tow HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 323 of 1681

The fuel supply system co

high pressure fuel pump, t

fuel pressure regulator. f

damper, and fuel delivery i

delivers pressure-regulated

cuts the luel delivery when

Fuel Supply System

System Description

consists of a fuel tank, in-tank

r, PGM-Fl main relay, fueffilter,

. fuel injectors, fuel pulsation

y and return lines. This system

ed fuel to the fuel injectors and

rn thq engine is not running.

Fuel Pressure

Relieving

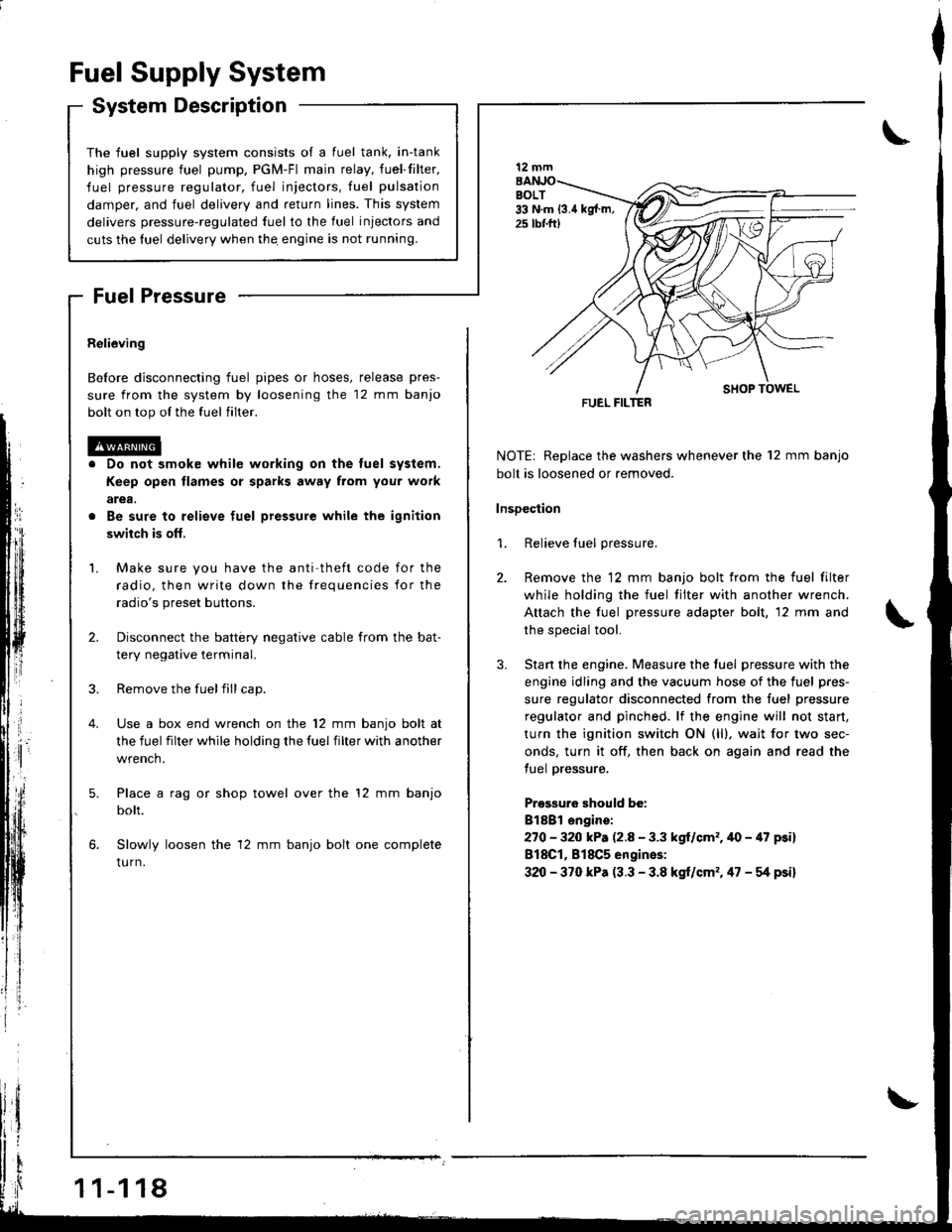

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top ol the fuel filter.

Do not smok€ while working on the tuel system,

Keep open flames or sparks away from you. work

arga.

Be sure to relieve fuel pressure while the ignition

swiich is ofl,

Make sure you have the anti theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuelfill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with another

wrench.

Place a rag or shop towel over the '12 mm banjo

bolt.

Slowly loosen the 12 mm banjo bolt one complete

tu rn.

1 1-1 18

I

NOTE| Replace the washers whenever the 12 mm banjo

bolt is loosened or removed.

lnsDection

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel tilter with another wrench.

Attach the fuel pressure adapter bolt, 12 mm and

the special tool.

3. Stan the engine. Measure the tuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch ON (ll), wait for two sec-

onds, turn it off, then back on again and read the

tuel pressure.

Pressuro should be:

Bl8Bl engire:

270 - 320 kP. (2.8 - 3.3 kgl/cm'�.40 - 47 psi)

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgt/cm'�. 47 - g psi)

