gearbox HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 668 of 1681

I

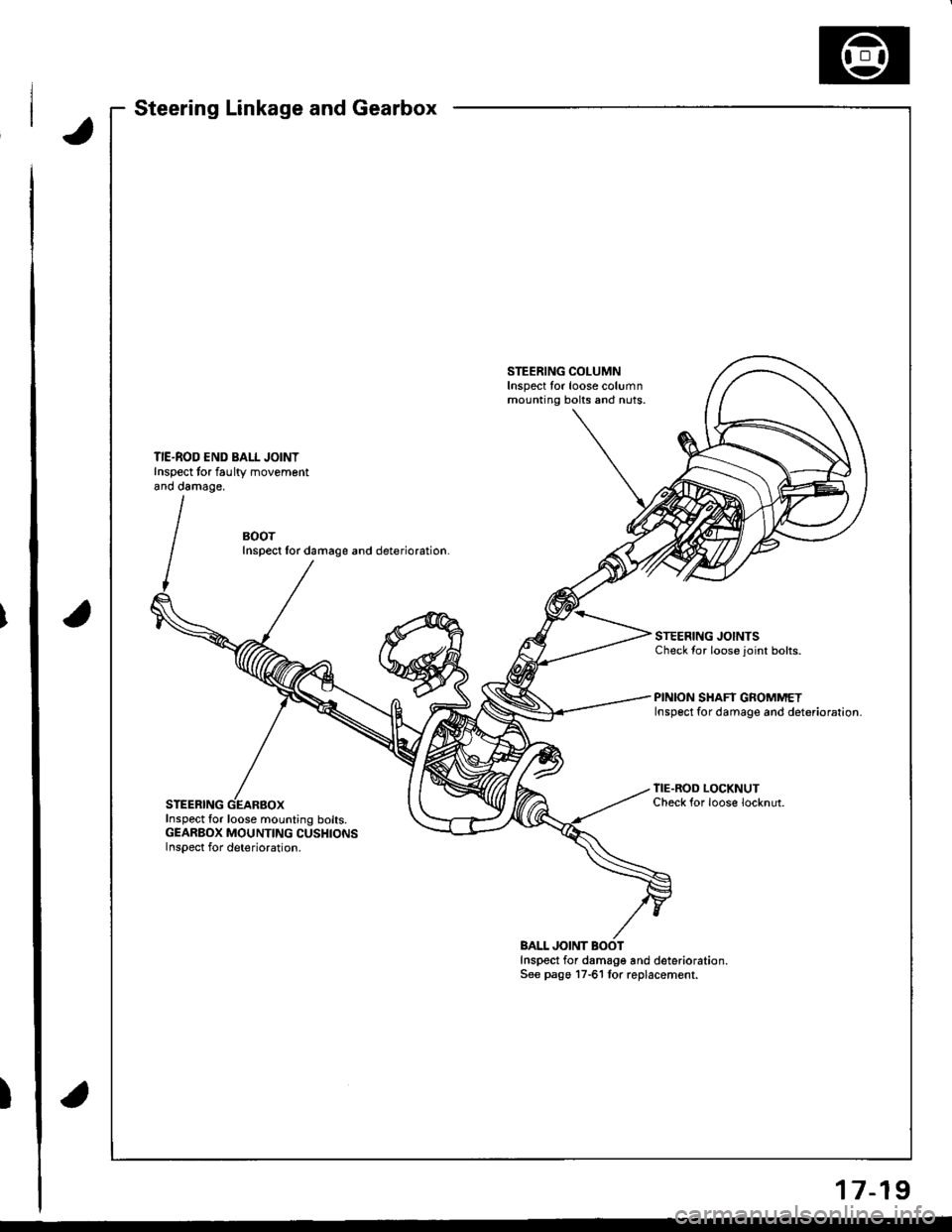

Steering Linkage and Gearbox

STEERING COLUMNInspect tor loose columnmounting bolts and nuts.

TIE.ROD END BALL JOINTInspect tor faultv movementano oamage,

BOOTInspect lor damage and deterioration.

STEERING JOINTSCheck {or loose joint bolts.

PINION SHAFT GROMMETInsp6ct for damage and deterioration.

STEERING

TIE.ROD LOCKNUTCheck {or loose locknut.

Inspect for loose mounting bolts.GEARBOX MOUNTING CUSHIONSInspect for deterioration.

BALL JOINTInspect for damage and deterioration.See pago 17-61 lor replacement.

