steering wheel HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 690 of 1681

Power Steering

Gearbox

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

l. Drain the power steering fluid as described on page

11-21.

2. Raise the front of vehicle, and support on safety

stands in the proper locations (see section 1).

3. Remove the front wheels.

4. When the vehicle is equipped with the SBS airbag

system, remove the steering wheel (see page 17-

24t.

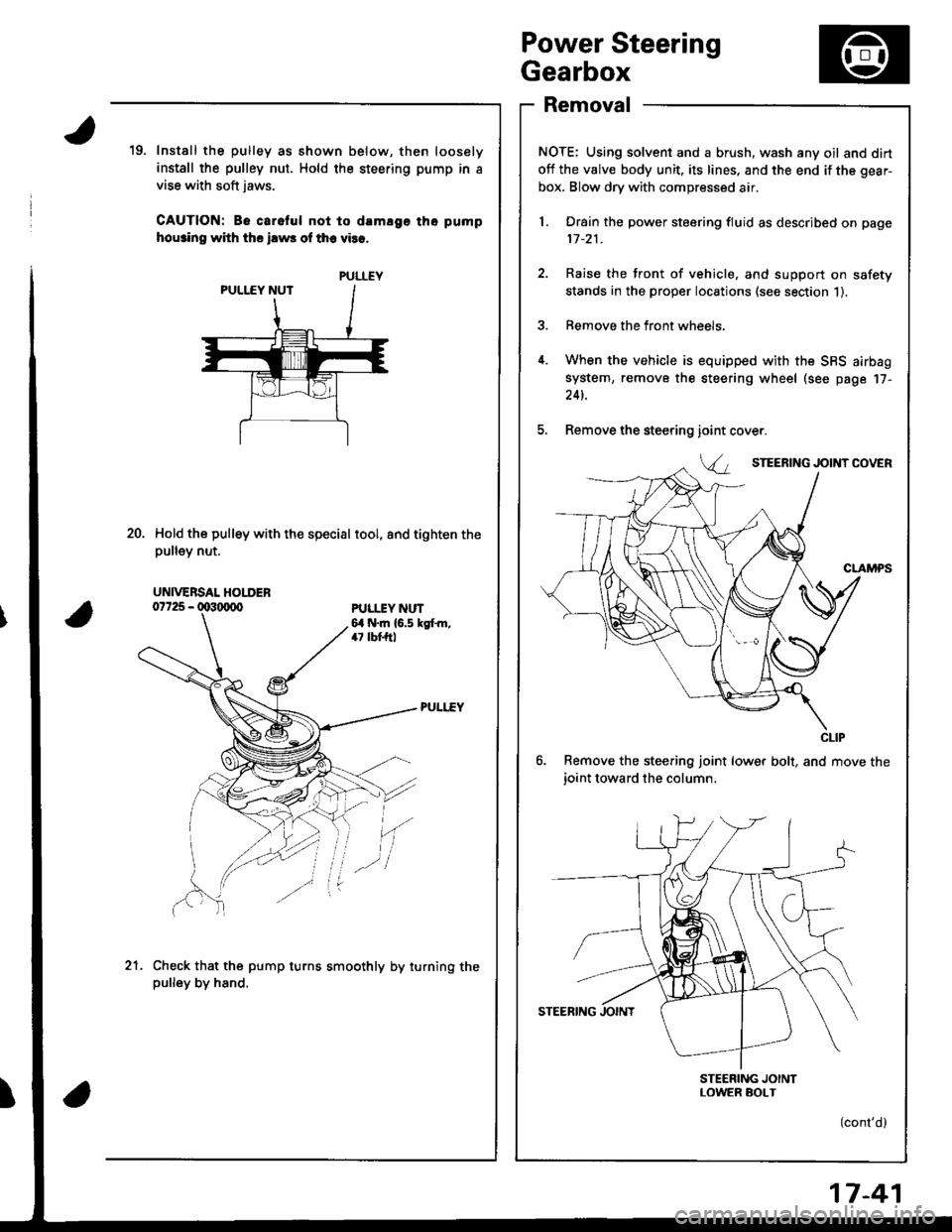

5. Remove the steering

6. Remove the steering joint lower bolt, and move the

ioint toward the column.

STEERING JOINTLOWER SOI-T

(cont'd)

19. Install the pulley as shown below, then loosely

install the pulley nut. Hold the steering pump in a

vise with soft jaws.

CAUTION: Be carelul not to damlge tho pump

hou3ino with ths ilws of th6 vies.

Hold the pulley with the special tool, and tighten thepu ey nut.

ioint

Va

20.

PULI.IY NUT6,1 N.m {6.5 kgt m,47 lbf,ftl

'(

Check that the pump turns smoothly by turning thepulley by hand.

.-l

21.

