor.

NOTE: Even if no oil is drained from the removed

comDressor, don't drain more than 50 m{ {1 2/3

fl.oz. 1.8 lmp.oz) from the new compressor.

O Dischargo hoso to the compressol (6 x 1.0 mml............................... 9.8 N'm (1.0 kgf.m, 7.2 lbf'ftl

@ Di3charge hose to the condenser {6 x 1,0 mm)

@ Condonser pipe to the condenser (6 x '1.0 mml

9.8 N'm (1.0 kgl.m, 7.2 lbf.ftl

.. 9.8 N.m (1.0 kgf.m,7.2lbl.ltl

@ Condenser pipe to the rec€ivor/dryer (6 x 1.0 mml

O Receiver pipe A to th8 recoiver/dryer (6 x 1.0 mml

@ Receiyar pipe A to lhe receiver pipe B ,...........

O Receiver pipe B to th8 .ocoiver pipe C ............

@ R€ceiver pipe C to the evaporator 16 x 1.0 mm)

@ Suction pipe B to th€ evaporator {6 x 1.0 mm) .......,.

@ Suqtion pipe A to the suction pipe B

O Suction hose to the suction pipe A ...........,.

@ Suction hose to the compressor 16 x 1.0 mml

9.8 N.m (1.0 kgf.m, 7.2 lbf.ftl

9.8 N'm (1.0 kgf.m, 7.2 lbf.fr)

13 N.m (1.3 kgf.m. 9.4 lbf.ft)

13 N.m (1.3 kgf.m,9.'l lbf.ftl

9.8 N.m (1.0 kgt m. 7.2 lbf.ftl

...... 9.8 N.m {1.0 kqf'm, 7.2 lbf.ft)

........ 31 N'm (3.2 kgf.m, 23 lbf.ft)

............ 31 N.m (3.2 kgf.m,23 lbtft)

..................... 9.8 N.m {r.0 kgf.m, 7.2 lbtft)

