fuel pump HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 327 of 1681

rr*

Fuel Supply System

Fuel Filter

Replacement

Do not smoke while working on fuel system. Koop

open flame away from your work atea.

While replacing the fuel filter, be qaretul to keep a

sate distanco between battery terminals and any

tools.

The fuel filter should be replaced whenever the fuel

pressure drops below the specified value I27o - 32O kPa,

2.8 - 3.3 kgf/cm', 40 - 47 psi (B18C'1, B l8C5 enginesi 320- 370 kPa (3.3 - 3.8 kgtcm'�,47 - 54 psi) with the fuel

pressure regulator vacuum hose disconnected and

pinchedl aiter making sure that the tuel pump and the

fuel pressure regulator are OK.

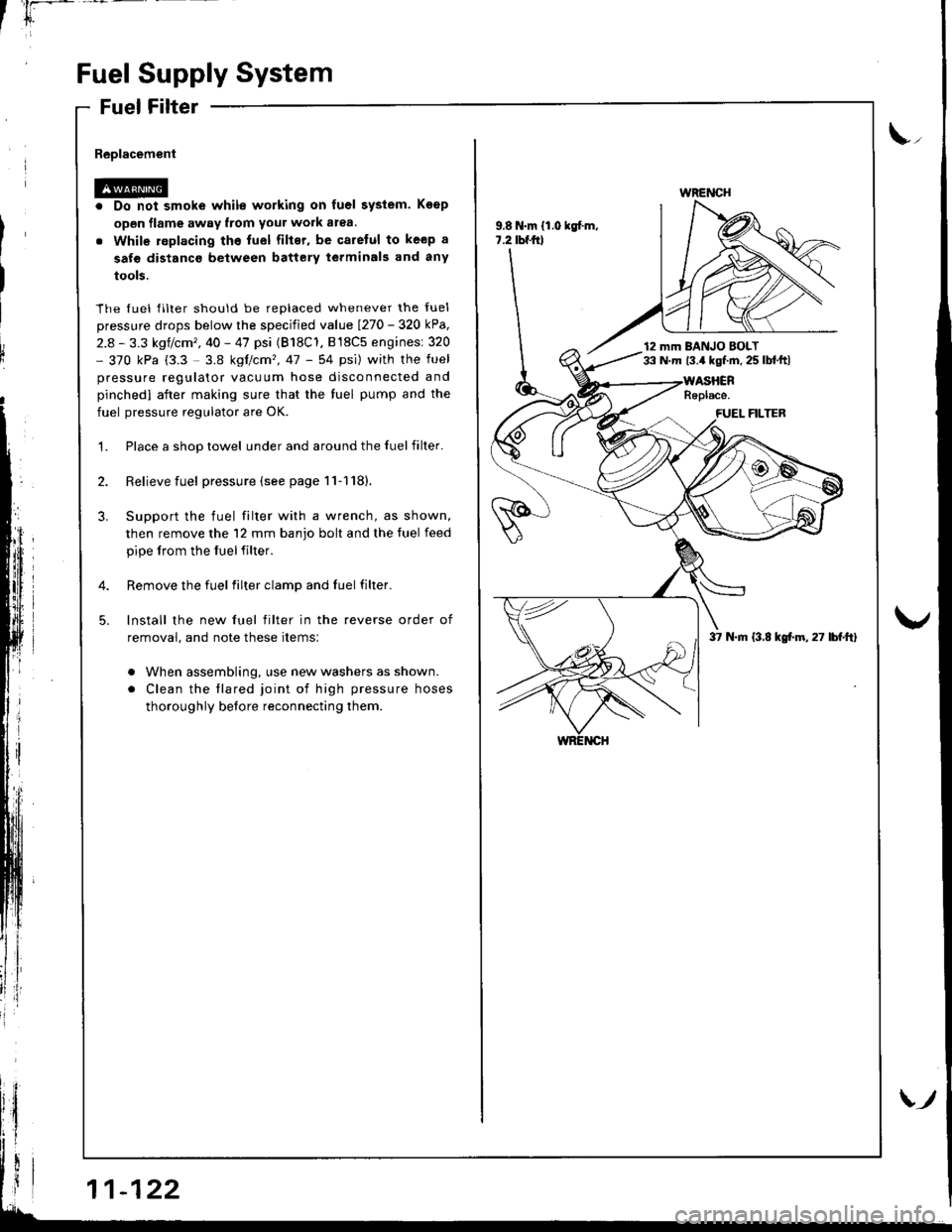

Place a shop towel under and around the fuelfilter.

Relieve fuel pressure {see page 11-1'18}.

Support the fuel filter with a wrench, as shown,

then remove the 12 mm banjo bolt and the tuel feed

pipe lrom the fuelfilter.

Remove the fuel filter clamp and fuel filter.

lnstall the new fuel filter in the reverse order of

removal, and note these items:

. When assembling, use new washers as shown.

. Clean the tlared joint of high pressure hoses

thoroughly before reconnecting them.

\,,

9.8 N.m {1.0 kgf.m,7.2 tbf.frl

WRENCH

12 mm BANJO BOLT33 N.m 13.4 kgf.m. 25 lbl.ftl

37 N.m (3.8 kgf.m,27 lbf.ft)

Page 328 of 1681

'*

1i

v3

I

l

i

I

1.

Testing

!@ Do not smoke during tho t€st. Keep open

flame away from your work area.

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is ON, you will hear

some noise it you hold your ear to the fuel fill pon with

the fuel fill cap removed. The fuel pump should run for

two seconds, when ignition switch is first turned on. lf

the fuel pump does not make noise, check as followsl

Remove the rear seat (see section 20).

Remove the access panel.

Disconnect the 2P connector from the tuel pump.

CAUTION: Be sure to turn the ignition switch OFF

before disconnecting the wires,

Connect the PGM-Fl main relay 7P connector termi-

nals No. 4 and No. 5 with a jumper wire.

PGM-FI MAIN RELAY CONNECTOR {C,14:}l

2.

3.

4.

5.

FUEL PUMP

{YEL/GRNI

IGN, 1

IYEL/GRN)

JUMPER WIRE

Wire side of female terminals

Check that battery voltage is available between the

fuel unit sub-harness connector terminal No. 2 and

body ground when the ignition switch is turned ON(

).

Wire side of female terminals

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK. replace the

fuel pump.

lf there is no voltage, check the wire harness (see

page 11'125).

FUEL PUMPCoNNECTOR 1C510)

L]l

lrl-r

6l FUEL PUMP

\:/ (YEL/GRNI

4.