17-19

Page 671 of 1681

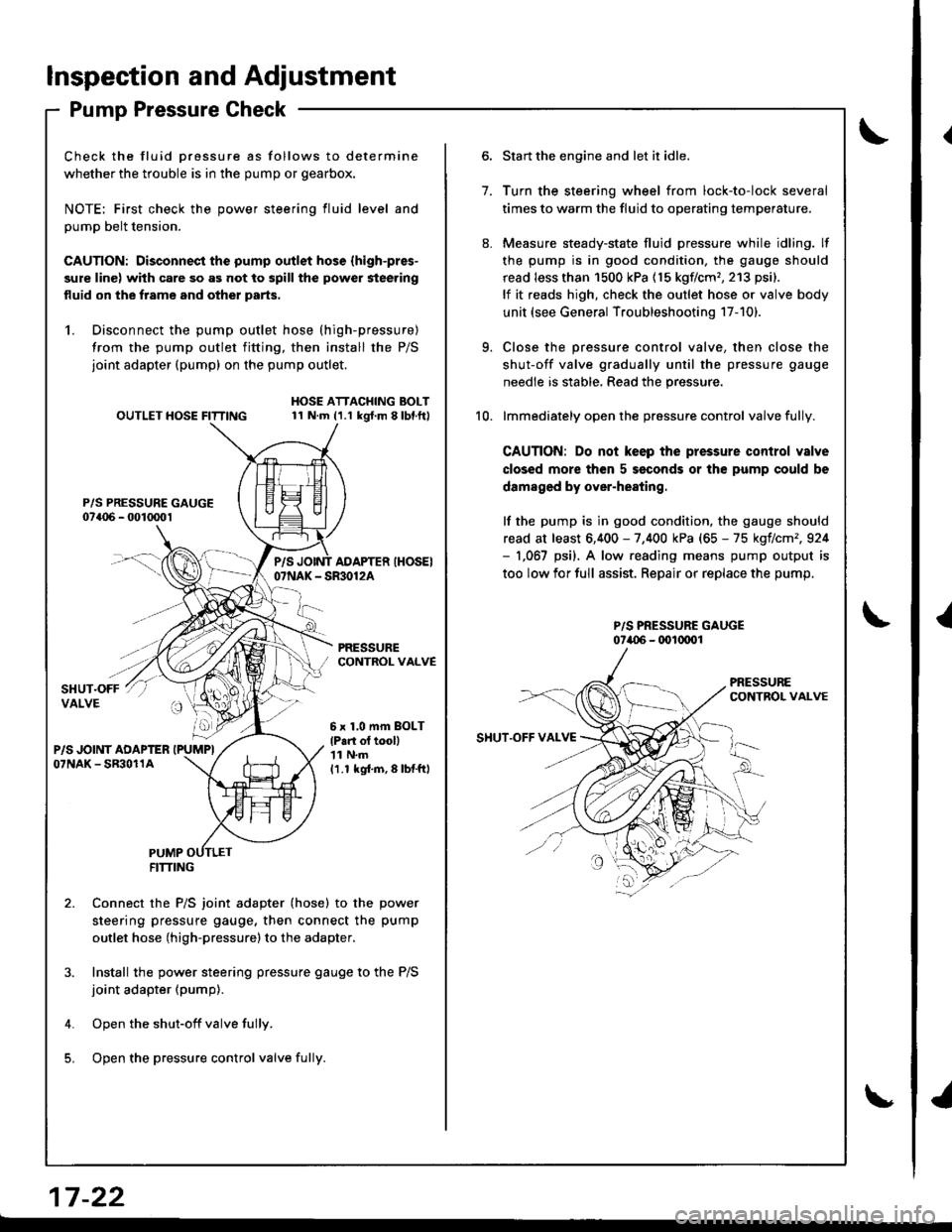

Inspection and Adjustment

Pump Pressure Check

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I

Page 672 of 1681

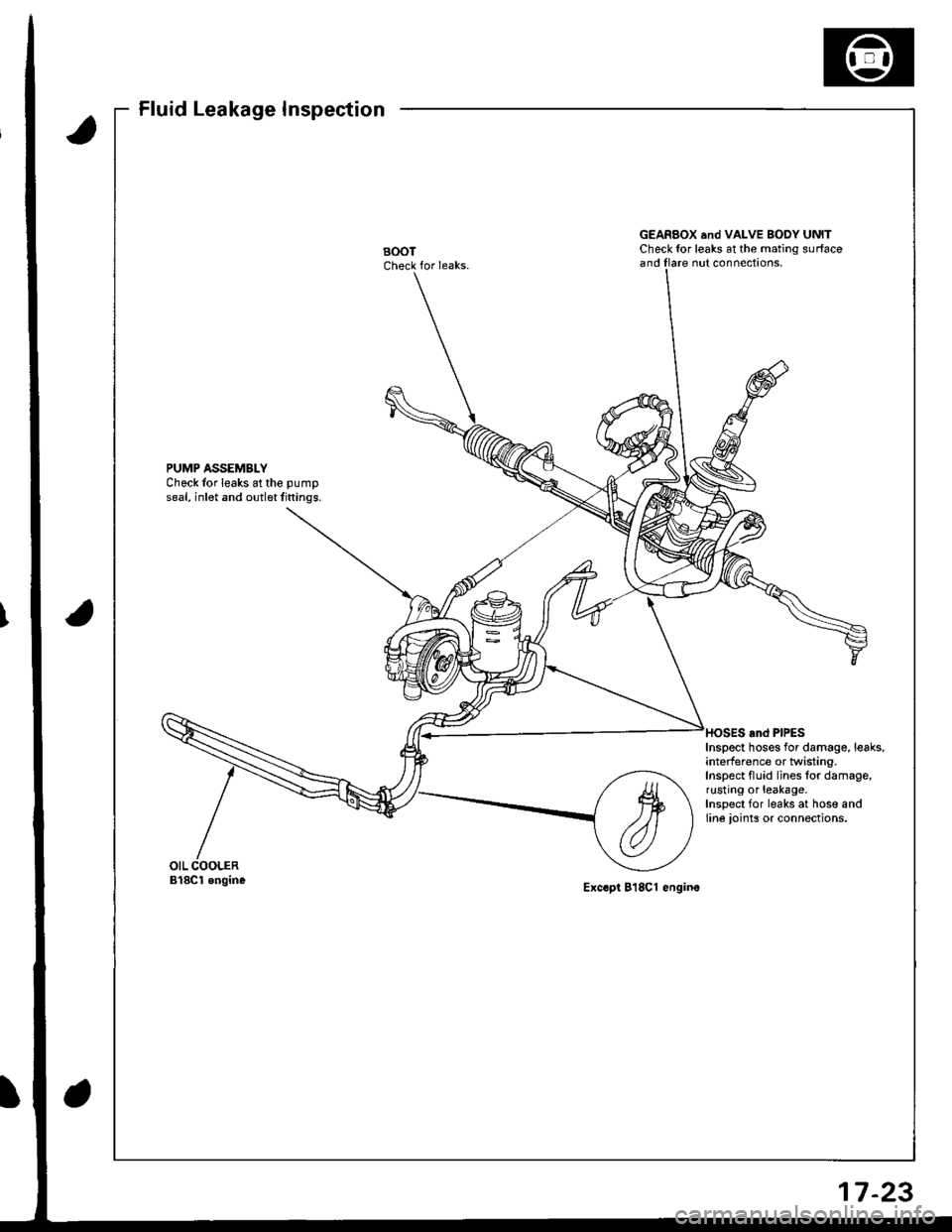

Fluid Leakage Inspection

BOOTCheck for Ieaks.

