ESP HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 700 of 1681

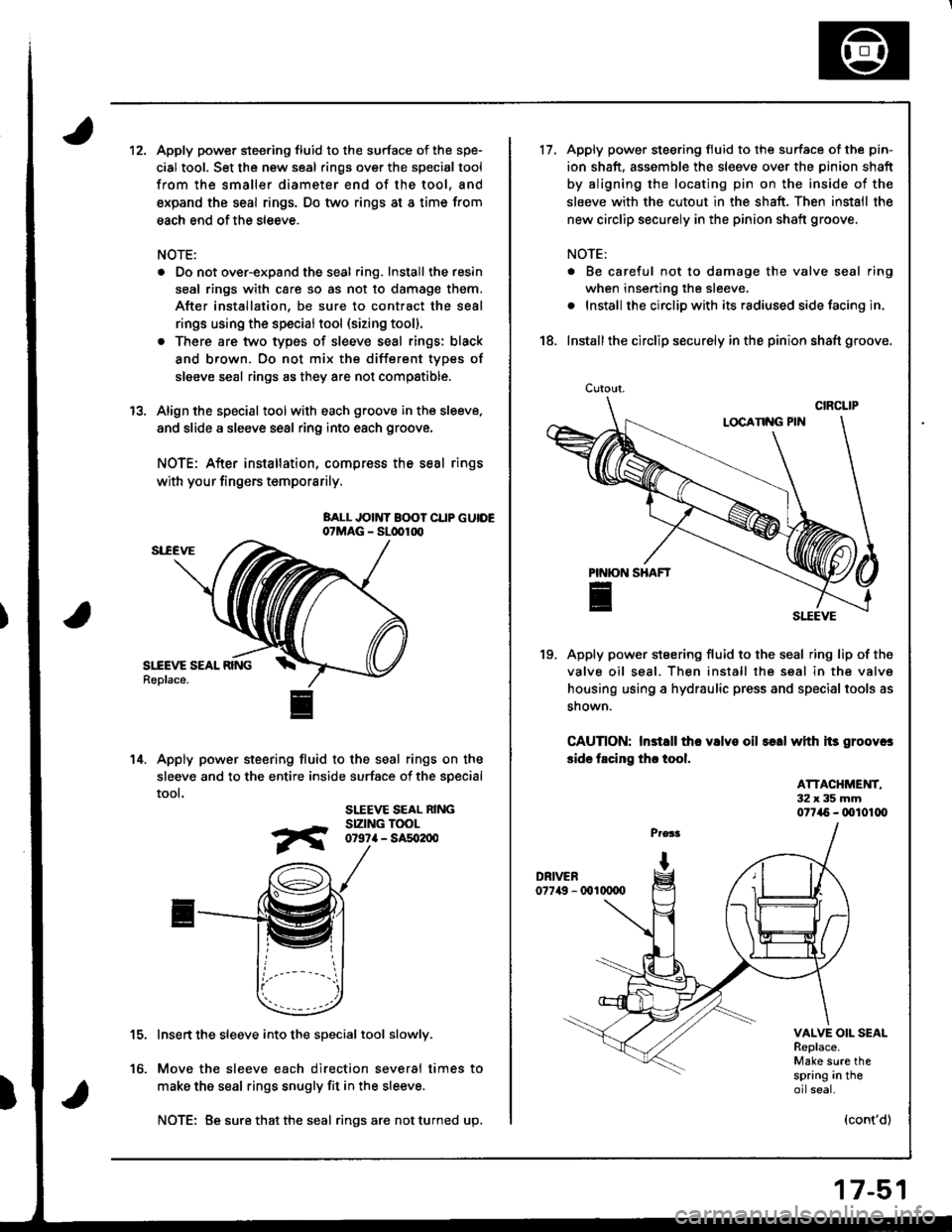

12.Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool, and

expand the seal rings. Do two rings at a time from

each end of the sleeve.

NOTE:

. Do not over-expand the seal ring. Install the resin

seal rings with care so as not to damage them.

After installation, be sure to contract the seal

rings using the specialtool (sizing tool).

. There are two types of sleeve seal rings: black

and brown. Oo not mix the different types of

sleeve seal rings as they are not compstible.

Align the special toolwith each groove in the sleeve.

and slide a sleeve seal ring into each groove.

NOTE: After installation, compress the seal rings

with your fingers temporarily.

BALL JOINT B(X)? CUP GUIDE07MAG - SLdrlrx,

Apply power steering fluid to the seal rings on the

sleeve and to the entire inside surface of the soecial

tool.

SLEEVE SEAL NINGSIZING TOOL0r9?a - sat02n0

Insert the sleeve into the special tool slowly.

Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve.

NOTE: Be sure that the seal ringsare notturned up.

13.

14.

to.

17-51

Cutout.

17.Apply power steering fluid to the surface of the pin-

ion shaft, assemble the sleeve over the pinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove.

NOTE:

. Be careful not to damage the valve seal ring

when inserting the sleeve.

. Install the circlip with its radiused side facing in,

18. Installthe circlip securely in the pinion shaft groove.

Apply power steering fluid to the seal ring lip of the

valve oil seal. Then install the seal in the valve

housing using a hydraulic press and special tools as

snown.

CAUnON: Instsll tho valvo oil s€.| with its groovcs

side facing th. tool.

19.

ATTACHMET{T,32x35mm077i15 - (xll01lX,

VALVE OIL SEALReplace.Make sure thespring in theoilseal.

