wheel HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 511 of 1681

Road Test

NOTE: Warm up the engine to operating temperature (the radiator fan comes on).

1. Apply parking brake and block the wheels. Start the engine, then shift to @ position while depressing the brake pedal-

Depress the accelerator pedal, and release it suddenly. The engine should not stall.

2. Repeat same test in E position.

3. Test drive the vehicle on a flat road in the @ position. Check that the shift points occur at approximate speeds shown.

Also check for abnormal noise and clutch slippage.

NOTE: Throttle position sensor voltage represents the throttle opening.

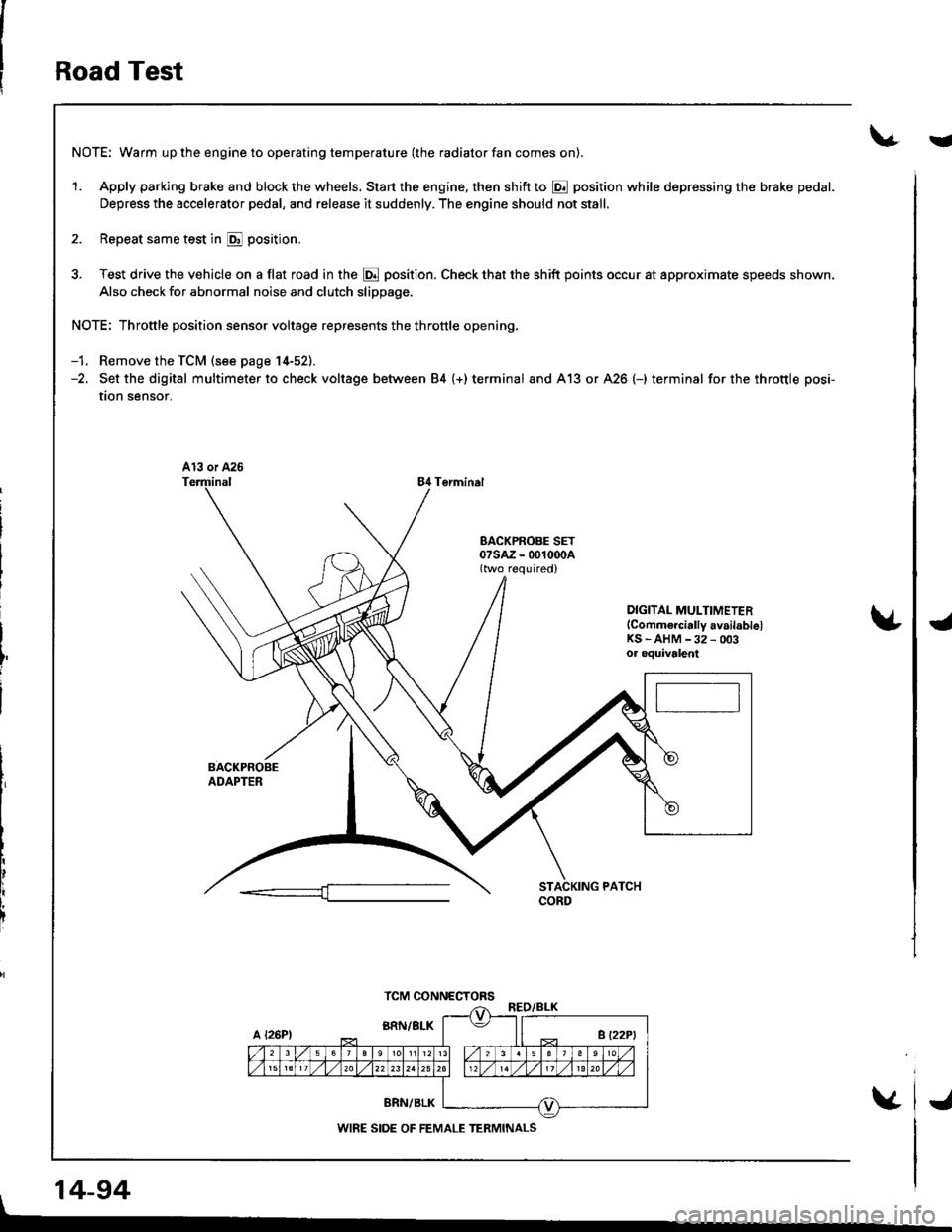

-1. Remove the TCM (see page 14-52).-2. Set the digital multimeter to check voltage between 84 (+) terminal and A13 or A26 (-) terminal for the throttle posi-

tion sensor.

84 Terminal

DIGITAL MULTIMETER(Commercially availablelKS - AHM -32 - 003oa oquivalent

, 14-94

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

i

J

Page 514 of 1681

Stall Speed

V

€nt transmission damage, do not tost stall speod for mol€ than

shitt tho lever while raising the engina speed,

10 soconds at a time.

L

CAUTION:

a To prev€nt transmission damage, do not tost stall speod for mol€ than 10 soconds at a time.

a Do not shitt tho lever while raising the engina speed,

a Be suro to remove tho plossule gaugo bolore testing st8ll spe€d.

1. Engage the parking brake. and block all lour wheels.

2. Connect the tachometer, and start the engine,

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature {the radiator fan comes on), shift into g position.

5. Fully depress the brake pedal and accelerator for 6 to I seconds. and note engine speed.

6. Allow two minutes for cooling, then repeat the test in [, [Dll and @ oositions.

NOTE:

a Stall speed tests should be used tor diagnostic purposes only.

. Stall speed should be the same in E, tr, tr and @ Fositions.