GEARBOX and VALVE BOoY UNITCheck tor leaks at the mating surfaceand Ilare nut connections,

PUMP ASSEMBLYCheck Ior leaks at the pumD

seal, inlet and outlet fittings.

Inspect hoses for damage, leaks,interfe re n ce or twisting,Inspect fluid lines for damage,rusting or leakage.Inspect for leaks at hose andline ioints or connections.

Bl8Cl engineExc.pl 818Cl engine

17-23

Page 690 of 1681

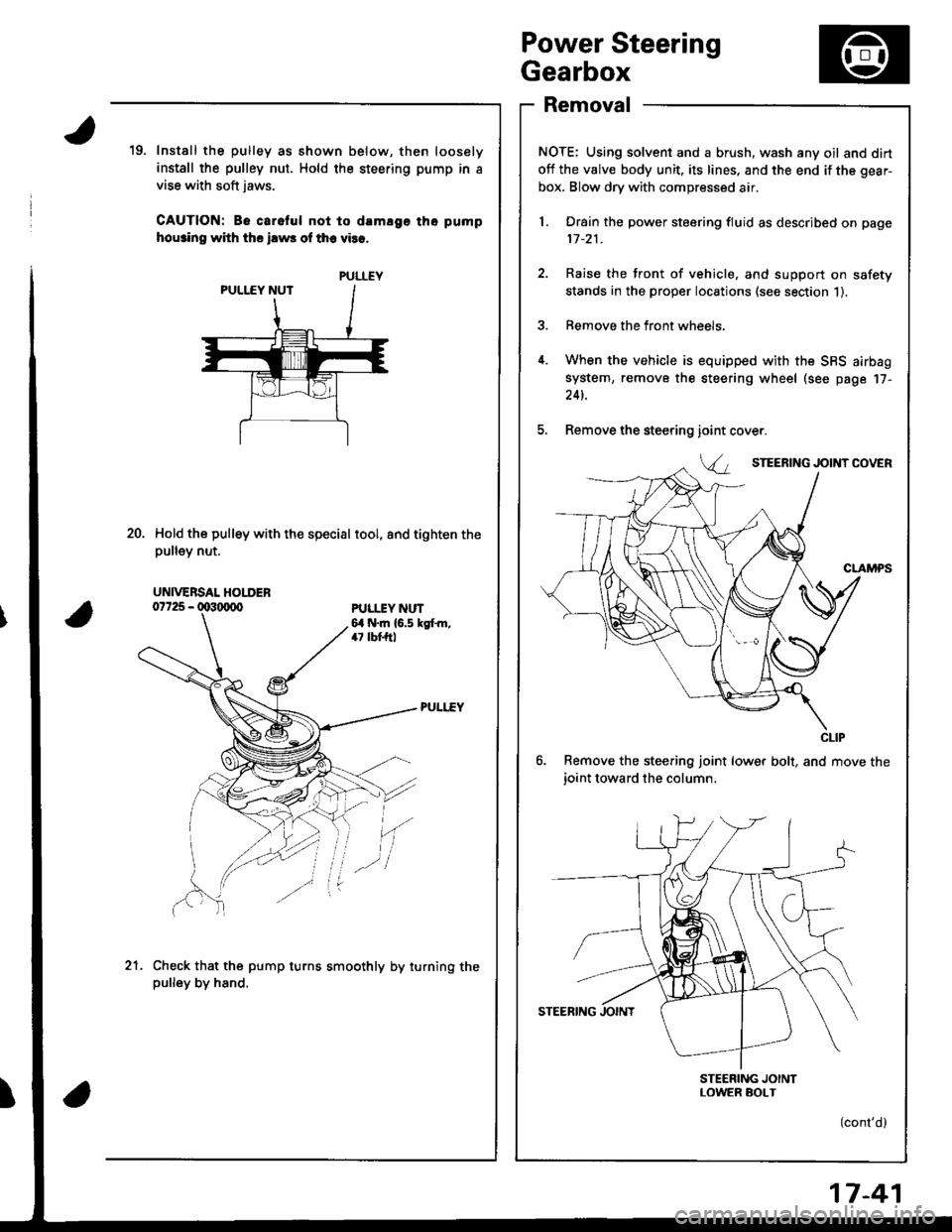

Power Steering

Gearbox

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

l. Drain the power steering fluid as described on page

11-21.

2. Raise the front of vehicle, and support on safety

stands in the proper locations (see section 1).

3. Remove the front wheels.

4. When the vehicle is equipped with the SBS airbag

system, remove the steering wheel (see page 17-

24t.

5. Remove the steering

6. Remove the steering joint lower bolt, and move the

ioint toward the column.

STEERING JOINTLOWER SOI-T

(cont'd)

19. Install the pulley as shown below, then loosely

install the pulley nut. Hold the steering pump in a

vise with soft jaws.

CAUTION: Be carelul not to damlge tho pump

hou3ino with ths ilws of th6 vies.

Hold the pulley with the special tool, and tighten thepu ey nut.

ioint

Va

20.

PULI.IY NUT6,1 N.m {6.5 kgt m,47 lbf,ftl

'(

Check that the pump turns smoothly by turning thepulley by hand.

.-l

21.