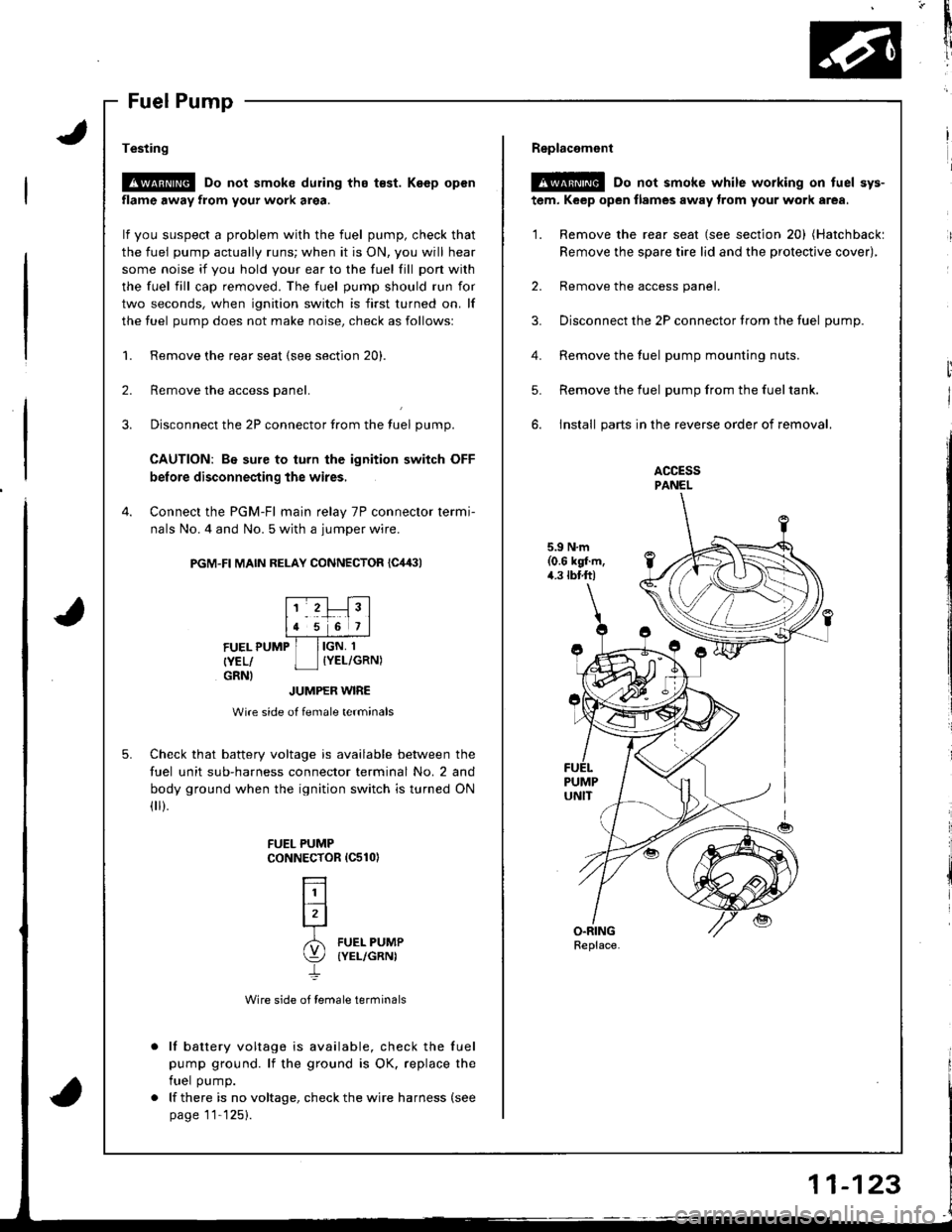

Replacemont

@ Do not smoke while working on tuel sys-

tem, Keep open flames away trom your work area.

'1. Remove the rear seat (see section 20) (Hatchbackl

Remove the spare tire lid and the protective cover),

2. Remove the access panel.

3. Disconnect the 2P connector trom the fuel oumD.

Remove the fuel pump mounting nuts.

Remove the fuel pump from the fueltank.

install parts in the reverse order of removal.

ACCESSPANEL

5.9 N.m(0.6 kgl.m,4.3 tbtft)

5.

Replace.

Page 329 of 1681

1L

i

!i

!

{

Fuel Supply System

PGM-Fl Main Relay

Description

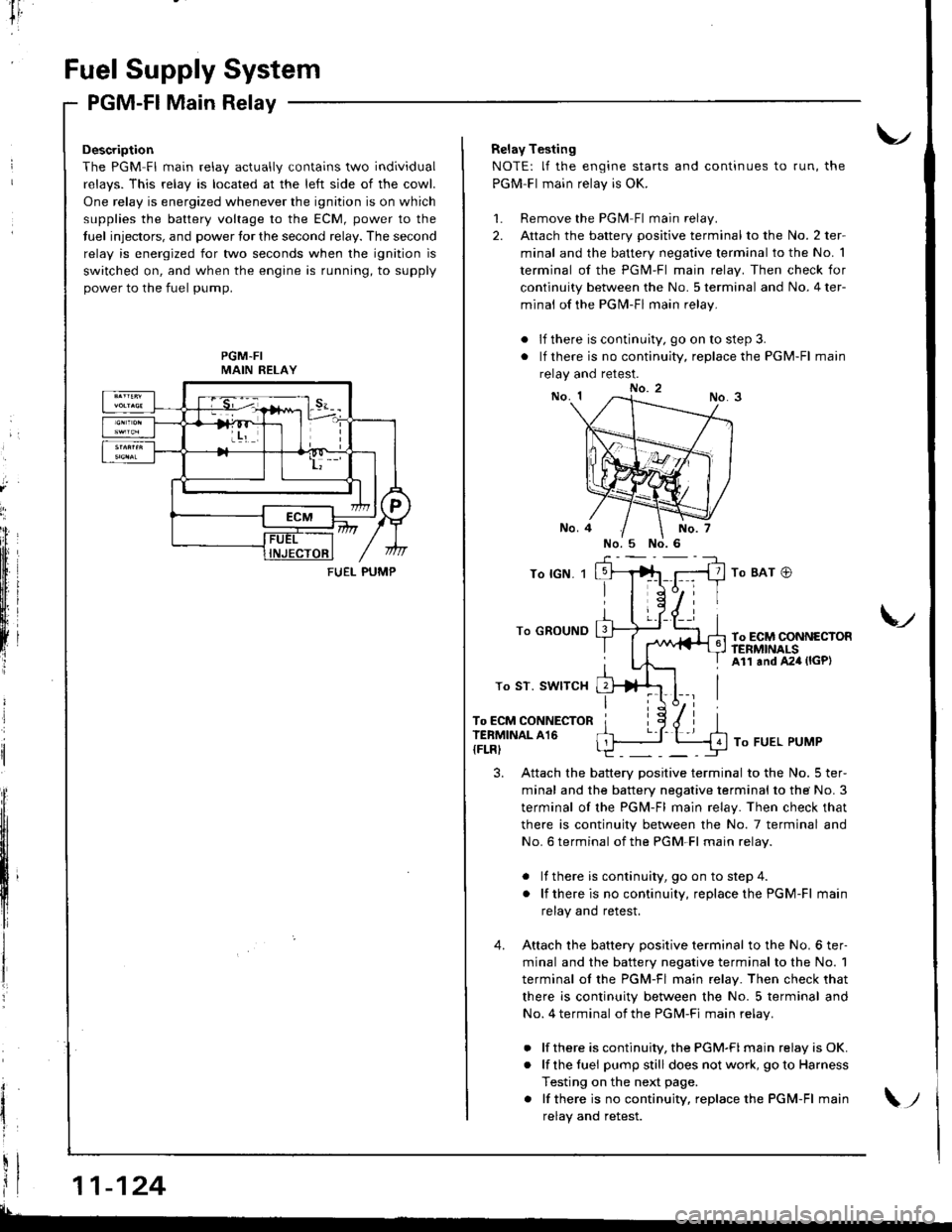

The PGM Fl main relav actuallv contains two individual

relavs. This relav is located at the left side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

tuel injectors, and power tor the second relay. The second

relay is energized for two seconds when the ignition is

switched on, and when the engine is running, to supply

power to the fuel pump.