Stall Speed FPM: rpm

Specification:

Bl88l €ngine 2,5q) rpm

Bl8Cl engine 2.i|{10 .pm

Sorvice Limit:

81881 engins 2,350 - 2,650 rpm

Bl8Ct ongine 2,250 - 2,550 rpm

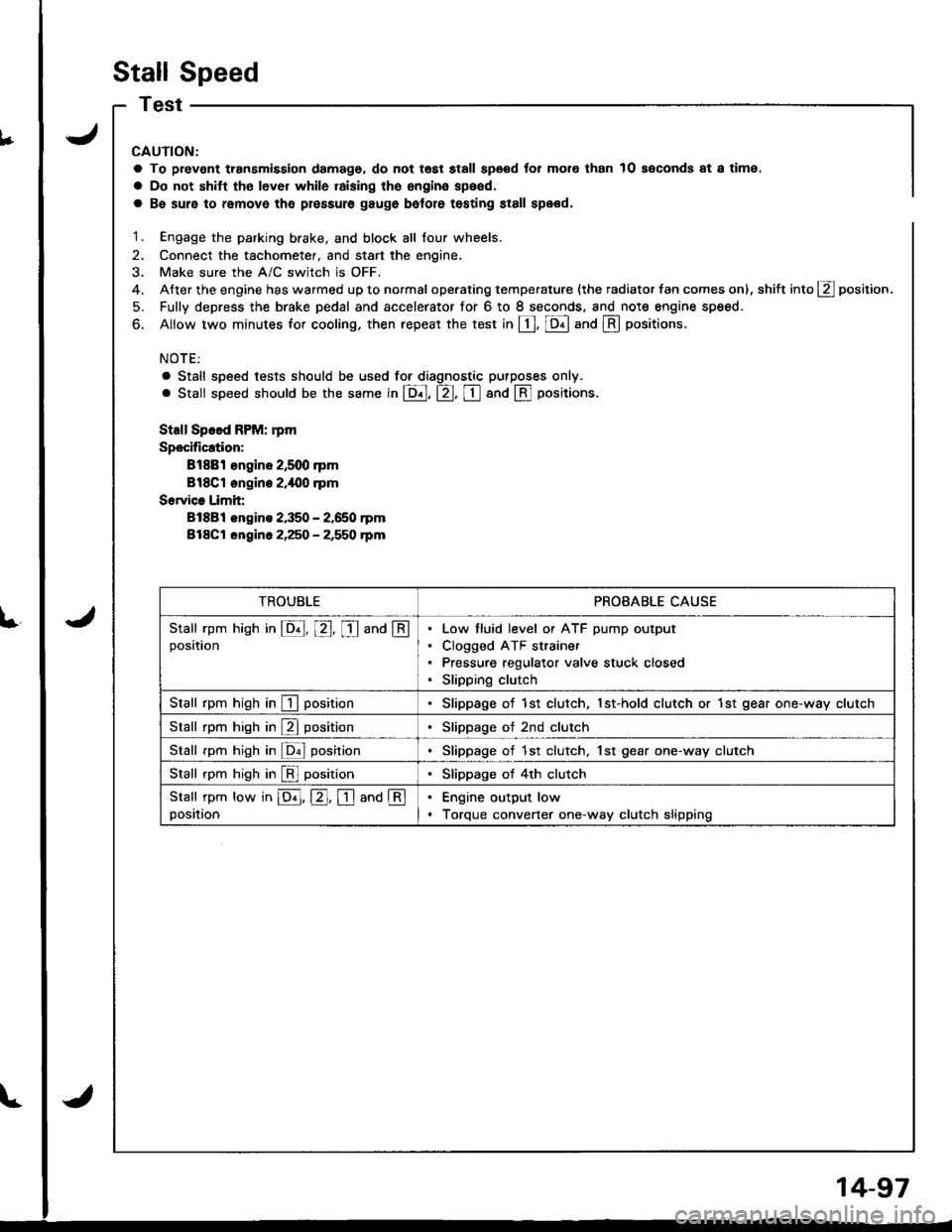

TROUBLEPROBABLE CAUSE

Stall rpm hish in E, E, I and @position

Low tluid level or ATF pump output

Clogged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in I positionSlippage of 1st clutch, 1st-hold clutch or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 2nd clutch

