automatic transmission HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 767 of 1681

1.

8.

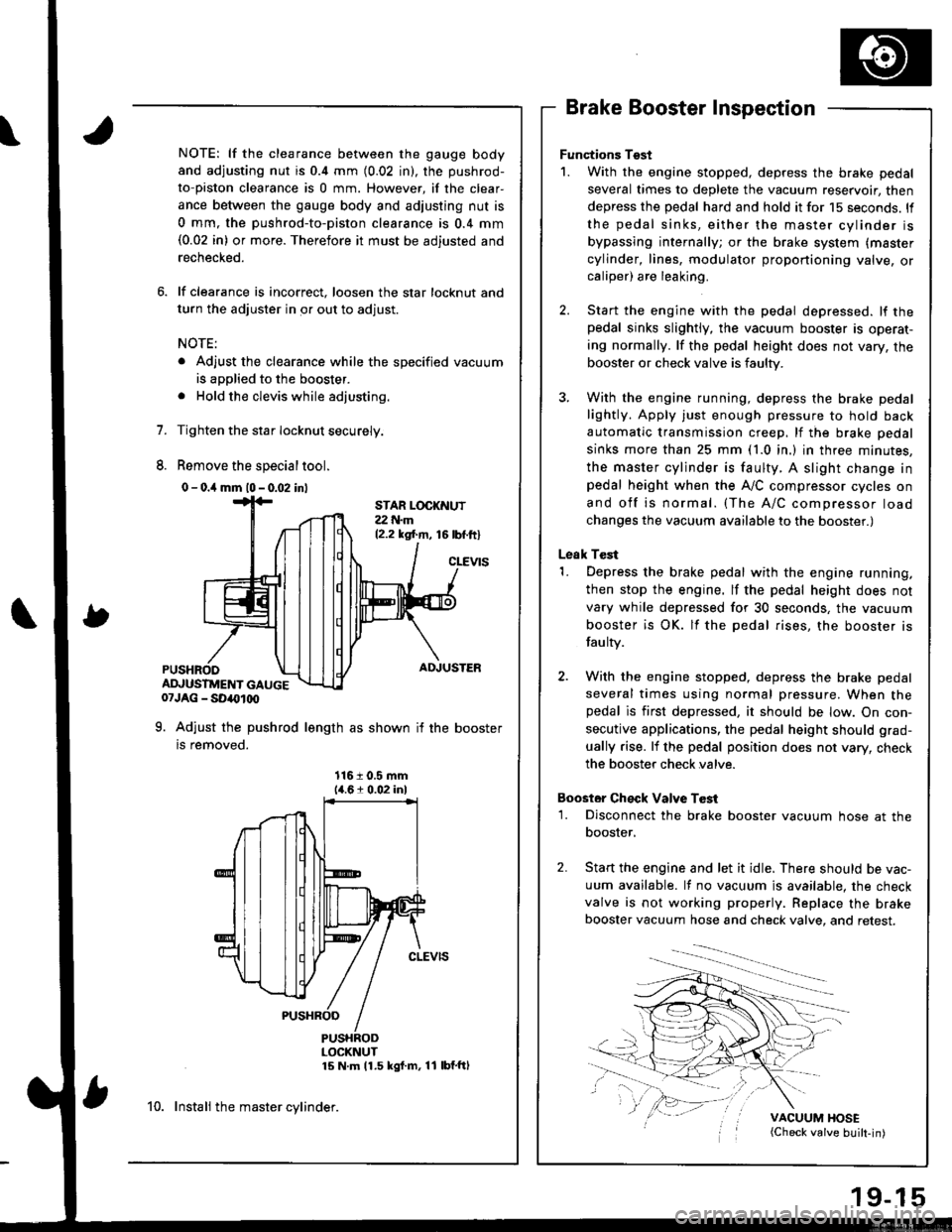

NOTE: lf the clearance between the gauge body

and adjusting nut is 0.4 mm (0.02 in), the pushrod-

to-piston clearance is 0 mm. However, if the clear-

ance between the gauge body and adjusting nut is

0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore it must be adjusted and

rechecked.

lf clearance is incorrect, loosen the star locknut and

turn the adjuster in or out to adjust.

NOTE:

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star Iocknut securely.

Remove the special tool.

0 - o.il mm l0 - 0.02 inl

Brake Booster Inspection

Functions Tgst

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. ll

the pedal sinks, either the master cylinder is

bypassing internally; or the brake system (master

cylinder, lines, modulator proportioning valve, orcaliper) are leaking.

Start the engine with the pedal depressed. lf thepedal sinks slightly, the vacuum booster is operat-

ing normally. lf the pedal height does not vary, the

booster or check valve is faulty.

With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep, lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cylinder is faulty. A slight change inpedal height when the A,,/C compressor cycles on

and off is normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises, the booster is

fau lty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When thepedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. lf the pedal position does not vary, check

the booster check valve.

Boostor Ch€ck Valve T6st

1. Disconnect the brake booster vacuum hose at the

booster,

Start the engine and let it idle. There should be vac-

uum available. It no vacuum is available. the check

valve is not working properly. Replace the brake

booster vacuum hose and check valve, and retest.

VACUUM HOSE(Check valve built-in)

STAR LOCKNUT22 t{.m12.2 ksl.m, 16lbf.ftl

cLEVtS

ADJUSTER

ADJUSTMENT GAUGE07JAG - SD40t00

9. Adjust the pushrod length as shown if the booster

is removed.