PGM-FIMAIN RELAY

11-124

FUEI- PUMP

Relay Testing

NOTE: lf the engine starts and continues to run, the

PGM-Fl main relay is OK.

1. Remove the PGlvl Fl main relay.

2. Attach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGN4-Fl main relay.

. lf there is continuity, go on to step 3.

. lf there is no continuity, replace the PGM-Fl main

relay and retest.

To lGN. 1

To GROUND

To ST. SWITCH

To ECM CONNECTORTERMINAL A16

{FLRI

To BAT @

To ECM CONNECTORftNMNALSAll and A24 (lGP)

V

To FUEL PUMP

3. Attach the battery positive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

terminal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-Fl main relav.

. lf there is continuity, goon tostep4.

. lf thereis nocontinuity, replacethe PGM-Fl main

relay and retest.

4. Attach the batterv oositive terminal to the No. 6 ter-

minal and the battery negative terminal to the No. 1

terminal ol the PGM-Fl main relay. Then check that

there is continuity between the No. 5 terminal and

No. 4 terminal of the PGM-Fi main relav.

. lf there is continuity, the PGM-FI main relay is OK.

. lf the fuei pumpstill does not work, goto Harness

Testing on the next page.

. lf thereis nocontinuity, replacethe PGM-Fl main

relav and retest.\;

Page 330 of 1681

I

tr,

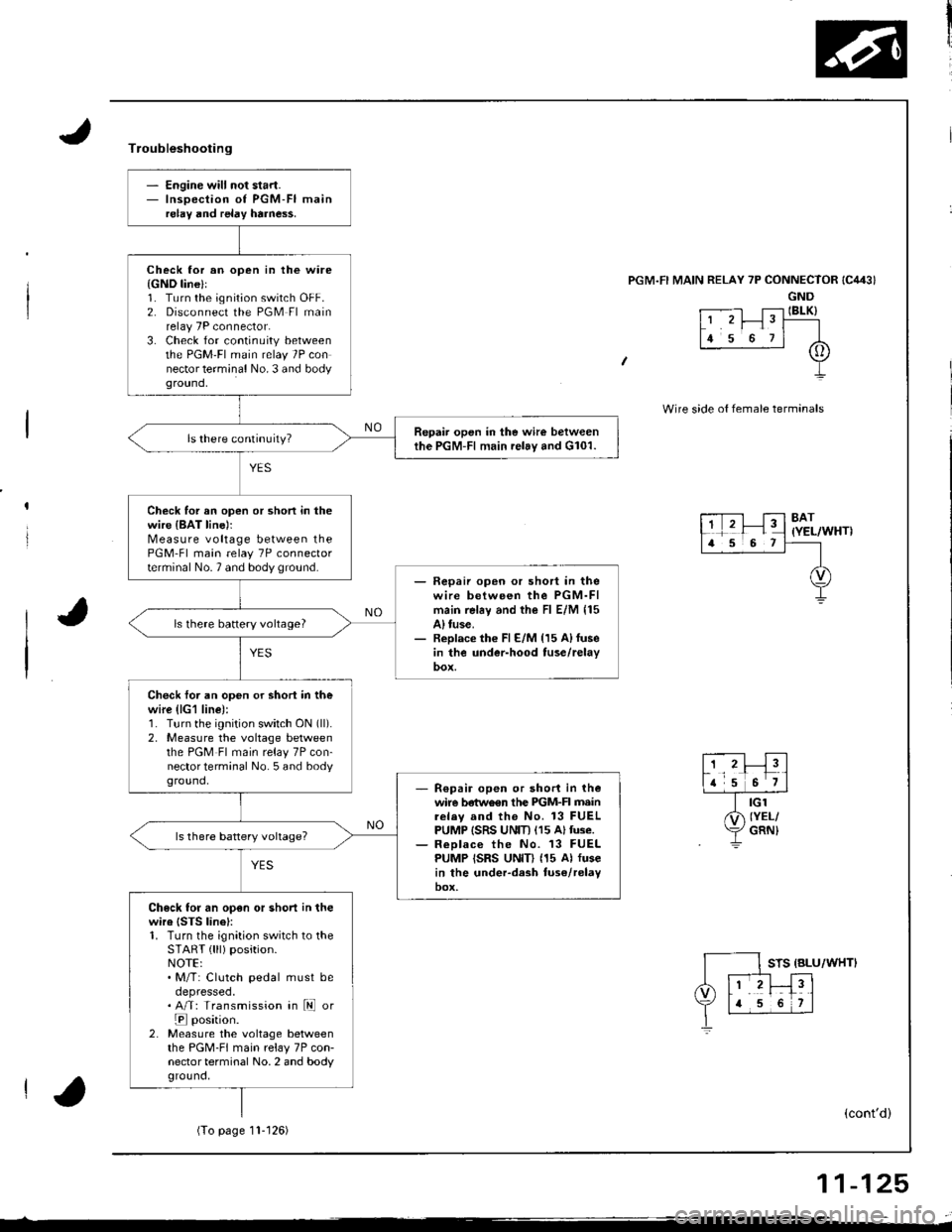

- Engine will not start.- Inspection of PGM-FI mainrelay and relay harne$.

Check lor an open in the ware{GND line}l1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P connector terminal No. 3 and bodyground,

Repair open in the wire betweenthe PGM-Fl main relay and G101.

Check for an open or shon in thewire {BAT line)rMeasure voltage between thePGM-Fl main relay 7P connectorterminal No.7 and body ground.- Fepaii open or short in thewire between the PGM-FImain rel6y and the Fl E/M 115A) tuse.- Replace th€ Fl E/M {15 A)fusein the under-hood tuse/relay

ls there battery vohage?

Check foi an open or shori in thewire (lG1 line):1. Turn the ignition switch ON (ll).