(cont'd)

Page 779 of 1681

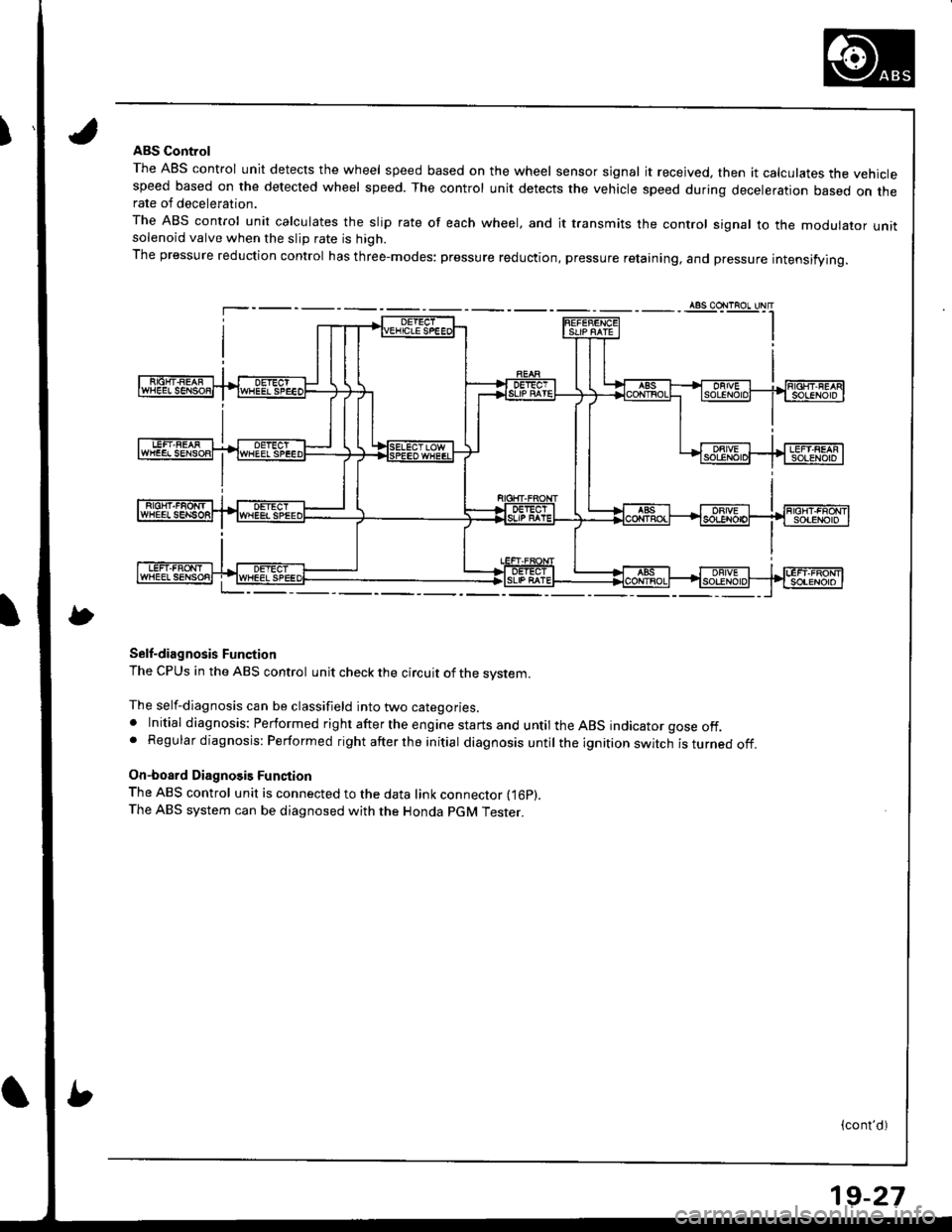

IABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehiclespeed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on therate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unitsolenoid valve when the slip rate is high.

The pressure reduction control has three-modes: pressure reduction, pressure retaining, and pressure intensifying.

Self-diagnosis Function

The CPUS in the ABS control unit check the circuit of the system.

The self-diagnosis can be classifield into two categories.. Initial diagnosis: Performed right after the engine starts and until the ABS indicator gose off.. Regular diagnosis: Performed right after the initial diagnosis until the ignition switch isturnedoff.

On-board Diagnosis Function

The ABS control unit is connected to the data link connector fi6p).The ABS system can be diagnosed with the Honda PGM Tester.

(cont'd)

19-27

Page 877 of 1681

Rear Window

{

lnstallation

2.

3.