1161 0.5 mm14.61 0.02 inl

PUSHRODLOCKNUT15 N m 11.5 kgf m, 11 lbf'ftl

10. Instali the master cylinder.

Page 1053 of 1681

J

A/G Compressor Belt

Replacement

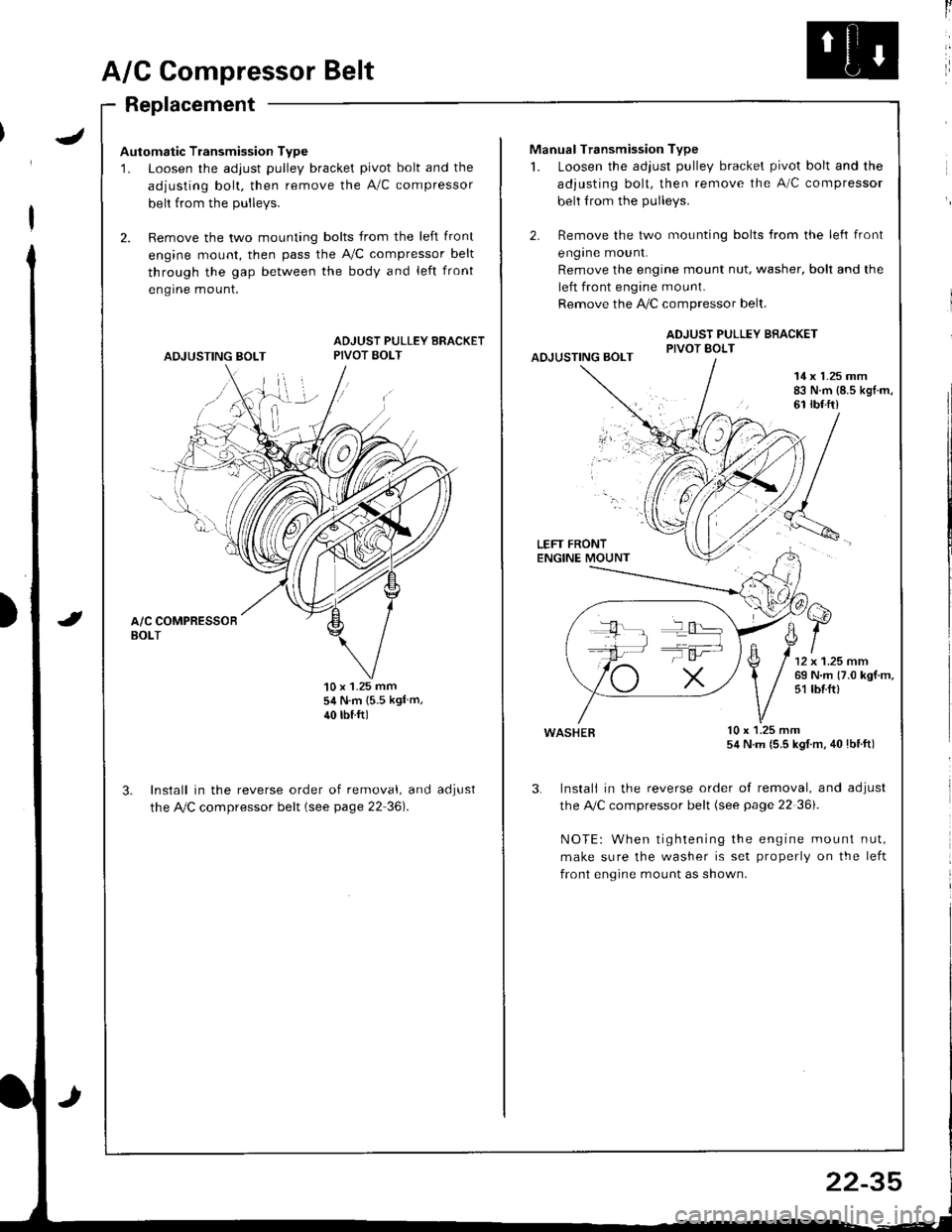

Automatic Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt. then remove the A/C compressor

belt from the Dullevs.

2. Remove the two mounting bolts from the left front

engine mount, then pass the A,/C compressor belt

through the gap between the body and left front

engrne mount.

ADJUSTING BOLT

ADJUST PULLEY BRACKETPIVOT BOLT

'10 x 1.25 mm54 N.m {5.5 kgl m,

40 rbtftl

Install in the reverse order of removal, and

the Ay'C compressor belt (see page 22 36).

aoJUsI

ll

Manual Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the pulleys.

2. Remove the two mounting bolts from the left front

engrne mount.

Remove the engine mount nut, washer, bolt and the

left front engine mount.

Remove the !i/C compressor belt.

ADJUST PULLEY BRACKETPIVOT BOLTAOJUSTING BOLT

14 x 1.25 mm83 N.m {8.5 kgl.m,61 rbf.ft)

LEFT FRONTENGINE MOUNT

wasHEB lu x l.z5 mm54 N.m (5.5 kgl m, 40lbtft)

3. Instali in the reverse order of removal, and adjust

the A,/C compressor belt (see page 22 36i.

NOTE: When tightening the engine mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

T':

22-35

Page 1135 of 1681

Starting System

Starter Test (cont'dl

Check Cranking rpmr

Engine speed during cranking should be above 1OO rpm.

lJ speed is too low, check for:

a Loose batlery or starter terminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Check Starter Disengagement:

Press the clutch pedal all the way in (M/T), turn rhe igni

tion switch to "lll" and release to "11".

The starter drive gear should disengage from the flywheel

or torque converter ring gear when you release the key.

It the drive gear hangs up on the flywheel or torque con-

verter ring gear, check for:

a Solenoid plunger and switch mallunction

a Dirty drive gear assembly or damaged overrunning

clutch

5. Check for an open in the BLK/WHT wire circuit be

tween the starter and ignition switch, and con-

necrors,

6. Check the ignition switch (see page 23-71).

7. On cars with automatic transmission, check the A/Tgear position switch (neutral position switch) and

connector. On cars with manualtransmission, check

the starter cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 42 (40 A) fuse in the under,hoodfuse/relay box for the starter cut relay.

Check Jor Wear and Damage:

The starter should crank the engine smoothly and stead,ily. lf the starter engages, but cranks the engine errati

cally, remove it. Inspect the starter, drive gear, andllywheel or torque converter ring gear lor damage.

a Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gears i{ damaged.