PULLEY

UNIVERSAL HOLDER

CLIP

17-41

Page 708 of 1681

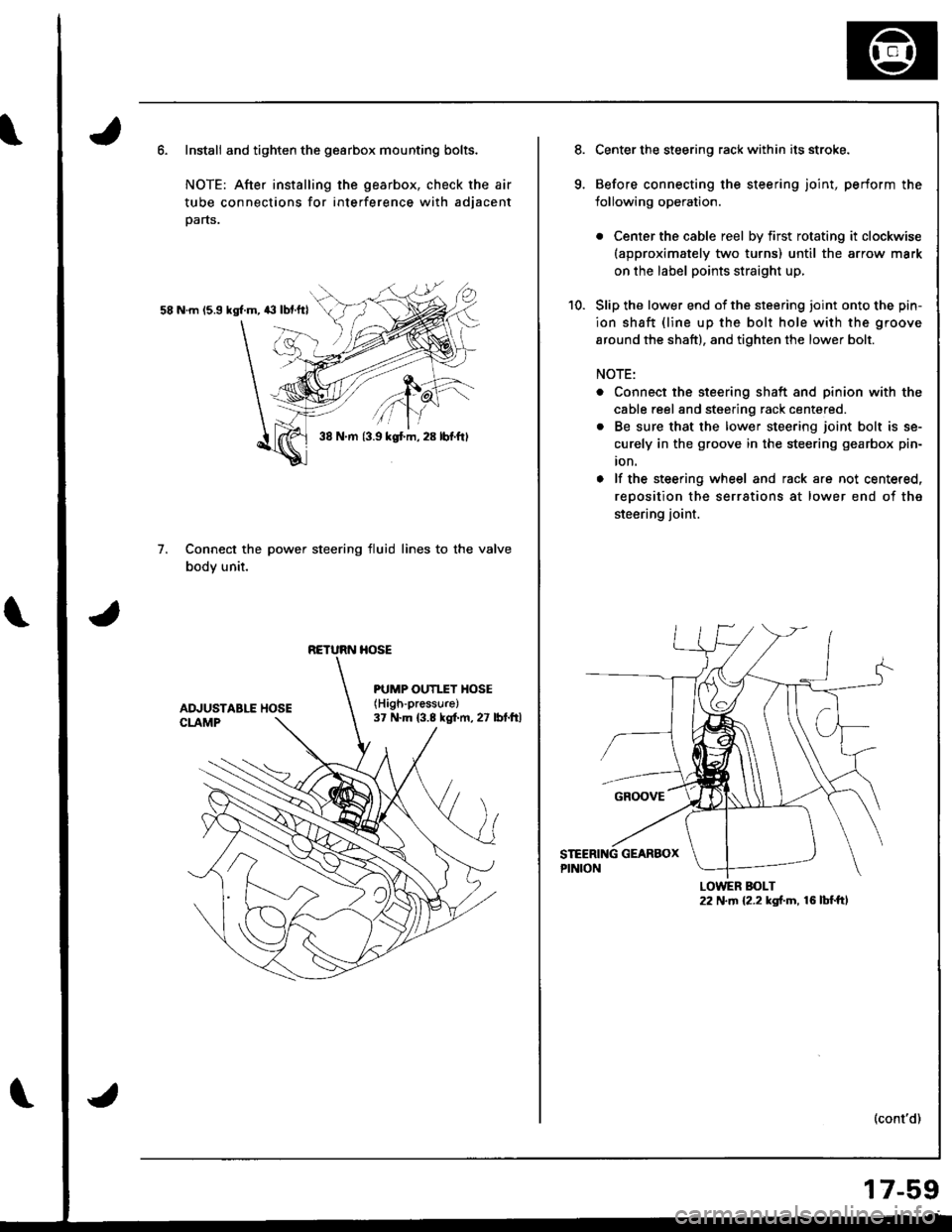

Install and tighten the gearbox mounting bolts.

NOTE: After installing the gearbox, check the air

tube connections for interference with adjacent

parts.

58 N.m 15.9 kgl.m, 43 lbf.ftl

Connect the power steering fluid lines to the valve

body unit.

7.

38 N.m {3.9 kgt m, 28 lbf.ftl

RETURN HOSE

PUMP OUTI.TY HOSE(High-pressure)

37 N.m (3.8 kgf.m, 27 lbt.ftl

Center the steering rack within its stroke.

Before connecting the steering joint, perform the

lollowing operation.

. Center the cable reel by first rotating it clockwise(approximately two turns) until the arrow mark

on the label points straight up,

Slip the lower end of the steering ioint onto the pin-

ion shaft {line up the bolt hole with the groove

around the shaft), and tighten the lower bolt.

NOTE:

. Connect the steering shaft and pinion with the

cable reel and steering rack centered.

. Be sure that the lower steering joint bolt is se-

curely in the groove in the steering gearbox pin-

ion.

o lf the steering wheel and rack are not centered,

reoosition the serrations at lower end of the

steering joint.

(cont'd)

LOWER BOLT22 N.m {2.2 kgf.m, 16 lbf.ft,

17-59

Page 710 of 1681

)

)