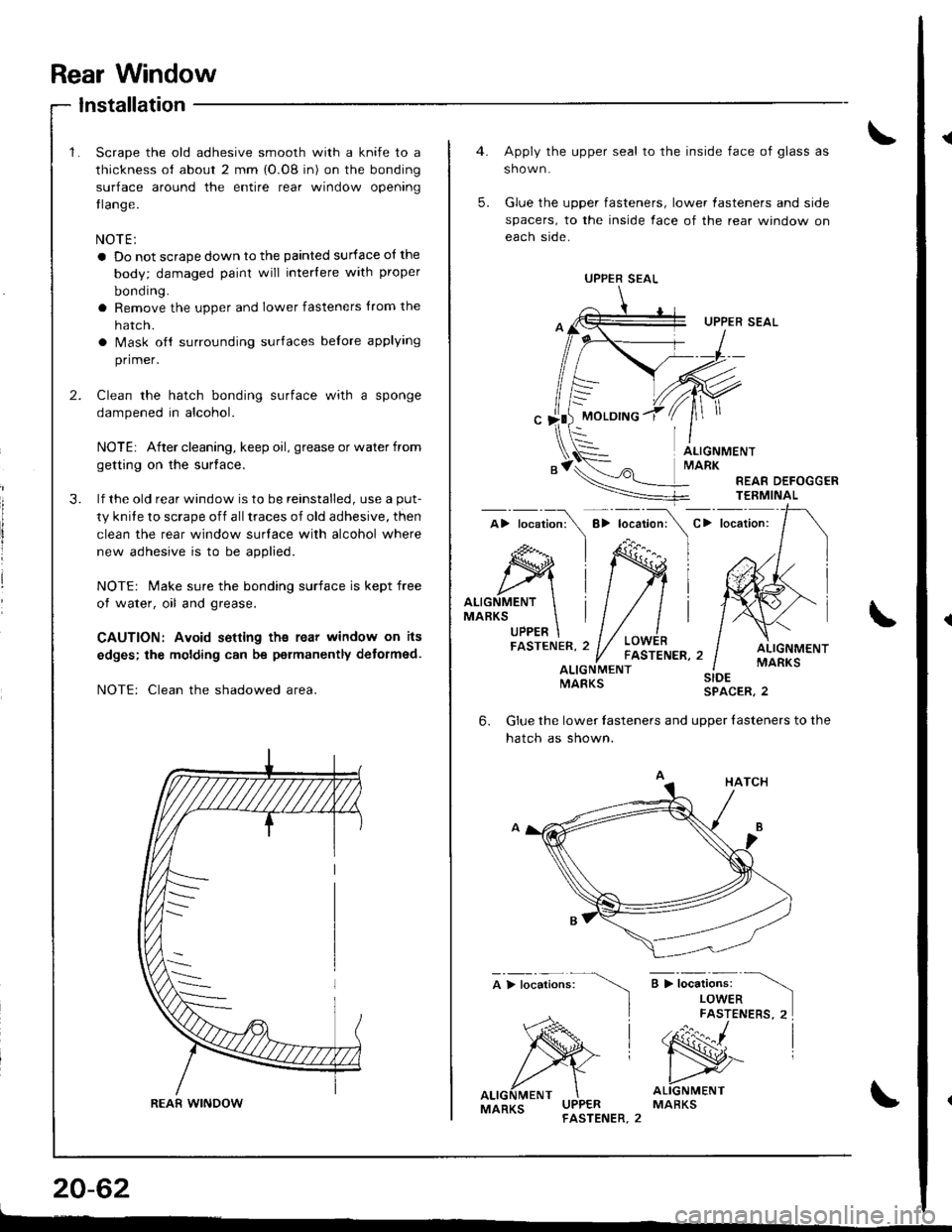

Scrape the old adhesive smooth with a knife to a

thickness of about 2 mm {O.08 in) on the bonding

surface around the entire rear window opening

tlange.

NOTE:

a Do not scrape down to the painted surface of the

body; damaged paint will interlere with proper

bonding.

a Remove the upper and lower fasteners trom the

hatc n.

a Mask oft surrounding surfaces belore applying

primer.

Clean the hatch bonding surface with a sponge

dampened in alcohol.

NOTEr After cleaning, keep oil, grease or water from

getting on the surface.

lf the old rear window is to be reinstalled, use a put-

ty knite to scrape off alltraces of old adhesive, then

clean the rear window surlace with alcohol where

new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setling ths rear window on its

edges; the molding can be permanently detormed.

NOTE: Clean the shadowed area.

REAfi WINDOW

20-62

Apply the upper seal to the inside face of glass as

shown.

Glue the upper fasteners, lower lasteners and side

spacers, to the inside face of the rear window on

each side.

UPPER SEAL

MOLDING

5.

ALIGNMENTMARK

REAR DEFOGGERTEEMINAL

C> locaiion:

ALIGNMENTMARKSUPPER

ALIGNMENTMARKSALIGNMENTMARKS

;>t";",i".",

)

SIDESPACER,2

6.Glue the lower lasteners and uooer {asteners to the

hatch as shown.

a > i*"ri".* -\

LOWERFASTENERS, 2I

'N^ |

ALIGNMENTMARKSMARKS

UPPER SEAL

Page 1061 of 1681

Troubleshooting

Tips and Precautions (cont'd)

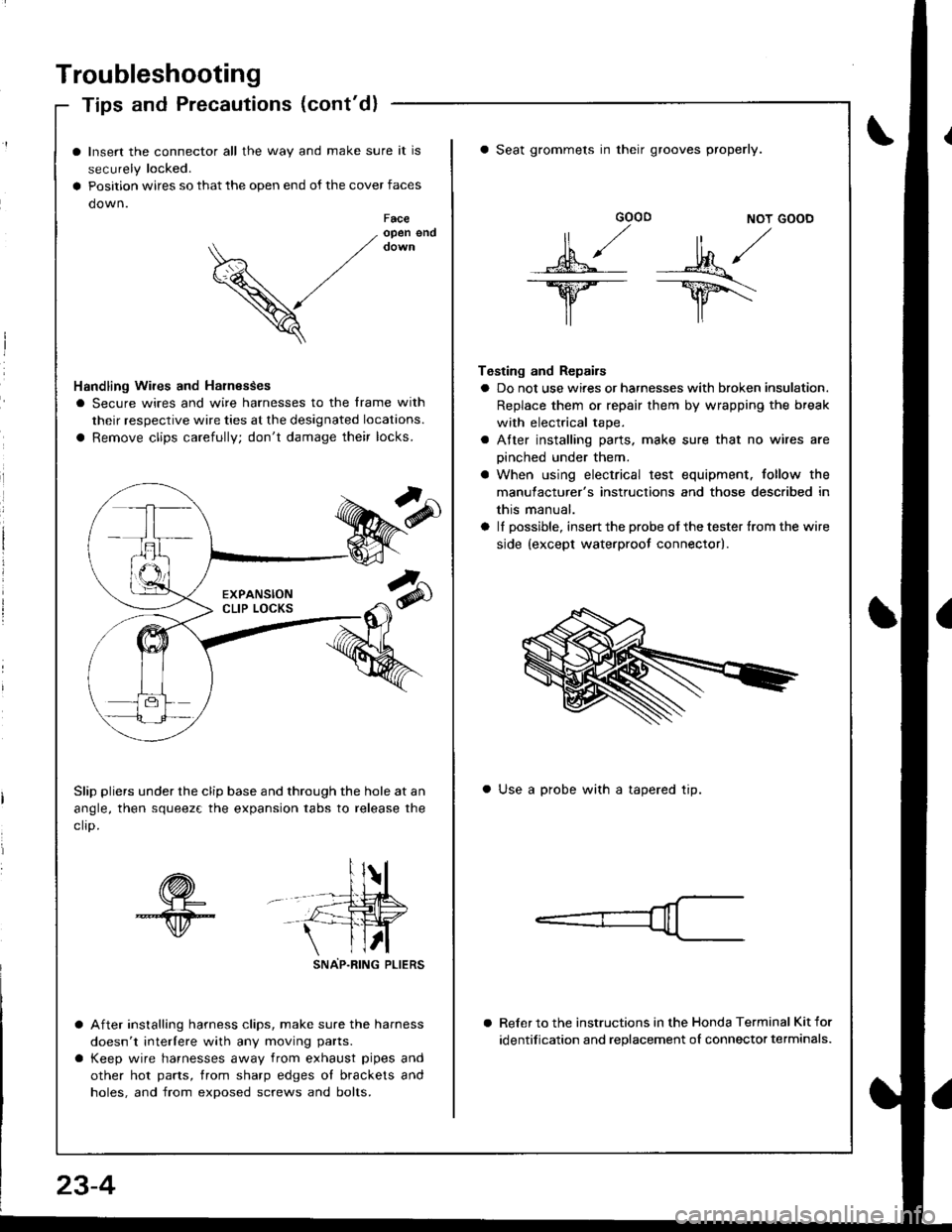

Insert the connector all the way and make sure it is

securely locked.