PULLEY

UNIVERSAL HOLDER

CLIP

17-41

Page 691 of 1681

Power Steering Gearbox

Removal (cont'd)

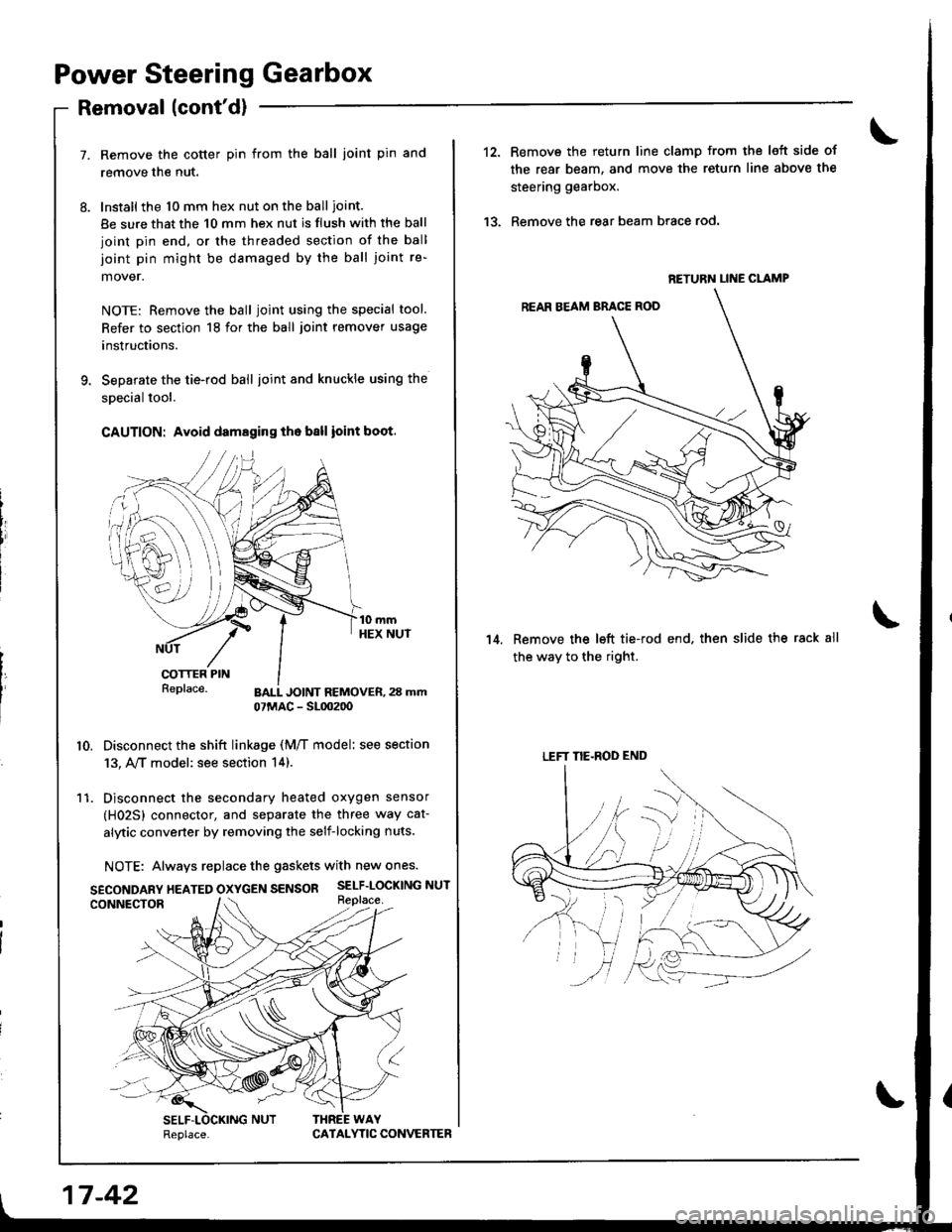

Remove the cotter pin from the ball joint pin and

remove the nut.

Install the 10 mm hex nut on the ball ioint.

Be sure that the 10 mm hex nut is flush with the ball

joint pin end, or the threaded section of the ball

joint pin might be damaged by the ball joint re-

mover.

NOTE: Remove the ball joint using the special tool.

Refer to section 18 for the ball joint remover usage

instructions.

Separate the tie-rod ball ioint and knuckle using the

special tool.

CAUTION: Avoid damaging th. ball ioint boot.

t{ePrace. BALL JOINT REMOVER,23 mm07MAC - SL0020o

10. Disconnect the shift linkage (M/T model: see section

13, A,/T model: see section 14).

11. Disconnect the secondary heated oxygen sensor

(H02Sl connector, and separate the three way cat-

alytic convener by removing the self-locking nuts.

NOTE: Always replace the gaskets with new ones.

SECONDARy HEATED OXycEN SENSOR SELF-LOCKING NUT

17 -42

Replace.CATAI.YTIC CONVERTER

12.

13.