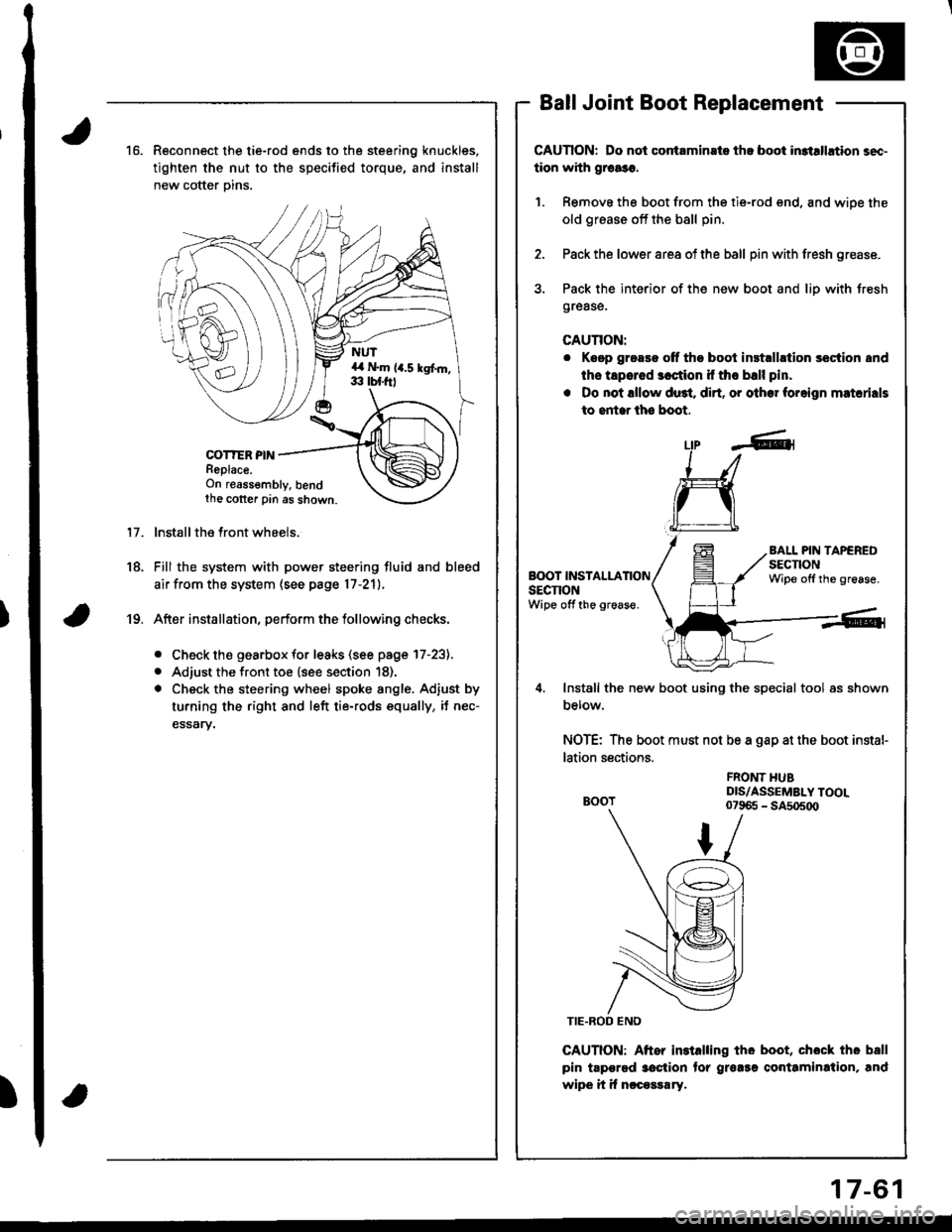

16.Reconnect the tie-rod ends to the steering knuckles,

tighten the nut to the specified torque, and install

new cotter Dins.

COT?ER PINReplace.On reassembly, bendthe cotter pin as shown.

lnstall the front wheels.

Fill the system with power steering fluid and bleed

air from the system (see page 17-21).

After installation, perform the tollowing checks.

. Check the gearbox for leaks (see page l7-23).

. Adjust the front toe (see section 18).

. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods equally, it nec-

essary.

Ball Joint Boot Replacement

CAUTION: Do not contaminste th! boot in3tllhtion sec-

tion with grca3o.

1. Remove the boot from the tie-rod end, and wiDe the

old grease off the bsll pin.

2. Pack the lower area of the ball pin with fresh grease.

3. Pack the interior of the new boot and liD with Jresh

grease.

CAUTION:

r Keep grease off tho boot inst.llrtion section 8nd

ths tapered 3cction if tho ball pin.

. Do not lllow du3t. dirt. or other foreign matcrials

to entar lh6 boot.

17.

18.

Lfp -A-1

L:I

ru

Install the new boot using the special tool as shown

Derow.

NOTE: The boot must not be a gap at the boot instal-

lation sections.

CAUTION: Aftor installing tho boot, chock tho ball

pin tapgrgd 3oction tor grorsg conttmination, and

wipe it if nccossary.

BALL PIN TAPEREDsEcnoNWipe offthe grease.BOOT INSTALLATIONsEcnoNWipe off the groaso.

19.

FROI{T HUBDIS/ASSEMBLY TOOL07965 - SA5o5o0

17-61

Page 715 of 1681

\

Front Toe Inspection/AdjustmentRear Toe Inspection/Adjustment

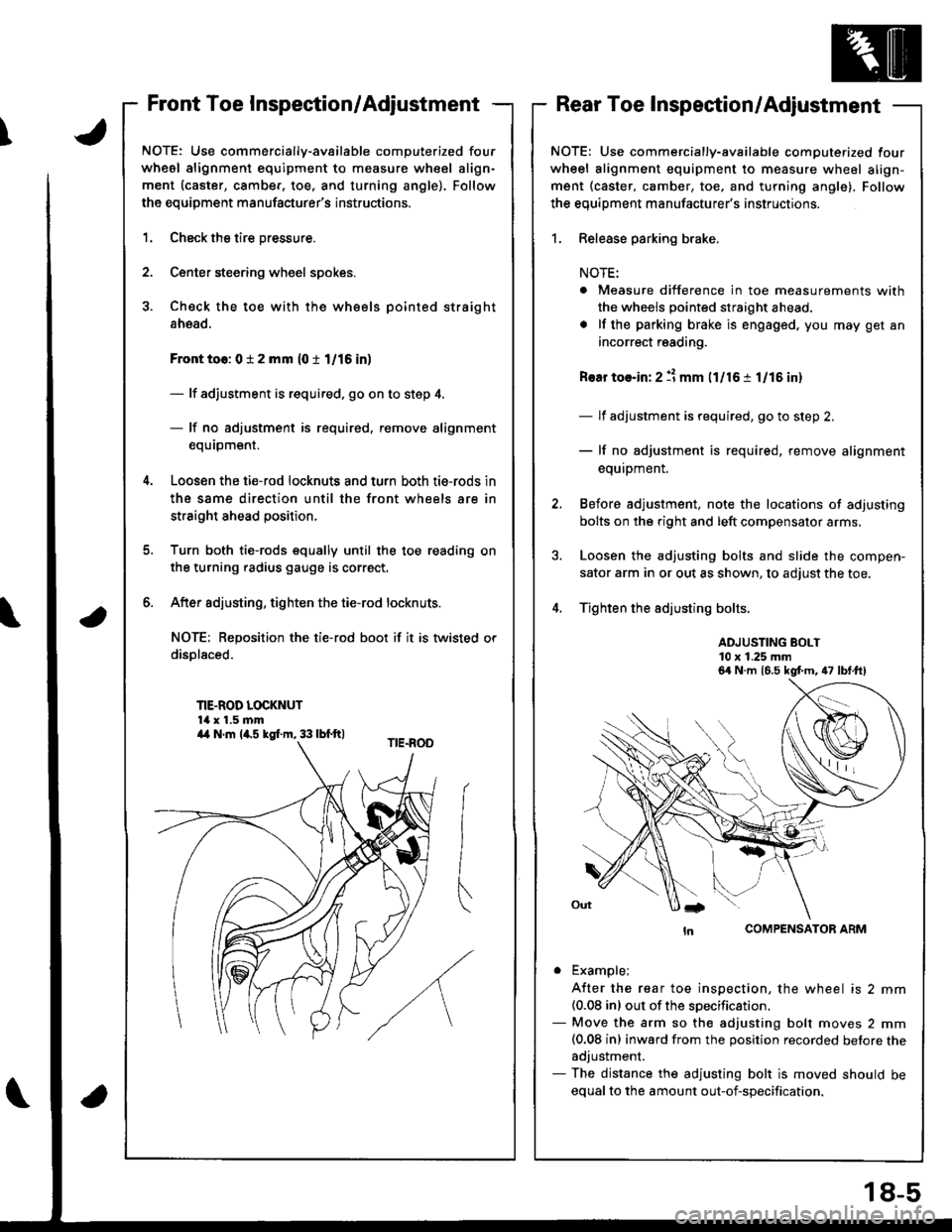

NOTE: Use commercially-available computerized four

whesl alignment equipment to measure wheel align-

ment (caster, camber, toe. and turning angle). Follow

the equipment manufacturer's instructions.