Check CJanking Voltage and Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than * amperes.* 1.2 kW: 27O A

1 .4 kW: 360 A

It cranking voltage is too low, or current draw too high,check for:

a Dead or low charged batterya Open circuit in starter armature commutator segmentsa Starter armalure dragging

a Shorted armature windinga Excessive drag in engine

Page 1245 of 1681

Back-up Lights

Test

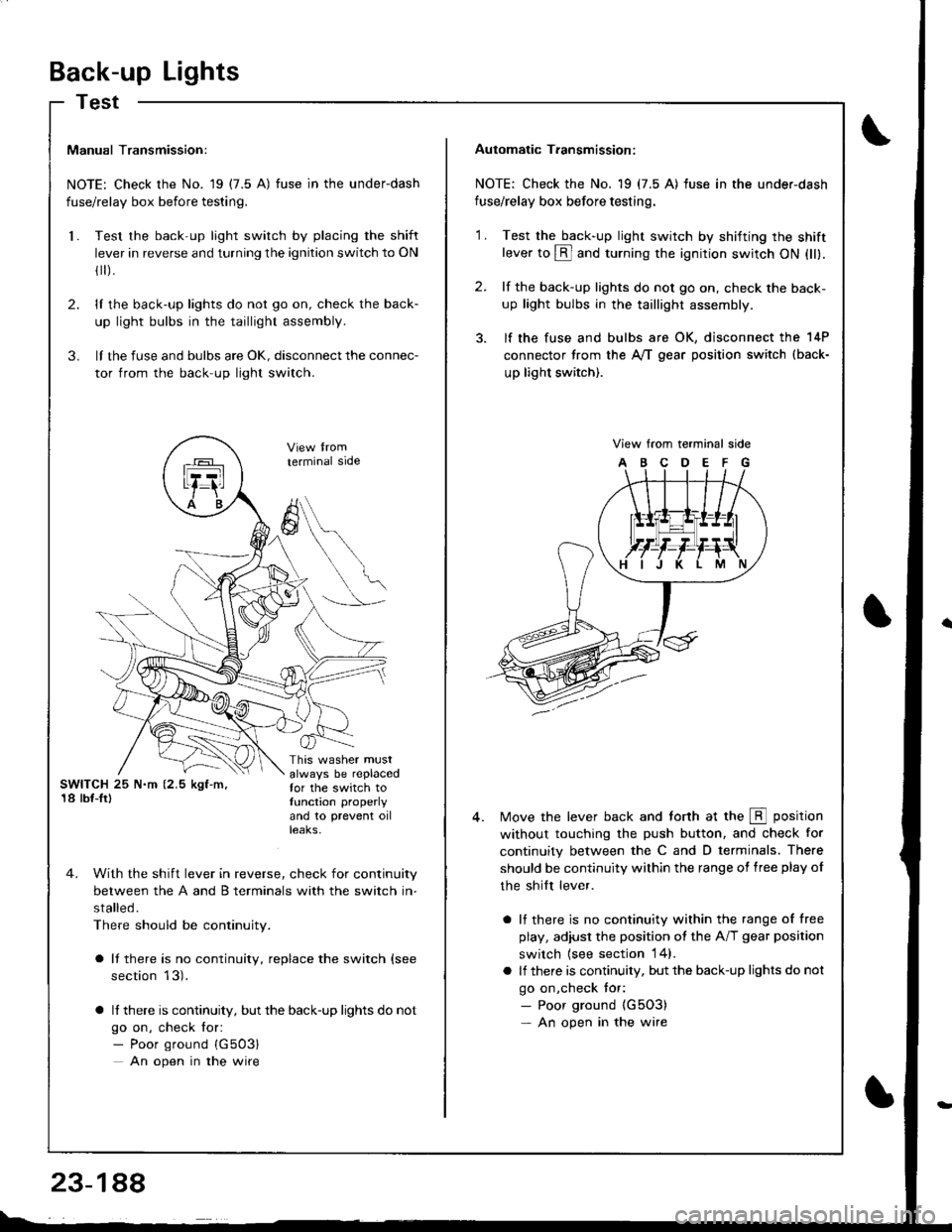

Manual Transmission:

NOTE: Check the No. 19 (7.5 A) fuse in the underdash

fuse/relay box before testing.

Test the back-up light switch by placing the shift

lever in reverse and turning the ignition switch to ON

fl r).

lI the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lI the fuse and bulbs are oK, disconnect the connec-

tor from the back-up light switch.

2.

3.

l.

SWITCH 25 N.m (2.5 kgf-m,'18 lbf-Ir)

This washer mustalways be replacedfor the switch totunction properly

and 10 prevent oilteaKs,

terminal side

4. With the shift lever in reverse, check for continuity

between the A and B terminals with the switch in-

stalled.

There should be continuity.

a It there is no continuity, replace the switch (see

section 13).

a lf there is continuity, but the back-up lights do not

go on, check for:- Poor ground {G503}

An open in the wire

A

6

Automatic T.ansmission:

NOTE: Check the No. 19 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2.

'1 .Test the back-up light swirch by shifting the shiftlever to @ and turning the ignition switch ON (ll).

lf the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lf the fuse and bulbs are OK, disconnect the 14P

connector from the A,/T gear position switch (back-

up light switch).

View from terminal side

ABCDEFG

Move the lever back and torth at the E position

without touching the push button, and check for

continuity between the C and D terminals. There

should be continuity within the range of free play of

the shilt lever.

a lf there is no continuity within the range of free

play, adiusl the position ot the A/T gear position

switch {see section 14}.