Stall rpm high in ldnl posirionSlippage of 1st clutch. 1st gear one-way clutch

Stall rpm high in [!l positionSlippage of 4th clutch

Stall rpm low in E, E. I and @position

Engine output low

Torque convener one-way clutch slipping

14-97

Page 516 of 1681

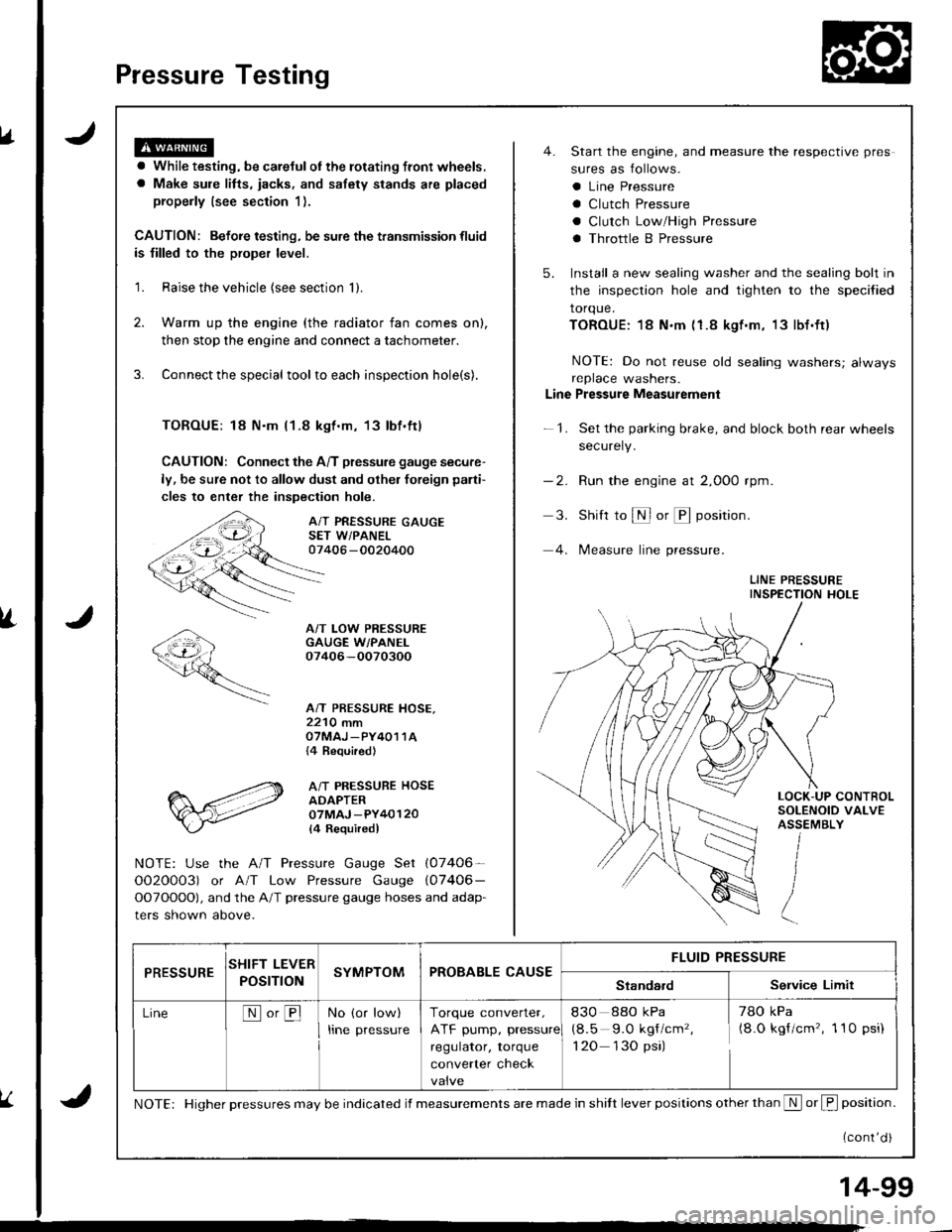

Pressure Testing

a While testing, be careJulot the rotating front wheels.

a Make sule litts, iacks, and safety stands are placed

properly (see section 1).

CAUTION: Befoie testing, be sure the transmission fluid

is filled to the proper level.

'1. Raise the vehicle {see section 'll.

2. Warm up the engine (the radiator fan comes on),

then stop the engine and connect a tachometer.

3. Connect the special tool to each inspection hole(s).

TOROUE: 18 N.m l1-8 kgt.m, 13lbf.ftl

CAUTION: Connect the A/T pressure gauge secure-

ly, be sure not to allow dust and olher foreign pani-

cles to enter the inspection hole.

A/T PRESSURE GAUGESET W/PANEL07406 -0020400

A/T LOW PRESSUREGAUGE W/PANEI.07406-OO70300

A/T PRESSURE HOSE,2210 mmOTMAJ _PY4O1 1A{4 Required}

A/T PRESSURE HOSEADAPTER07MAJ -PY40120

l4 Requiredl

NOTE: Use the A/T Pressure Gauge Set (07406-

OO2O0O3) or A/T Low Pressure Gauge (07406-

OOTOOOO), and the A/T pressure gauge hoses and adap-

ters shown above.

4. Start the engine, and measure the respective pres

sures as follows.

a Line Pressure

a Clutch Pressure

a Clutch Low/High Pressure

a Throttle B Pressure

5. Install a new sealing washer and the sealing bolt in

the inspection hole and tighten to the specified

torque.

TOROUE:18 N.m (1.8 kgf.m, 13lbf.ft)

NOTE: Do not reuse old sealing washers; alwaysreplace washers.

Line Pressure Measurement

-1. Set the parking brake, and block both rear wheels

securely.

-2. Run the engine at 2,000 rpm

3. Shift to S or @ position.

4. lMeasure line pressure.

LINE PRESSUREINSPECTION HOLE

LOCK-UP CONTROLSOLENOID VALVEASSEMBLY

PRESSURESHIFT LEVER

POST ONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineNo,BNo (or low)

Irne pressure

Torque converter,

ATF pump, pressure

regulator, torque

converter check

830 88o kPa

(8.5 9.O kgf/cm'�,

1 20 130 psi)

78O kPa(8.O kgf/cm'�, 1 10 psi)

NOTE: Higher pressures may be indicated if measurements are made in shitt lever positions other than S or f, position.

{cont'd )