22-21

Page 1040 of 1681

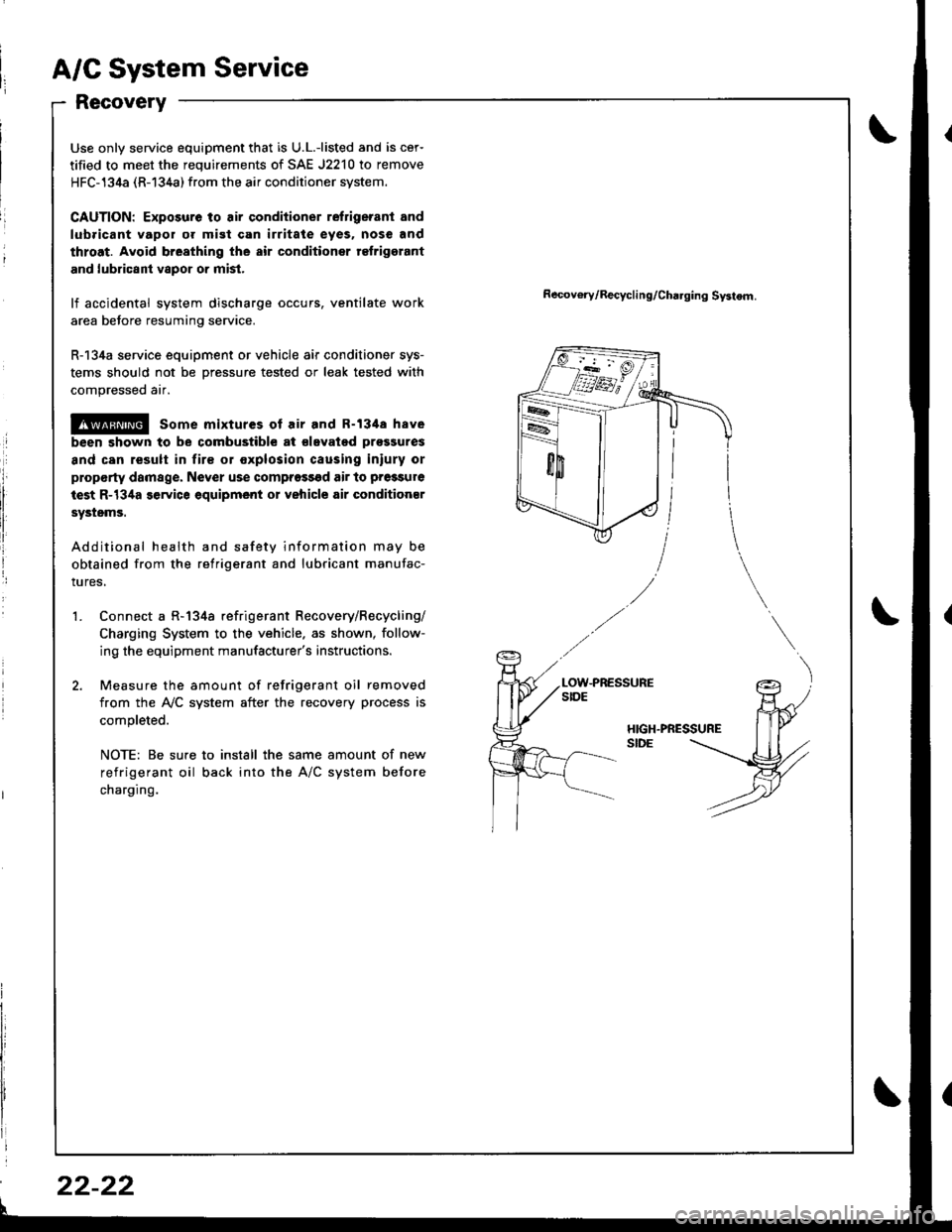

A/C System Service

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritale eyes. nose and

throat. Avoid breathing the air conditioner rclrigerant

and lubricant vapor o. mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be Dressure tested or leak tested with

compressed air.

@ some mixtures of air and R-134a have

been shown to be combustible at €levated pros3ures

and can result in lire or explosion causing iniury or

plop€rty damage. Never use comprossgd air to pressure

iest R-134a service equipment or vehicle air conditioner

sYstsms.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufac-

tures,

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle. as shown, follow-

ing the equipment manufacturer's instructions.

Measure the amount of refrigerant oil removed

from the IVC system after the recovery process is

completed.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before

charging.

Recov€ry/Recycling/Cha.ging Systom.

HIGH.PRESSURESIDE

't.