a lf there is continuity, but the back-up lights do not

go on,check tor:- Poor ground {G5O3)- An open in the wire

Page 1383 of 1681

).1

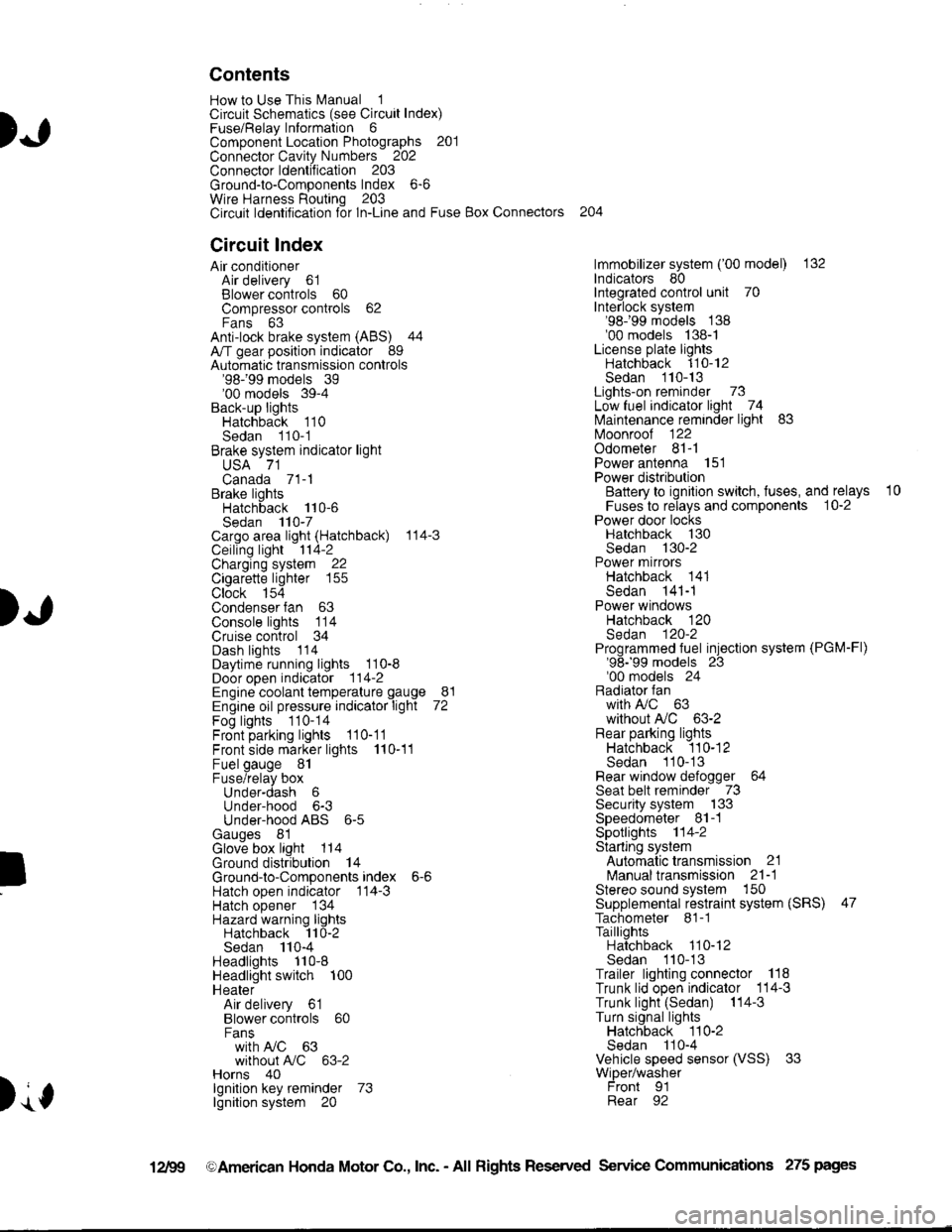

Contents

How to Use This l\.4anual 1Circuit Schematics (see Circuit Index)Fuse/Relaylnformation 6ComponentLocation Photographs 201

Connector Cavity Numbers 202Connectorldentification 203

Ground-to-Components Index 6-6Wire Harness Routing 203Circuit ldentification lor ln-Line and Fuse Box Connectors

Circuit Index

Air conditionerAir delivery 61Blower controls 60Compressor controls 62Fans 63Anti-lock brake system (ABS) 44A/T gear position indicator 89Automatic transmission controls'98199 models 39'00 models 39-4Back-up lightsHatchback 110Sedan 110- 1Brake system indicator light

USA 71Canada 71-1Brake lightsHatchback 110-6Sedan 110-7Cargo area light (Hatchback) 114-3Ceiling light 114-2Charging system 22Cigarette lighter 155

Clock 154Condenser fan 63Console lights 114Cruise control 34Dash lights 1 14Daytime running lights 110-8Door open indicator 114-2Engine coolant temperature gauge 81Engine oil pressure indicator light 72Fog lights 110-14Front parking lights 110-11Front side marker lights 110-11Fuel gauge 81Fuse/relay boxUnder-dash 6Under-hood 6-3Under-hood ABS 6-5Gauges 81Glove box light 114Ground distribution 14Ground-to-Componentsindex 6-6Hatch open indicator '114-3

Hatch opener '134

Hazard warning lightsHatchback 'l l0-2Sedan 110-4Headlights 1'10-8Headlight switch 100HeaterAir delivery 61Blower controls 60Fanswith A,/C 63without A,/C 63-2Horns 40lgnilion key reminder 73lgnition system 20

204

lmmobilizer system ('00 model) 132lndicators 80Integrated control unit 70Interlock system'98199 models 138'00 models 138-1License plate lightsHatchback 110-12Sedan 110-13Lights-on reminder 73Low fuel indicator light 74l\,4aintenance reminder light 83l\iloonroof 122Odometer 81-1Power antenna 151Power distributionBattery to ignilion switch, fuses, and relays

Fuses to relays and components 10-2Power door locksHatchback '130

Sedan 130-2Power mirrorsHatchback 141Sedan 141-1Power windowsHatchback 120Sedan 120-2Programmed fuel injection system (PGM-Fl)'98199 models 23'00 models 24Radiator fanwith tuC 63without A,/C 63-2Rear parking lightsHatchback 110-12Sedan 110- 13Rear window defogger 64Seat belt reminder 73Security system 133Speedometer Il-1Spotlights 114-2Starting syslemAutomalictransmission 21l\.4anualtransmission 21-1Stereo sound system 150Supplemental restraint system (SRS) 47Tachometer 81- 1TaillightsHatchback 110-12Sedan 110-13Trailer lighting conneclor 118Trunk lid open indicator 114-3Trunk light (Sedan) 114-3Turn signal lightsHatchback 110-2Sedan 110-4Vehicle speed sensor (VSS) 33Wiper/washerFront 91Rear 92

