engine coolant HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 80 of 1681

Gylinder Head

Removal (cont'dl

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ltosE

VACUUM HOSE

6-18

10.

9.

11.

Remove the throttle cable,

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (s€e section 11 and 14).

THROTTLE CONTROLCABLE

ADJUSTING NUT

Remove the engine wire harness connectors and

wire harness clamps f.om the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lATl sensor connector

Engine coolant temperature {ECT) sensor con,

nector

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute pressure (MAP) sensor con-

necto r

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

Crankshaft speed fluctuation (CKF) sensor con-

nector

a

a

a

a

a

a

a

a

ADJUSTING

Page 195 of 1681

Cooling

lllustrated Index ........

Radiator

Replacement ..............

Engine Coolant Refilling and

Bleeding

Cap Testing

Pressure Testing

Thermostat

Replacement ..............

Testing

Water Pump

lllustrated Index .........

Inspection

Replacement ...............

10-2

10-5

10-6

10-8

10-8

10-9

10-9

10-10

10-11

10-11

Page 196 of 1681

lllustrated Index

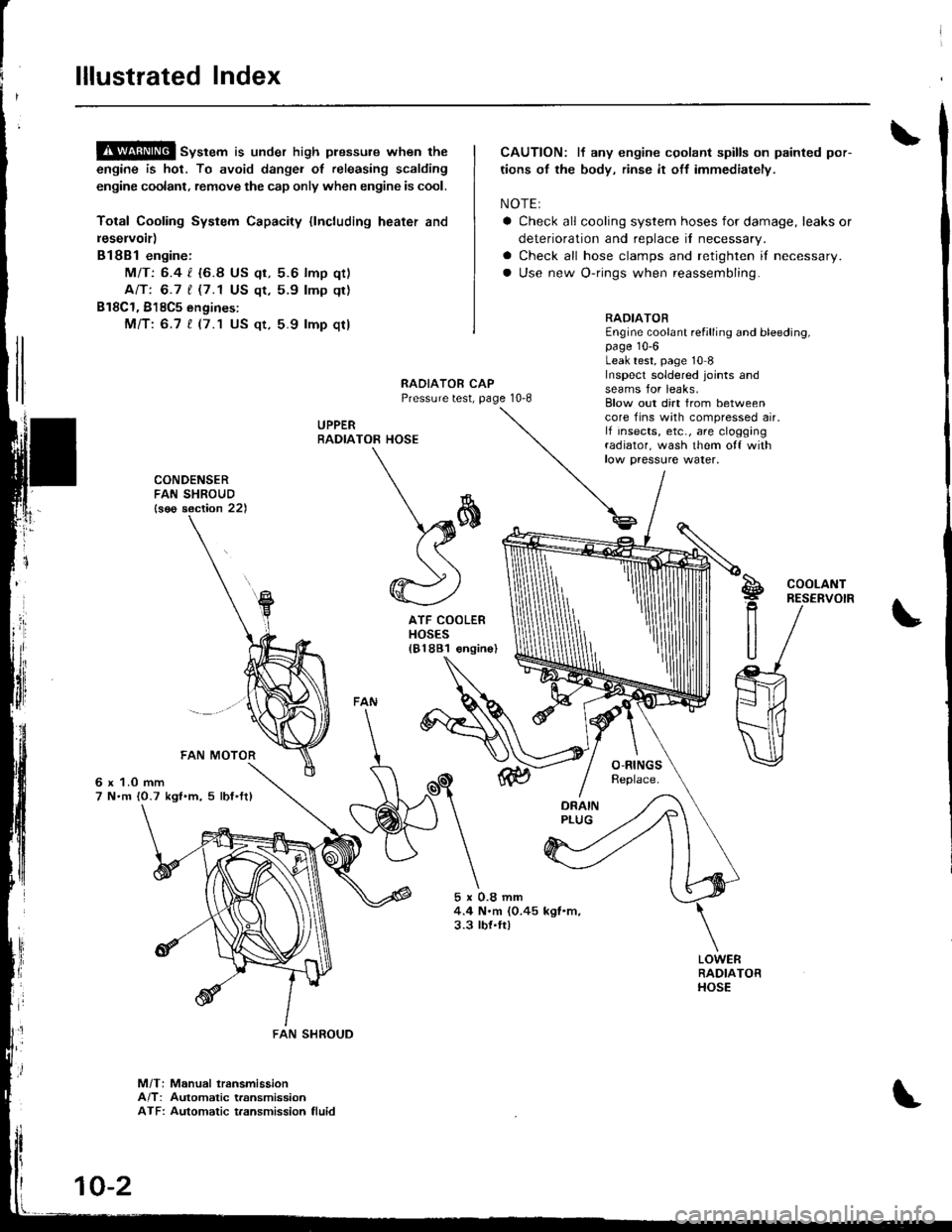

!$!!@ sv"t"m is under high plessure when the

engine is hot, To avoid dangei of releasing scalding

engine coolant, remove the cap only when engine is cool.