2, Measure the voltage betweenthe PGM Fl main relay 7P con-nector terminal No. 5 and bodyground,R€pair open or short in thewire betwo€n the PIGM-FI mainrelav and the No. 13 FUELPUMP ISRS UNIT) (15 Altuse.ReDlace the No. 13 FUELPUMP ISRS UNID (15 Al fusein the under-dash tuse/relayoox,

Check for an open or short in thewire {STS linel:1. Turn the ignition switch to theSTART { lll) position.NOTE:. M/T: Clutch pedal must beoepresseo.. A/T: Transmission in ld or

E position.2. Measure the voltage betweenthe PGM-FI main relay 7P con-nector terminal No. 2 and bodyground,

Troubleshooting

'l RELAY 7P CONNECTOR

GND

t .--.-l T;-l IBLK)L' 'r I" T----

lr s o rl A

+

Wire side o{ female termanals

8AT(YEL/WHT)

STS {BLU/WHTI

(cont'd)

(To page11- t 26)

11-125

Page 351 of 1681

Il

1l

Iil

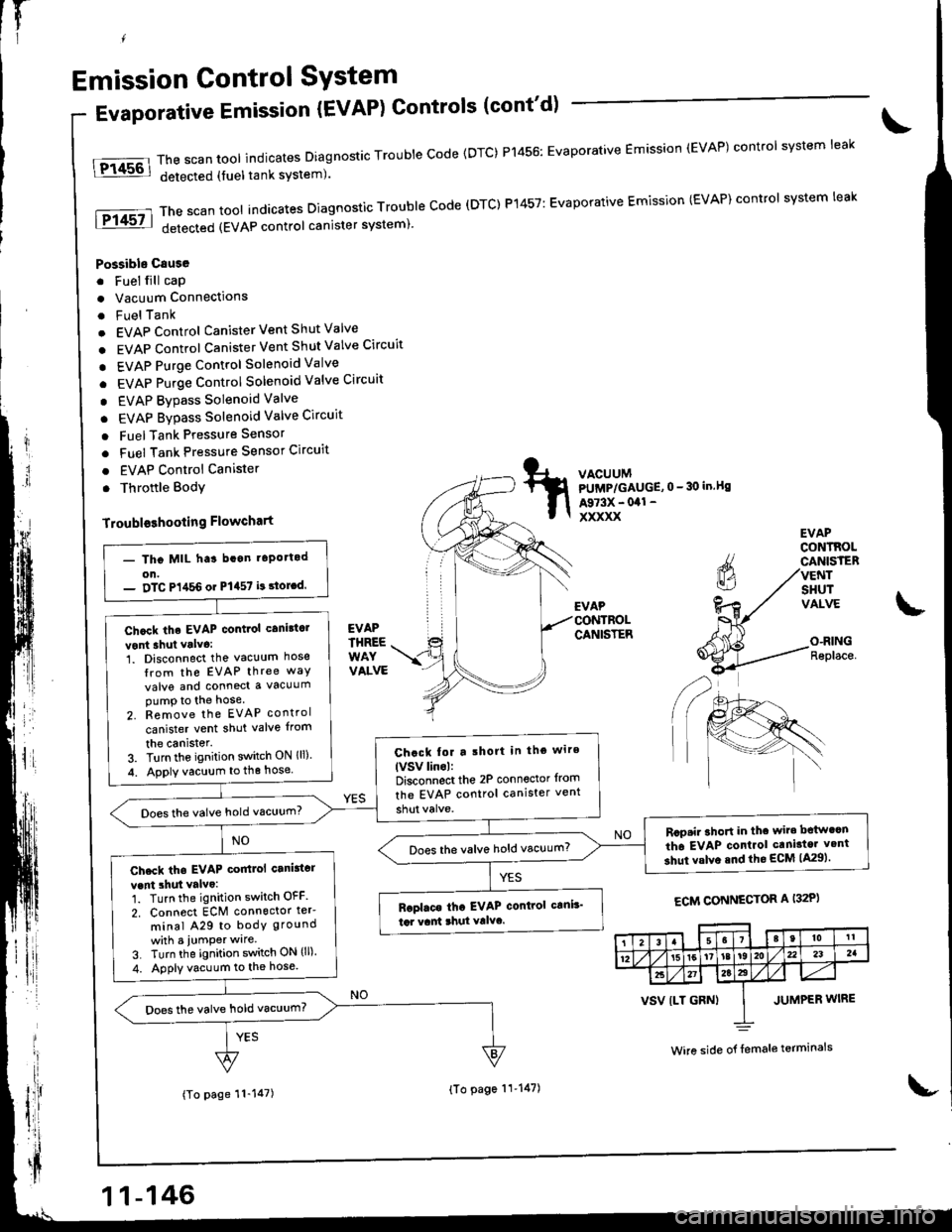

Emission Control SYstem

EVAPrHREEWAYVALVE

tFi4s6l

fPf 45? I

Evaporative Emission {EVAP) Controls (cont'd)

Possible Csuse

. Fuel fill cap

. Vacuum Connections

. FuelTank

. EVAP Control Canister Vent Shut Valve

. EVAP Control Canister Vent Shut Valve Circuit

. EVAP Purge control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Bypass Solenoid Valve

. EVAP Bypass Solenoid Valve Circuit

o FuelTank Pressure Sensor

. Fuel Tank Pressure Sensor Circuit

. EVAP Control Canister

. Throftle Body

Troubloshooling Flowchart

The scan tool indicates Diagnostic Trouble Code {DTC) P1456: Evaporative Emission (EVAP) control system leak

detected (fuel tank system).

ThescantoolindicatesDiagnosticTroubleCode(DTC)P't457:EvaporativeEmission(EVAP)controlsystemleak

detected (EVAP control canister system)'

VACUUMPUMP/GAUGE,0 - 30 in.Bs

A973X - 041 -

xxxxx

EVAP

CANISTER

EVAPCONTROLCANISTERVENTSHUTVALVE

O-RINGReplace.

ECM CONNECTOR A I32P)

(To page 11-147)

- Tho MIL ha3 bcan t6po.tod

on.- DTC P1,t56 or P1457 i! 3toLd.

Chcck the EVAP contiol canittc.

vont shut valva:1. Disconnect the vacuum hose

Irom the EVAP three way

valve and conned a vacuumpump to the hose

2. Remove the EVAP control

canister vent shut valve {rom

the canister.3. Turn the ignition switch ON lll)

4. Apply vacuum to the hose

Chack tor a lhort in tho wire

lVSv linol:Disconnect the 2P conn€ctor from

the EVAP control canister vent

Does the valve hold vacuum?

Rcp.i. ahoft in thc wir. bctw.cn

th6 EVAP conlrol caniator v.nt

3hut valve snd the ECM lA29).Does the valve hold vacuum?

Check tha EVAP coitlol canittcr

vent 3hut valvo:1. Turn the ignition switch OFF

2. Connect ECM connoctor ter'

minal A29 to bodY ground

whh a iumPer wlre

3. Turn the ignition switch ON (ll).

4. Apply vacuum to the hose.

Baplaca tha EVAP control c!ni!'

td vant 3hul Yalvc.