10

).1

I

Xr

12Fg oAmerican Honda Motor Co., Inc. - All Rights Reserved Service Communications 275 pages

Page 1387 of 1681

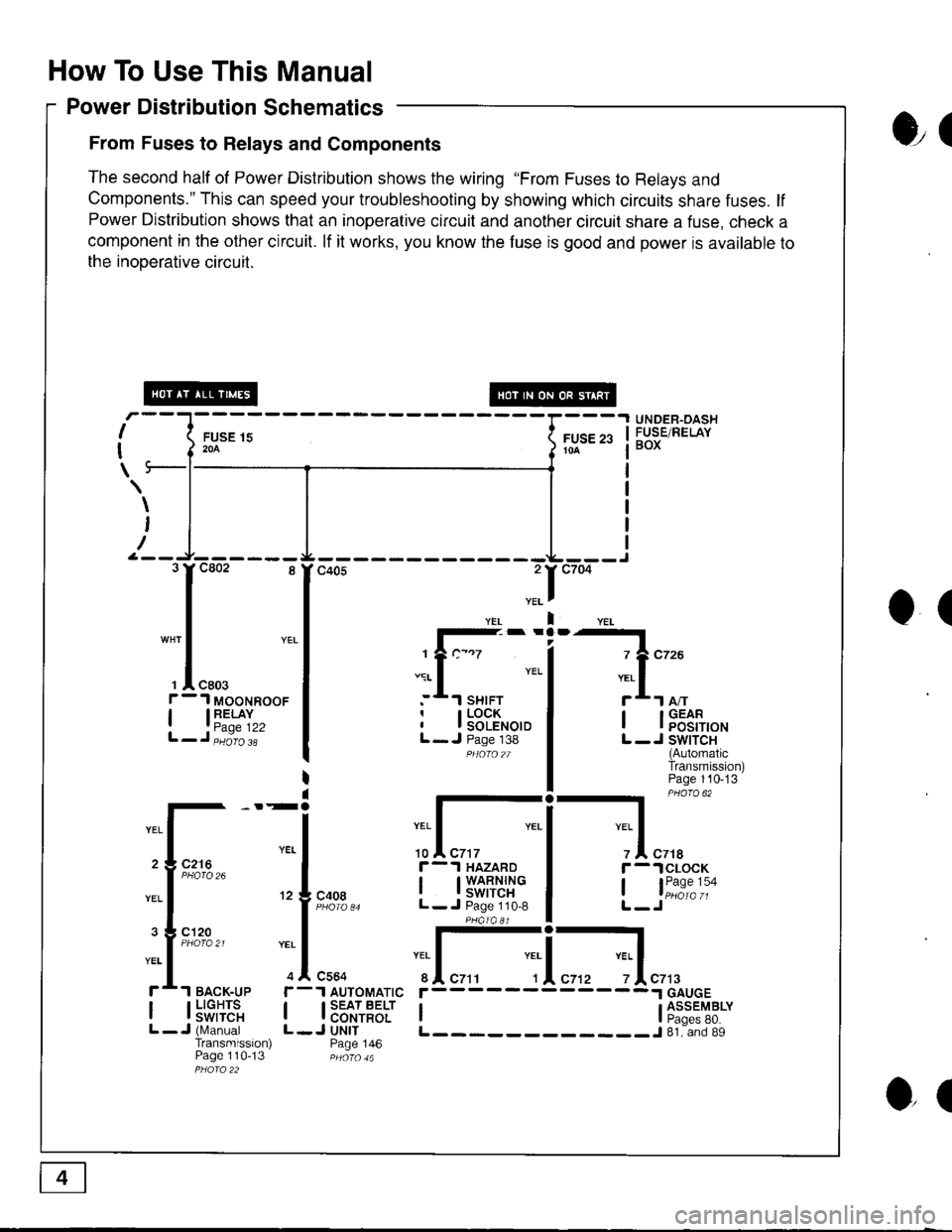

How To Use This Manual

Power Distribution Schematics

From Fuses to Relays and Components

The second half of Power Distribution shows the wiring "From Fuses to Relays and

Components." This can speed your troubleshooting by showing which circuits share fuses. lf

Power Distribution shows that an inoperative circuit and another circuit share a fuse, check a

component in the other circuit. lf it works, you know the fuse is good and power is available to

the inooerative circuil.

ol

I

I

\

FUSE 15204

UNDER-OASHFUSE/RELAYBOXFUSE 2310A

\

I

/

O(

.II

l-- -

1?c-.7

.:r- I YEL

:*.l sHrFTr I LOCKI I SOLENOIDL- J Page 138PHOfO2T

I lFEt[,o'

L -J SWITCH(AutomaticTransmission)Page 110-13

-l PHaro 62

IYEL Iz I czrar -.lclocK

, l"i1:"':oL-Jc408

r-.l HAZARD

I t3'�S[t''i"L- J Page 110,8

:I-c564

1 AUTOMATIC

I SEAT BELTI CONTROLJ UNITPage 146

YEI

r

IL

c7t3

I l5"f,TE'"L -J (N,4anualTransmission)Page 110-13

r------

I ti:*'"T8*L____________J 81. and 89

3rc802 8

I

"* | YEL

I

', I "ro.f - 1 MooNRooF

| 13"'^TI",L-J,iiio'i'