14-99

Page 517 of 1681

Pressure Testing

.Y

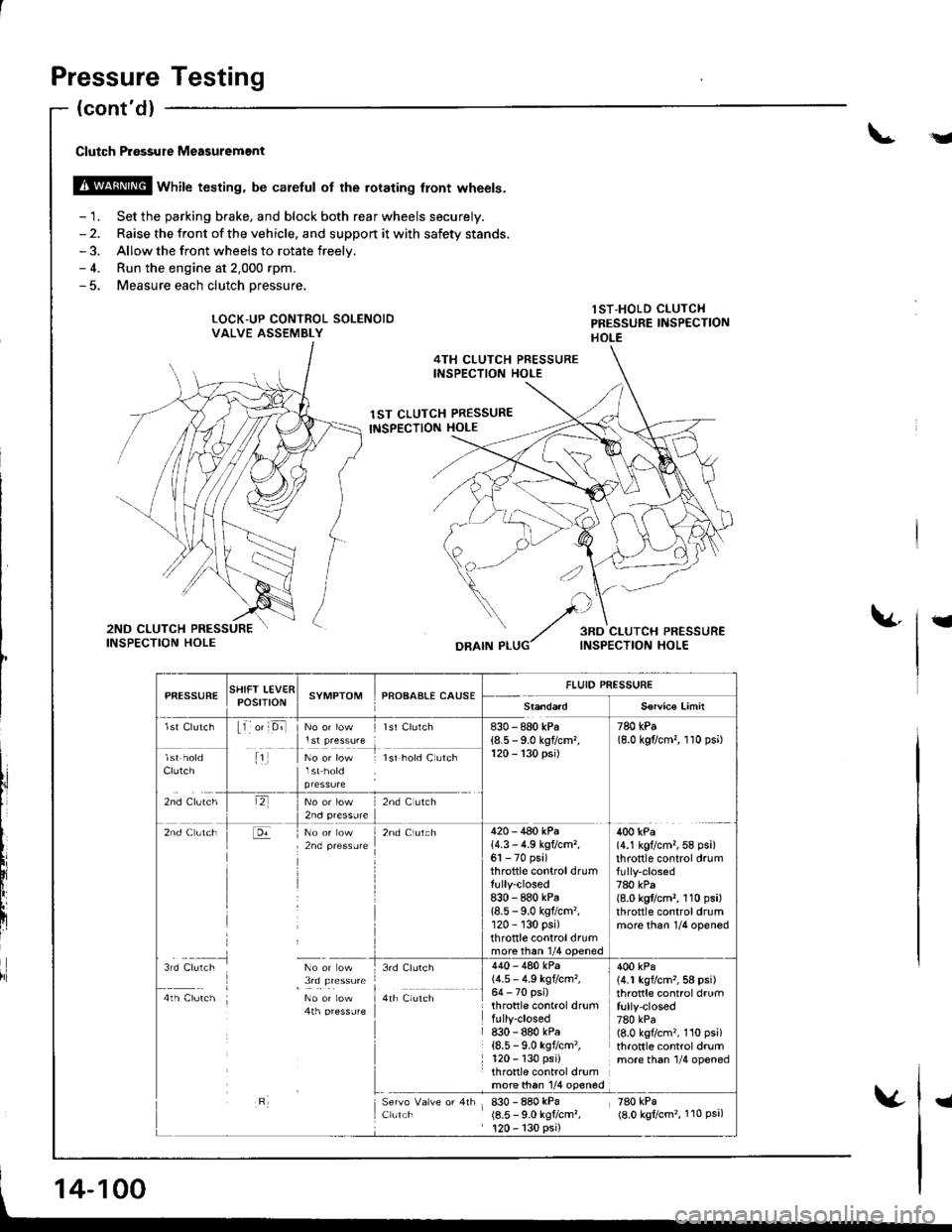

Clutch P.6ssure Measuremgnt

@ wnirc testing. be caretul ot the rorating tront wheels.

- 1. Set the parking brake, and block both rear wheels securely.- 2. Raise the front of the vehicle, and support it with safety stands.- 3. Allow the front wheels to rotate freelv.- 4. Run the engine at 2.000 rpm.- 5. Measure each clutch oressure.

LOCK"UP CONTROL SOLENOIDVALVE ASSEMBLY

lST-HOLD CLUTCHPRESSURE IiISPECTIONHOLE

4TH CLUTCH PRESSUREINSPECTION HOLE

1ST CLUTCH PRESSURE

INSPECTION HOLE

t

DRAIN P

l,i

PfiESSURESTIIFT LEV€RPOStTtONSYMPTOMPROAAALE CAUSEFLUID PRESSURE

S€rvico Limit

lst Clutch11 o' D;llst Clurch830 - 880 kPa(8.5 - 9.0 kgflcm,120 - 130 psi)

780 kPa(8.0 kgflcm,, 1 10 psi)

Clutch

zno cruiltr

1No or low lsr hold C utch

lr,2nd C ltch

2nd Clutch420 - 440 kPa14.3 - 4.9 kg?cm,,61 - 70 psi)throttle controldrumtully-closed8:|0 - 880 kPa18.5 - 9.0 kgflcm'�,120 - 130 psi)throttle controldrummore than 1/4 ooened

400 kPa(4.1 kg?cm,,58 psi)throttle control drum

780 kPa(8.0 kgflcm,, 110 psi)throttle controldrummore than 1/4 opened

3rd Clulch No or ow

I , !,q !le"**4th Clutch No or Low4th pressufe

3rd Clurch

a,r il","r,

Clulch

440 - 480 kPa(4.5 - 4.9 kgtcm,,64 - 70 psi)throttle control drumfully-closed830 - 880 kPa{8.5 - 9.0 ksf/cm'�,120 - 130 psi)throttle control drumrn9l9!q l/4 olqg

830 - 880 kPa(8.5 - 9.0 kgtcm?,120 - 130 psi)

400 kPa14.1 kgvcm,,58 psi)throttle control drumfully-closed780 kPa(8.0 kgflcm'�, 110 psi)throttle control drummore th6n 1/4 opened