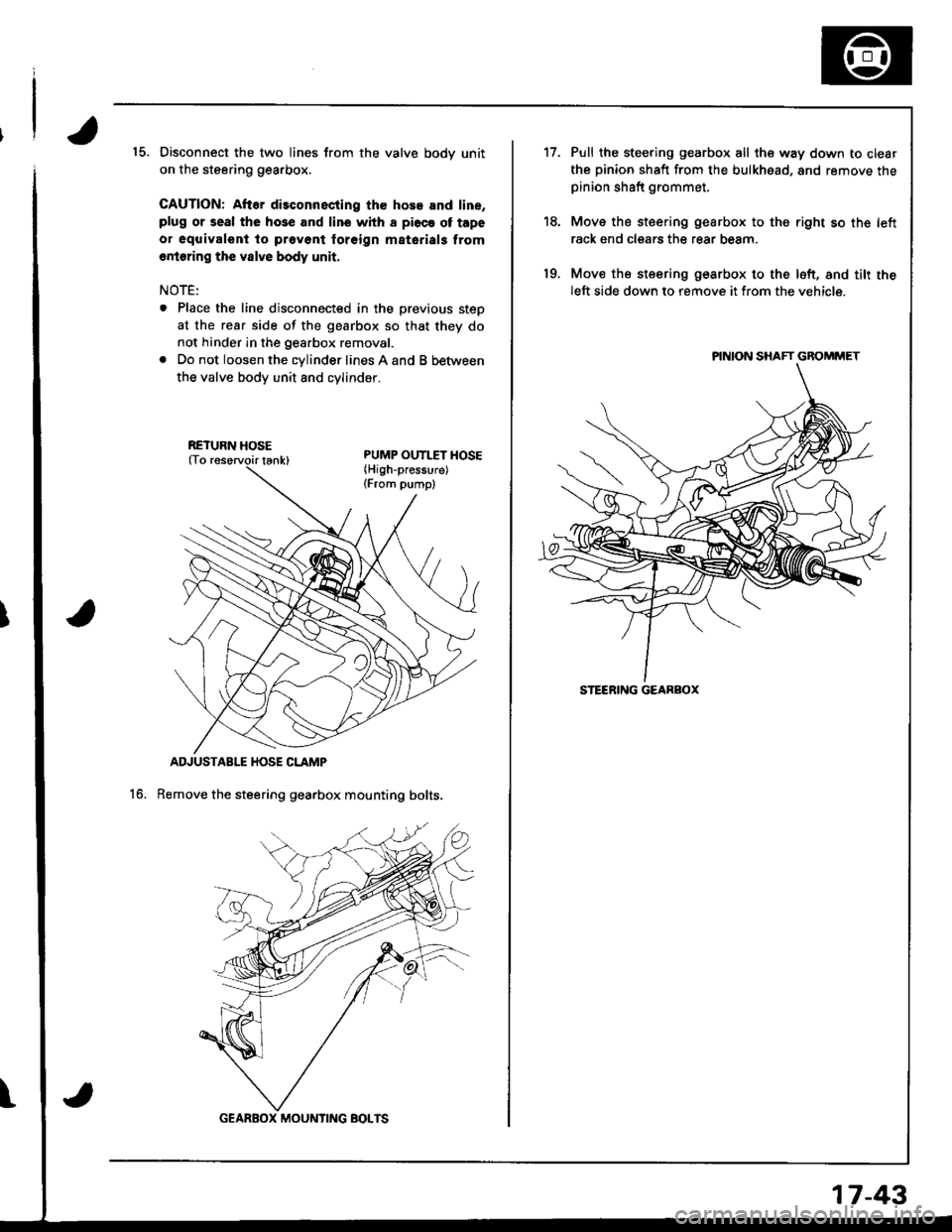

Remove the return line clamp from the left side of

the rear beam, and move the return line above the

steering gearbox.

Remove the rear beam brace rod.

Remove the left tie-rod end. then slide the rack all

the way to the ri9ht.

14.

RETURN LINE CLAMP

LEFT NE-ROD END

Page 692 of 1681

15. Disconnect the two lines from the valve bodv unit

on the steering gearbox.

CAUTION: After disconnscting the hose and line,plug or seal the hose and lino whh I pi6ce ot tape

o. oquivalent to prevont foreign matarials from

6rioring the vslve body unit,

NOTE:

. Place the line disconnected in the previous steD

at the rear side of the gearbox so that they do

not hinder in the gearbox removal.

. Do not loosen the cylinder lines A and B between

the valve body unit 8nd cvlinoer.

ADJUSTABLE HOSE CLAMP

Remove the steering gearbox mounting bolts.16.

\

RETURN HOSE

GEARBOX MOUNTING BOTTS

17-43

't7.

19.

Pull the steering gearbox all the way down to clear

the pinion shaft from the bulkhead, and remove thepinion shaft grommet.

Move the steering gearbox to the right so th€ left

rack end clears the rear beam.

Mov€ the steering gearbox to the loft, and tilt theleft side down to remove it from the vehicle.