Does the valve hold vacuum?

38t0tl

1215[6'tat92Au232a

2t27a22

VSV {LT GRN) I JUMPER WIRE

Wire side o{ {emale terminals

11-146

{To page 11'147)

Page 356 of 1681

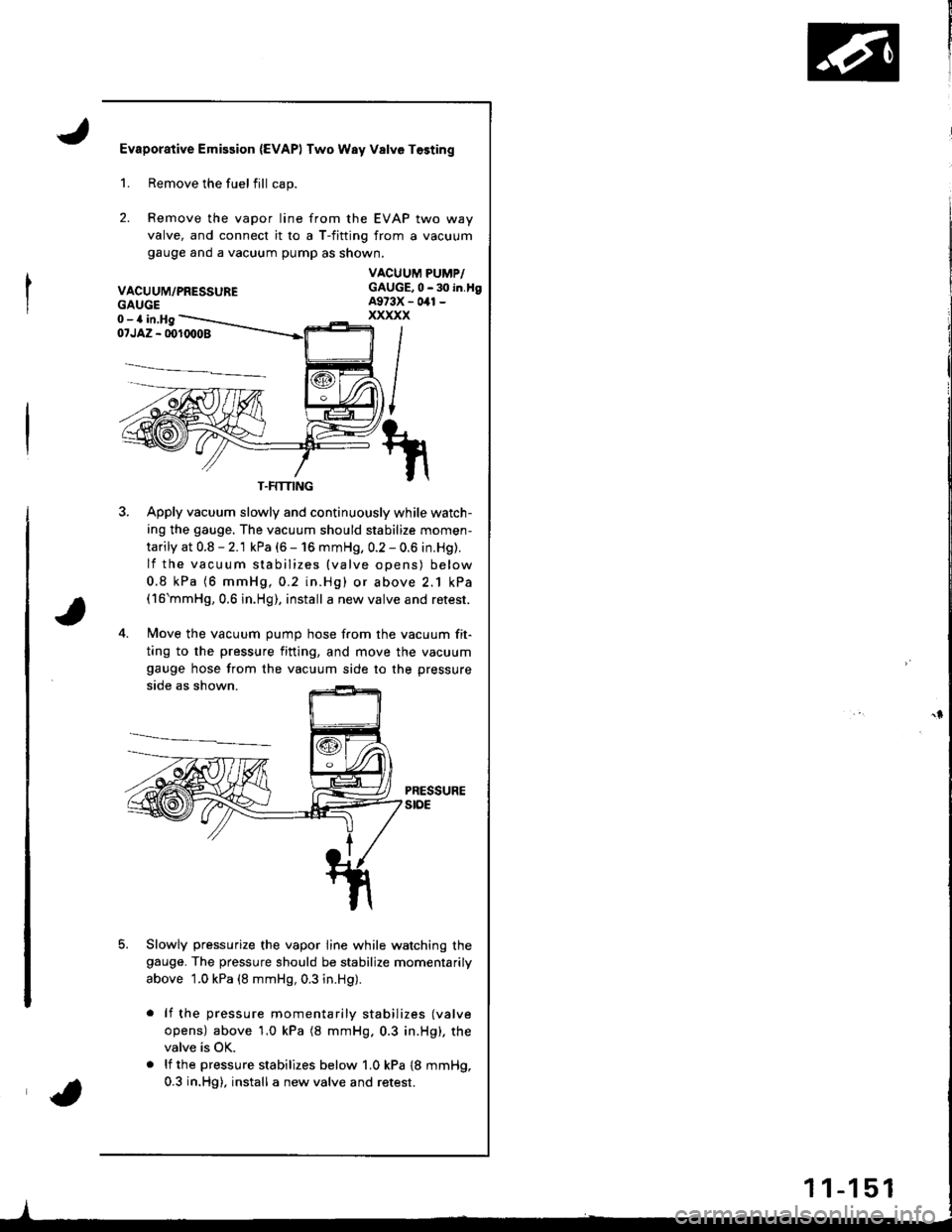

Evaporative Emission {EVAPI Two Way Valve Tosting

2.

Remove the fuelfill cap.

Remove the vapor line from the EVAP two way

valve, and connect it ro a T-fitting from a vacuum

gauge ano a vacuum pump as shown.

VACUUM/PRESSURE

1.

GAUGE0-a in,Hg

VACUUM PUMP/GAUGE,0 - 30 in.tlgA973X - 041 -

xxxxx

i/NI

t/

il\/

1il|

07JAZ - 001(X)08

3. Apply vacuum slowly and continuously while watch-

ing the gauge. The vacuum should stabilize momen-

tarily at 0.8 - 2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).

lf the vacuum stabilizes {valve opens) below

0.8 kPa (6 mmHg,0.2 in.Hg) or above 2.1 kPa(16'mmHg,0.6 in.Hg), install a new valve and retest.

4. Move the vacuum oumo hose from the vacuum fit-

ting to the pressure fining, and move the vacuum

gauge hose from the vacuum side to the pressure

side as shown.

PRESSUREstoE

Slowly pressurize the vapor line while watching thegauge. The pressure should be stabilize momentarily

above 1.0 kPa (8 mmHg, 0.3 in.Hg).

lf the pressure momentarily stabilizes (valve

opens) above'1.0 kPa (8 mmHg.0.3 in.Hg), the

valve is OK.

lf the pressure stabilizes below 1.0 kPa {8 mmHg,

0.3 in.Hg), install a new valve and retest.