zeo rpi(8.0 kgtcm'�, 110 Psa,

14-100

I

Page 518 of 1681

\a

t

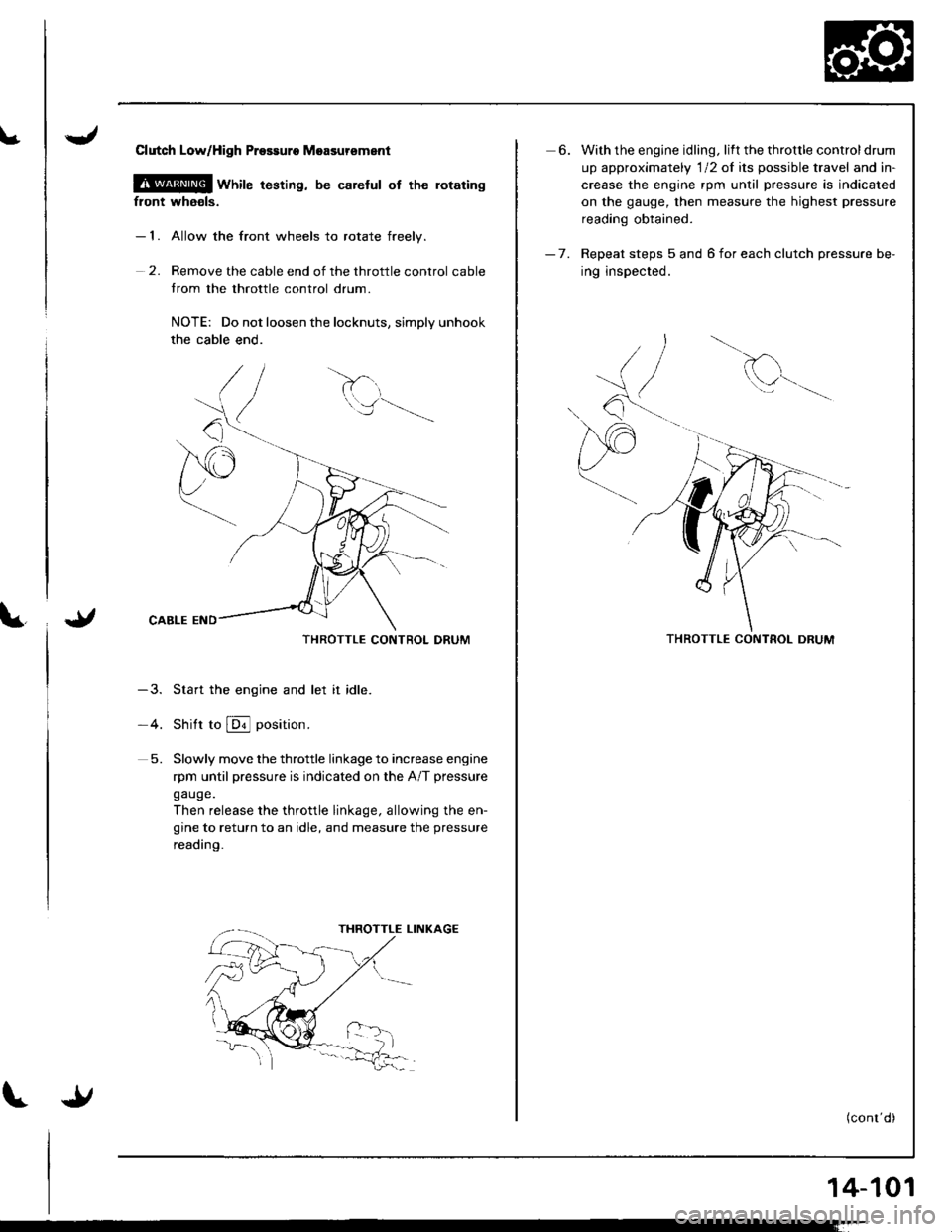

Clutch LoWHigh Prossuro Moasursment

@ wnire t6sting, be carelul of the rotating

front whaols.

- 1. Allow the front wheels to rotate freelv.

2. Remove the cable end of the throttle control cable

trom the throttle control drum.

NOTE: Do not loosen the locknuts, simply unhook

the cable end.

THROTTLE CONTROL DRUM

-3. Start the engine and let it idle.

-4. Shitt to @ position.

5. Slowly move the throttle linkage to increase engine

rpm until pressure is indicated on the A/T pressure

gauge.

Then release the throttle linkage, allowing the en-

gine to return to an idle, and measure the pressure

reading.

6. With the engine idling. lift the throttle controldrum

up approximately 'l12 of its possible travel and in-

crease the engine rpm until pressure is indicated

on the gauge, then measure the highest pressure

reading obtained.

- 7. Repeat steps 5 and 6 for each clutch pressure be-

ing inspected.

d

Q^--,'.-

THROTTLE CONTROL DRUM

(conr'd)