12 mm

FUEL FILTER

Page 324 of 1681

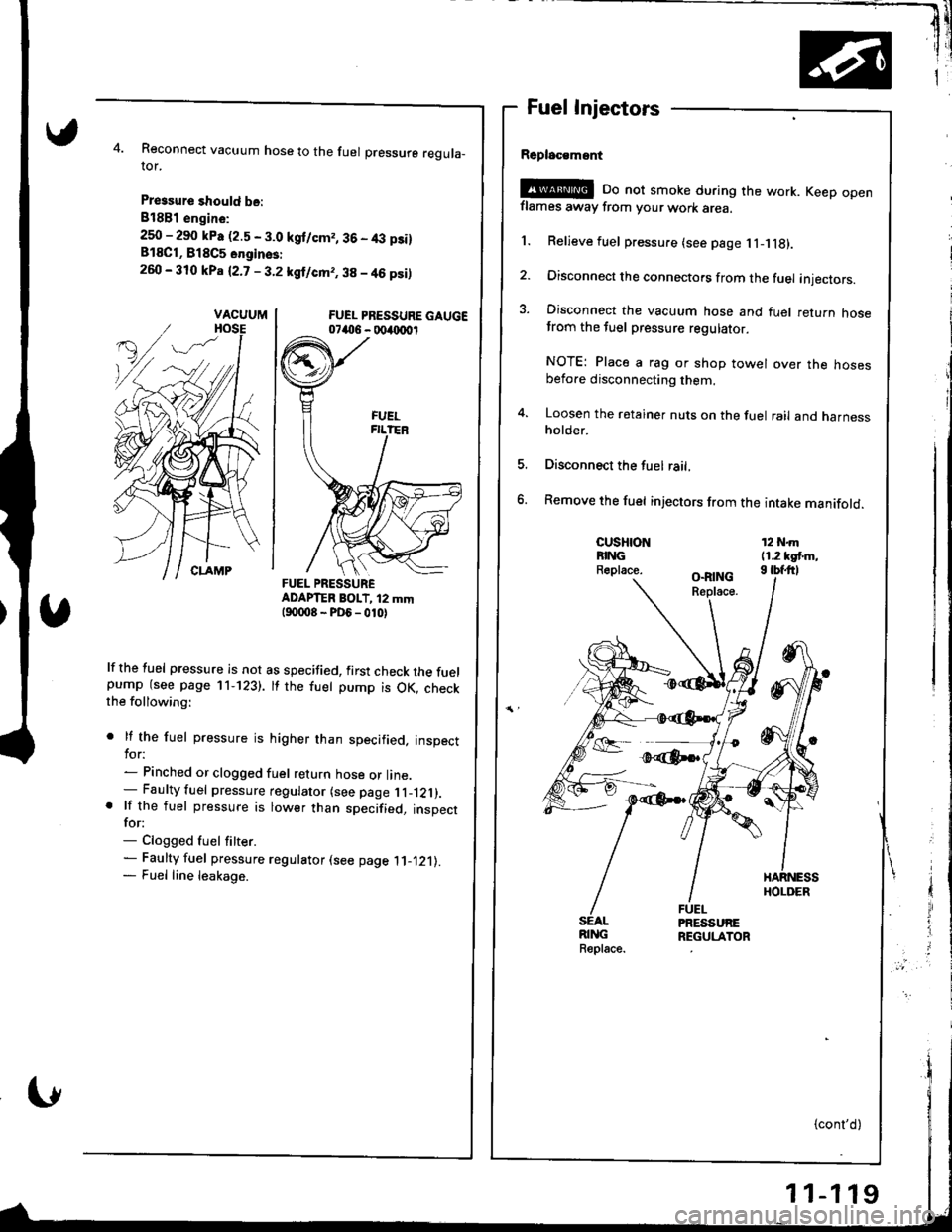

Reconnect vacuum hose to the fuel pressure reguta_ror.

Pressure should be:

818B1 engin€:

250 - 290 kPa (2.5 - 3.0 kgt/cm,, 36 - 4,:t p3i)818C1, B18C5 onginss:

260 - 310 kPa (2.7 - 3.2 kgl/cm,, 38 - 46 psi)

FUEL PRESSURE GAUGE07406 - 004{xr0r

ADAPTER BOIT, i2 mmt90008-PD6_010)

lf the fuel pressure is not as specified, first check the fuelpump (see page 11-123). tf the fuet pump is OK, checkthe following:

. lf the fuel pressure is higher than specified, inspecttor:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page l l _121).. lf the fuel pressure is lower than specified, inspectfor:- Clogged fuel fitter.- Faulty fuel pressure regulator (see page .ll-.121).

- Fuel line leakage.

Fuel Injectors

Rsplac€msnt

!@E oo not smoke during the work. Keep openflames away from your work area.

1. Relieve fuel pressure (see page 1l- g).

2. Disconnect the connectors from the fuel injectors.

3. Disconnect the vacuum hose and fuel return hosetrom the tuel pressure regulatot.

NOTE: Place a rag or shop towel over the hosesbefore disconnecting them.

4. Loosen the retainer nuts on the fuel rail and harnessholder.

Disconnect the fuel rail,

Remove the fuel injectors from the intake manifold.

CUSHIONFINGR.place.

12 N.m11.2 kgt m,I tbfftl

SEALRINGReplace.