T.FMING

1 1-1 51

Page 1085 of 1681

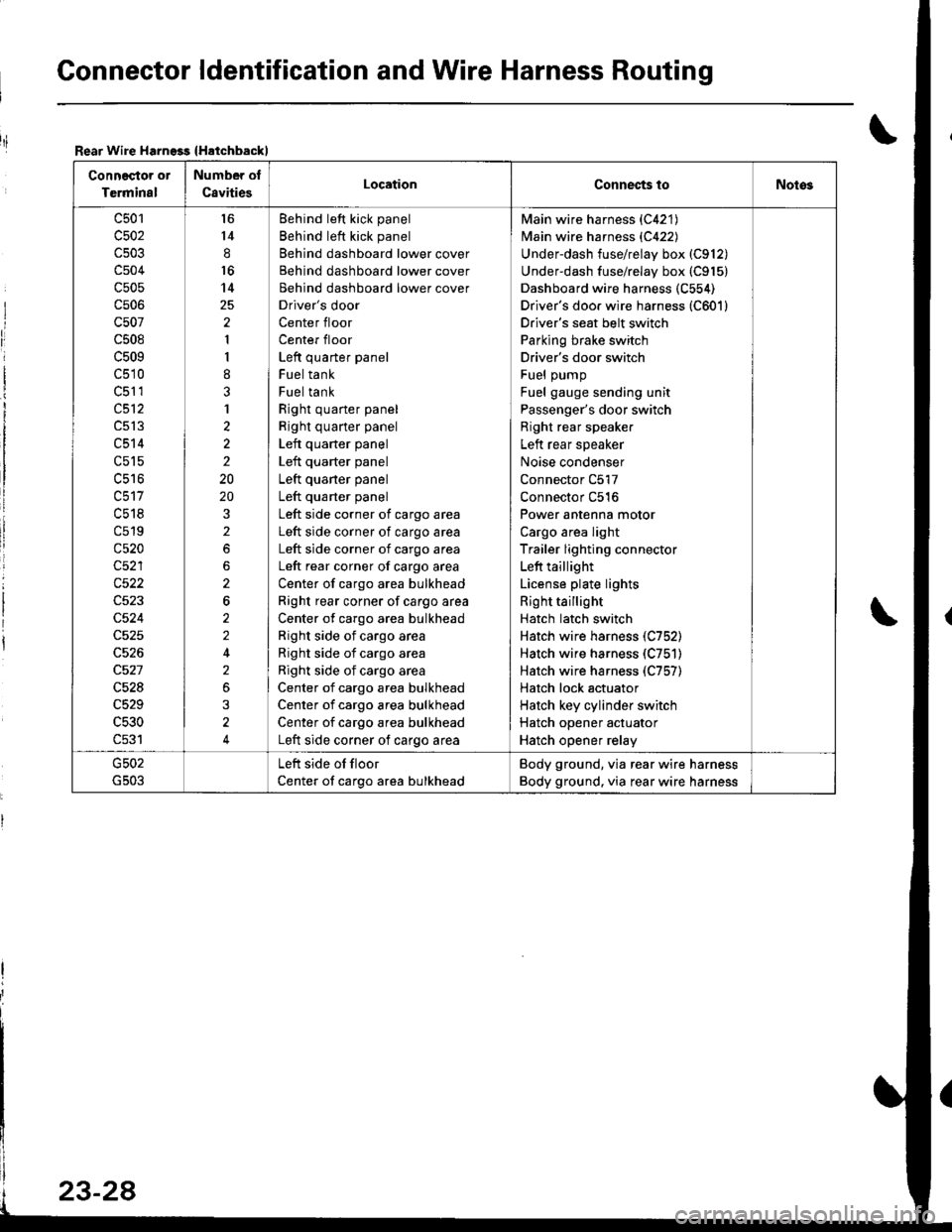

Gonnector ldentification and Wire Harness Routing

Rear Wire Harngss {Hatchbackl

Connector or

Terminal

Number of

C8vitiesLocationConnec{s toNotos

c501

c502

c504

c505

cs06

c507

c508

c509

c510

c51 1

c512

c513

c514

c515

uc to

c518

c519

c520

c522

c524

c528

c529

c530

c531

l6

14

8

16

14

2

1

I

8

3

1

2

2

2

20

20

2

2

6

2

2

2

3

4

Behind left kick panel

Behind left kick panel

Behind dashboard lower cover

Behind dashboard lower cover

Behind dashboard lower cover

Driver's door

Center floor

Center floor

Left quarter panel

Fuel tank

Fuel tank

Right quarter panel

Right quarter panel

Left quarter panel

Left quarter panel

Left quaner panel

Left quarter panel

Left side corner of cargo area

Left side corner of cargo area

Left side corner of cargo area

Left rear corner of cargo area

Center of cargo area bulkhead

Right rear corner of cargo area

Center of cargo area bulkhead

Right side of cargo area

Right side of cargo area

Right side of cargo area

Center of cargo area bulkhead

Center of cargo area bulkhead

Center of cargo area bulkhead

Left side corner of cargo area

Main wire harness {C421)

Main wire harness {C422)

Underdash fuse/relay box (C912)

Underdash fuse/relay box (C915)

Dashboard wire harness (C554)

Driver's doo. wire harness (C601)

Driver's seat belt switch

Parking brake switch

Driver's door switch

Fuel pump

Fuel gauge sending unit

Passenger's door switch

Right rear speaker

Left rear speaker

Noise condenser

Connector C517

Connector C516

Power antenna motor

Cargo area light

Trailer lighting connector

Left taillight

License plate lights

Right taillight

Hatch latch switch

Hatch wire harness (C752)

Hatch wire harness (C751)

Hatch wire harness (C757)