14-101

Page 520 of 1681

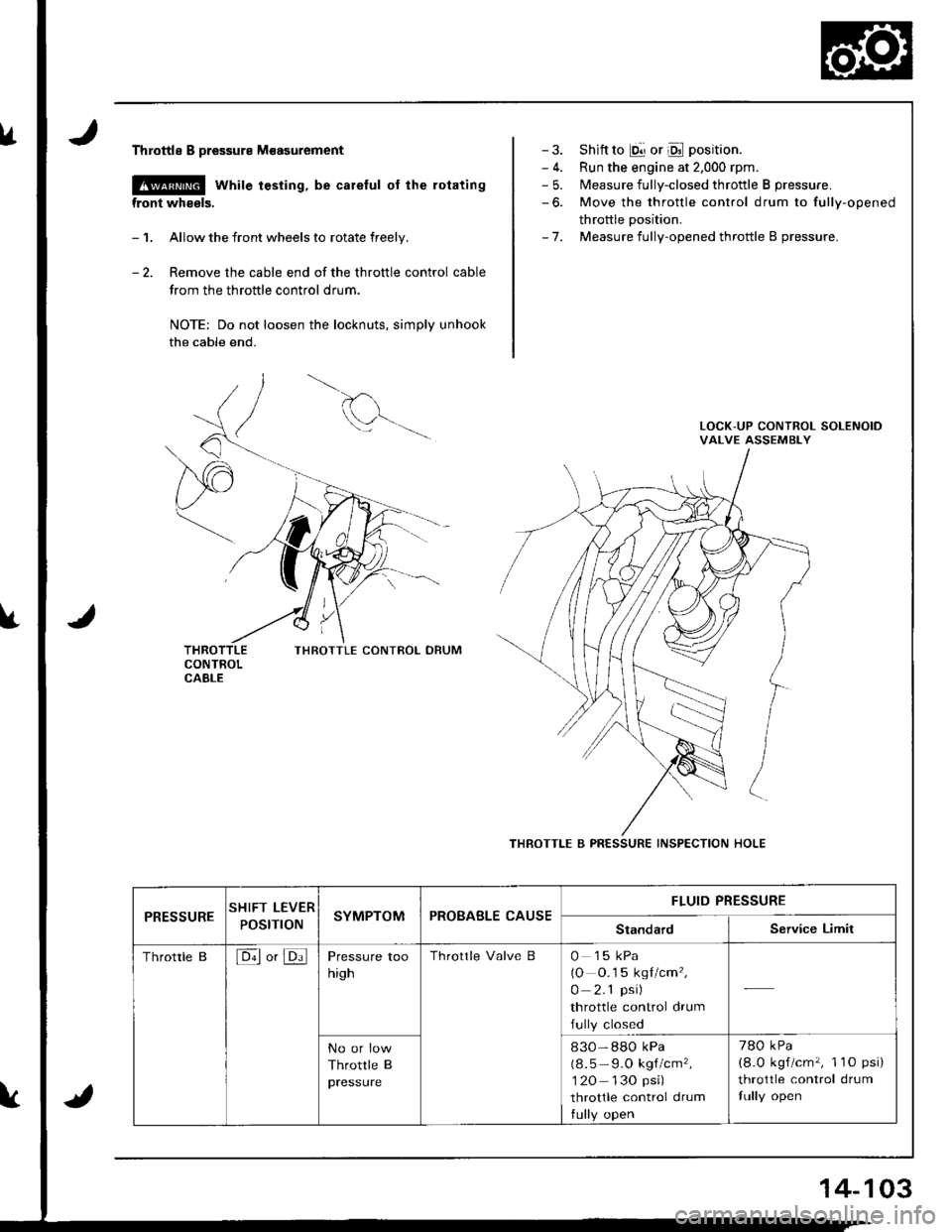

lrThrottle B pressure M€asurement

@ while testing, be careful of the rotating

front wheels.

- 1. Allow the front wheels to rotate freely.

- 2. Remove the cable end of the throttle control cable

trom the throttle control drum.

NOTE: Do not loosen the locknuts, simply unhook

the cable end.

THROTTLE CONIBOL DRUM

- 3. Shift to E!] or Oll position.

- 4. Run the engine at 2.000 rpm.- 5. Measure fully-closed throttle B pressure.

-6. Move the throttle control drum to fully-opened

throttle Dosition.- 7. Measure fully-opened throttle B pressure.

THROTTLE B PRESSURE INSPECTION HOLE

PRESSURESHIFT LEVER

POStnONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

Throttle B[6ll or JDi]Pressure too

high

Throttle Valve B0 15 kPa(O O.1 5 kgl/cm',

0 2.1 psi)

throttle control drum

fully closed

No or low

Throttle B

pressure

830-88O kPa

(8.5 - 9.O kgf/cm',

1 20 130 psi)

throttle control drum

tully open

780 kPa

(8.0 kgf/cm'�, 1 1O psi)