Total Cooling System Capacity {lncluding heater and

leservoir)

Bl8Bl engine:

MIT: 6.4 l. {6.8 US qt, 5.6 lmp qt)

Ant 6.7 t (7.1 US qt,5.9 lmp qt)

B18C1, 818C5 engines:

Mfi:6.7 t (7.1 US qt, 5.9 lmp qt)

CAUTION: lf any engine cgolant spills on painted por-

tions of the body, rinse it off immediately.

NOTE:

a Check all cooling system hoses for damage, leaks or

deterioration and replace il necessary.

a Check all hose clamps and retighten if necessary.

a Use new O-rings when reassembling.

RADIATOREngine coolant refilling and bleeding,page 10-6Leak test, page 10 8Inspecl soldered joints andseams for leaks,RAOIATOR CAPPressure test, page 10-8

UPPERRADIA

rl

]

CONDENSERFAN SHROUD{s€o section 22)

6 x 1.0 mm7 N.m {0.7 kgl.m, 5 lbf'ftl

5x0.8mm4.4 N.m (0.45 kgl.m,3.3 tbt.ft)

Blow out dirt from betweencore fins with compressed air.lf insects, etc., are cloggingradiator, wash them o{f withlow paessure water,

TOR HOSE

\*

\sffi((

@)

ATF COOLERHOSES181881 €ngin

S!g

R

U

COOLANTRESERVOIR

M/T: Manual lransmissionA/T: Automatic transmissionATF: Automatic t.ansmission fluid