Position wires so that the open end of the cover faces

down.Faceopen end

V

Handling Wires and Harnesses

I Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

a Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at an

angle, then squeez€ the expansion tabs to release the

clro.

sNAP-R|NG PLtERS

After installing harness clips, make sure the harness

doesn't interlere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges ol brackets and

holes, and from exposed screws and bolts.

GOOD NOT GOOD

MA/

lr lr\

Testing and Repairs

a Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

a Atter installing parts. make sure that no wires are

oinched under them.

a When using electrical test equipment. follow the

manulacturer's instructions and those described in

this manual.

a lI possible, insert the probe of the tester {rom the wire

side {except waterproot connector).

a Seat grommets in their grooves properly.

a Use a probe with a tapered tip.

Reler to the instructions in the Honda Terminal Kit for

identification and replacement oI connector terminals.

23-4

Page 1144 of 1681

J

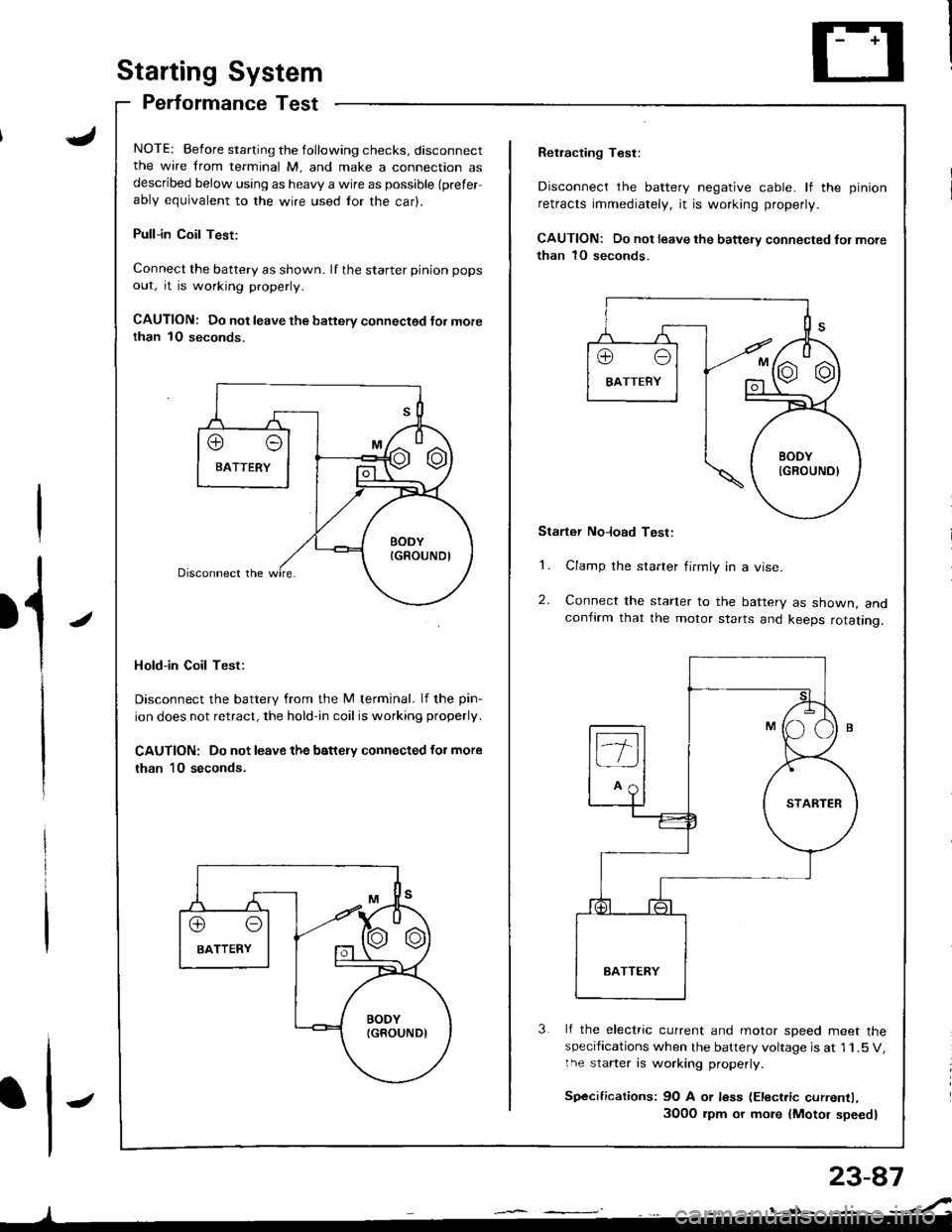

Starting System

Performance Test

NOTE: Before starting the following checks, disconnectthe wire from terminal M, and make a connection asdescribed below using as heavy a wire as possible (prefer

ably equivalent to the wire used for the car).

Pull-in Coil Test:

Connect the battery as shown. If the starter pinion pops

out, it is working properly.

CAUTION: Do not leave the battery connectsd Jor morethan 1O seconds.

Hold-in Coil Test:

Disconnect the battery from the M terminal. lf the pin-

ion does not retract, the hold-in coil is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

J

Retracting Test:

Disconnect the battery negative cable. lf the pinion

retracts immediately, it is working properly.

CAUTION: Do not leave the battery connected fol more

than 1O seconds.

Starter No]oad Test:

1. Clamp the starter firmly in a vise.

2. Connect the starter to the battery as shown, andconfirm that the motor starts and keeps rotating.

3 lf the electric current and motor soeed meet thespecifications when the battery voltage is at 1 1.5 V,the starter is working properly.