VACUUM

FUEL PRESSURE

Page 326 of 1681

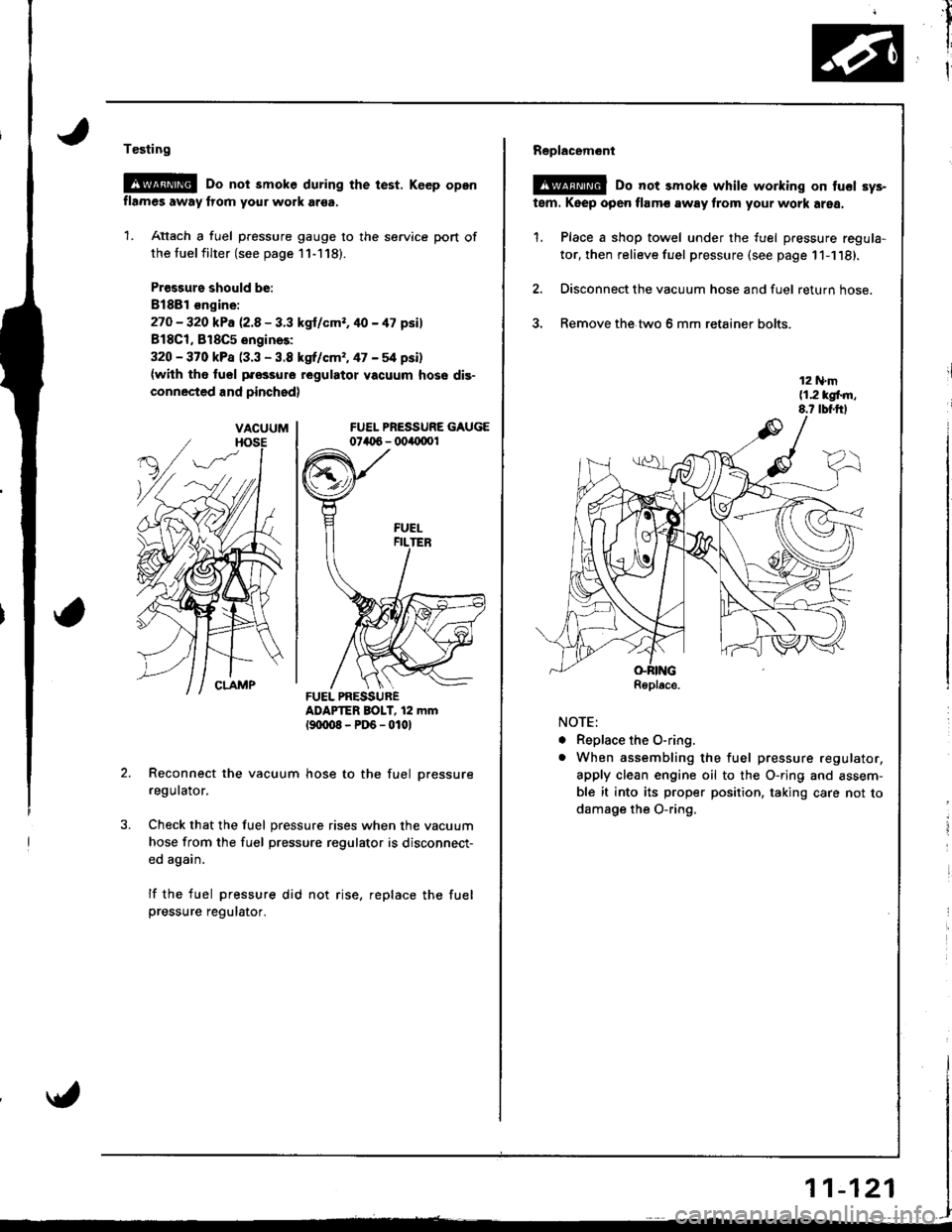

Testing

@G Do not smoke during the test. Keep opon

flames away lrom your work ar€a.

1. Attach a fuel pressure gauge to the service port of

the tuel filter (see page 11-118).

Pr€ssurs should be:

8188l €ngine:

27O - 320 kPa 12.8 - 3.3 kgl/cmr. 40 - 47 psil

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgrf/cm,, 47 - 54 psi)

{with tho fuol pfossure regulatot vacuum hose dis-

connected and pinchsd)

FUEL PRESSURE GAUGE074t 6 - 004{1001

ADAPTER BOIT, 12 mm(9txt08-PD6-0101

Reconnect the vacuum hose to the fuel pressure

regulator.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed again.

lf the fuel pressure did not rise, replace the fuelpressure regulator.

VACUUM

FUEL PRESSURER€place.

AA

,il

I

I

Replacem6nl

@ Do not smoke while working on tucl sys-

tem. Keep open flamc away from your work area.

1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1'18).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the.two 6 mm retainer bolts.

NOTE:

. Replace the O-ring.

o When assembling the fuel pressure regulator,

apply clean engine oil to the O-ring and assem-

ble it into its proper position, taking care not to

damage the O-ring.

r1

i

i

11-121

Page 327 of 1681

rr*

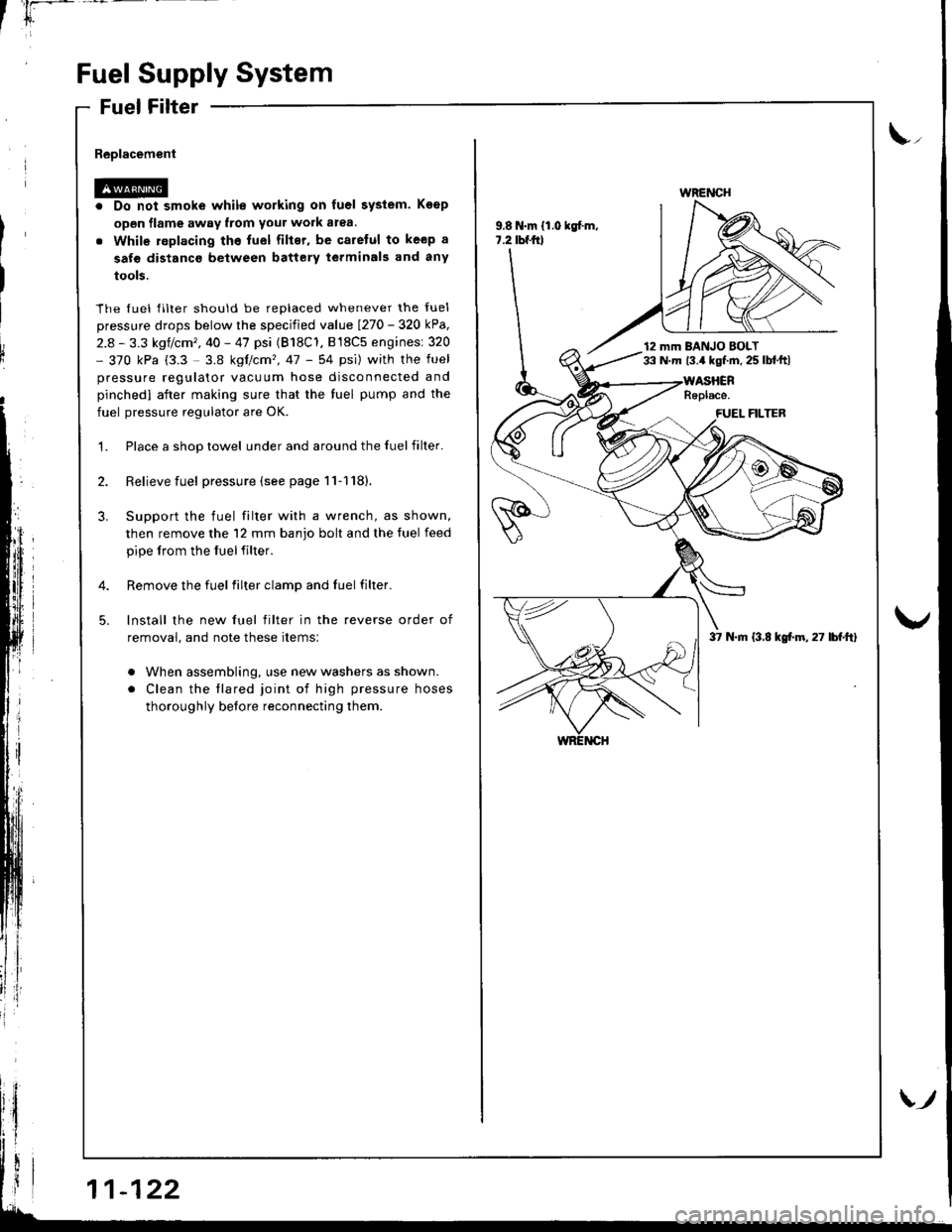

Fuel Supply System

Fuel Filter

Replacement

Do not smoke while working on fuel system. Koop

open flame away from your work atea.