1.

2.

Check the tire pressure.

C€nter steering wheel spokes.

Check the toe with the wh€els pointed straight

ahead.

Front to6: 0 i 2 mm (0 t 1/16 in)

- lf adjustment is required. go on to step 4.

- lf no adjustment is required, remove alignment

equrpm€nr,

Loosen the ti€-rod locknuts and turn both tie-rods in

the same direction until the front wheels are in

straight ahead position.

Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

After sdjusting, tighten the tie-rod locknuts.

NOT€: Reposition the tie-rod boot if it is twisted or

displaced.

TIE-ROD LOCKNUT14 x 1.5 mm

6.

a

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle), Follow

the equiDment manufacturer's instructions.

1. Release parking brake.

NOTE:

. Measure difference in toe measurements with

the wheels pointed straight ahead.

. lf the parking brake is engaged. you may get an

incorrect reading.

Rear toe-in: 2 11 mm l1l16 i 1/15 in)

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts and slide the compen-

sator arm in or out as shown, to adjust the toe.

Tighten the adjusting bolts.

ADJUSTING BOLT10 x 1.25 mm

COMPENSATOR ARM

. Example;

A{ter the rear toe inspection, the wheel is 2 mm(0.08 inl out of the soecification.- Move the arm so the adjusting bolt moves 2 mm(0.08 inl inward from the position recorded betore theadjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

6a N.m 16.5 kgt m, 47 lbt.ft)

a4 N.m la.s kgI.m, 33 lbf.ft)

18-5

Page 1077 of 1681

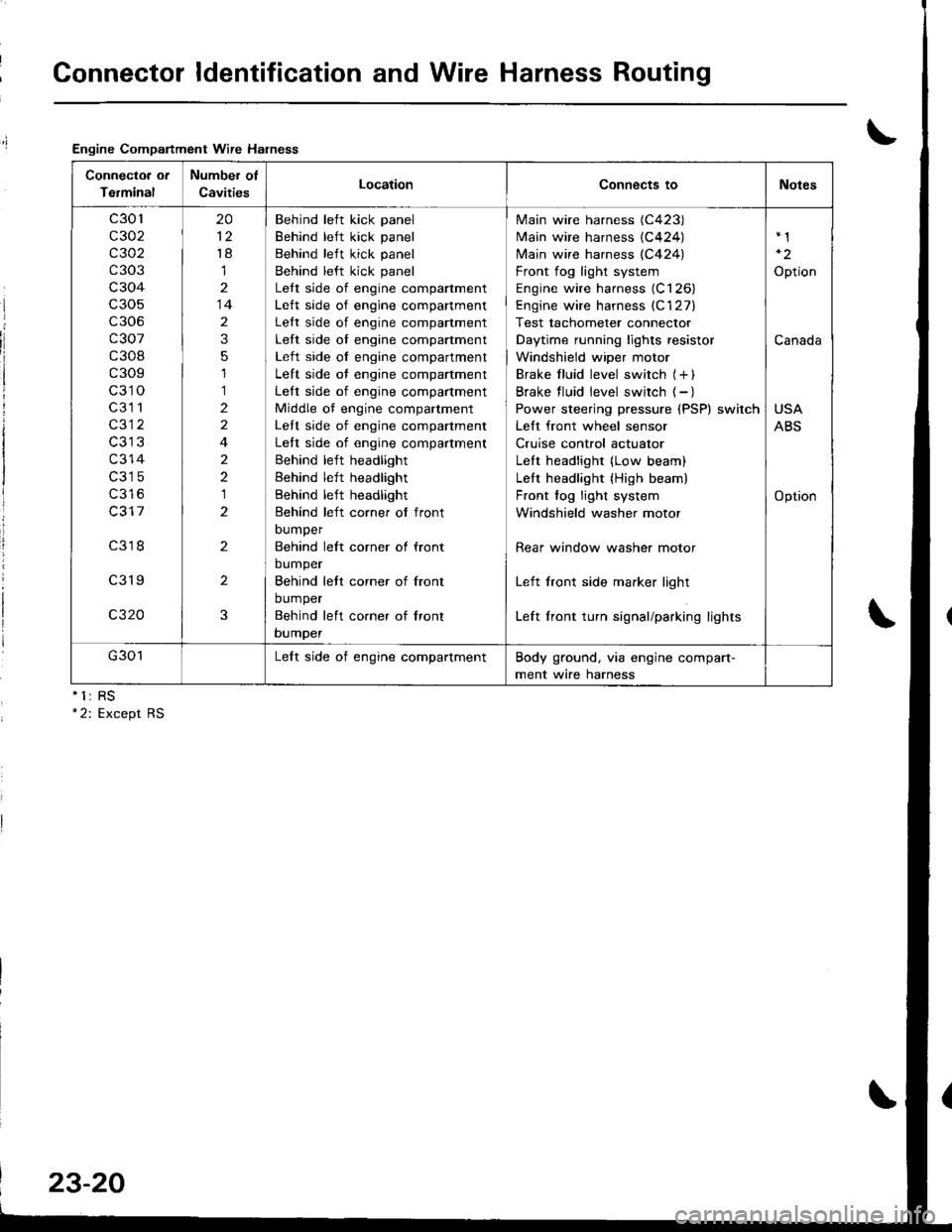

Connector ldentification and Wire Harness Routing

Engine Compartment Wire Halness

nll

Connectoa ot

Terminal

Number of

CavitiesLocationConnects toNotes

c301

c302

c 302

c303

c304

c306

c307

c308

c309

c310

c3l 1

c312

c314

c316

c317

c318

c319

c320

20

't8

1

14

2

3

5

1

1

2

2

4

2

2

1

2

2

2

3

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Lett side of engine compartment