22-22

Page 1042 of 1681

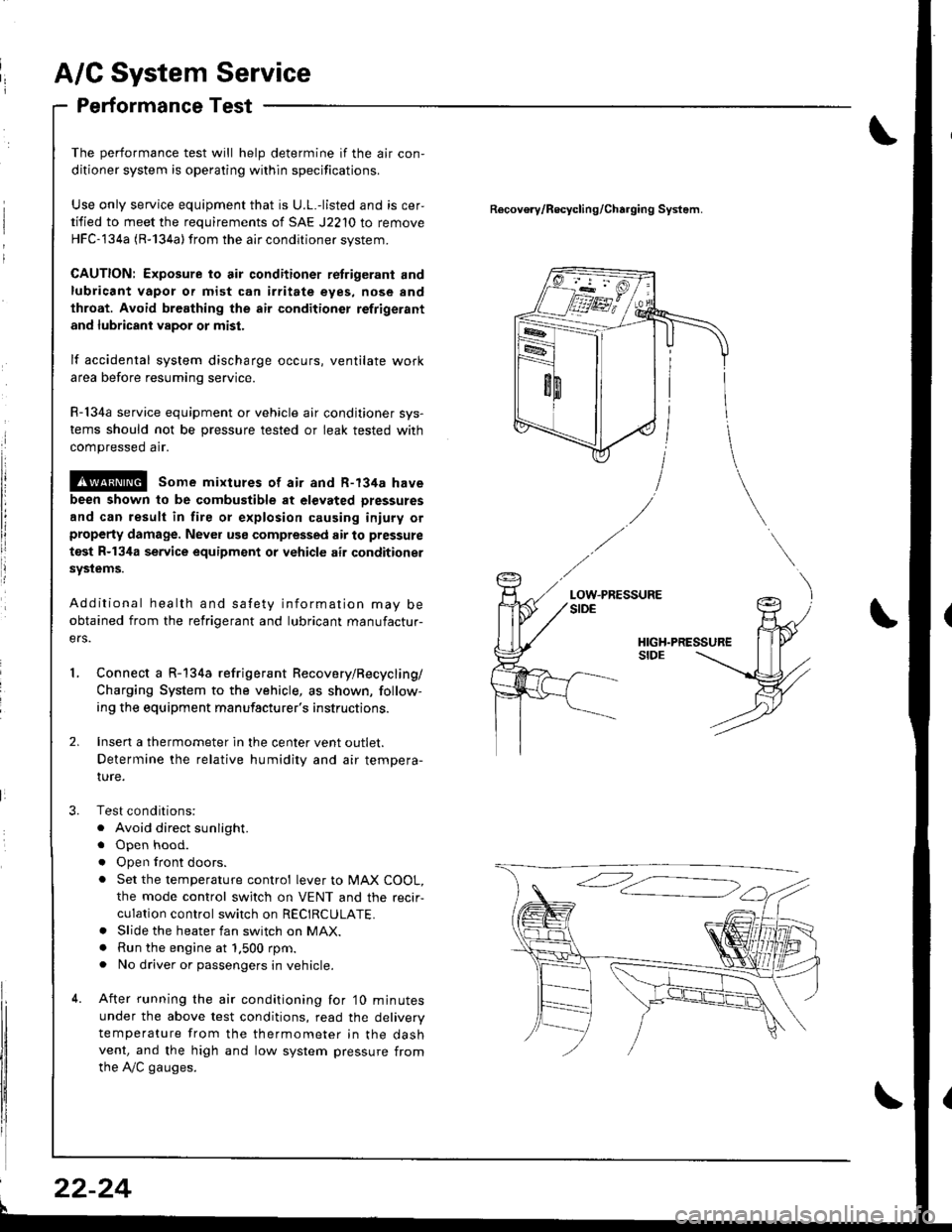

A/C System Service

Performance Test

The performance test will help determine if the air con,

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer,

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air conditioner retrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

@ some mixtures of air and R-134a have

been shown to be combustible at elevated Dressures

and can result in fire or explosion causing iniury orproperty damage. Never use compressed air to pressure

test R-134a service equipment or vehicle air conditioner

systems.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

Insen a thermometer in the center vent outlet.

Determine the relative humidity and air tempera-

IUre.

Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open lront doors.

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.. Slide the heater fan switch on MAX.. Run the engine at 1.500 rpm.. No driver or passengers in vehicle.

After running the air conditioning for'10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dashvent, and the high and low system pressure from

the A,/C gauges.

Recovo.v/Recycling/Charging System.