While replacing the fuel filter, be qaretul to keep a

sate distanco between battery terminals and any

tools.

The fuel filter should be replaced whenever the fuel

pressure drops below the specified value I27o - 32O kPa,

2.8 - 3.3 kgf/cm', 40 - 47 psi (B18C'1, B l8C5 enginesi 320- 370 kPa (3.3 - 3.8 kgtcm'�,47 - 54 psi) with the fuel

pressure regulator vacuum hose disconnected and

pinchedl aiter making sure that the tuel pump and the

fuel pressure regulator are OK.

Place a shop towel under and around the fuelfilter.

Relieve fuel pressure {see page 11-1'18}.

Support the fuel filter with a wrench, as shown,

then remove the 12 mm banjo bolt and the tuel feed

pipe lrom the fuelfilter.

Remove the fuel filter clamp and fuel filter.

lnstall the new fuel filter in the reverse order of

removal, and note these items:

. When assembling, use new washers as shown.

. Clean the tlared joint of high pressure hoses

thoroughly before reconnecting them.

\,,

9.8 N.m {1.0 kgf.m,7.2 tbf.frl

WRENCH

12 mm BANJO BOLT33 N.m 13.4 kgf.m. 25 lbl.ftl

37 N.m (3.8 kgf.m,27 lbf.ft)

Page 362 of 1681

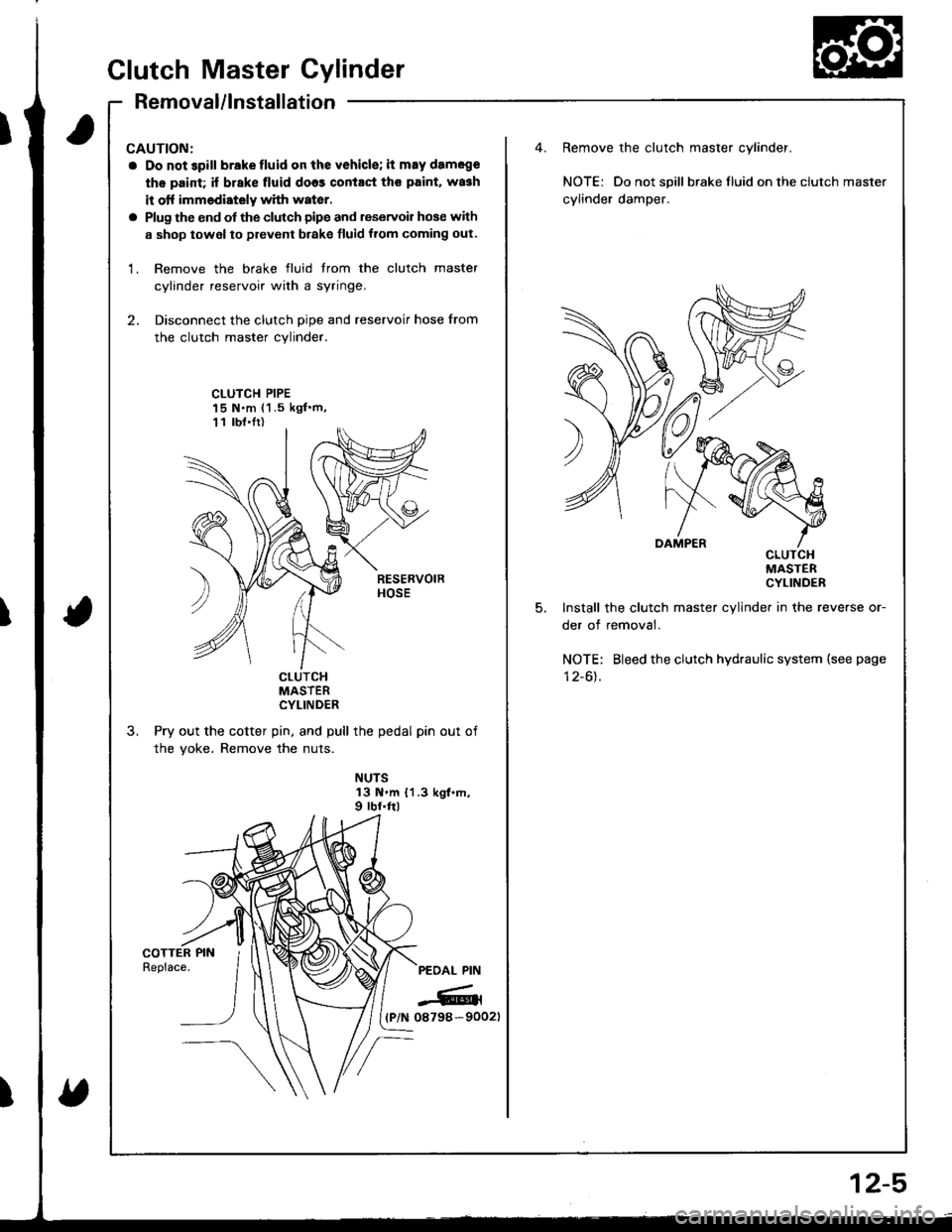

CAUTION:

a Do not 3pill brakefluid on the vehicle; it may damege

th€ paid; if brake fluid do63 contact th€ paint. wa3h

it otf immediately with water.

a Plug the end of the clutch pipe and reservoir hose with

a shop towel to prevent brake fluid from coming out.

1. Remove the brake fluid trom the clutch master

cylinder reservoir with a syringe,

2. Disconnect the clutch pipe and reservoir hose from

the clutch master cylinder.