2 3 C216

3 g cl20

ol

Page 1431 of 1681

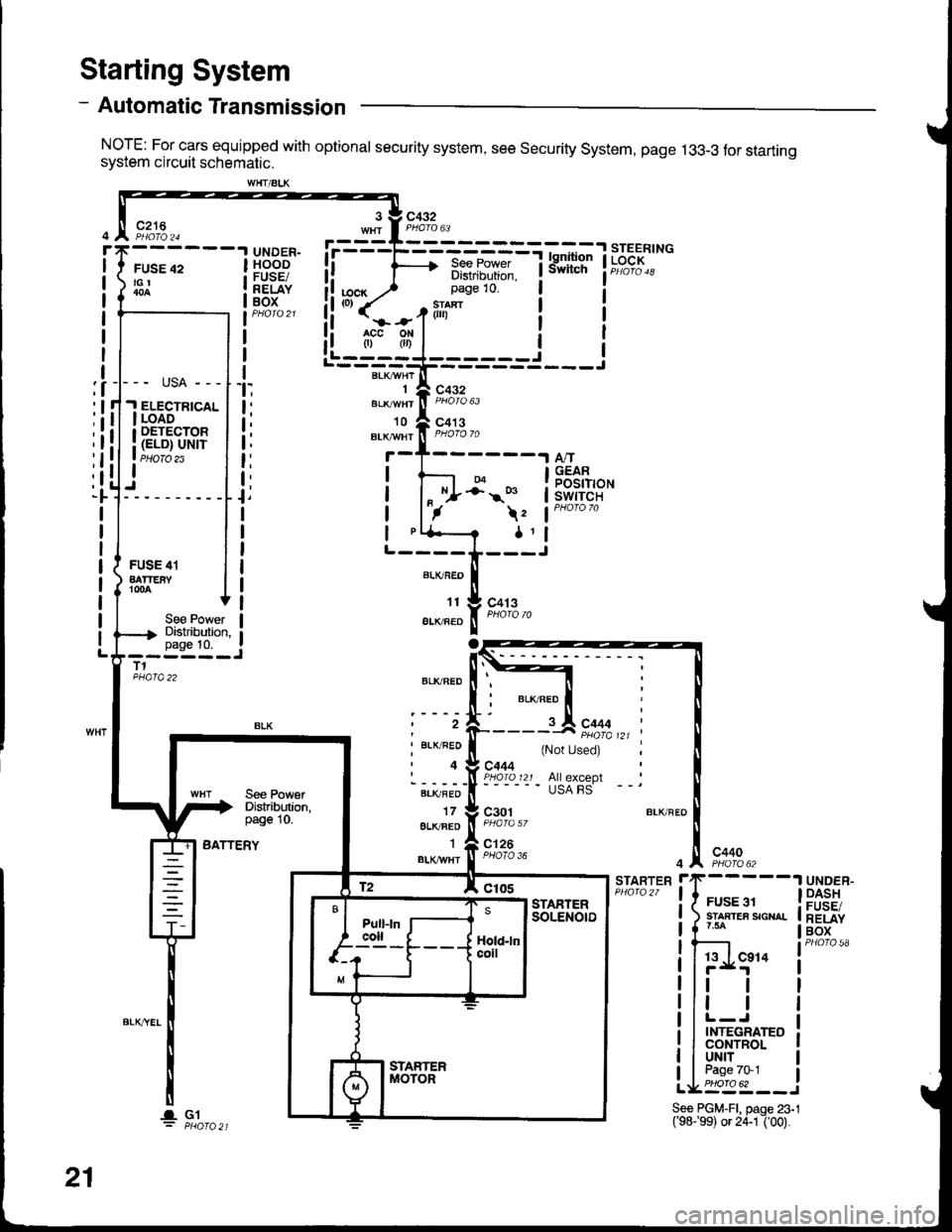

- Automatic Transmission

NorE: For cars equipped with optional security system, see security system, page 13g-3 tor startrngsystem circuit schematic.

Starting System

c216

FUSE 42tGt

UNDER-HOODFUSE/RELAYBOX

See PowerDistributian,page 10.

liu.) 3:i:it1-i*!

i!'''{=o1ili"' i i!i (=r.f(',ii i I

!i rfi,l.l i I

!L----J------j Ir'---BLK;HrT---------=---r

".o"rnrfi F,i% u.,

'to A co' s

3 V C432

BLr!,Y/Ht ll PHoro 70

04-;' s

\z

1l

t:

t,

t;

t:

t:

t,N^/.

A,/TGEARPOSITIONswtTcH

ALKFEO

't1

EIIVRED

BLKFED

t2

I BLK/RED

'4

BLI(FED

178LK/BEO'I

BLKII/HT

FUSE 41BATTEiYr00A

To

c413

See PowetDistribution,page 10.--i--;-JT1

BATTERY

c444

{Not Used)

All exceplUSA FS

c301

c126PHOTO 36c4404 ^, PHO|O 62

STARTERrrF-----1

! i rur..r !| snnrea sour- || 1 '* |

! Ir-'Lg"' i

llttl

llr | |

llL-J Ir I INTEGRATEo I! I CONTROL I

I luNrr I

tIbEt:_J

UNDER-DASHFUSE/RELAYBOX

WHT/ALK

--- usA ---

.I ELECTBTCALI LOADI DETECTOR

i (ELD) uNrr. PHOIO 23I

21

lGlSee PGM-FI, paqe 23.1('98.'99) or 24-1I OO).

Page 1457 of 1681

Cruise Control (cont'd)

- How the Circuit Works

The cruise control system uses mechanical and

electrical devices to maintain the car's soeed at a

setting selected by the driver.

System Description

The cruise control unit receives command signals

from the cruise control main switch and the cruise

control SevBesume switch. With the ignition switch

in ON (ll) or START (lll), voltage is provided to the

cruise control main switch. When you push the

switch to on, power is provided to the cruise control

unit and the brake switch.

The cruise control unit receives information about

operating conditions from the brake switch, the

ignition control module (lCM), the vehicle speed

sensor (VSS), and the clutch switch (manual

transmission) or the A,/T gear positton switch

(automatic transmission). The cruise control unit

then sends signals to the cruise conirol actuator

which regulates the throttle position to maintain the

selected speed. The control unit compares the

aclual speed of the car to the selected speed. The

control unit then uses the result of that comoarison

to oDen or close the throttle.

The brake switch releases the system's control of

the throttle at the instant you press on the brakepedal. The switch sends a signal to the control unit

by removing power from the normally closed brake

input (GRY wire), and providing power at the

normally open brake input (GRNMHT wire). The

control unit responds by allowing the throttle to

close. The clutch switch or the A/T gear position

switch sends a "disengage" signal to the control unit

that also allows the throttle to close.

The cruise control system will set and automatically

maintain any speed above 25 mph (40 km/h). To set

it, make sure the main switch is on and the switch

indicator is on. Then, after reaching the desired

speed, press the set switch. This sends a "set"

signal to the cruise control unit which, in turn,

controls the cruise control actuator to maintain the

set soeed.