FAN SHROUD

10-2

Page 199 of 1681

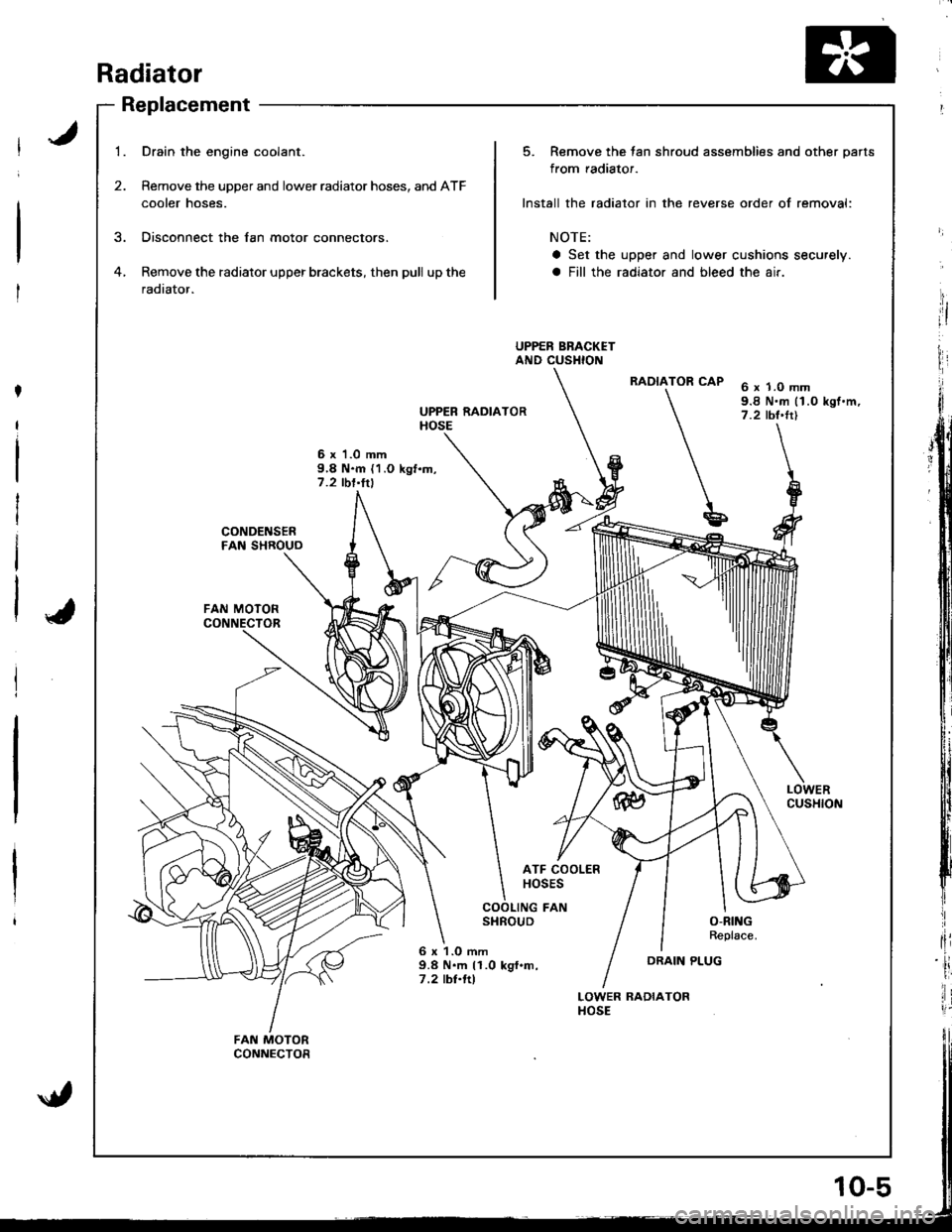

Radiator

Replacement

1.

2.

Drain the engine coolant.

Remove the upper and lower radiator hoses, and ATF

cooler hoses.

Disconnect the lan motor connectors.

Remove the radiator upper brackets, then pull up the

radiator.

6 x 'l .0 mm9,8 N.m {1.O kgf.m,7.2 tbl'ltl

UPPER RADIATORHOSE

6 x 1.0 mm9.8 N.m (1.0 kgf.m,7.2 tbt'trl

LOWERCUSHION

CONDENSERFAN SHROUO

FAN MOTOR

ATF COOLERHOSES

COOLING FANSHROUDO-RINGReplace.

6 x 1.O mm9.8 N.m 11.0 kgf.m,7 .2 tbl.ftl

LOWER RADIATORHOSE

FAN MOTORCONNECTOR

5. Remove the tan shroud assemblies and other parts

from radiator.

Install the radiator in the reverse order of removal:

NOTE:

a Set the upper and lower cushions securely.

a Fill the radiator and bleed the air.