Remove the clutch master cylinder.

NOTE: Do not spill braketluid ontheclutch master

cylinder damper.

CLUTCH PIPE15 N.m {1 .5 kgf'm,11 lbt.Ir)

5.

cLulcHMASTERCYLINDER

Install the clutch master cylinder in the reverse or-

der of removal.

NOTE: Bleed the clutch hydraulic system {see page

I z-ol.cturcHMASTERCYLINDER

Pry out the cotter pin, and pull the pedal pin out of

the yoke. Remove the nuts.

NUTS13 N.m {1.3 kgt.m,9 rbf.ftl

PEOAL PIN

-6rl(P/N 08798-90021

Clutch Master Cylinder

Removal/lnstallation

2-5

Page 363 of 1681

T

fi

;ill

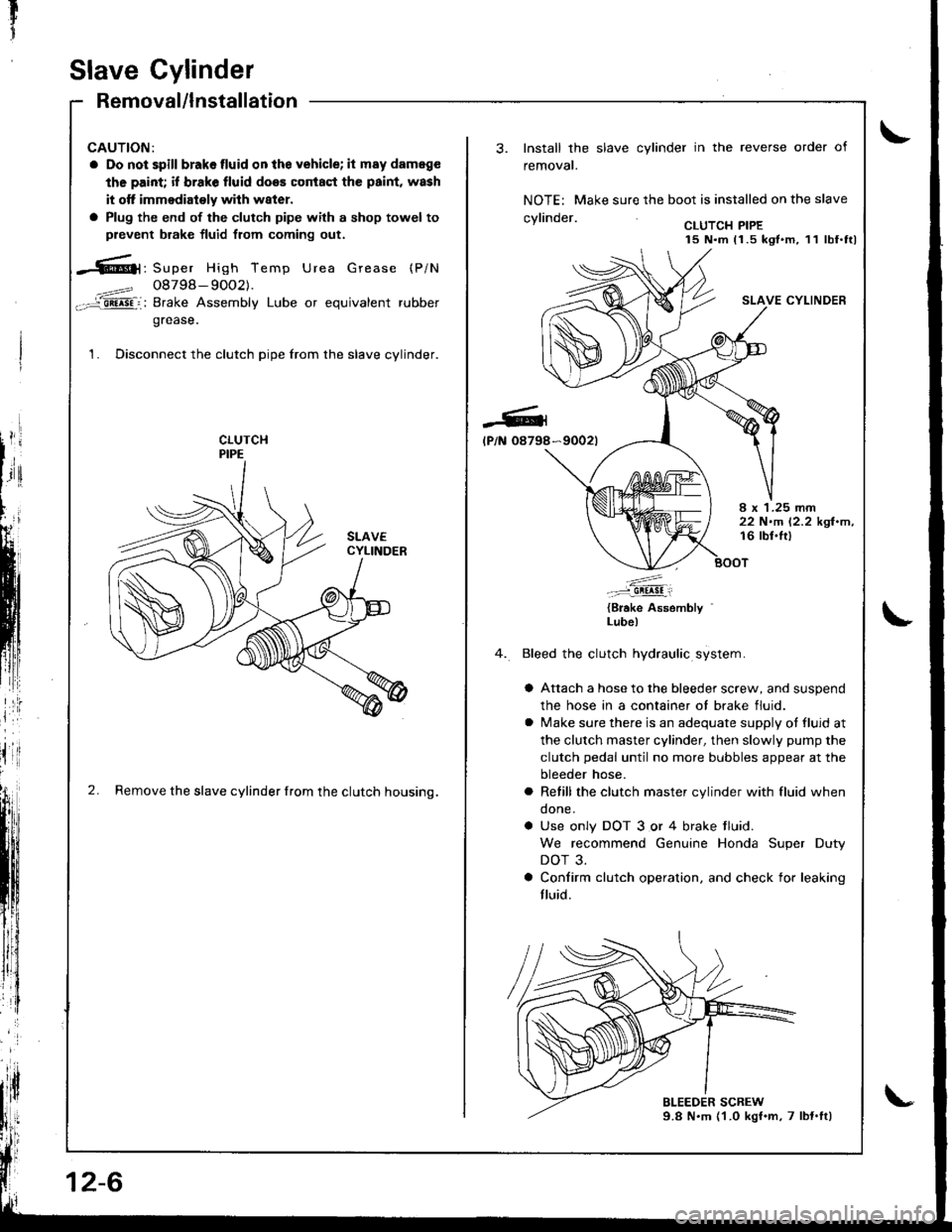

Slave Cylinder

Removal/lnstallation

CAUTION:

a Do not spill brakelluid onthe vehicle; it may dameg€

the paint; if brake fluid does coniaqt the paint, wash

it otf immodiaioly wilh w8ter.

a Plug the end of the clutch pipe with a shop towel to

prevent brake fluid from coming out.

-6|1, Super High Temp Urea Grease (P/N

4==? 08798- 9OO2).-='aii^5Fi: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch pipe from the slave cylinder.

2. Remove the slave cylinder from the clutch housing.

12-6

-Gl

lP/N 08798

Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

.wlin.larCLUTCH PIPE15 N.m 11.5 kgt.m, 11 lbf.ttl

SLAVE CYLINDER

*9002t

I x 1.25 rnm22 N.m 12.2 kgl.m,16 lbl.lt)

.'....-..-:::-9!!!!!i

{Brake Assembly '

Lube)

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container ot brake fluid.

a lvlake sure there is an adequate supply ot fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

a Refill the clutch master cylinder with fluid when

done.

a Use only DOT 3 or 4 brake tluid.

We recommend Genuine Honda Super Duty

DOT 3.

a Confirm clutch operation. and check for leaking

fluid.