PINION SHAFT GBOMMET

STEERING GEARBOX

Page 693 of 1681

Power Steering Gearbox

Disassembly

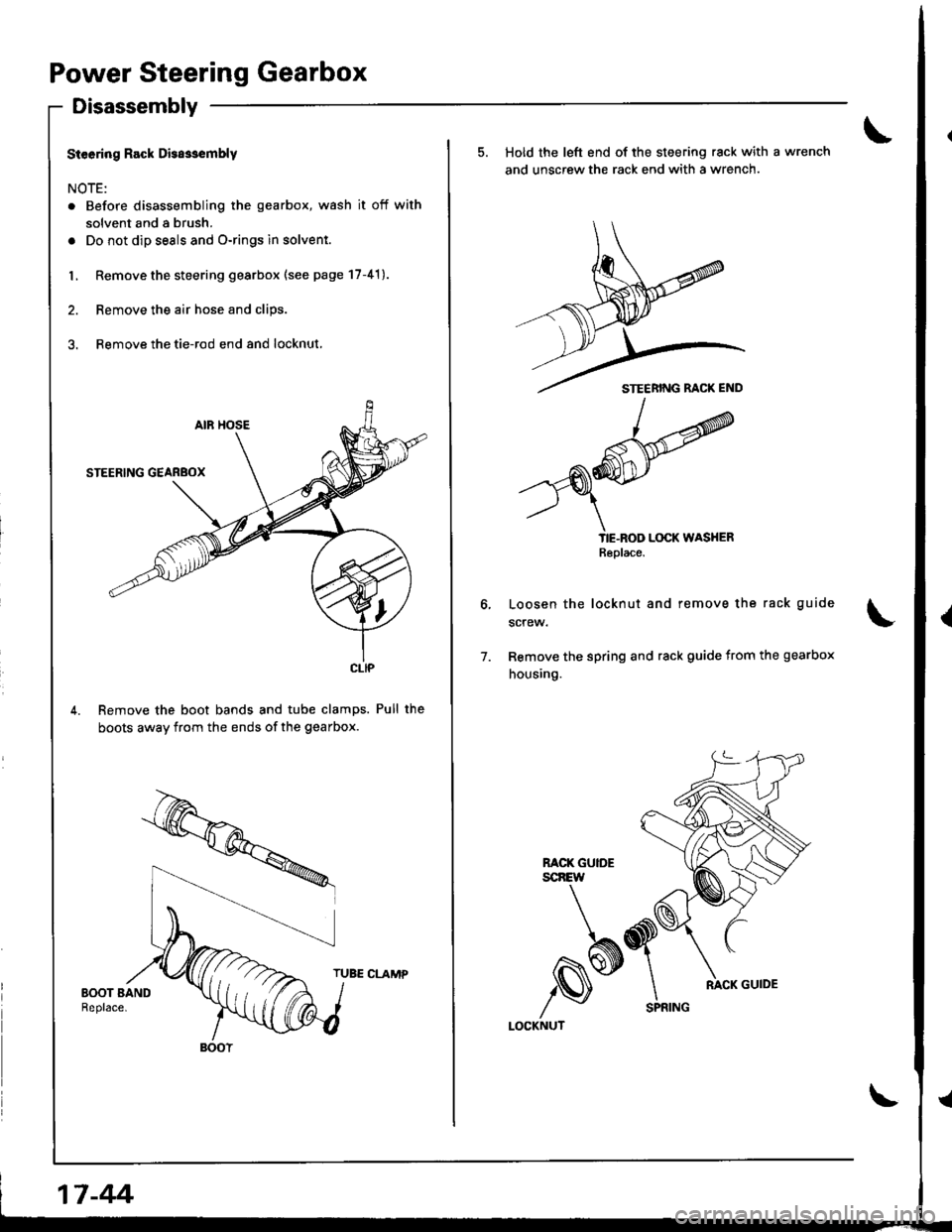

Steering Rack Disa3sembly

NOTE:

. Before disassembling the gearbox, wash it off with

solvent and a brush.

. Do not dip seals and O-rings in solvent.

L Remove the steering gearbox (see page 17-41).

2. Remove the air hose and clips.

3. Remove the tie-rod end and locknut,

Remove the boot bands and tube clamps. Pull the

boots away from the ends of the gearbox.

TUBE CLAMP

CLIP

BOOT

17-44

SPRING

5. Hold the left end of the steering rack with a wrench

and unscrew the rack end with a wrench.

TIE-ROD LOCK WASHERBePlace

Loosen the locknut and remove the rack guide

screw.

Remove the spring and rack guide from the gearbox

housing.

7.

RACK GUIDEscnEw

,s*LOCKNUT

RACK GUIDE

Page 694 of 1681

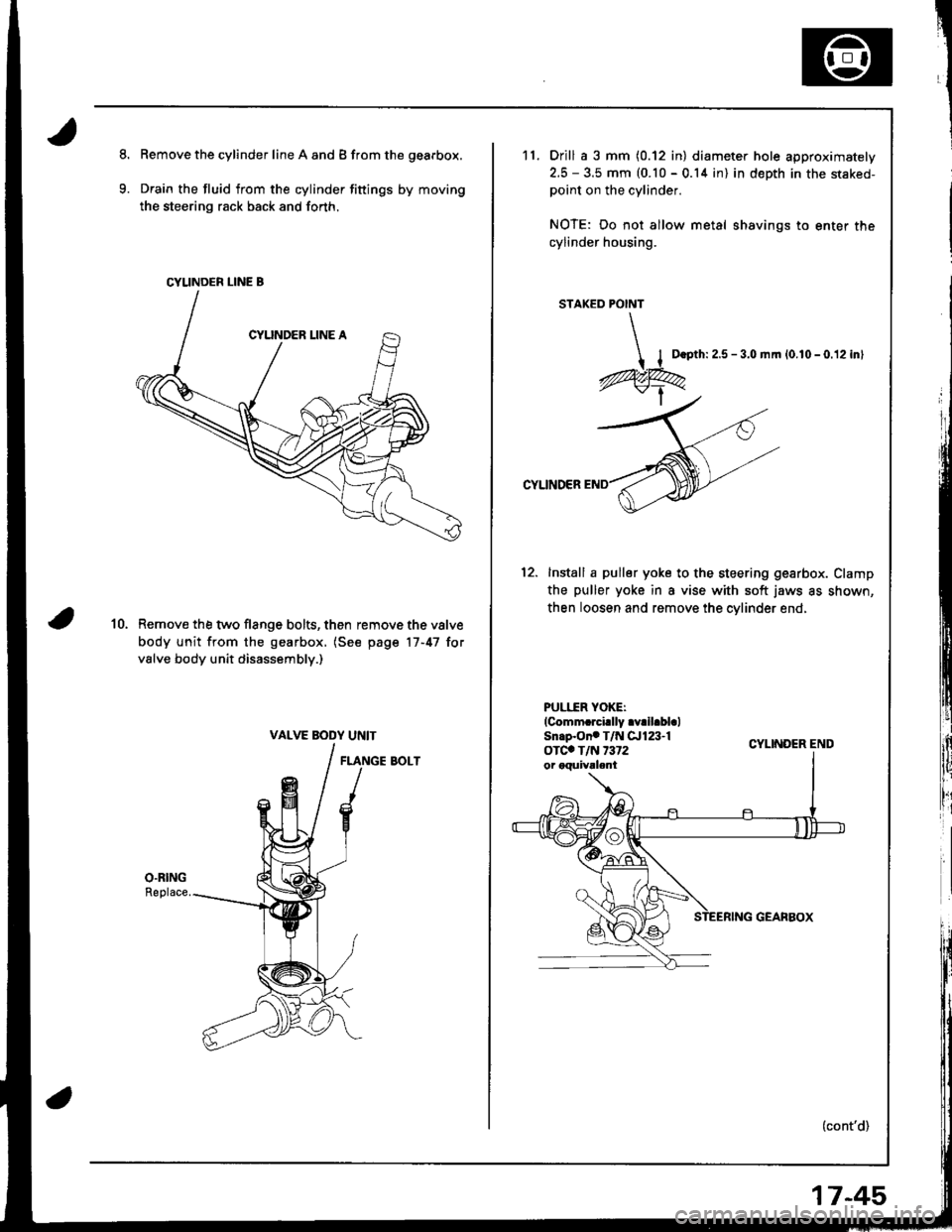

8.Remove the cylinder line A and B from the gearbox.