Lett side of engine companment

Lett side of engine compartment

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Middle of engine compartment

Lett side of engine companment

Left side of engine compartment

Behind left headlight

Behind left headlight

Behind left headlight

Behind left corner of front

DUmper

Behind left corner ol front

bumper

Behind lett corner of front

bumper

Behind left co.ner of lront

bumper

Main wire harness (C423)

Main wire harness {C424)

N4ain wire harness (C424)

Front fog light system

Engine wire harness (C126)

Engine wire harness (C'127)

Test tachometer connector

Daytime running lights resistor

Windshield wiper motor

Brake f luid level switch (+ )

Brake f luid level switch ( - )

Power steering pressure (PSP) switch

Lett front wheel sensor

Cruise control actuator

LeIt headlight (Low beam)

Lett headlight {High beam)

Front fog light system

Windshield washer motor

Rear window washer motor

Left front side marker light

Left front turn signal/parking lights

Option

Canada

USA

ABS

Option

G301Lelt side of engine compartmentBody ground, via engine compart-

ment wire harness

23-20

Page 1130 of 1681

;

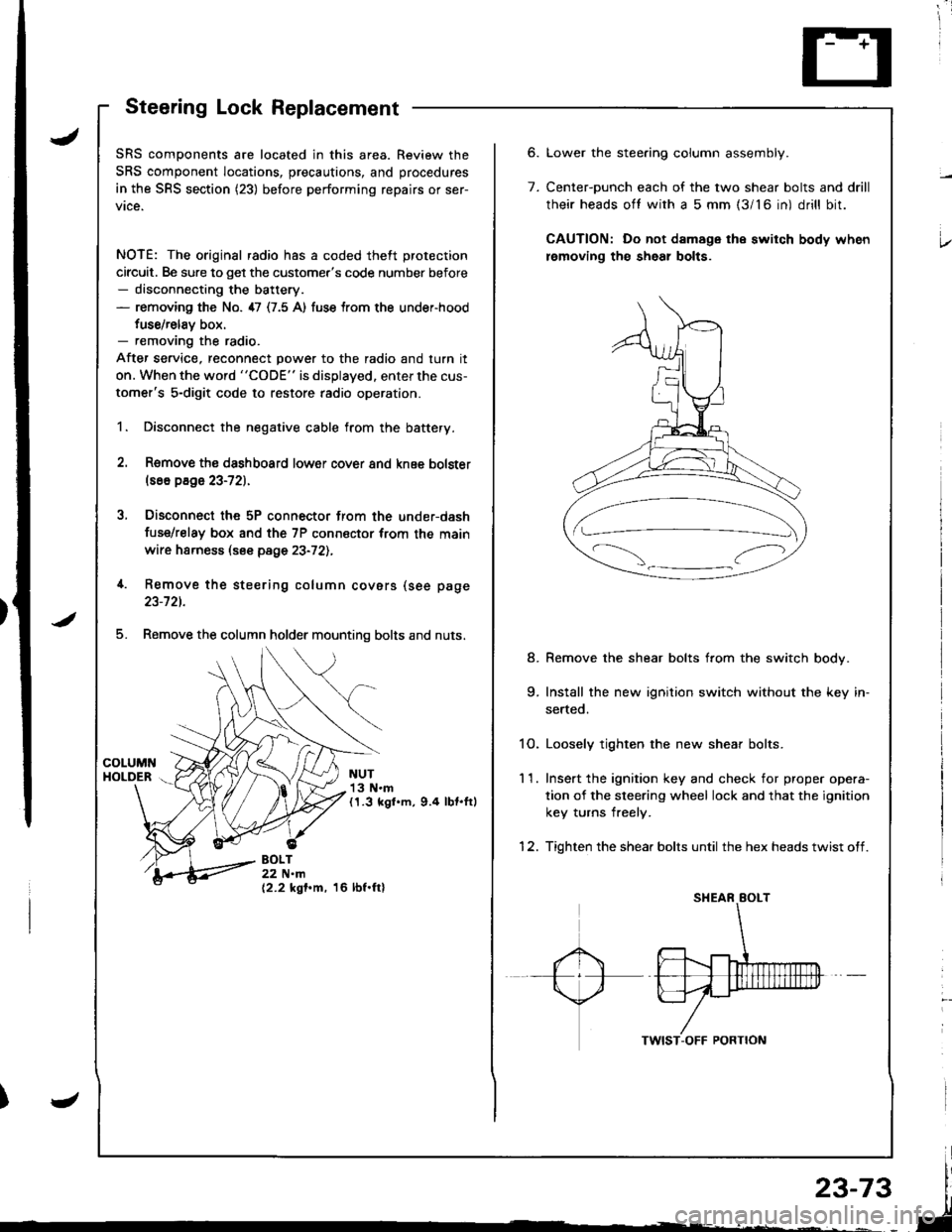

Steering Lock Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vice.

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 (7.5 A) fuse trom the under-hood

fuse/relav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

2. Remove ths dsshboard lower cover and knee bolster(s6o p8ge 23-72).

3, Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connsctor from th€ main

wire harness (see page 23-72l.,

4. Remove the steering column covars (see page

23-721.

5. Remove the column holder mounting bolts and nuts.

NUT13 N.m(1.3 kgl.m, 9.4 lbt.ftl

BOLT22 N.m(2.2 kgf.m, 16 lbf.ftl

6.

7.

Lower the stee.ing column assembly.

Center-ounch each of the two shear bolts and drill

their heads oft with a 5 mm {3/16 in) drill bit.

CAUTION: Do not damage the switch body when

lemoving th€ sheal bolts.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

1O. Loosely tighten the new shear bolts.

11. Ins€rt the ignition key and check for proper opera-

tion of the sleering wheel lock and that the ignition

key turns freely.

12. Tighten the shear bolts until the hex heads twist off.

8.