UPPER BRACKETAND CUSHION

RADIATOR CAP

u

DRAIN PLUG

jit

I

HI

I

fli

ii

lir

Page 200 of 1681

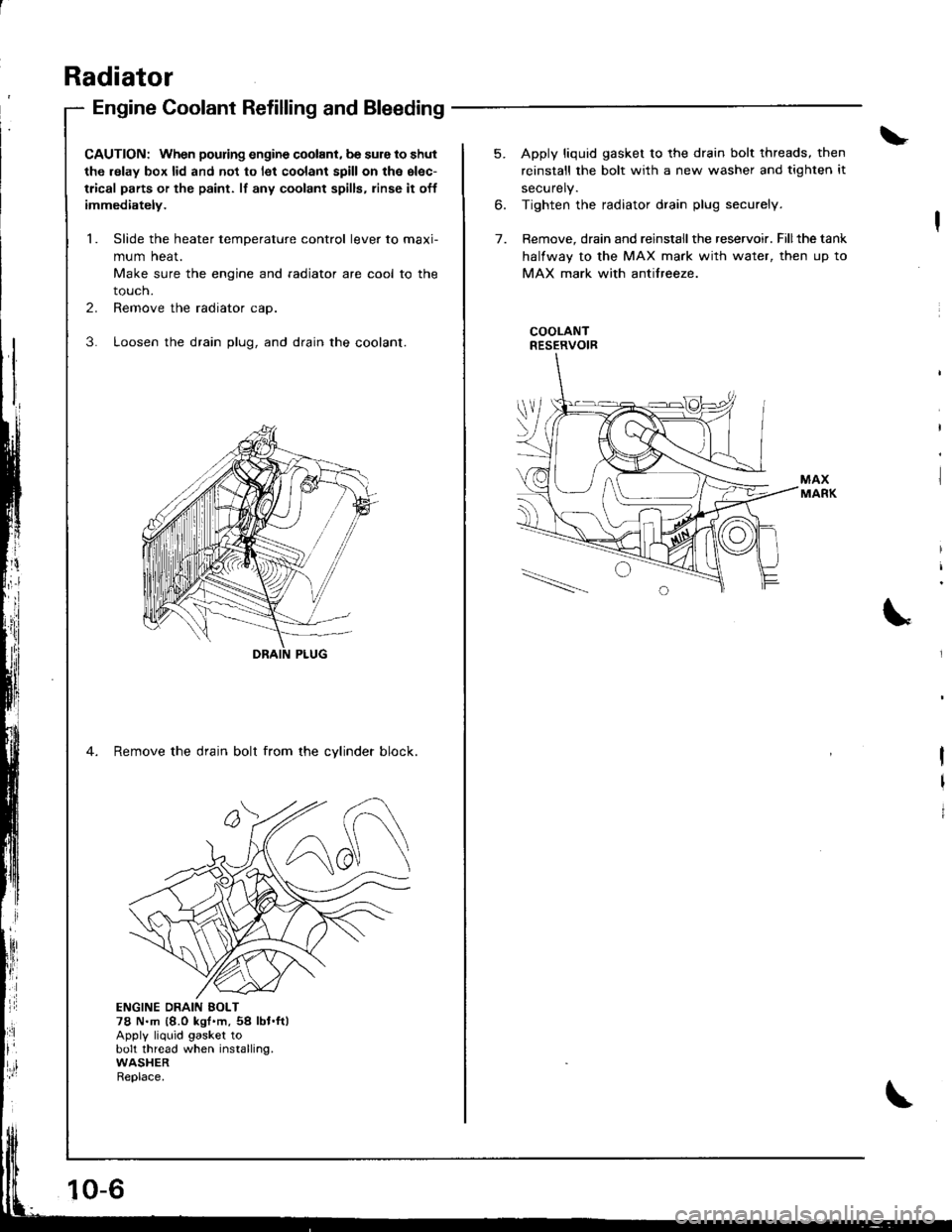

Radiator

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to shut

th6 relay box lid and not to l€t coolant spill on th6 el€c-

trical parts or the paint. lf any coolant spills, rinse it off

immediately.

1. Slide the heater temDerature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cap.

3. Loosen the drain plug, and drain the coolant.

4. Remove the drain bolt from the cvlinder block.

ji

Ii'

l:ll

ENGINE DRAIN EOLT78 N.m {8.0 kgt'm,54 lbt.ft)Apply liquid gasket tobolt thread when installing.WASHERReplace.

10-6

5. Apply liquid gasket to the drain bolt threads, then

reinstall the bolt with a new washer and tighten it

securely.

6. Tighten the radiator drain plug securely.

7. Remove, drain and reinstall the reservoir. Fillthe tank

halfway to the MAX mark with water, then up to

MAX mark with antifreeze.