Sp€cifications: 9O A or less (Electric currentl,

3O0O rpm or more {Motor speed}

Page 1153 of 1681

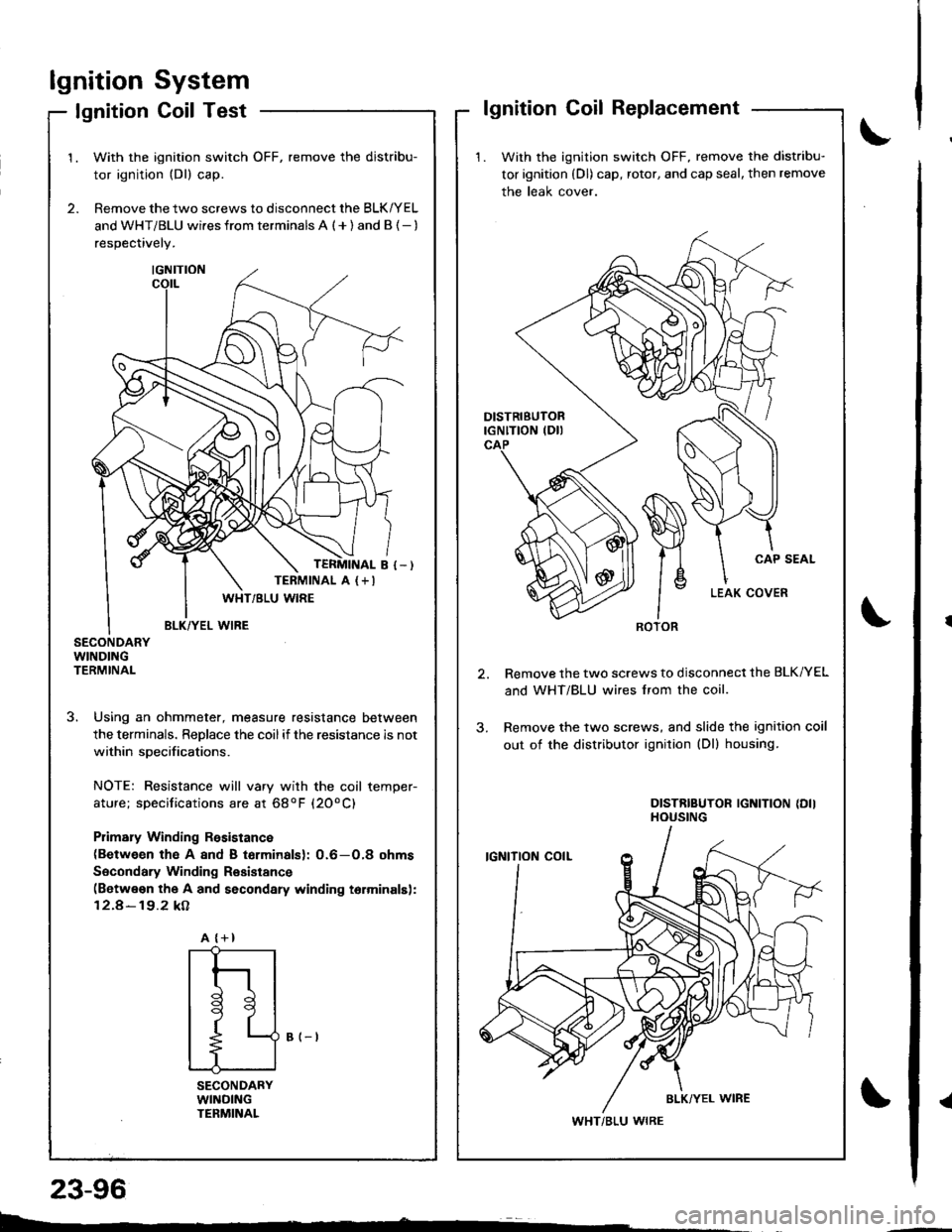

lgnitionSystem

Coil TestlgnitionlgnitionCoilReplacement

1. With the ignition switch OFF, remove the distribu-

tor ignition (Dl) cap, rotor, and cap seal, then remove

the leak cover.

Remove the two screws to disconnect the BLK/YEL

and WHT/BLU wires lrom the coil.

Remove the two screws, and slide the ignition coil

out of the distributor ignition (Dl) housing.

DISTRIBUTOR IGNITION {DIIHOUSING

ROTOR

WHT/BLU WIRE

2.

1.With the ignition switch OFF, remove the distribu-

tor ignition (Dl) cap.

Remove the two screws to disconnect the BLK/YEL

and WHT/BLU wi.es from terminals A ( + ) and B {- )

respectively.

SECONDARYWINDINGTERMINAL

3. Using an ohmmeter, measure resistance between

the terminals. ReDlace the coilif the resistance is not

within soecifications.

NOTE: Resistance will vary with the coil temper-

ature; specifications are at 68oF (20oC)

Plimary Winding Rssistance(Between th€ A 8nd B torminalsl: 0.6-O,8 ohms

Socondary Winding Resistance(Betwe€n the A and secondary winding torminalsl:

12.4-19.2 kA

B (-t

SECONDARYWllrlDlNGTENMINAL

TERMINAL A (+I

A {+}

{

t

l

tl

t9

t

L--

23-96

Page 1178 of 1681

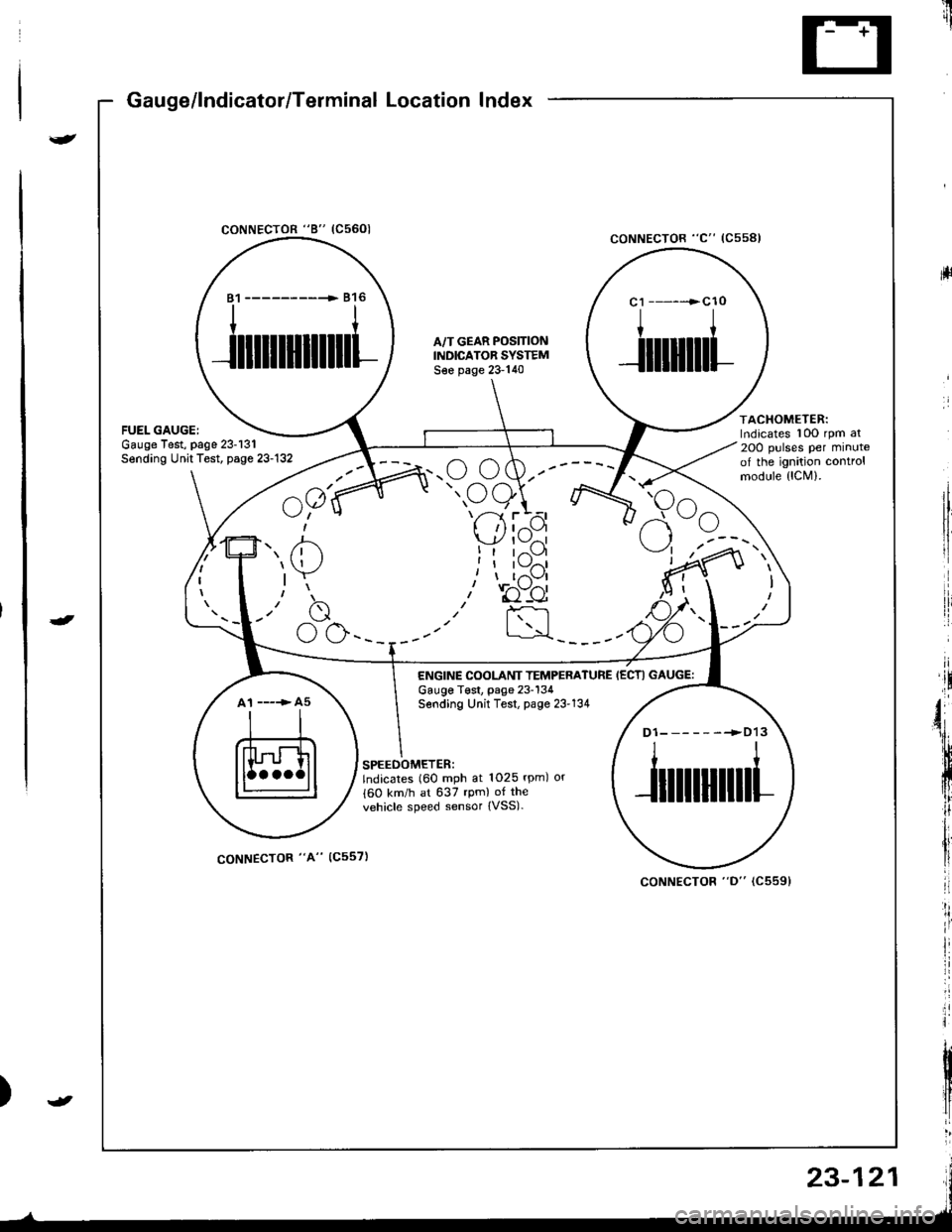

Gauge/lndicator/Terminal Location Index

coNNECTOR "8" (C5601

ltrii

rll

coNNECTOR "C" (Css8l

ACHOMETER:rdicates 10O rpm al

OO pulses per minutef the ignition controlrodule {lCM).

81 ------------ 816

ililllllilll

A,/T GEAR POS]TIONINDICATOR SYSTEMS€e page 23-140

c1 ------>cl0

I

Jilliltl

atespage 23-131t Test, page 23-132

^a1(

u;" u

7' /'- /n.u (,w.--

" oe)\r- -7 ttt'-1 r --

I 'l I z{.-a\y' | \-./^l

!t tr--',9I I l\-//11, I t,-\Jl

.r' to"-ei

I :rl

F<

elrle

ENGINE COOLANT TEMPERATUREGauge T€st, page 23-134Sending Unit Test, page 23'134

IECTI GAUGE:

A1 ----> A5

D1-------->D13

ililtl|illl

SPEEOOMETER:lndicates (60 mph at 1025 rpm) or

{60 km/h at 637 rpm) of the

vehicle speed sensor {VSS).

coNNECTOR "A" (C557)