Page 1183 of 1681

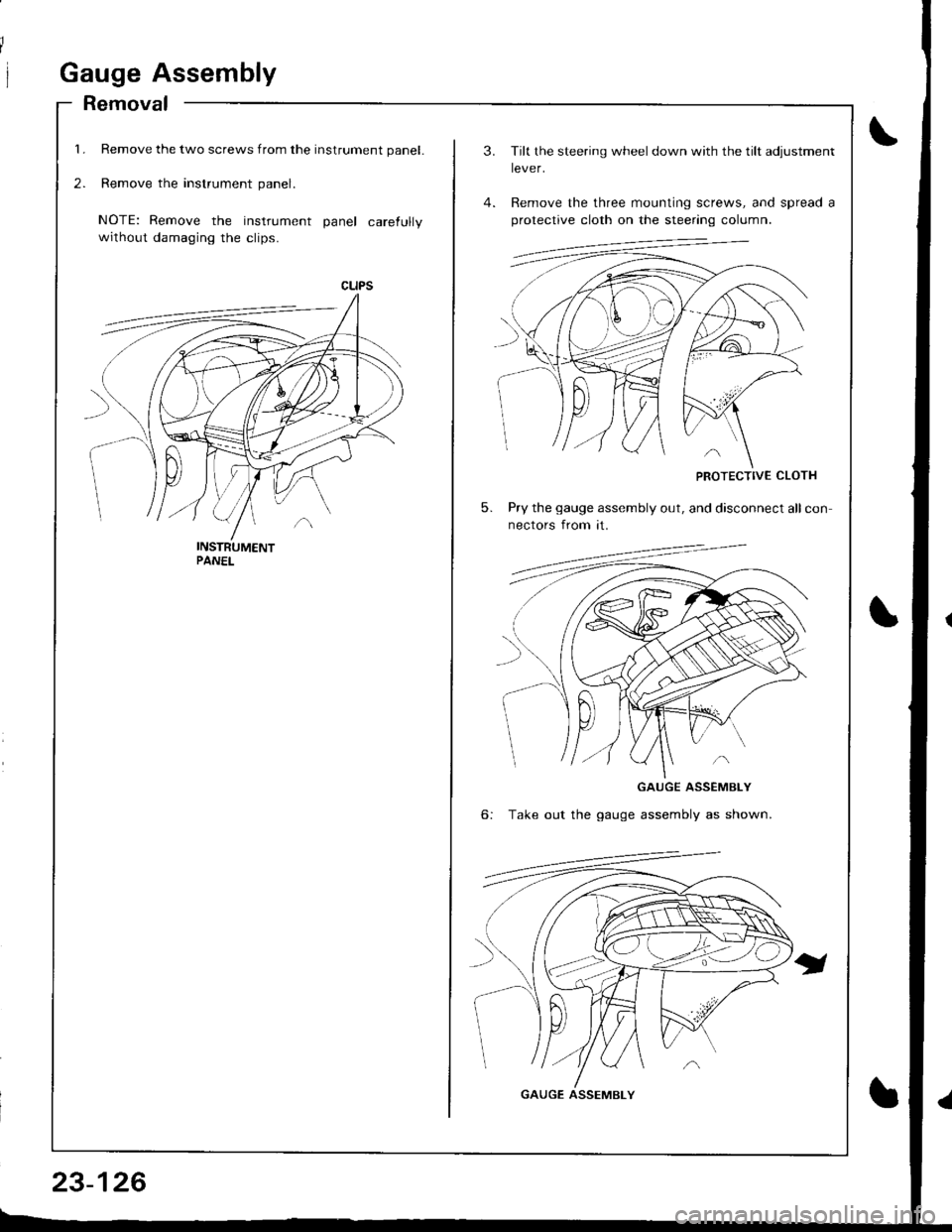

1.

2.

Gauge Assembly

Removal

Remove the two screws from the instrument panel.

Remove the instrument panel.

NOTE: Remove the instrument panel carefully

without damaging the clips.

23-126

3.

5.

Tilt the steering wheel down with the tilt adjustment

lever.

Remove the three mounting screws, and spread a

protective cloth on the steering column.

PROTECTIVE CLOTH

Pry the gauge assembly out, and disconnect all con

nectors from it.

6:

GAUGE ASSEMBLY

Take out the gauge assembly as shown.