Drain the fluid from the cylinder fittings by moving

the steering rack back and forth.

Remove the two flange bolts, then remove the valve

body unit from the gearbox, (See page 17-47 for

valve body unit disassembly.)

FLANGE BOLT

10.

CYLINDER LINE B

VAI.VE BODY UNIT

11.Orill a 3 mm (0.12 in) diameter hole approximately

2.5 - 3.5 mm (0.10 - 0.14 in) in depth in the staked-point on the cylinder.

NOTE: Oo not allow metal shavings to enter the

cylinder housing.

12. Install a puller yoke to the steering gearbox. Clamp

the puller yoke in a vise with soft jaws as shown,

then loosen and remove the cvlinder end,

CYLINDER END

STAKED POINT

\\

i D.pth:2.5 - 3.0 mm {0.10 - 0.'12 inl

re

17-45l

Page 695 of 1681

Power Steering Gearbox

Disassembly (cont'dl

VINYL TAPE

12 mmFLANGE NUT

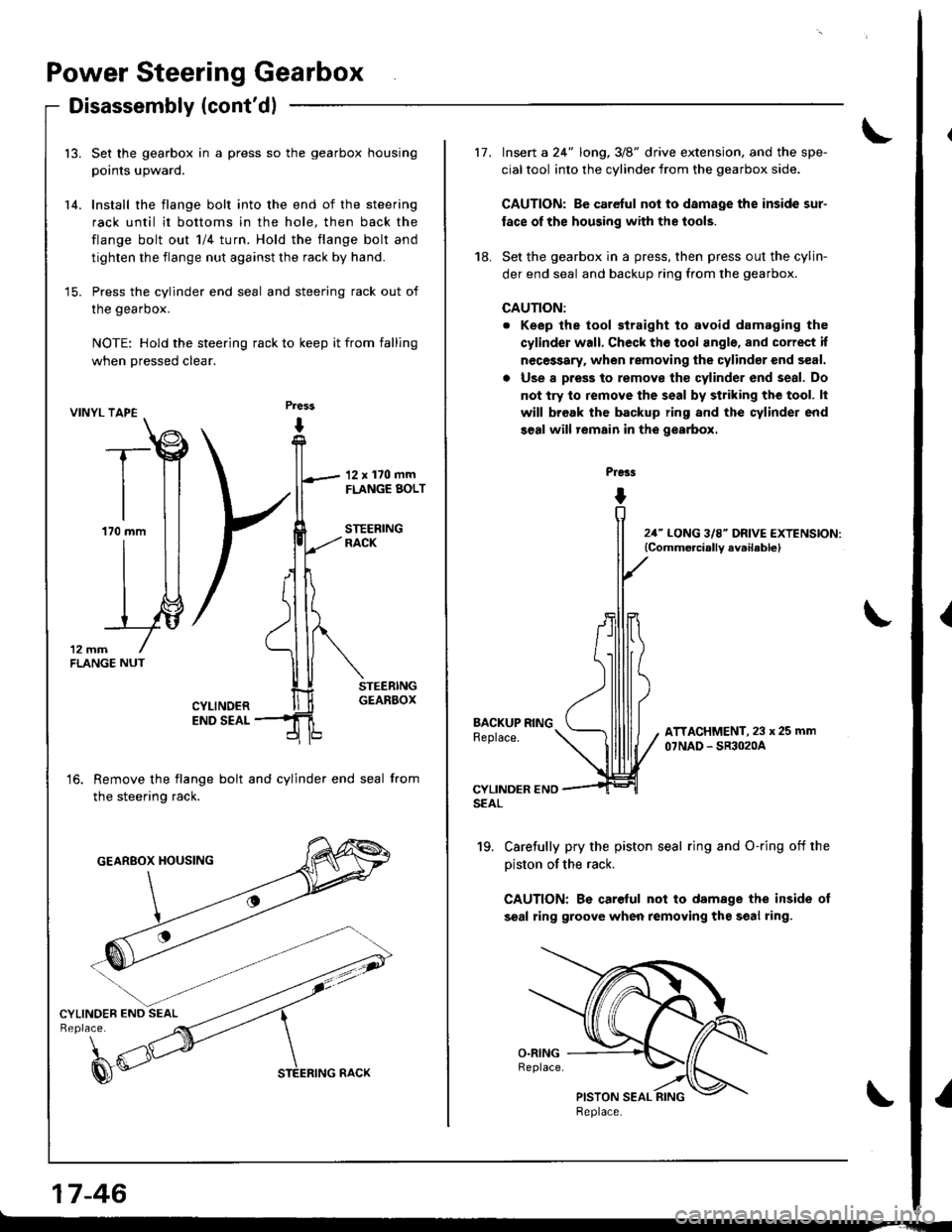

13. Set the gearbox in a press so the gearbox housing

pornts upward.

14. Install the flange bolt into the end of the steering

rack until it bottoms in the hole, then back the

flange bolt out 1/4 turn. Hold the flange bolt and

tighten the flange nut against the rack by hand.

15. Press the cylinder end seal and steering rack out of

the gearbox.

NOTE: Hold the steering rack to keep it from falling

when pressed clear.

T-

I

I170 mm

CYLINDEREND SEAL

Remove the flange bolt and cylinder end seal from

the steering rack.

Press

t

18.

17.