Hatch lock actuator

Hatch key cylinder switch

Hatch opener actuator

Hatch opener relay

Left side of floor

Center of cargo area bulkhead

Body ground, via rear wire harness

Body ground. via rear wire harness

riI

Page 1087 of 1681

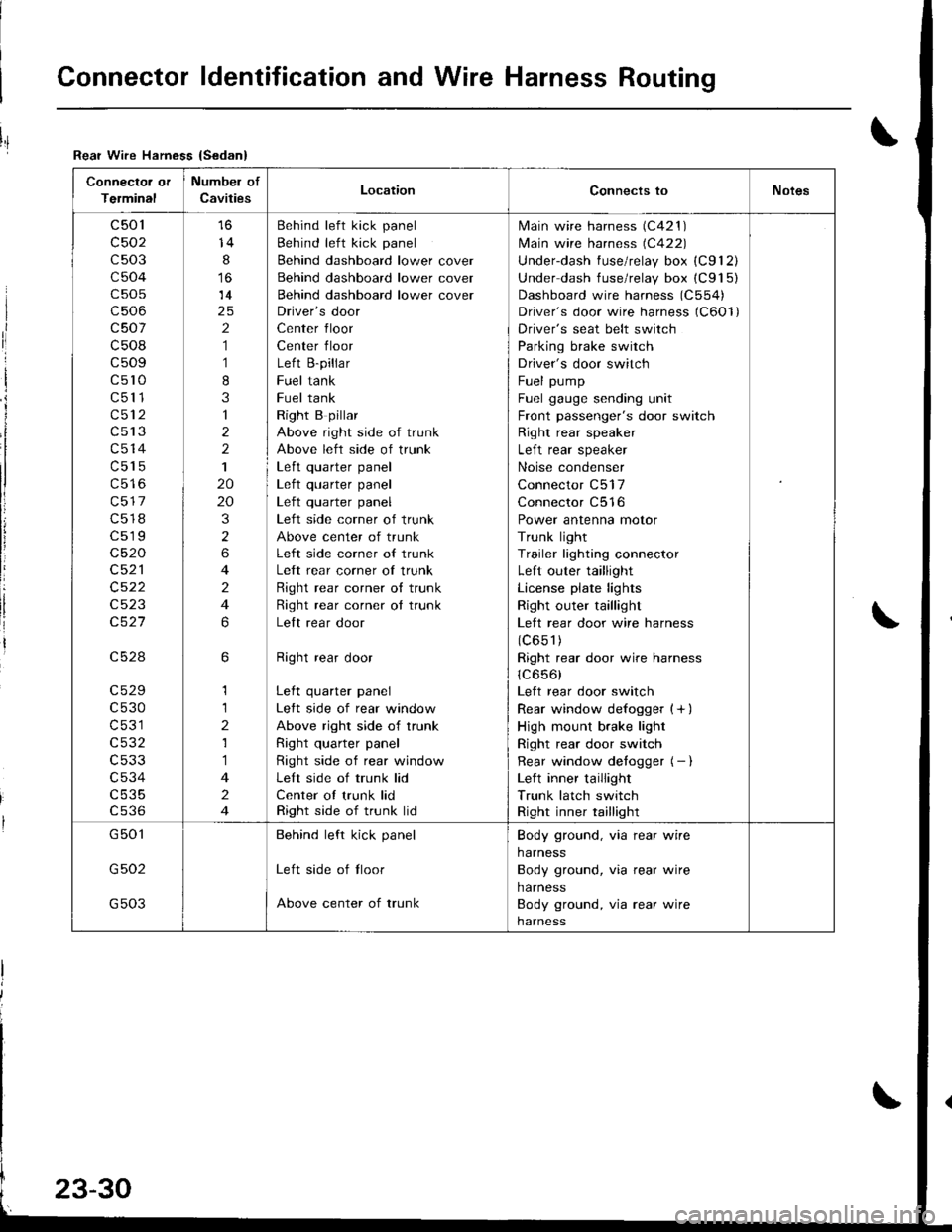

Connector ldentification and Wire Harness Routing

Connector or

Terminal

Numbel of

CavitiesLocationConnects toNotes

c501

c502

c503

c504

c505

c506

c507

c508

c509

c5l0

c511

c512

c513

c514

c515

c517

c518

c519

c520

c521

c522

c523

c527

c528

c529

c530

c531

c532

c533

c534

c535

cs36

14

8

14

2

1

1

8

3

1

2

2

1

20

20

3

2

6

4

2

4

6

6

1

1

2

1

1

4

2

4

Behind left kick panel

Behind left kick panel

Behind dashboard lower cover

Behind dashboard lower cover

Behind dashboard lower cover

Driver's door

Center floor

Center floor

Left B-pillar

Fuel tank

Fuel tank

Right B pillar

Above right side of trunk

Above left side of trunk

Left quarter panel| .{+ ^',rrrar ^rnal

Left quarter panel

Left side corner of trunk

Above center of trunk

Left side corner of trunk

Left rear corner of trunk

Right rear corner o{ trunk

Right rear corner ot trunk

Lelt rear door

Right rear door

Left quarter panel

Left side of rear window

Above right side of trunk

Right quarter panel

Right side of rear window

Left side of trunk lid

Center of trunk lid

Right side of trunk lid

lvlain wire harness (C421 )

lvlain wire harness (C422)

Underdash fuse/relay box (C912)

Under dash fuse/relay box (C915)

Dashboard wire harness (C554)

Driver's door wire harness (C6Ol)

Driver's seat belt switch

Parking brake switch

Driver's door switch

Fuel pump

Fuel gauge sending unit

Front passenger's door switch

Right rear speaker

Left rear speaker

Noise condenser

Connector C517

Connector C516

Power antenna motor

Trunk light

Trailer lighting connector

Left outer taillight

License plate lights

Right outer taillight

Lett rear door wire harness

(c651)

Right rear door wire harness

1C656)

Left rear door switch

Rear window defogger {+ )

High mount brake light

Right rear door switch

Rear window detogger (- I

Left inner taillight

Trunk latch switch

Right inner taillight

G501

G502

G503

Behind left kick panel

Left side of tloor

Above center of trunk

Body ground, via rear wire

harness

Body ground, via rear wire

harness

Body ground, via rear wire

harness

Rear Wire Hamess {Sedan}

I

ri

I

i

I

li

!

Page 1122 of 1681

I "tl

III

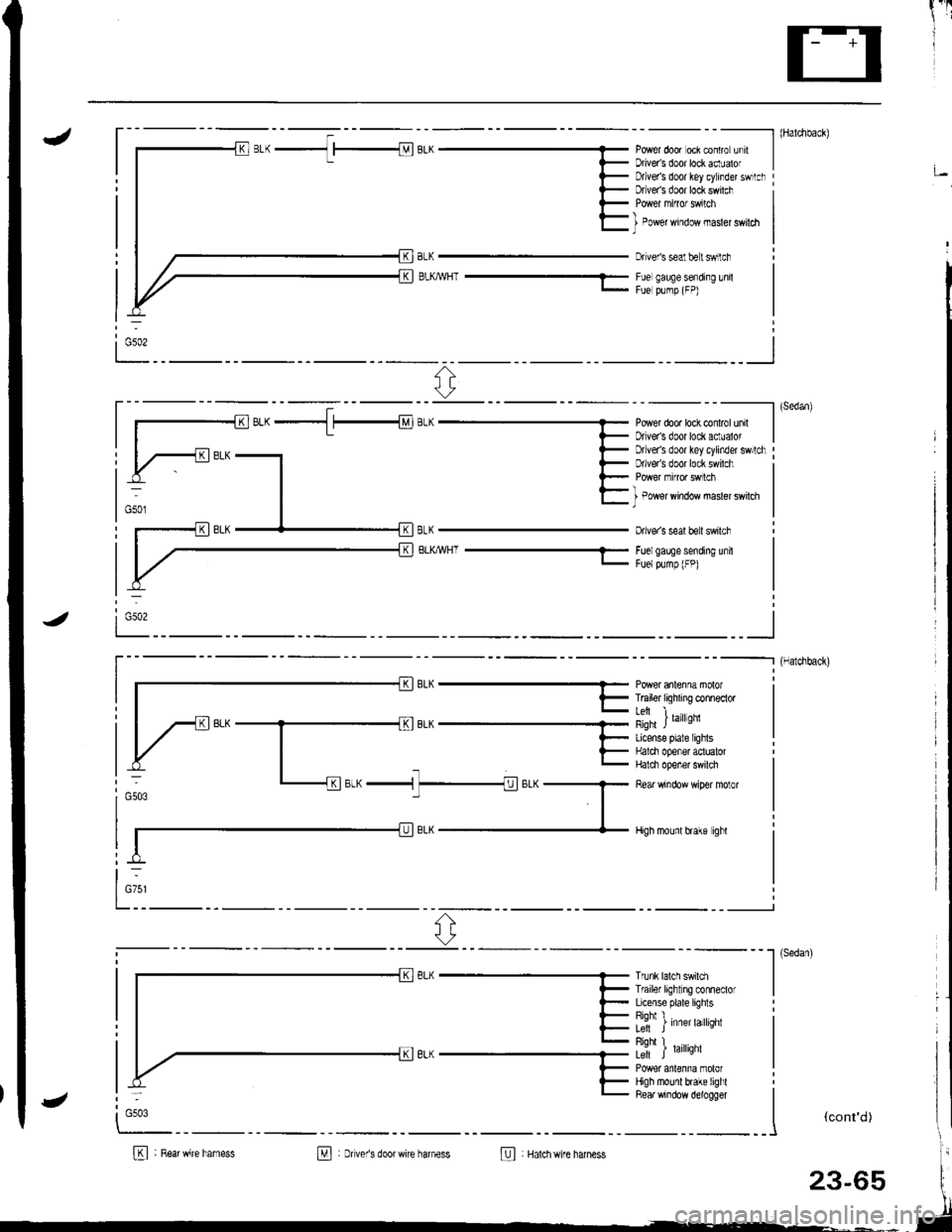

J- - - - --------- l (Haldlback)