When you push the SET switch and the cruise

control system is on, the "cruise control" ON

indicator lights up.

34-4

You can cancel the cruise control system by

turning the main switch off. This removes power to

the control unit and erases the set sDeed from

memory. lf the system is disengaged temporarily

by the brake switch, or clutch switch, and the car's

speed is still above 25 mph, press the RESUME

switch: the car will automatically return to the

previously set speed.

For gradual acceleration without pressing the

accelerator pedal, push the RESUME switch and

hold it there. This will send an "acceleration" signal

to the control unit. When you release the switch, the

system will be reprogrammed tor the new speed. To

slow the car down, push the SET switch in and hold

it there. This sends a "deceleration" signal to the

control unit, causing the car to coast. When the

desired speed is reached, release the SET switch.

This reprograms the system for the new speed.

Reter to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

Page 1458 of 1681

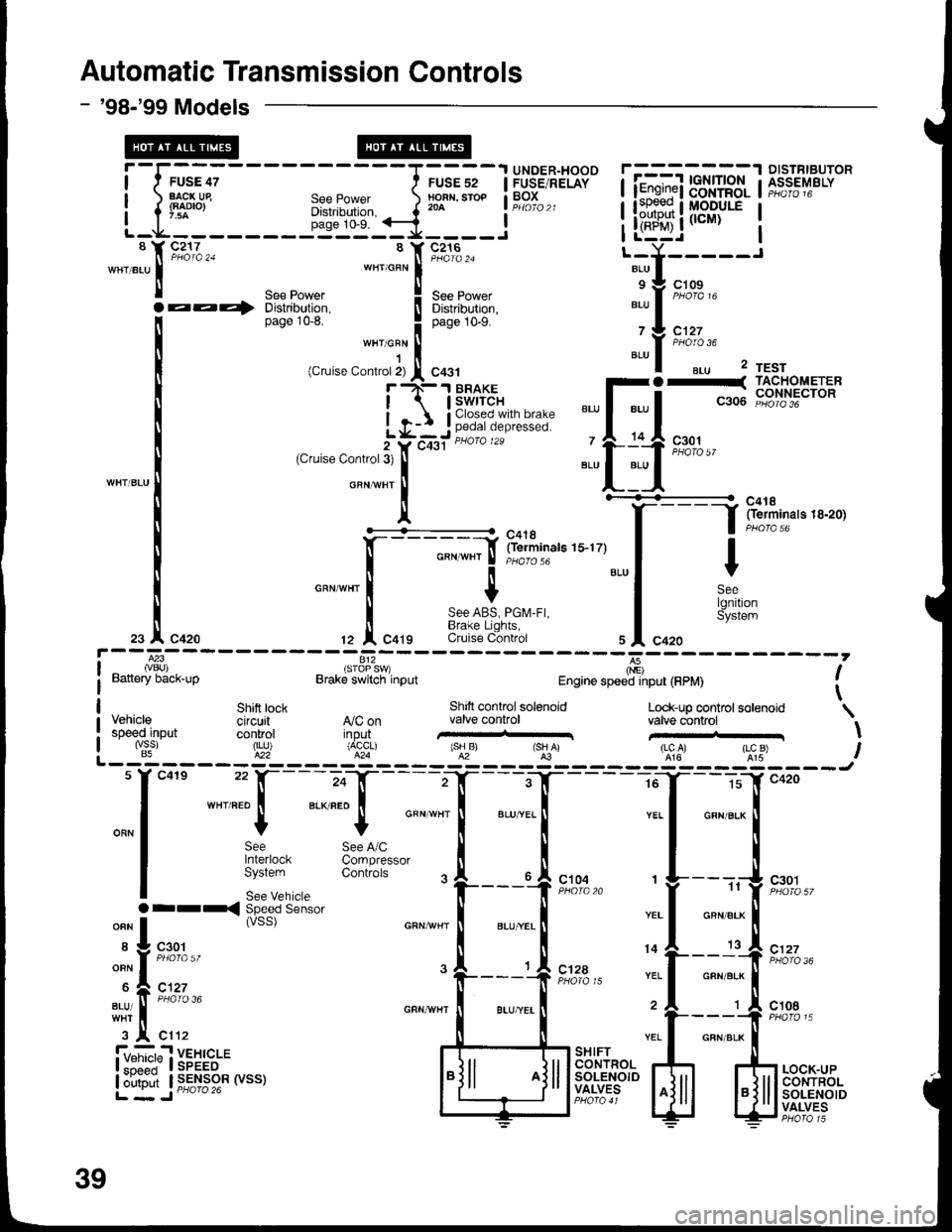

Automatic Transmission Controls

- '98-'99 Models

-I,;;;

EACK Ue

-l'::-

FUSE 52NOFN, STOP204

UNDER-HOODFUSE/RELAYBOXSee PowerDistribution,page 10-9.

isToP s

v)Brake switch input

8c217

aa+

I Y C216ll PHaTa 24wHrcFN iSee Power ! See power

Distribution. I Distributron,page 1G8. I OuO" tO-S.

""t o:"

I(Cruise Contror 2) I C431

r rN-.t BRAKE

I | swrrcH

L q-: j ;,,?i,i?'Y,i *i,i:5"

2Ycqst "u'o '*

(Cfuise Control3t

IGFNvHT

Il'+^..6'f- - - --_- -

:f irlliin"r" r s-r zy

I

GFN wHr I 'r'oro'o

cnrwnr I t

i 8:i^i?i,i":"tZ I Cqtg Cruise C-ontrol

] fii1f,,",.,..,,

Y

SeelgnitionSystem

l---83ivBU)Battery back-up

812',

I(nE)Engine speed input (FPM)

Shitt tock Shift controlsotenoid Look_up coo.trol solenoid \VehiCle Cifcuit A,/C on valve control valve controlspeed-input control ilp"ui' ,-'H...,.,,,,..r \"&. ,j5? ,X%""r' ,"lru' rsHAr 'lgl' ,l:"u) IL _ iq - _ _ _ _ E?_ _ _ _ g'_ _ _ _ 5i _ _ _E: _ _ _ _ _ !t- _ _ _:&: _ _ _ - _tu

f

"0"

-",:: [-;"f

-

"- "T-. -T----=T--_5

"-'

*"

I p*t ^", 3rl**.,*""

-"'

il

-'-..

|

-.

|

"* *^

|

| $:'"::""

33n:Ji.'*' .

|___{ r*,," ,

f----,{ r*:,,

.ri-,-:-

ssc"ds"n'o.