Page 406 of 1681

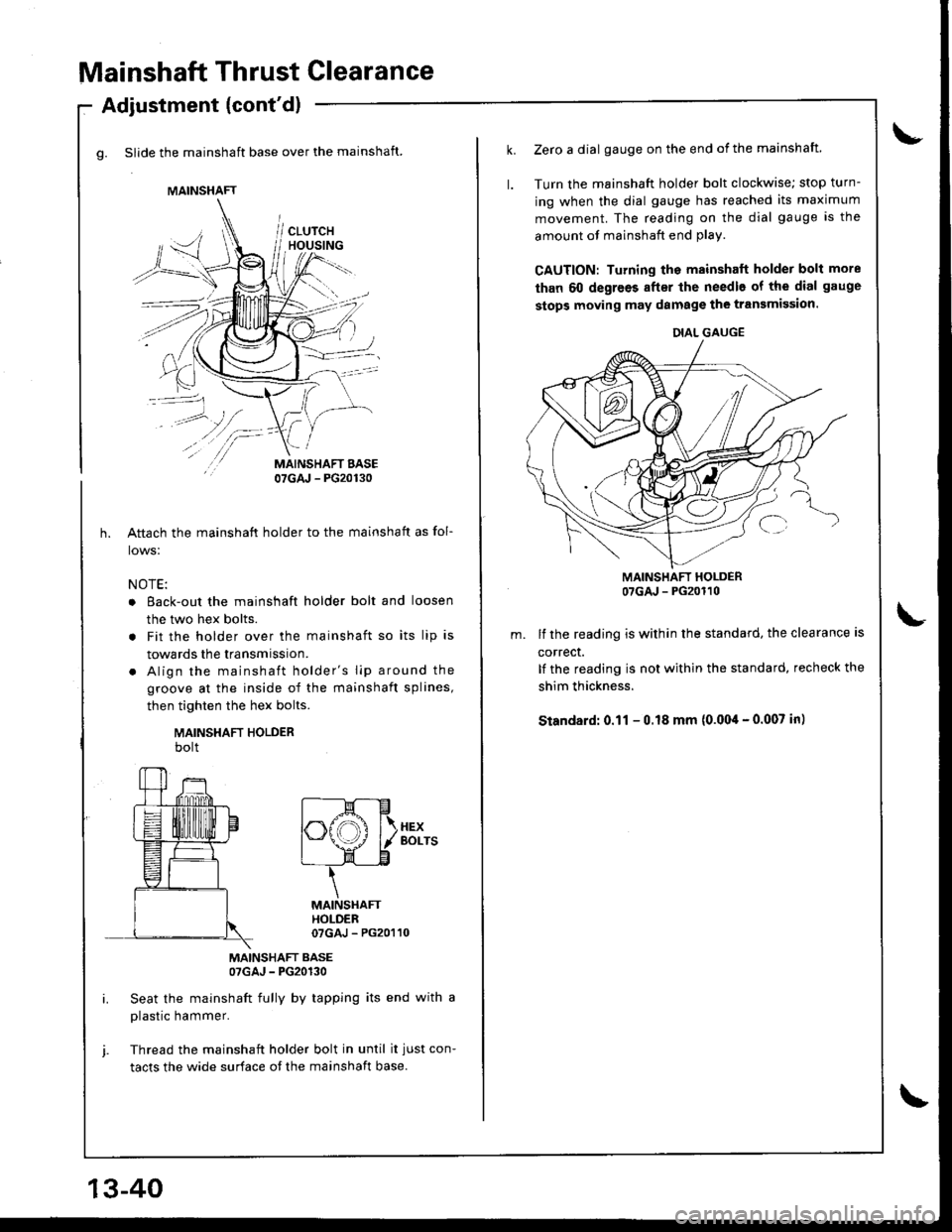

Mainshaft Thrust Clearance

g. Slide the mainshaft base over the mainshaft.

Adjustment (cont'dl

/\

/-

MAINSHAFT BASE07GAJ - PG20130

Aftach the mainshaft holder to the mainshaft as fol-

lows:

NOTE:

o Eack-out the mainshaft holder bolt and loosen

the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft splines,

then tighten the hex bolts.

MAINSHAFT HOLDERbolt

MAINSHAFT BASE07GAJ - PG20130

Seat the mainshaft fully by tapping its end with a

plastic hammer.

Thread the mainshaft holder bolt in until it just con-

tacts the wide surface of the mainshaft base.

MAINSHAFT

f----M---E

|".ffi f\.xex

I \J \--l./ l/ Borrs

L- LE

\

MAINSHAfiHOLDER07GAJ - PG20110

13-40

Zerc a dial gauge on the end of the mainshaft.

Turn the mainshaft holder bolt clockwise; stop turn-

ing when the dial gauge has reached its maximum

movement. The reading on the dial gauge is the

amount of mainshaft end plav.

CAUTION: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial gauge

stops moving may damage the transmission.

MAINSHAFT HOLDER07GAJ - PG20110

lf the reading is within the standard, the clearance is

correct.

It the reading is not within the standard, recheck the

shim thickness.

Standard: 0.11 - 0.18 mm (0.004 - 0.007 in)