throttle control drum

fully open

14-103

Page 521 of 1681

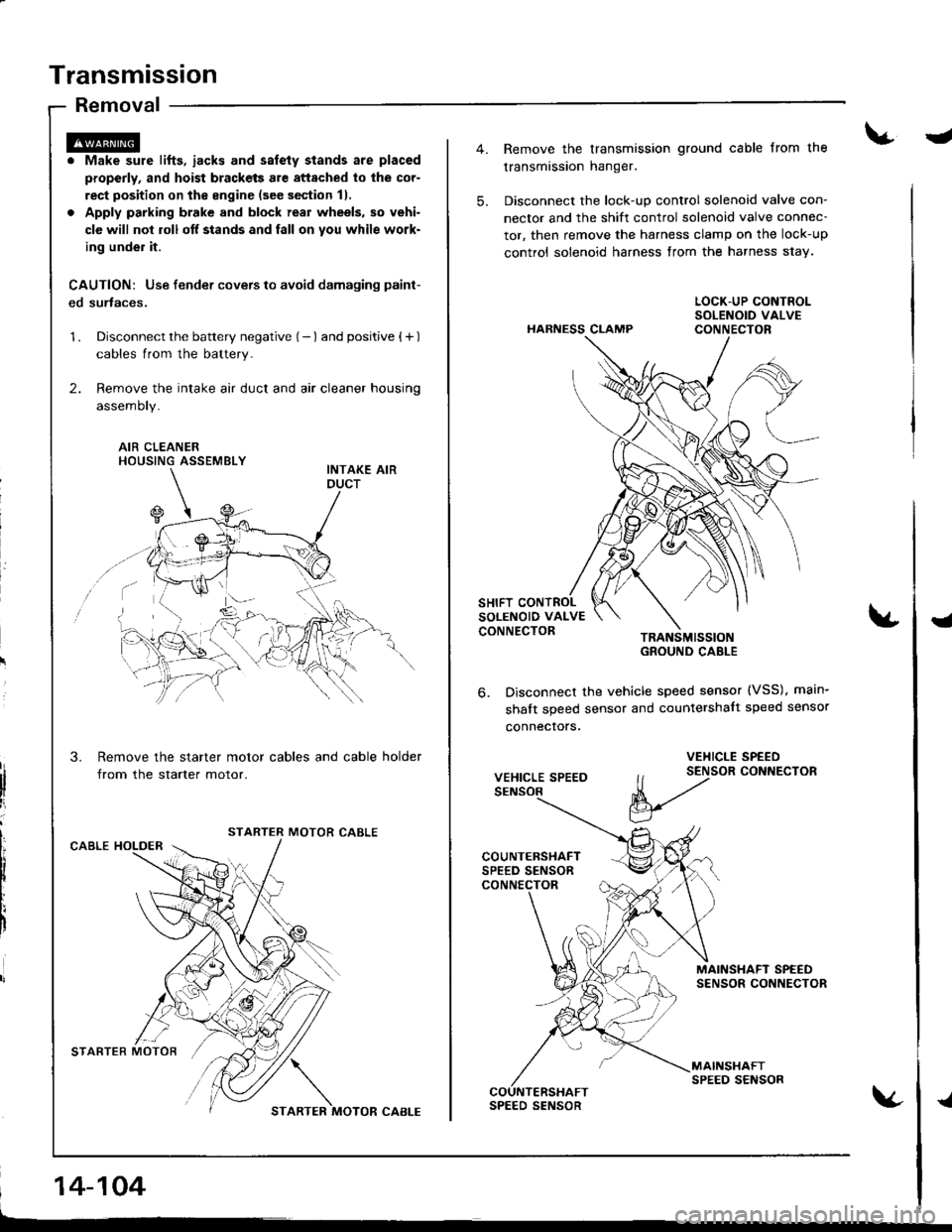

Transmission

Removal

. Make sure lifts, iacks and salety stands are placed

properly, and hoist brackets are attached to lhe cor-

rect position on the engine (see section 11.

. Apply parking brake and block real wheels, so vehi-

cle will nol roll off stands and fall on you while work-

ing under it.

CAUTION: Use fender covers to avoid damaging paint-

ed surtaces.

1 . Disconnect the battery negative (- ) and positive { + )

cables from the battery.

2. Remove the intake air duct and air cleaner housing

assemoty.

AIR CLEANERHOUSING ASSEMBLY

Remove the starter motor cables and cable holder

from the starter motor.

MOTOR CABLECABLE HOLDER

STARTER MOTOR'/,/ \

STARTER MOTOR CABI-E

14-104

-

5.

Remove the transmission ground cable from the

transmission hanger.

Disconnect the lock-up control solenoid valve con-

nector and the shift control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness s1ay.

HARNESS CLAMP

TRANSMISSIOIGROUND CABLE

Disconnect the vehicle speed sensor (VSS), main-

shalt speed sensor and countershalt speed sensor

connecrors.

{

6.

VEHICLE SPEED

VEHICLE SPEED

ll t2tor coNNEcroR

V

MAINSHAFT SPEEDSENSOR CONNECTOR

MAINSHAFTSPEED SENSORCOUNTERSHAFTSPEED SENSOR{

Page 587 of 1681

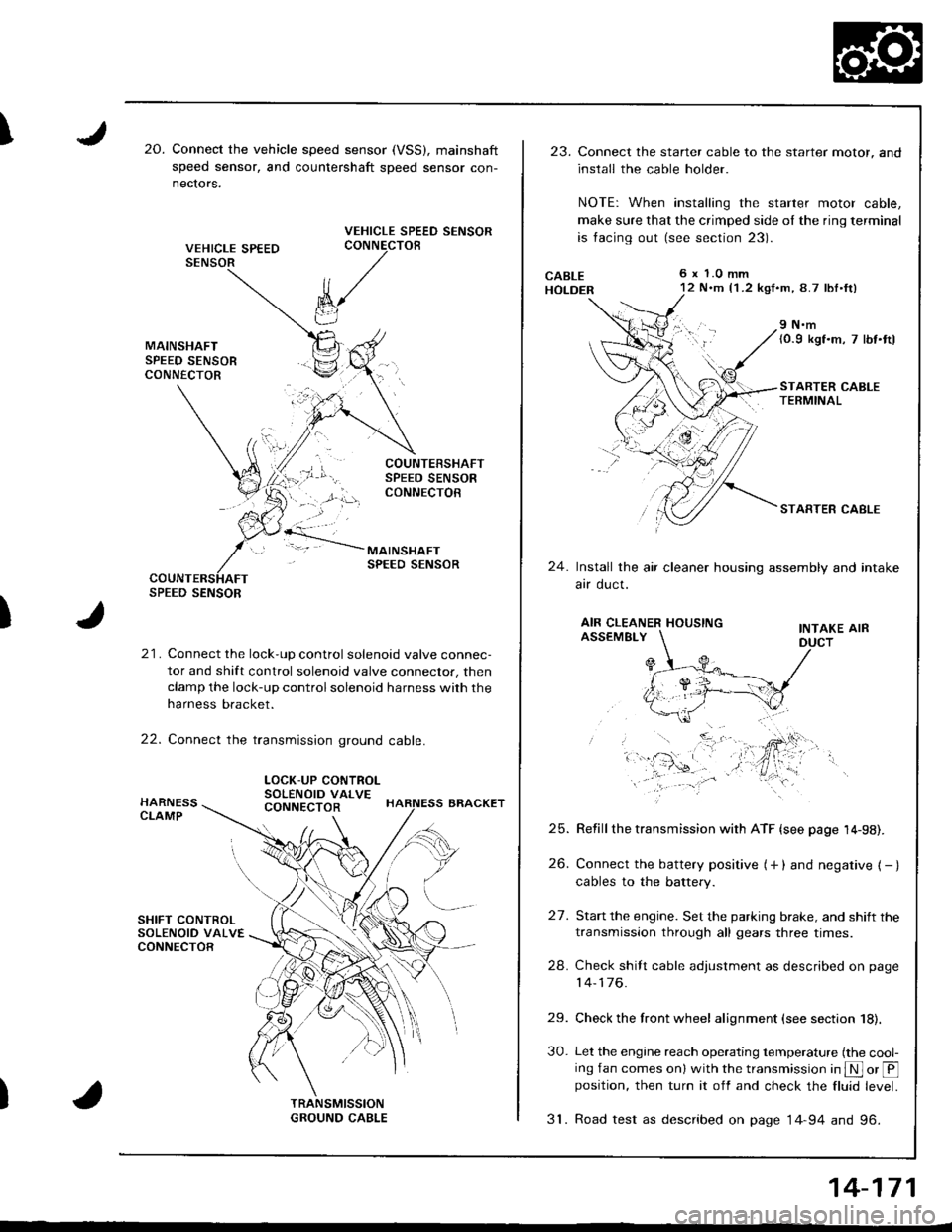

I20.Connect the vehicle speed sensor (VSS), mainshaft

speed sensor, and countershaft sDeed sensor con-

nectors.