Ple3s

I

ATTACHMENT, 23 x 25 mm

07NAD - SR3020A

CYLINDER ENDSEAL

19. Carefully pry the piston seal ring and O-ring off the

oiston of the rack.

CAUTION: Be carelul not to damage the inside of

seal ring groove when remoying the seal ring.

lnsert a 24" long, 3/8" drive extensjon, and the spe-

cial tool into the cylinder from the gearbox side.

CAUTION: Be careful not to damage the inside sur-

lace of the housing with the lools.

Set the gearbox in a press, then press out the cylin-

der end seal and backup ring from the gearbox.

CAUTION:

. Keep the tool straight to avoid damaging the

cylinder wall, Chcck thc tool angle, and correct il

necessary, when removing the cylinder end s€al.

. Use a press to remove the cylinder end seal. Do

not try to remove the seal by striking the tool. lt

will brcak the backup ring and the cylinder end

seal will remain in the gesrbox.

Replace

17-46

Page 697 of 1681

Power Steering Gearbox

Disassembly (cont'd)

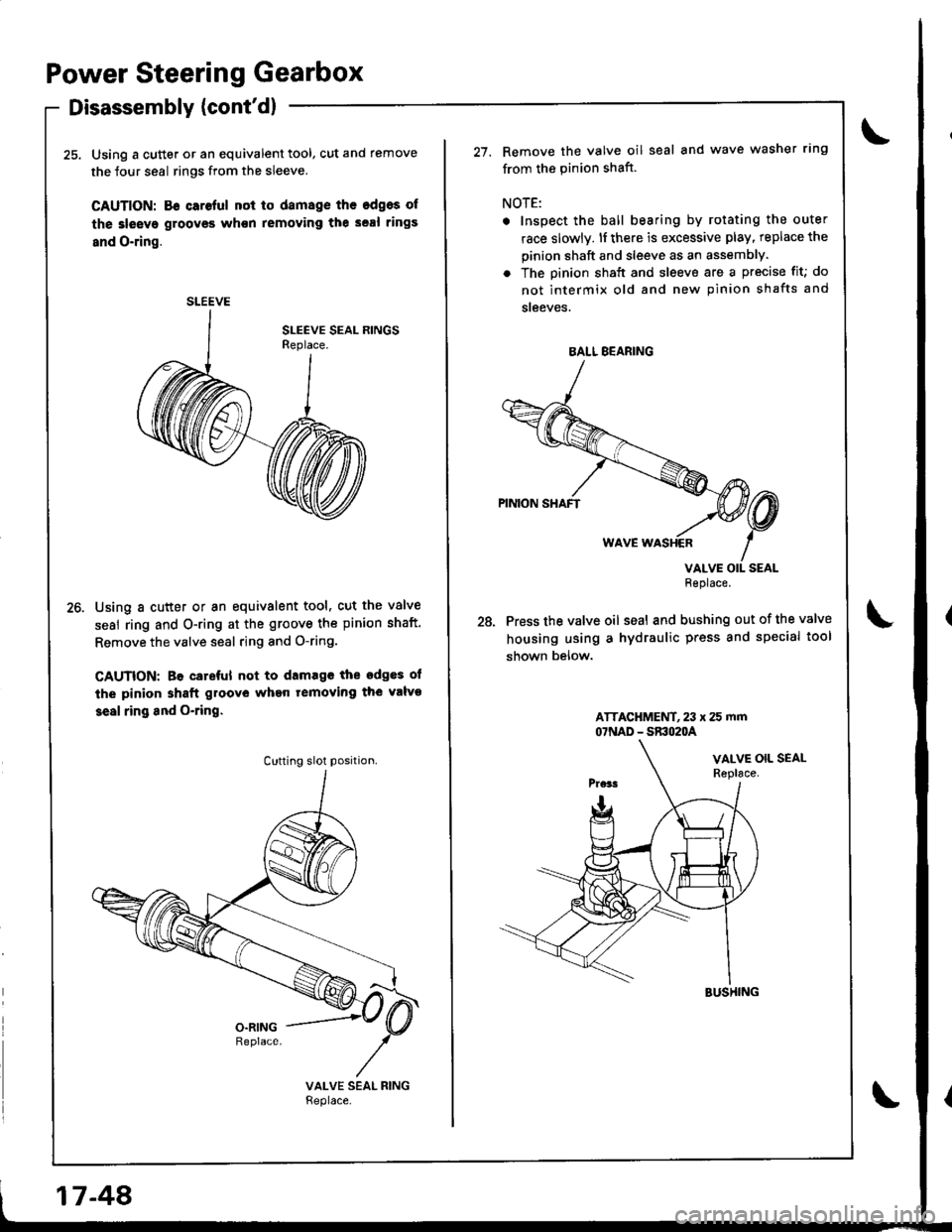

25. Using a cutter or an equivalent tool, cut and remove

the four seal rings from the sleeve.

CAUTION: 86 caroful not to damage the edgos of

the 3leeve grooves whon removing the scal rings

and O-ring.

Using I cutter or an equivalent tool, cut the valve

seal ring and O-ring at the groove the pinion shaft.

Remove the valve seal ring and O-ring.

CAUTION: 86 careful not to d.mago the sdges ol

lhe pinion shaft groove whgn removing the valvo

seal ring and O-ring.

SLEEVE

Cutting slot position.

17 -48

t"fRemove the valve oil seal and wave washer ring

from the pinion shaft.

NOTE:

. Inspect the ball besring by rotating the outer

race slowly. lf there is excessive play, replace the

pinion shaft and sleeve as an assembly.

. The pinion shaft and sleeve are a precise fit; do

not intermix old and new pinion shafts and

steeves.

VALVE OII- SEALReplace.

Press the valve oil seal and bushing out of the valve

housing using a hydraulic press and special tool

shown below.

ATTACHMENT, 23 x 25 mm

07NAD - SB3020A

VALVE OIL SEALReplace.

28.

BALL EEARING

BUSHING