Power door oci contro unrt IDriveas door lockaclualof I;Dtlver's door key cylinder swrtclrDfveas door lock swilch

BLKMHT ---1-

I Power window masler swildl)

Dr veis seal belt swilch

Fue gauge sending lnilFue plmp (FP)

ri:

----------l (sedan)

Power dooa lock conlrol unil IDriveas door lock aclualor I

BLKWHT-

Drlver's door key cylinder swllchDrlve/s door lock swilch

I Power window masler swilch)

Dive. s seal beit swilch

Foelgaee sending unitFuelpump (FP)

i Gso2

_ _ _--_______.] {Halchback)

r- || | F T6iler tiqhxng conneclor I

lil i ,",rror,'nqfi JLicense plale lighlsHalci opener aotualorHalci opener swilch

Rear window wiper molor

High mounl hake ighl

otw ^ -n1

t-

l_:1' ^r;-"-1 7_1;.^G503

Trunk lalch swildlTf ailer light ng conneclorLicense plate lighlsRiohl I�L; J Inner larqnr

Riohl I� .Le-ft J raflqnl

High mounl brake lighlRea. window d€logger

I

""*'�

I

(cont'd)

B : R6arwire hamessM : Dver's doorwire harness@ Hatchwire harness

:

G503

23-65

Page 1388 of 1681

)a

)a

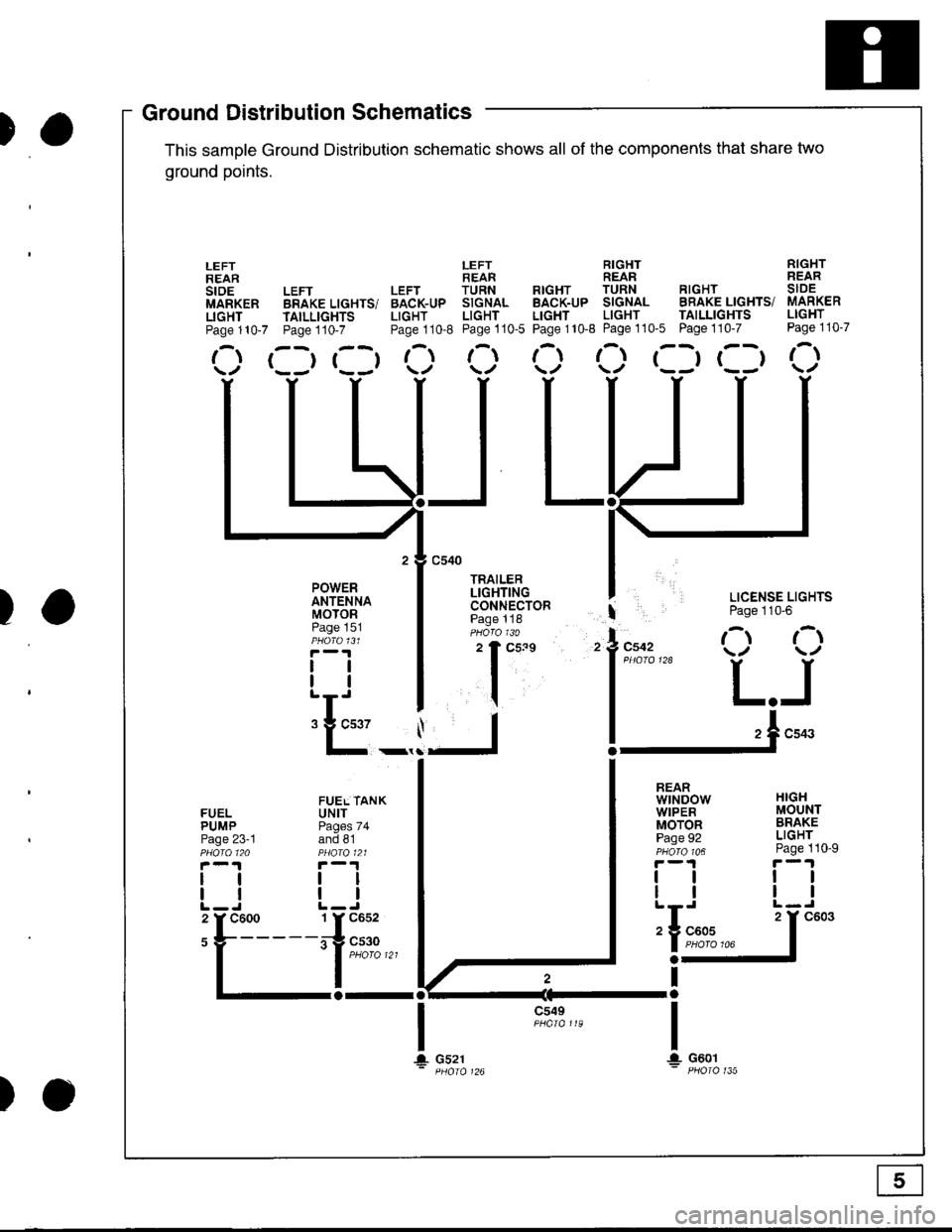

'ouno ulslnoulron Scnemarlcs -

This samDle Ground Distribution schematic shows all of the components thal share two

ground points.

LEFT RIGHT RIGHTREAR REAR REARLEFT LEFT TURN RTGHT TURN RIGHT SIDEBRAKE LIGHTS/ BACK-UP SIGNAL BACK-UP SIGNAL BRAKE LIGHTS/ MARKER

TAILLTGHTS LIGHT LIGHT LIGHT LIGHT TAILLIGHTS LIGHT

Page110-7 Page110-8 Page110-5 Page110-8 Page110'5 Page110-7 Page110-7

r--r r--t t- t-l t-t ,-t r--r r--t r-\t*-r r--r \./ \/ \./ \/ \/

I LICENSE LIGHTS

I Page 110'6

l"uo, O O

l*"''* L.J

!-.1**

FUELPUMPPage 23-1

lltl

LEFTREARstoEMARKERLIGHTPage 110-7

POWERANTENNAMOTORPage 151

tlll

:E_,

a-al

JL

c549

t\

HIGHMOUNTBRAKELIGHTPage 110-9

ttll

REARwtNDowWIPERMOTORPage 92

tlll

iIn*

a-

Ira

T!. G601

FUEL TANKUNITPages 74and 81

tltl

1 Y C652

irg c530- | puoro tzt

I

106

T+ Gs21

c603

Ground DistributiSchematics

E

)o