DIAL GAUGE

Page 450 of 1681

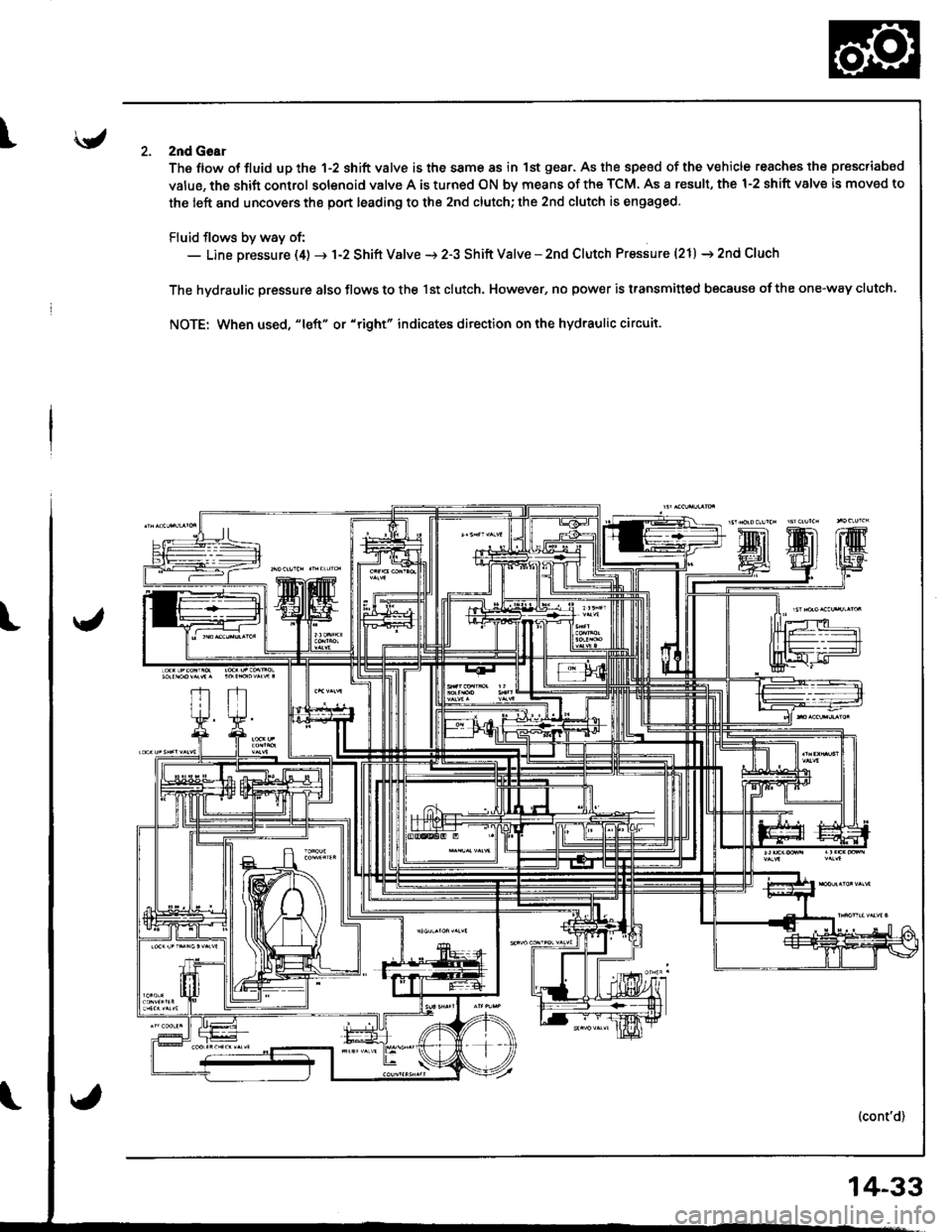

Iznd Goar

The ftow ot fluid up the 1-2 shift valve is the same 8s in 1st gear. As the speed of the vehicle reaches the prescriabed

value, the shift control solenoid valve A is turned ON by means of the TCM. As a result, the 1-2 shift valve is moved to

the left and uncovers the port leading to the 2nd clutch; the 2nd clutch is engaged.

Fluid flows by way of:- Line pressure (4) -r 1-2 Shift Valve i 2-3 Shift Valve - znd Clutch Pressure (21) i 2nd Cluch

The hydraulic pressure also flows to the lst clutch. However, no pow€r is transmitted because ofthe one-way clutch.

NOTE: When used, "Ieft" or "right" indicates ditection on the hydraulic circuit.

14-33

Page 537 of 1681

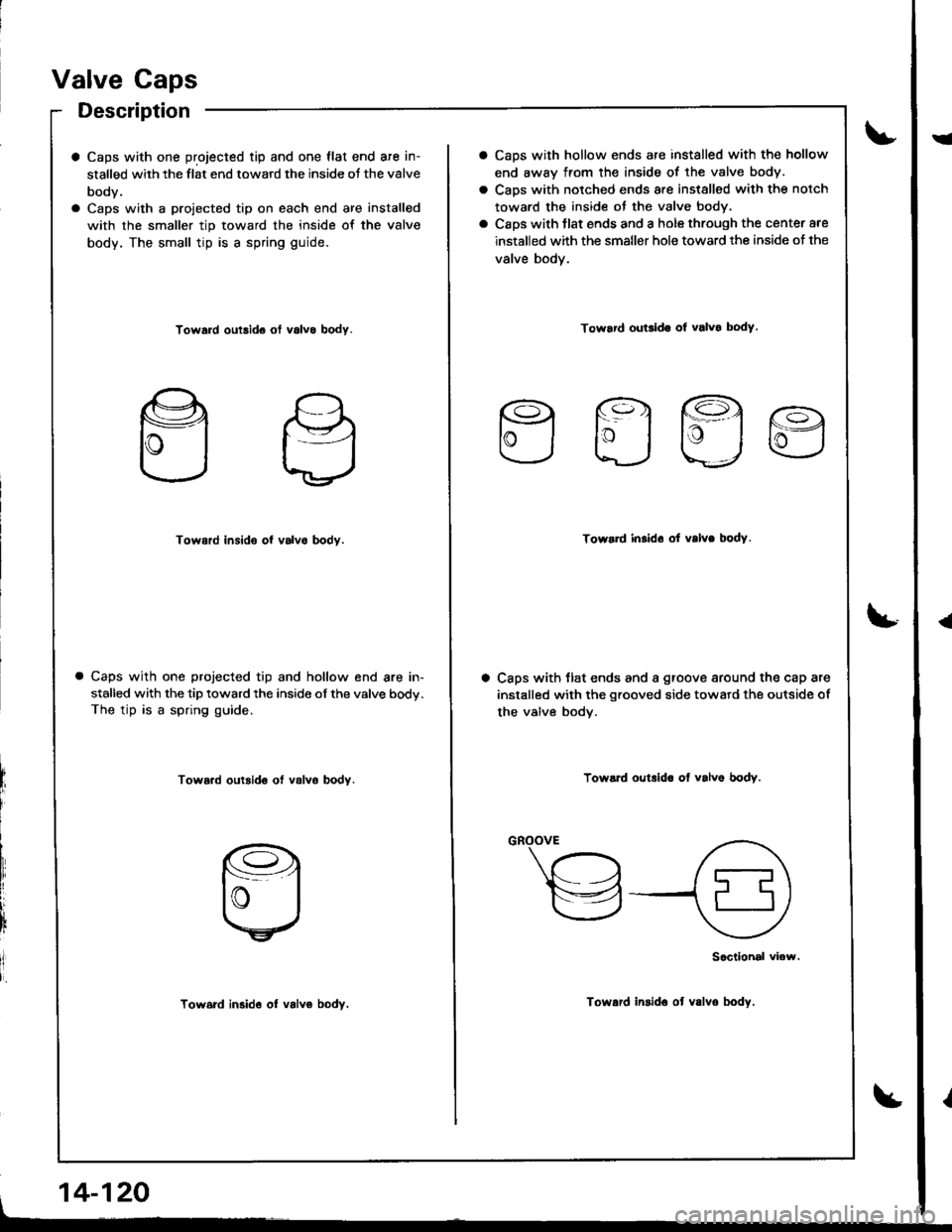

Valve Caps

Description

a Caps with one projected tip and one flat end are in-

stalled with the flat end toward the inside oJ the valve

body.

a Caps with a proiected tip on each end are installed

with the smaller tip toward the inside of the valve

body. The small tip is a spring guide.