GAUGE ASSEMBLY

Page 1266 of 1681

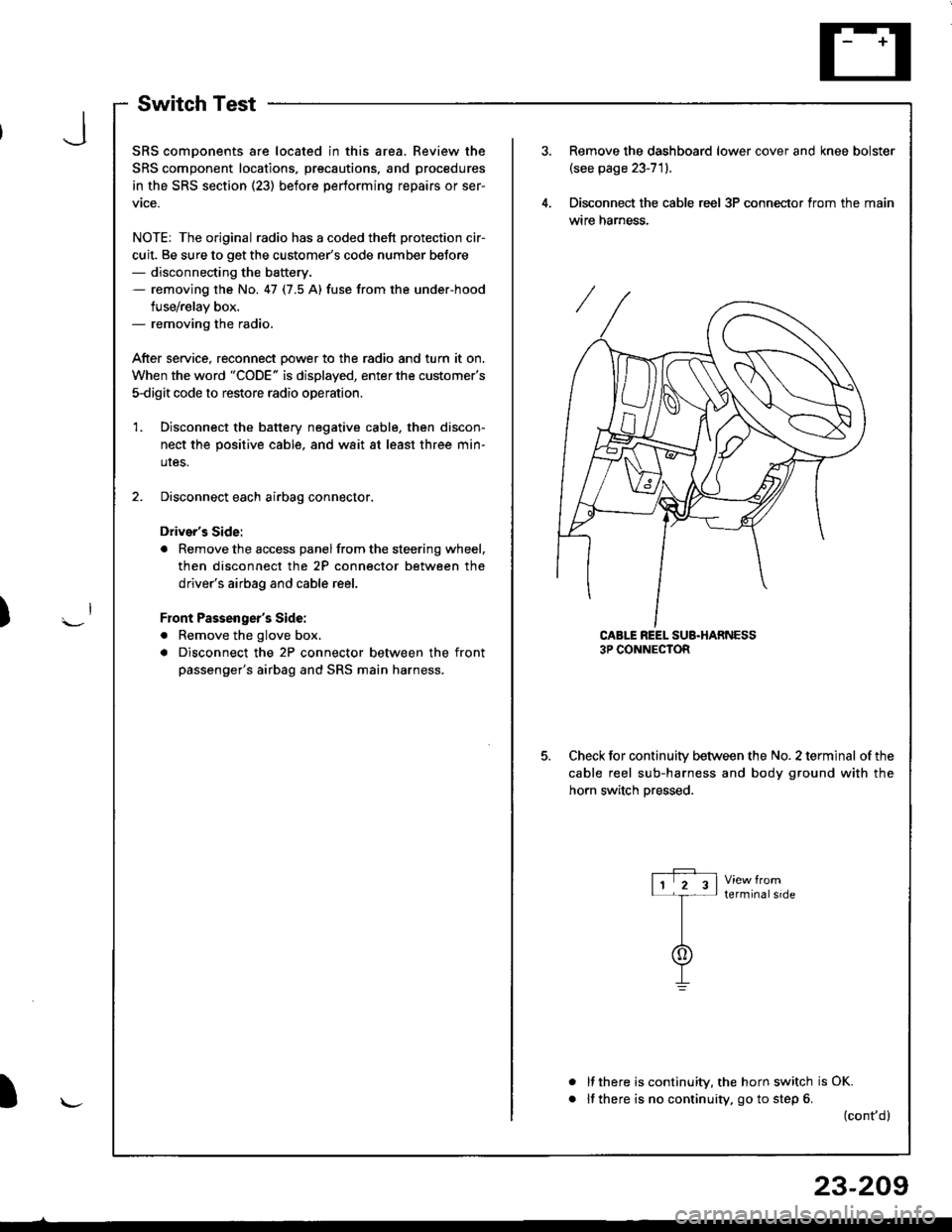

SwitchTest

SRS comDonents are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vtce.

NOTE: The original radio has a coded thett protection cir-

cuit. Be sure to get the customer's code number beJore- disconnecting the battery.- removing the No. 47 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect Dower to the radio and turn it on.

When the word "CODE" is displayed, enter the customer's

5-digit code to restore radio operation

Disconnect the battery negative cable, then discon-

nect the positive cable, and wait at least three min-

uIes.

Disconnect each airbag connector.

Driver's Side:

a Remove the access panel from the steering wheel,

then disconnect the 2P connector between the

driver's airbag and cable reel.

Front Passenger's Side:

. Remove the glove box,

a Disconnect the 2P connector between the front

passenger's airbag and SRS main harness.

1.

Remove the dashboard lower cover and knee bolster(see page 23-71).

Disconnect the cable reel 3P conneclor from the main

wtre narness.

CABLE REEL SUB.HARNESS3P CONNECTOR

Check for continuitv between the No. 2 terminal of the

cable reel sub-harness and body ground with the

horn switch Dressed.

terminalside

a

It there is continuity, the horn switch is OK.

lf there is no continuity, go to step 6. (cont,d)

r-P r11 2 3l-t-

I

I\-J

)

I

23-209

Page 1267 of 1681

Horn

Switch Test (cont'd)

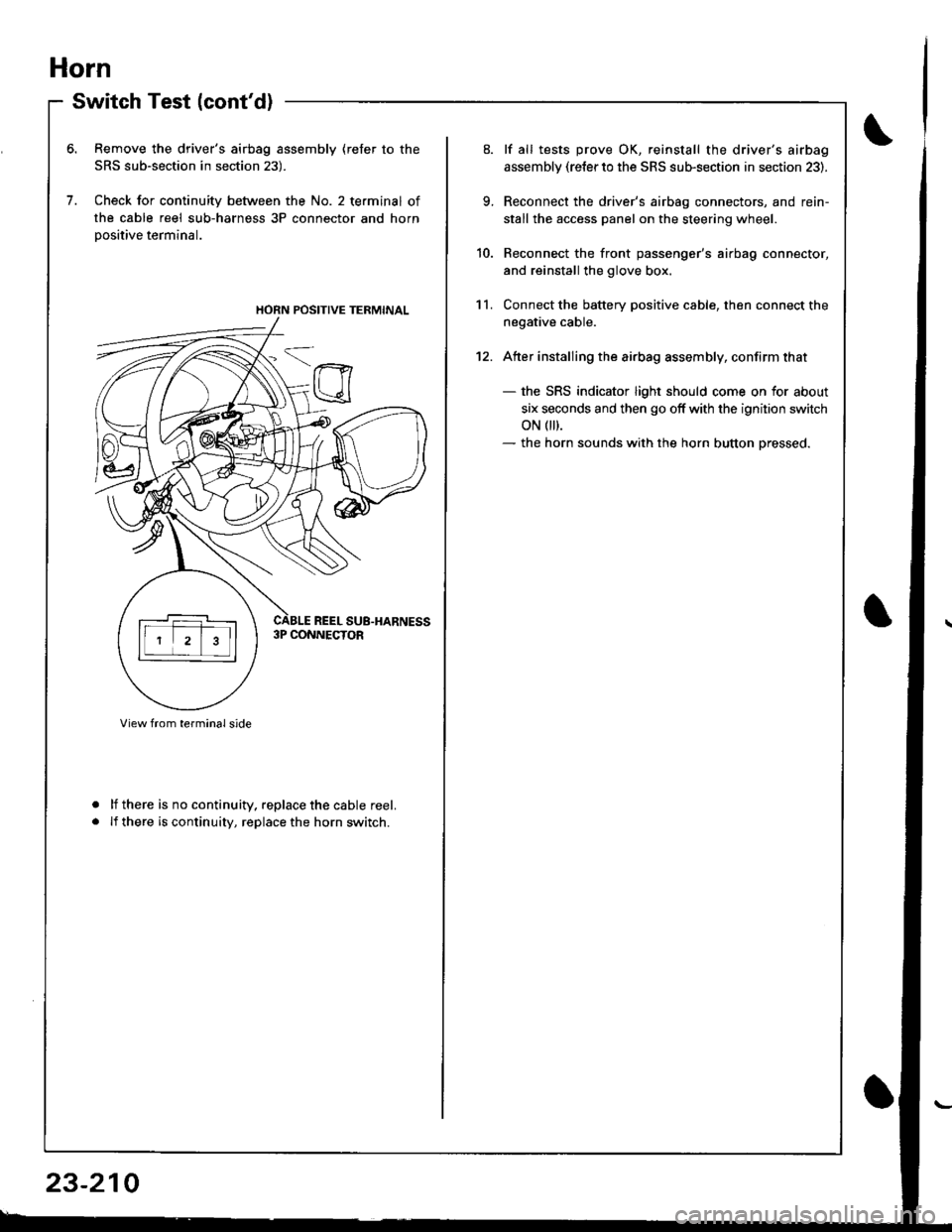

Remove the driver's airbag assembly (refer to the

SRS sub-section in section 23).