COOLANTRESERVOIR

I

I

I

Page 201 of 1681

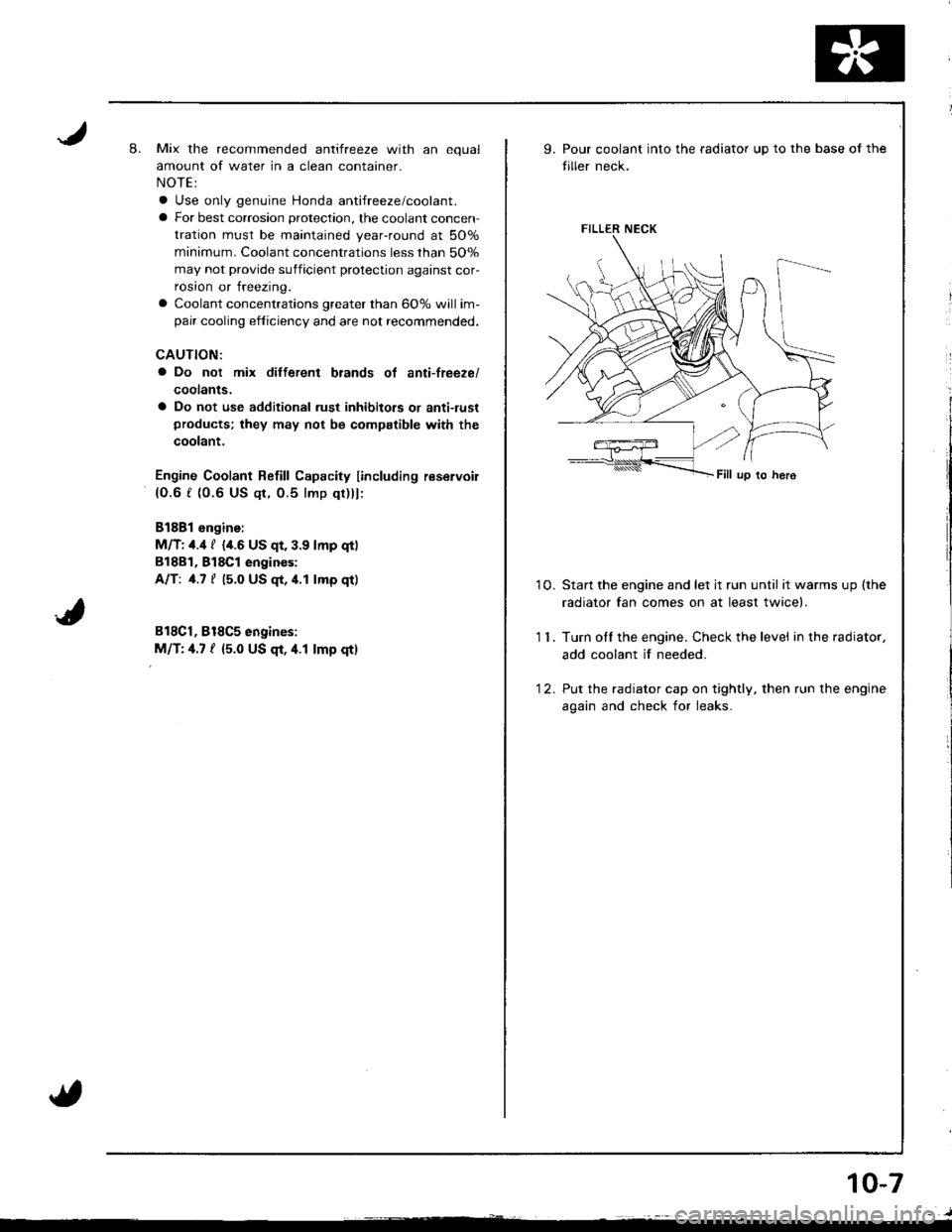

8.Mix the recommended antifreeze with an equal

amount of water in a clean container.

NOTE:

a Use only genuine Honda antifreeze/coolant.

a For best corrosion protection, the coolant concen-

tration must be maintained year-round at 500,6

minimum. Coolant concentrations less than 507o

may not provide sufficient protection against cor,

rosion or freezing.

a Coolant concentrations greater than 60% will im-

pair cooling efliciency and are not recommended.

CAUTION:

a Do not mix different brands of anti-lrcezel

coolants.

a Do not use additional rust inhibitots or anti-tustproducts; they may not be compatible with the

coolant.

Engine Coolant Refill Capacity [including reservoir

{0.6 { (0.6 US qt, 0.5 lmp qr)ll:

81881 engine:

Ml7:1-1t {/t.6 US qt. 3.9 lmp qtl

818B1, 818C1 engin€s:

AlTt 1.7 | 15.0 US qt, 4.1 lmp qt)

818C1, B18C5 engines:

MlTt 1.7 t 15.0 US $, 4.1 lmp qtl

FILLER NECK

9.Pour coolant into the radiator up to the base of the

tiller neck.

10. Startthe engine and let jt run until itwarmsup(the

radiator fan comes on at least twice).

1 1 . Turn olf the engine. Check the level in the radiator,

add coolant if needed.

'12. Put the radiator cap on tightly, then run the engine

again and check for leaks.