LOW.PRESSURE

l

22-24

Page 1048 of 1681

Compressor

Replacement

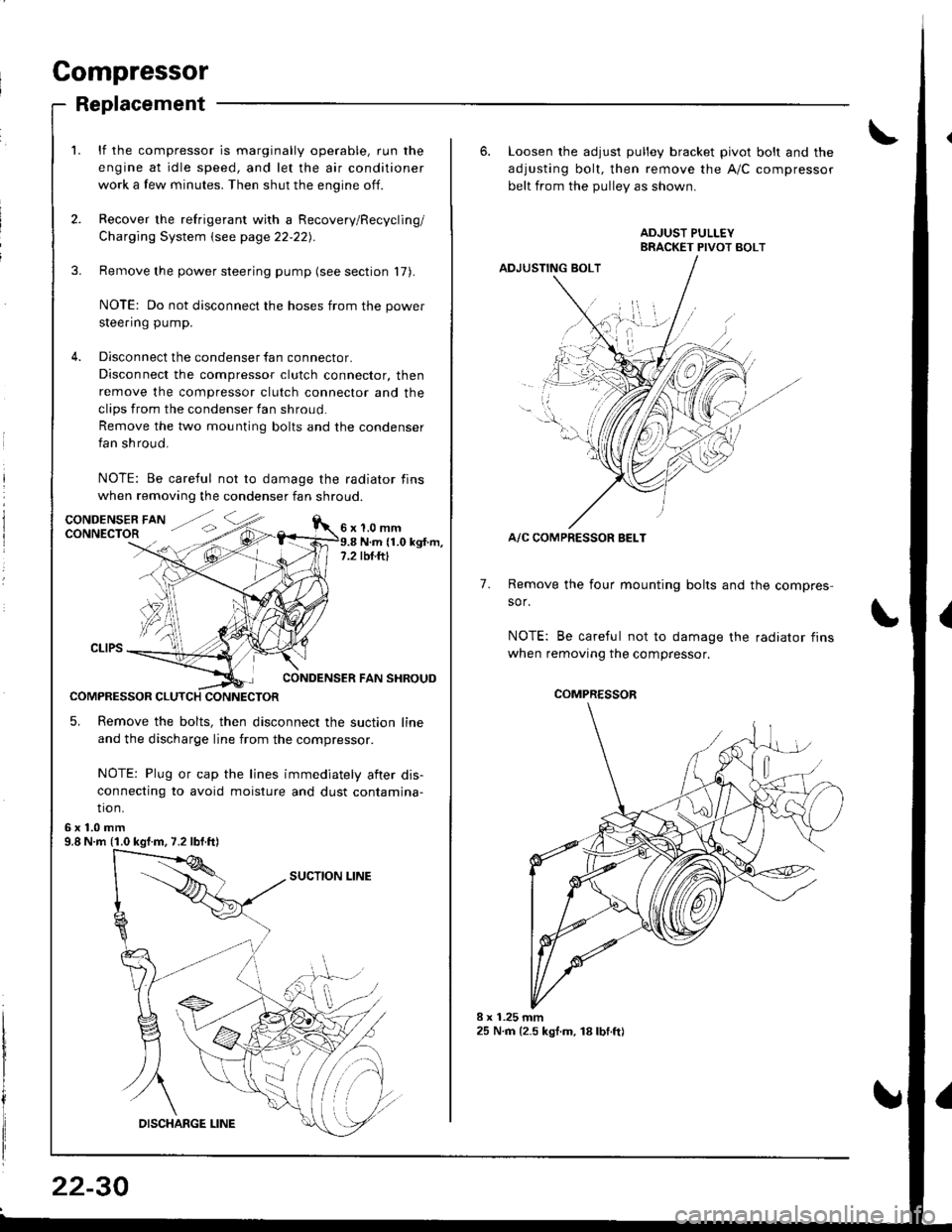

lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work a few minutes. Then shut the engine off.

Recover the refrigerant with a Recovery/Recycling/

Charging System \see page 22-22).

Remove the power steering pump (see section 17).

NOTE: Do not disconnect the hoses from the power

steering pump.

Disconnect the condenser fan connector.

Disconnect the compressor clutch connector, then

remove the compressor clutch connector and the

clips from the condenser fan shroud

Remove the two mounting bolts and the condenser

fan shroud.

NOTE: Be careful not to damage the radiator fins

when removing the condenser fan shroud.

1.0 mmN.m (1.0 kgt.m,rbf.ftt

CONDENSER FAN SHROUD

COMPRESSOR CLUTCH CONNECTOR

5. Remove the bolts, then disconnect the suction line

and the discharge line from the compressor.

NOTE: Plug or cap the lines immediately aiter dis-

connecting to avoid moisture and dust contamina-

tio n.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

22-30

6. Loosen the adjusl pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the Dullev as shown.

ADJUSTING BOLT

A/C COMPRESSOR BELT

Remove the four mounting bolts and the compres-

sor.

NOTE: Be careful not to damage the radiator fins

when removing the compressor.

7.