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

Dositive terminal.

lf there is no continuity. replace the cable reel.

lf there is continuity, replace the horn switch.

a

a

HORN POSITIVE TERMINAL

23-210

9.

10.

11.

12.

lf all tests prove OK, reinstall the driver's airbag

assembly (re{er to the SRS sub-section in section 23).

Reconnect the driver's airbag connectors, and rein-

stall the access panel on the steering wheel.

Reconnect the front passenger's airbag connector,

and reinstall the glove box.

Connect the battery positive cable, then connect the

negative cable.

Atter installing the airbag assembly, confirm that

- the SRS indicator light should come on for about

six seconds and then go off with the ignition switch

oN 0t).- the horn sounds with the horn button pressed.

Page 1314 of 1681

Set/Resume Switch Test/Replacement

SRS comDonents are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vice.

NOTE: The original radio has a coded theft protection cir-

cuit, Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 {7.5 A} fuse from the under-hood

fuse/relav box.- removing the radio.

Atter service, reconnect Dower to the radio and turn it on.

When the word "CODE" is displayed, enter the customer's

s-digit code to restore radio operatior..

1. Disconnect the battery negative cable, then discon-

nect the oositive cable, and wait at least three min-

utes,

2. Disconnect each airbag connector.

Drivor's Side:

a Remove the access panel from the steering wheel,

then disconnect the 2P connector between the

driver's airbag and cable reel,

Front Passenge;'s Side:

a Remove the glove box.

. Disconnect the 2P connector between the front

passenger's airbag and SRS main harness.

)

Remove the dashboard lower cover and knee bolster(see page 23-71).

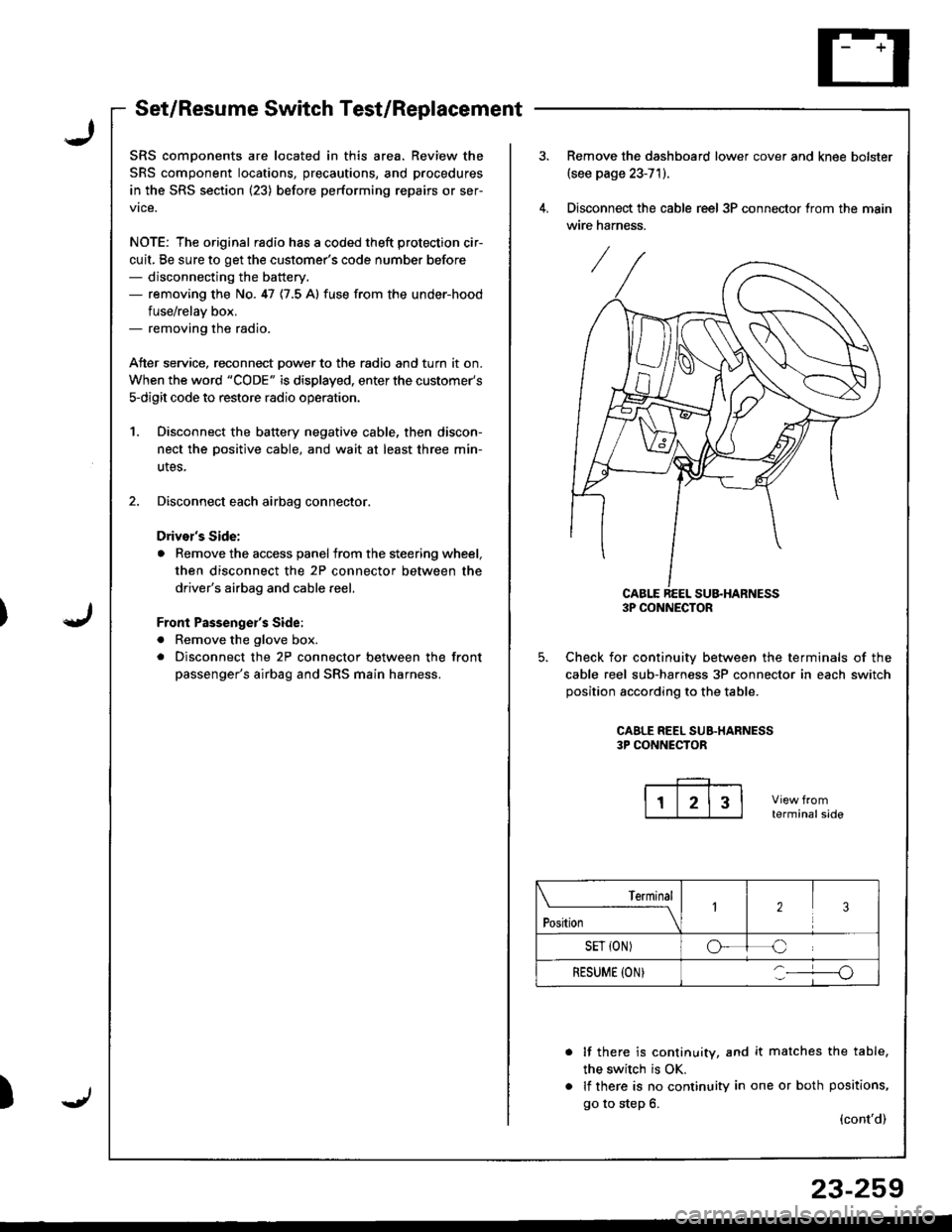

Disconnect the cable reel 3P connector trom the main

wire harness.

CABLE REEL SU&HARNESS3P CONNECTOR

Check for continuiw between the terminals of the

cable reel sub-harness 3P connector in each switch

position according to the table.

CAALE REEL SUB.HARNESS3P CONNECTOR

terminalside

lf there is continuity, and it matches the table,

the switch is OK.

lf there is no continuity in one or both positions,

go to step 6.(cont'd)

Terminal

t"*-

---\23

SET {ON)oC

RESUME (ON}o

23-259