coNNECTOR "D" (C5591

23-121

Page 1389 of 1681

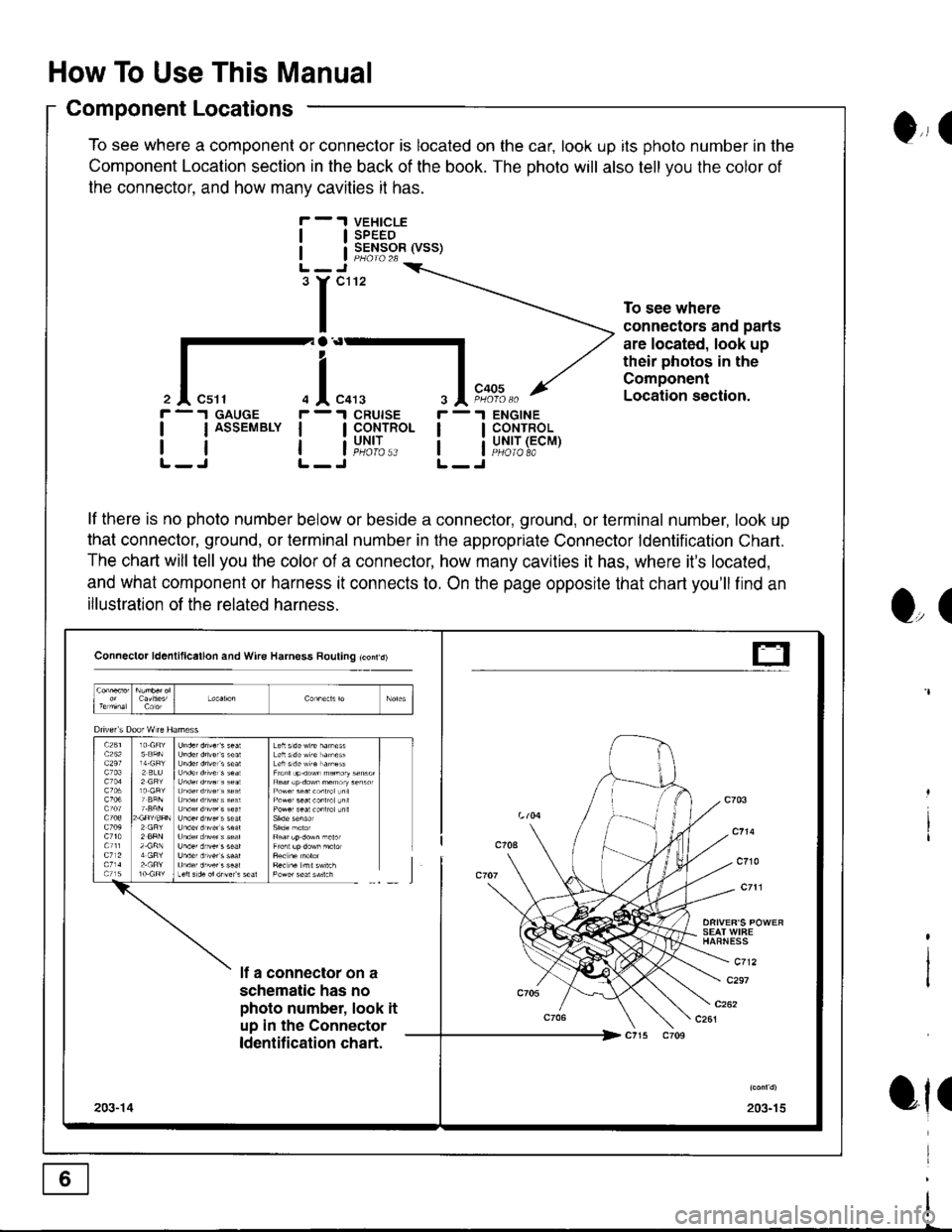

How To Use This Manual

Component Locations

To see where a component or connector is located on the car, look up its photo number in the

Component Location section in the back of the book. The photo will also tell you the color of

the connector. and how manv cavities it has.

VEHICLESPEEDSENSOR (VSS)

ENGINECONTROLUNIT (ECMPHOIO 8A

0,, I

tl

tl

'r"'

To see where

connectors and parts

are located, look up

their photos in the

Component

Location section.

r -.I GAUGE

| | ASSEMBLY I

rtlL-J L-

r -'l

ll

ll

O,(

ot(

il"l,*.I CRUISE

I CoNTROL

i"u,t',:..

lf there is no photo number below or beside a connector, ground, or terminal number, look up

that connector, ground, or terminal number in the appropriate Connector ldentification Chart.

The chart will tell you the color of a connector, how many cavities it has, where it's located,

and what component or harness it connects to. On the page opposite that chart you'll find an

illustration of the related harness.

Connector ld6nlillcallon and Wire Harness Rouling tconrd)

SEAT WIFEHAFNESS

c712lf a connector on a

schematic has no

photo number, look it

up in the Connector

ldentification chart.

c297

203-15203-14

t-

Page 1419 of 1681

TRANSMISSION

I

I

T4

PGM-FIMAIN RELAYPage 23 ('98-'99)or 24 ( 00)

tl

tlL-J

* : '98-'99 Models

i---------\L---------J(- 10) r-- -;-;.11, (c408.)(- 23)10

'98- 99.. GS.R' l/odel

inrrarerrn i

I

I

.-- GS-R. TYPE.R

VEHICLESPEEDSENSORRADIATOBFAN SWITCH

and 63 2

tl

tlL-Jcl08

(vss)Page

PHATO 6IIITJ

I

I

33

I

I

c3o1 ;