"""**

|

*,"*! ""1 o"n"'* |

*f n';,, . L__J

" [--:'] ,';7..

-.: t "';%,.

-i,.!..,,, ""^"-l'-;;{t**' j:l#r-

iyi,:?n$i,:*""" ffiBB'rI"o."L*.."'.i-ii.*'ji"[!si"""' ,,_r_,"'liiif+:rm U;1f$+f,

:[ilrF""#**F.tr

39

Page 1460 of 1681

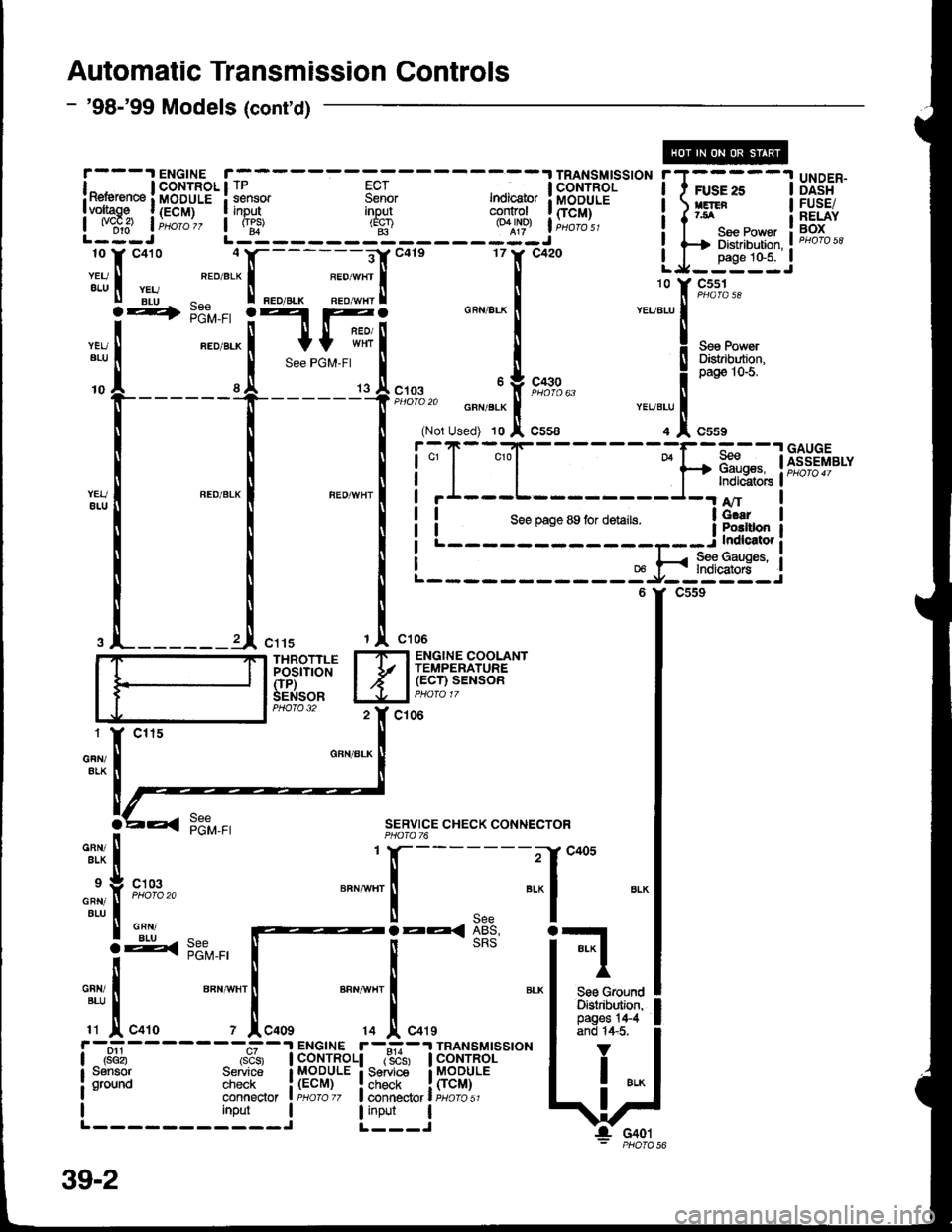

Automatic Transmission Controls

- '98-'99 Models (cont'd)

YEUatu

-ry

UNDER-DASHFUSE/RELAYBOX

SERVICE CHECK CONNECTOR

1l[----- -i-f c+os

"""t"'

I see

-^

|.EE< ABS,

i-1

Ti:

t':,;"'1...,

*";'1".,,

- sRS

""1

#t*r-^:----- ENGTNE r--:-I TRANSM|SS|ON I rI r*ib rsis, I coNTRoLl r"sb'sr I coNTRoL I i

fl i$yjHlr'!;f#n",!ffiii:' \i- !- G401- PHOTO 56

r)J-1

i*J itTffe.- ir:";-

- - - -

s:I-

- - - -

;;; I HffilEr''". i T r.s:;

- -

II voliage l{ECM) | input

I w,?- | i.o, o,, L :t - - - - - jrfl - - - - - Si

j hfiY:t'

".

i 1-%** i

l_: f, "o'oror c410 4tr-------E[c4ts 17tr' c420 LJ__HSIJ

:ii t Hb ^f'""'* ! "."".* :;;! !

';l "lz*"

-

-[ ;;

"*i*'*i[Try[",".

""."]1,**^ "'""'"!

*u*u''o

ft_ _ _____+___ _ _'lfi g;to,..,. o"n,"J, f t",",,