10-7

Page 202 of 1681

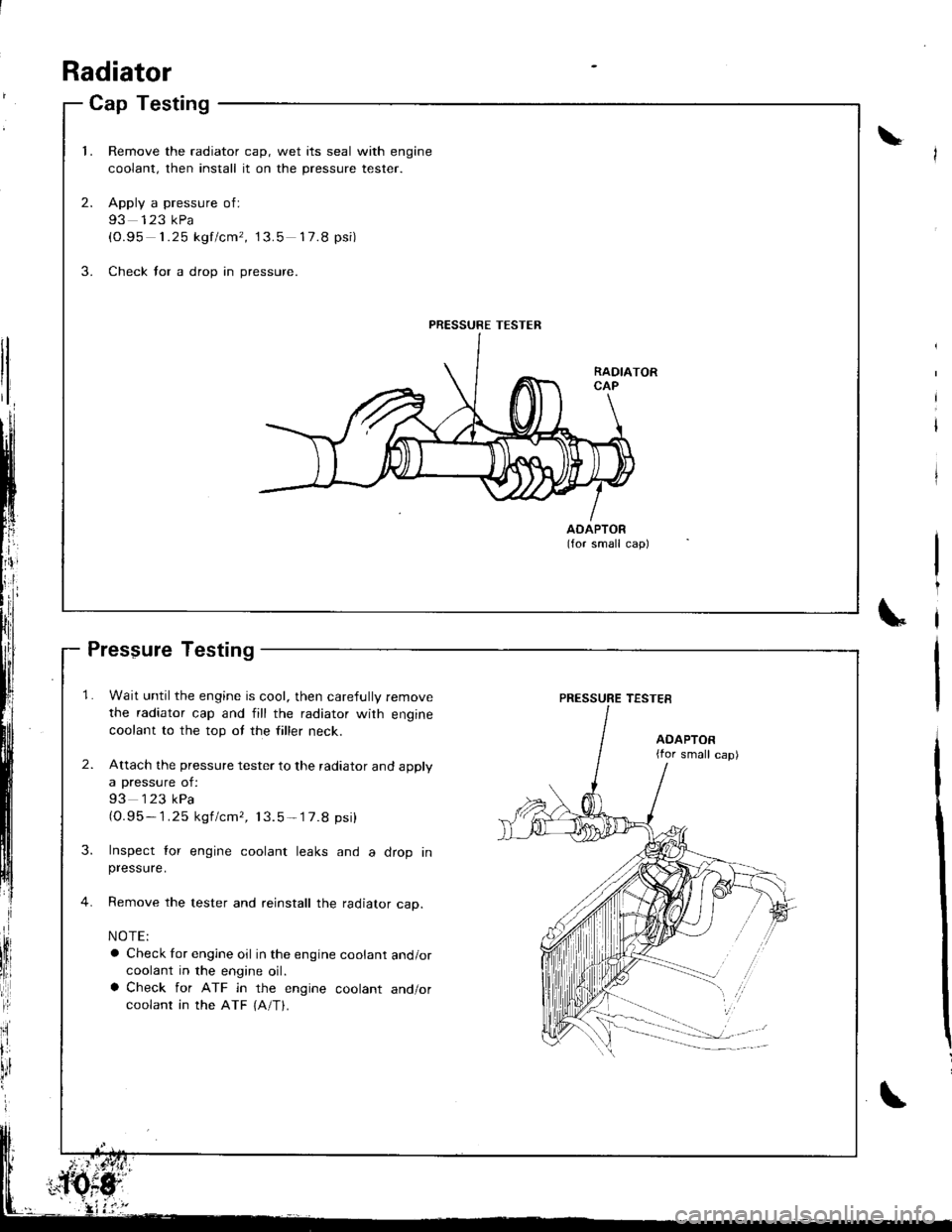

Cap Testing

1.Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

Apply a pressure of:

93 123 kPa(0.95 1.25 kgf/cm', 13.5 17.8 psi)

Check for a drop in pressure.

2.

3.

AOAPTOR(for small cap)

PRESSURE TESTER

Radiator

Pressure Testing

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top ot the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of:

93 123 kPa(O.95- 1.25 kgf/cmr, 13.5-'17.8 psi)

3. Inspect lor engine coolant leaks and a drop inpressure.

4. Remove the tester and reinstall the radiator cap.

NOTE:

a Check for engine oil in the engine coolant and/orcoolant in the engine oil.a Check for ATF in the engine coolant and/orcoolant in the ATF {A/T}.

\

PRESSURE TESTES

AOAPTOR{for small cap)