Toward outsid6 ot v6lvo body.

Toward insido of valvo bodv.

Caps with one projected tip and hollow end are in-

stalled with the tip toward the inside of the valve body.

The tip is a spring guide.

Tow6.d outsid€ ot valvo bodY.

Tow6rd in3id6 ol valvo bodv.

, 14-120

CaDs with hollow ends are installed with the hollow

end away from the inside of the valve body.

Caps with notched ends are installed with the notch

toward the inside ot the valve body.

Caps with tlat ends and a hole through the center are

installed with the smaller hole toward the inside of the

valve body.

Toward ouGida ol valvo body.

Efla

Toward in.ldo ot valve bodY.

Caps with tlat ends and a groove around the cap are

installed with the grooved side toward the outside of

the valve bodv.

Toward oulrlda of valve bodv.

"-\"h

,a\

v{9

Sociiohal viow.

Toward insido ot v.lvo body.

I

{

Page 566 of 1681

I

T

)

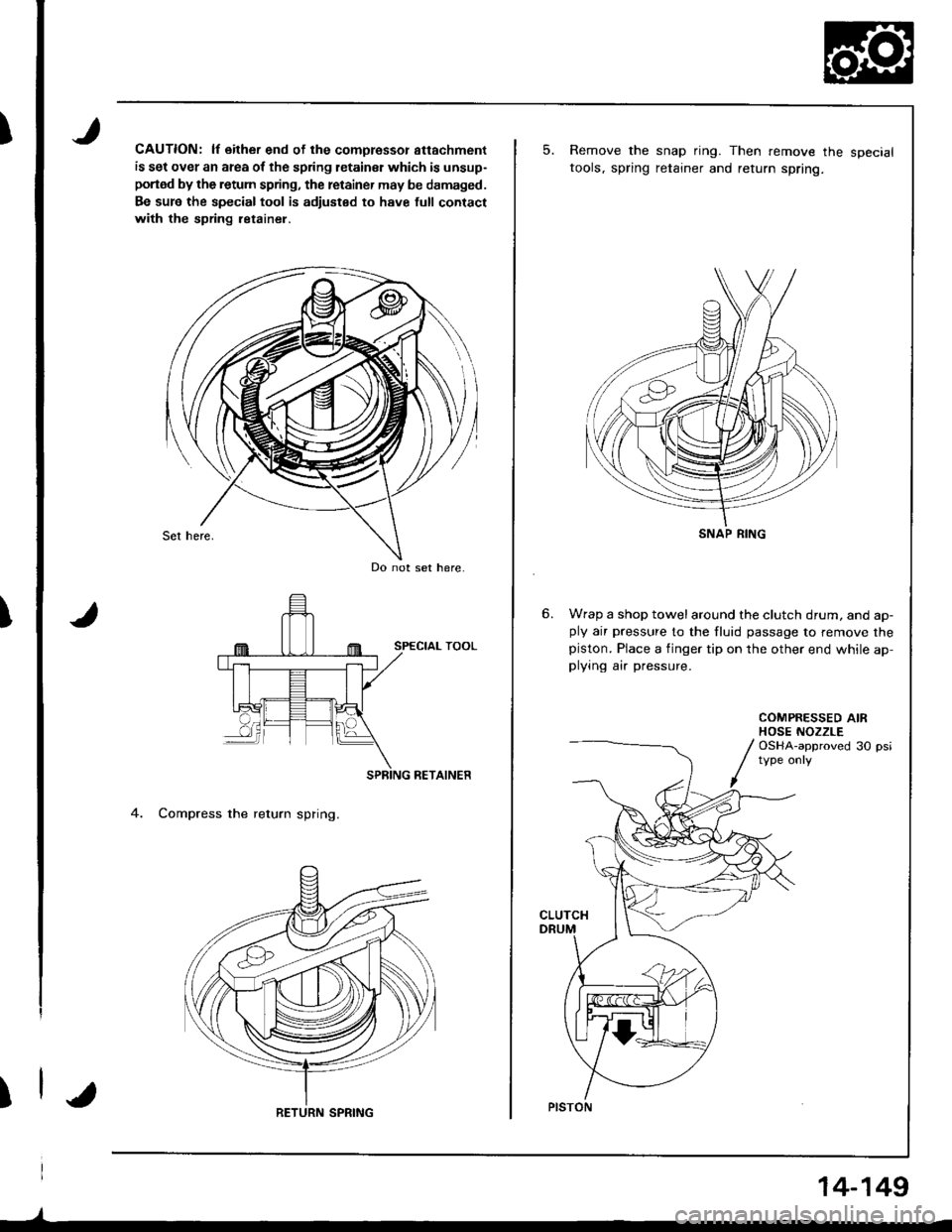

CAUTION: lf either end of the comoressor attachment

is set over an area of the spring letainsr which is unsup-

portod by the retum spring, the retainer may be damaged.

Be sur6 the special tool is adiusted to have full contact

with the spring ietainel,

RETAINER

4. Compress the return spring.

Do not set here.

RETURN SPRING

)

14-149

5.Remove the snap ring. Then remove the specialtools, spring retainer and return spring.

Wrap a shop towelaround the clutch drum, and ap-ply air pressure to the fluid passage to remove thepiston. Place a finger tip on the other end while ap,plying air pressure.

COMPRESSED AIRHOSE NOZZLEOSHA-approved 30 psi

CLUTCH

SNAP RING

PISTON