./.,

COMPRESSOR

Page 1056 of 1681

A/C System Service

Evacuation

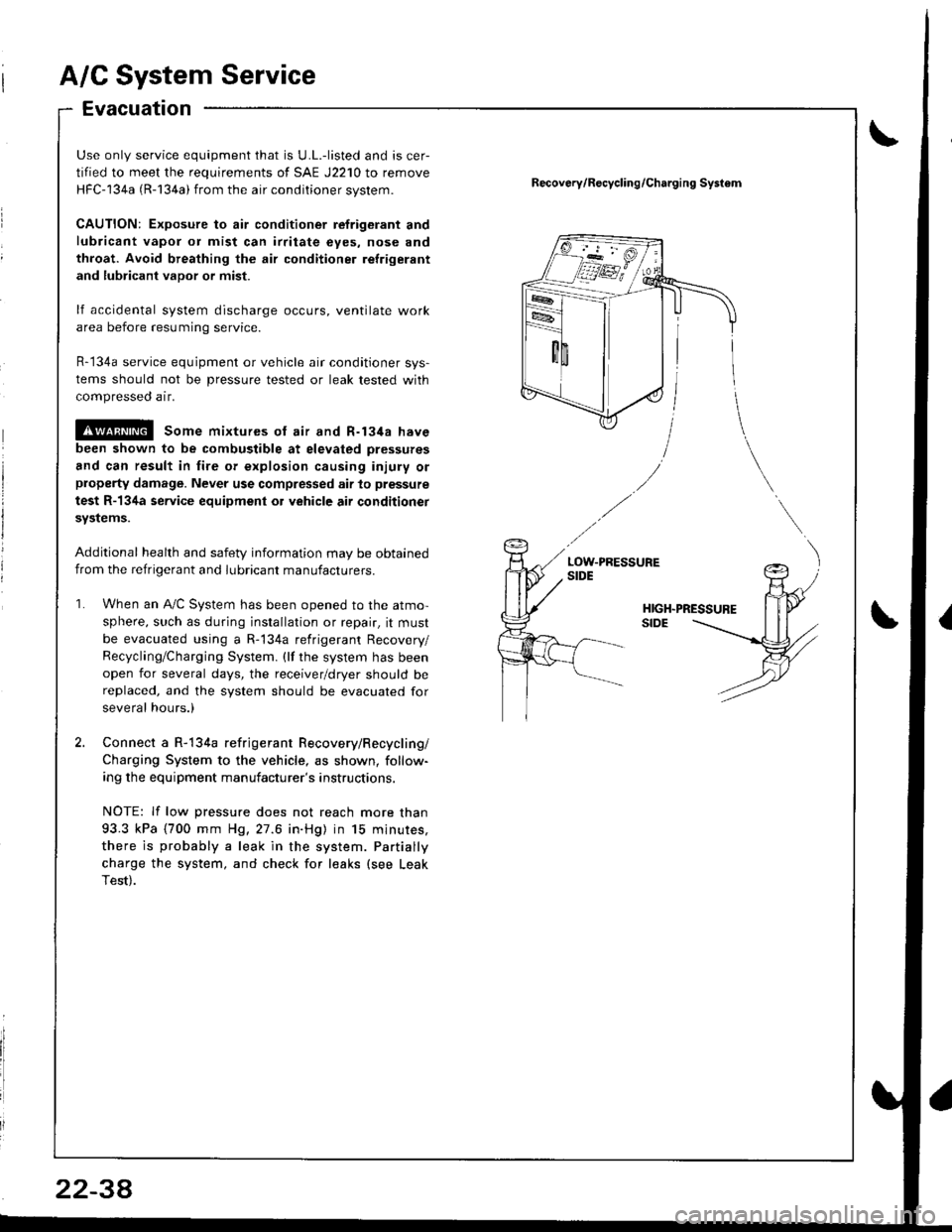

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irtitate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

!@@l some mixtures ot air and R-t3ita have

been shown to be combustible at elevated pressures

and can result in fire of explosion causing injury orproperty damage. Never use compressed air to pressure

test R-134a service equipment or vehicle air conditionet

svstems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

When an A"/C Svstem has been ooened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. (lf the system has been

open for several days, the receiver/dryer should bereplaced, and the system should be evacuated for

several hours.)

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE: lf low pressure does not reach more than

93.3 kPa (700 mm H9,27.6 in.Hg) in 15 minures,

there is probably a leak in the system. Partially

charge the system, and check for leaks (see Leak

Test).

Recov6ry/R€cycling/Charging Systom

2234