Page 204 of 1681

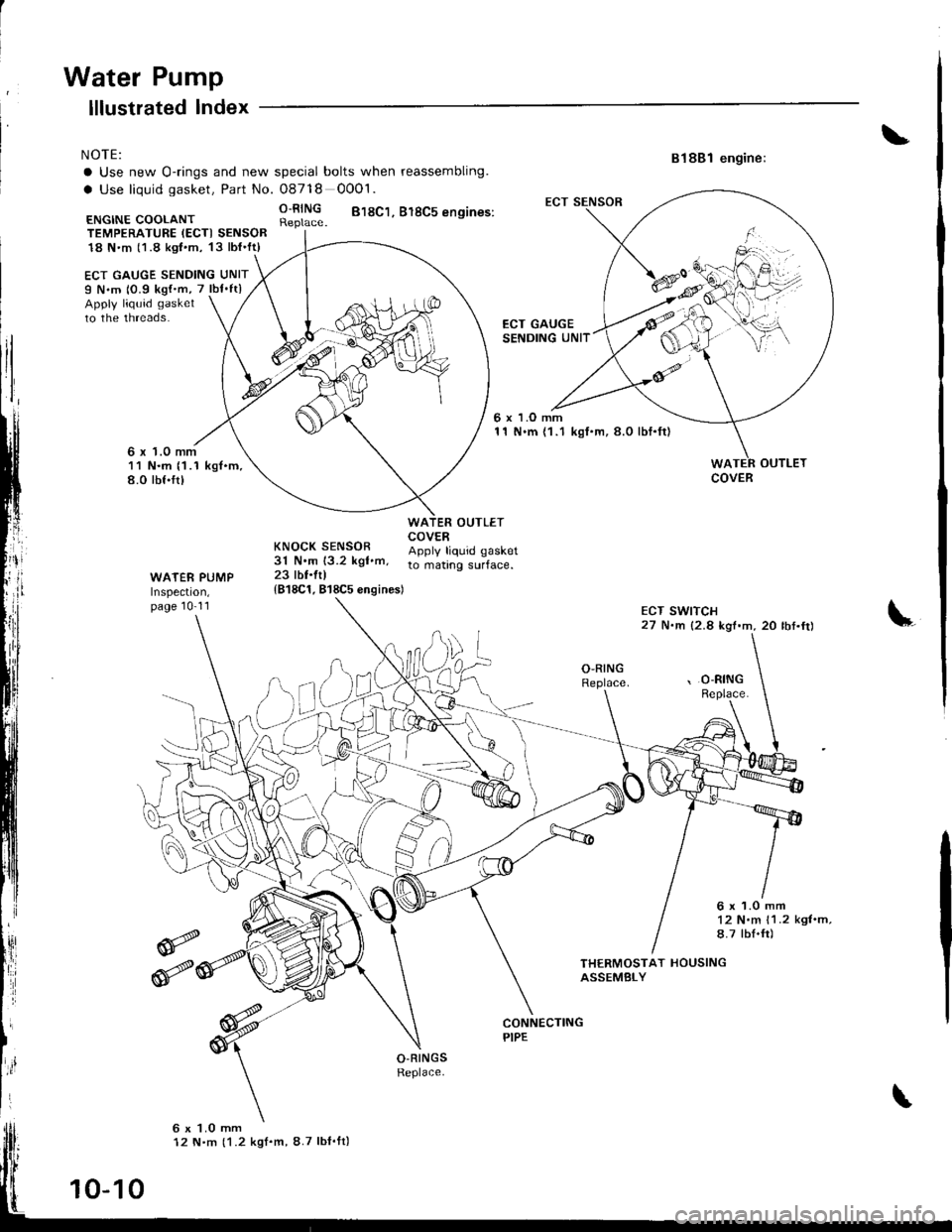

Water Pump

NOTE:

a Use new O-rings and new spgcial bolts when reassembling.

a Use liquid gasket, Part No. O8718 0001.

R;lll$ 818c1. 818c5 ensines:

ECT GAUGE SENDING UNITI N.m 10.9 kg{'m, 7 lbf'ftlApply liquid gasket

to the threads.

lllustrated lndex

6 x 1.0 mm11 N.m (1 .1 kgt.m.8.0 rbf.frt

ECT GAUGESENDING UNIT

818B1 engine:

OUTLET

ECT SWITCH27 N.m {2.8 kgf.m,20 lbf.fr)

ECT SENSOR

ENGINE COOLANTTEMPERATT,IRE IECTI SENSOR18 N'm (1.8 kgt.m, 13lbl'ft)

6 x 1.O mm11 N.m {1.1 kgI.m, 8.0 lbf.ft}

OUTLETCOVER

WATER PUMPInspecl|on,page 10-11

KNOCK SENSOR ADotv trouid oasket31 N.m 13.2 kgt.m, to ."t,nq .uif""".23 lbl.ftl

{818C1. 818C5 engines)

\,

O,RINGReplace.',O-RINGReplace.

6x1.0mm'12 N.m 11.2 kgt.m,8.7 lbI.fr)

THERMOSTAT HOUSINGASSEMBLY

O-RINGSReplace.

6 x 1.0 mm12 N.m (1.2 kgf.m, 8.7 lbI'ft)