10

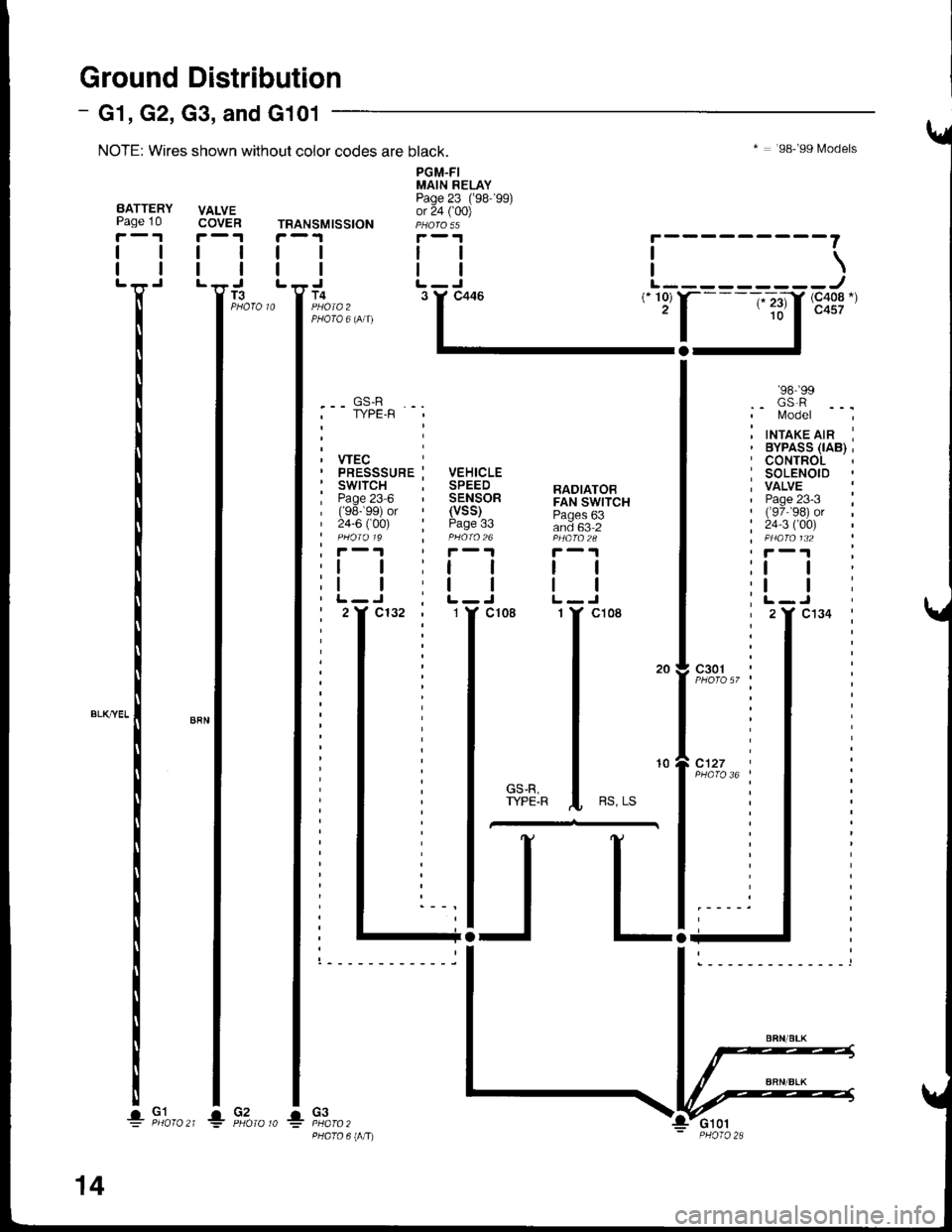

Ground Distribution

NOTE: Wires shown without color codes are black.

VALVECOVER

I

I

- G1, G2, G3, and G101

I

I

T3

BATTERYPage 10

r-'r

tl

ll'n'

I

I

I

I

I*-*rl

I

I

I

I

! F,to,o^_l1io,o,o *

14

Page 1451 of 1681

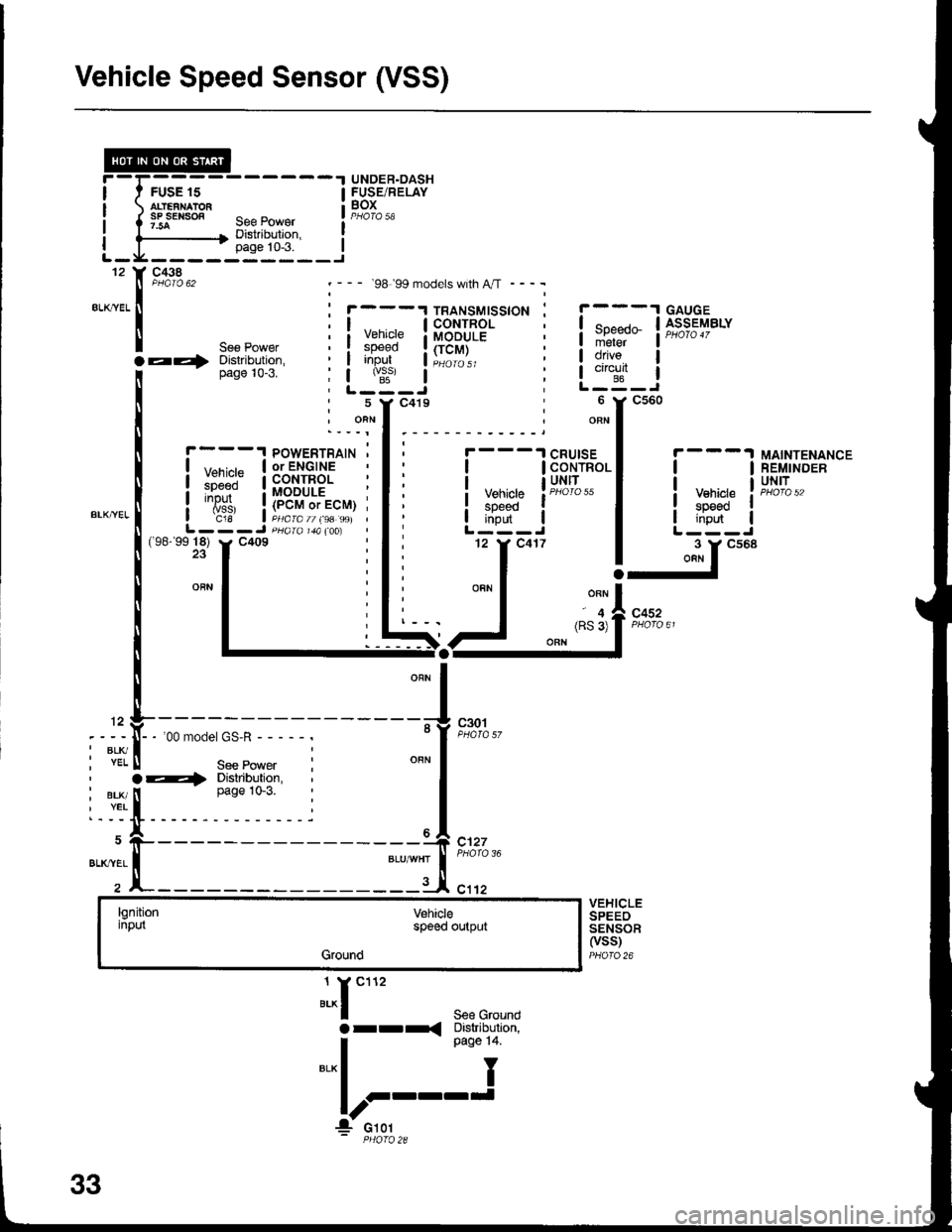

Vehicle Speed Sensor (VSS)

FUSE 15

.t UNDER.DASH

! SBiE/RELAY

'--- 98 99 models with A,rT ----

1

5

J^r""'See Groundarr< Diskibulion,

I o"o" t+

"'*l I

!r::'-'

c438

".,,::.x

POWERTRAIN '| ,,--,^,- | or ENGINEI l:li.:" a coNrRoLi ::J:" : MODULE :

i

'{is,

i!""""9;li"S, j

L---J pHaral&(oo)

ll

Vehiclespeedinput

c30t

CRUISECONTROLUNITtl

! y::g" II i,ifi- |L---J

-ir""'

MAINTENANCEREMINDERUNIT

(98-'9918) y. C409

c452

12

I BLK/. YEL

, BLK/I YEL

BLK'YEL

-'oomodel GS'R-----.

See Powera4 Distribution,

I

ease 1o-3.

x-----

l

c127

c1't2VEHICLESPEEOSENSOF(vss)PHOfO 26

lgnitioninputVehiclespoed output

Ground

33