COVER

10-10

Page 205 of 1681

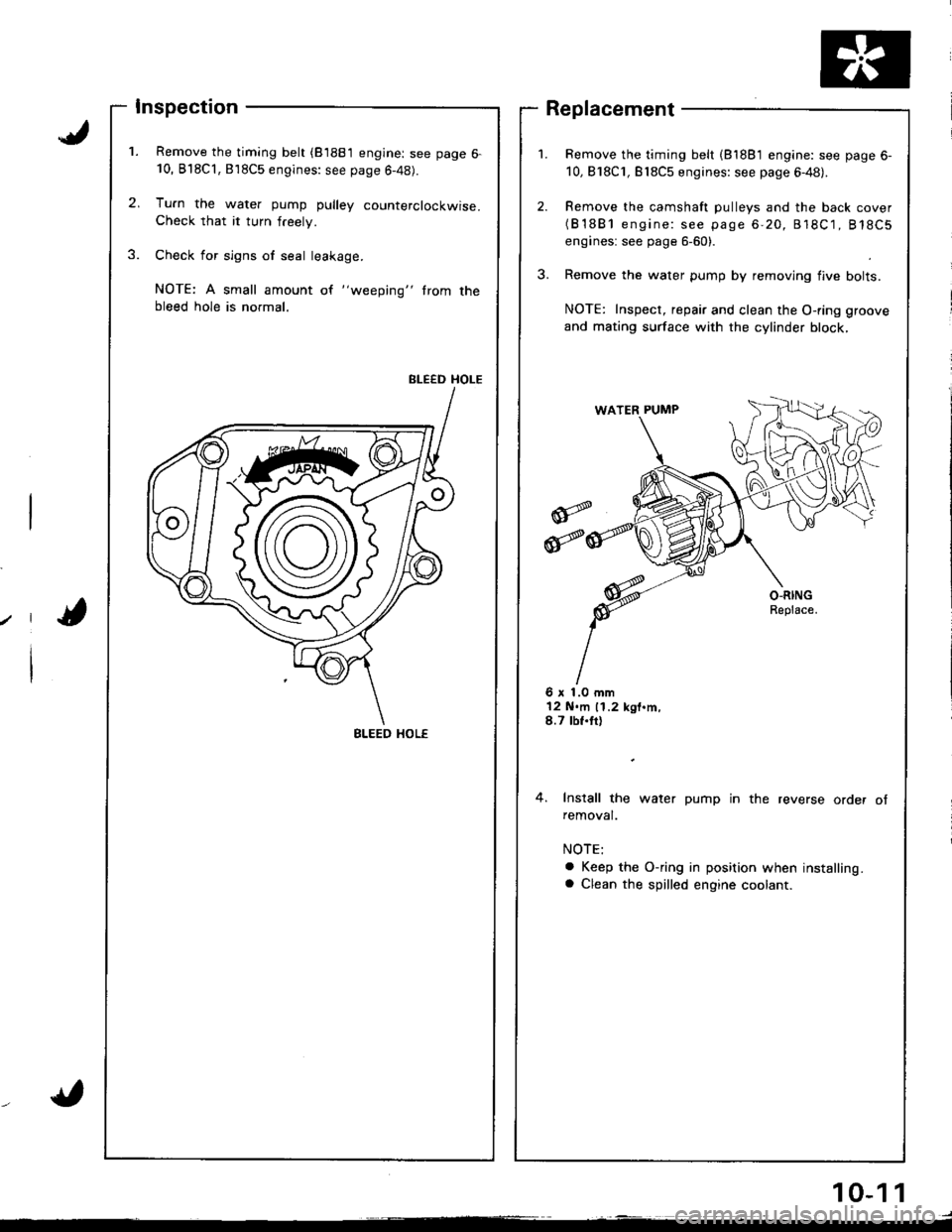

Inspection

Remove the timing belt (81881 engine: see page 6-10, B'l8Cl,818C5 engines: see page 6-48).

Tu.n the water pump pulley counterclockwise.Check that it turn freely.

Check for sign6 of seal leakage.

NOTE: A small amount of "weeping" trom thebleed hole is normal.

BLEED HOLE

Remove the timing belt (81881 engine: see page 6-

10,818C1, Bl8C5 engines: see page 6-48).

Remove the camshaft pulleys and the back cover(B'1881 engine: see page 6-20, 818C1, 818C5

engines: see page 6-60).

Remove the water pump by removing flve bolts.

NOTE: Inspect, repair and clean the O-ring groove

and mating surface with the cylinder block,

Replacement

6 x 1.0 mm12 N.m 11.2 kgt.m,8.7 tbf.tt)

4. Install the water pump in the reverse order ofremoval.

a Keep the O-ring in position when installing.a Clean the spilled engine coolant.

BLEED HOL€

10-1 1

Page 206 of 1681

i

iFuel and Emissions

SDeciaf Toofs ..,...,...............11-2

Component Locations

Index.,..,.,..................................,.,.,.,.,.,..,.,....... 11-3

System Description

Vacuum Connections ..................................,. 11-8

Electrical Connections ................................... 1 1-14

System Connectors ....,.,.,.,............................ 1 1-22

Troubleshooting

Troubfeshooting Procedures ........................ 11.32

Engine Control Module T€rminalArrangement .,.,.,..,.,. 11-39

Diagnostic Trouble Cods Chart .......-.-.......... 11-42

Howto Read Flowcharts ......,..,.,................... 1147

PGM-Fl System

System Description ............ 11-4

Troubleshooting Flowcharts

Engine Control Module ............,...,..,.,........... 11-50

Manifold Absolute PressureSensor...............................,..,.,...,................ 11-54

Intake Air TemDerature Sensor ..........,...,..... 11-58

Engine Coolant TemperatureSensor ....................,.,...,.,........................... 11-60

Throttle Position Sensor .,...........................,. 11-63

Primary Heated Oxygen Sensor(Sensor'l) .......,......,.,. 11-67

Secondary Heated Oxygen Sensorlsensor 2) .................. 11-71

Heated Oxygen Sensor Heater .....................'t1.74

Fuel Supply System ....................................... 1 1-76

Random Mistire ............. 11-78

Misfire Detected in One Cylinder .....,..:,,.,.... 11-79

Knock Sensor .........,.,..,. f -A2

Crankshaft Position/Top Dead Center/Cylinder Position Sensor .,........................ 11-83

Vehicle Speed Sensor .............,.,.,.,....,........... 11-85

Barometric Prsssute Sensor ..,...................... 11-86

Electrical Load Detector ...................,.,.......... 11-88

Crankshaft SDeed FluctuationSensor ...........................................,...,........ 11-90

ECM lnternal Circuit,..............................-......, 11-92

A/T Fl Date Line ............ 11-93

A/T Fl Signal A/B .......... 11-95

I,-1