VEHICLE SPEED SENSORCONNECTOB

)

k/

t"J

21. Connect the lock-up control solenoid valve connec-

tor and shift control solenoid valve conneclor, then

clamp the lock-up control solenoid harness with the

harness bracket.

22. Connect the transmission ground cable.

SPEED SENSOR

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

23.Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side ol the ring terminal

is facing out (see section 23).

6 x 1.0 mm12 N.m {1 .2 kgf.m, 8.7 lbl.ft)

9 N.m(0.9 kgf.m, 7 lbt.ttl

STARTER CABLETERMINAL

STARTER CABLE

24.Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGINTAKE AIRASSEMBLY

27.

Refill the transmission with ATF {see page 14-98).

Connect the battery positive (+ ) and negative { - }cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shilt cable adjustment as described on page

14-176.

Check the front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-ing fan comes onl with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-94 and 96.

25.

26.

24.

29.

30.

14-171

Page 618 of 1681

Limited Slip Differential (818C5 engine)

Description

t

f1t

1. Function

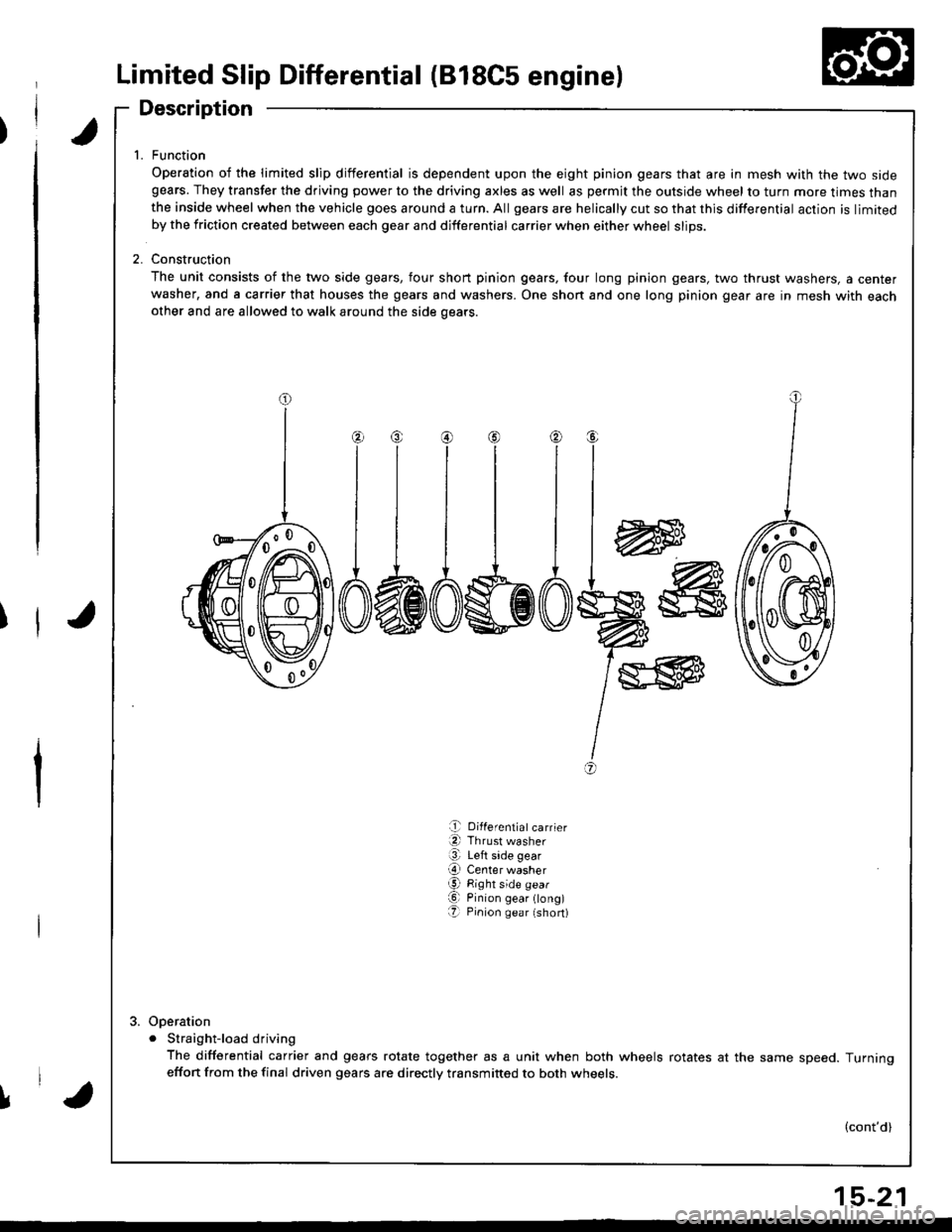

Operation of the limited slip differential is dependent upon the eight pinion gears that are in mesh with the two sidegears. They transfer the driving power to the driving axles as well as permjt the outside wheel to turn more times thanthe inside wheel when the vehicle goes around a turn. All gears are helically cut so that this differential action is limitedby the friction created between each gear and differential carrier when either wheel slips.

2. Construction

The unit consists of the two side gears, four short pinion gears, four long pinion gears, two thrust washers, a centerwasher, and a carrier that houses the gears and washers. One shon and one long pinion gear are in mesh with eachother and are allowed to walk around the side oears.

w

I

I

I

+

@

a,

e Differentiatcarrier

a Thrust washer

@ Left side gear

O Center washerg Right side gear

O Pinion gear ong)O Pinion gea r (short)

Ooeration

. Straight-load driving

The differential carrier and gears rotate together as a unit when both wheels rotates at the same speed. Turningeffon from the final driven gears are directly transmitted to both wheets.

(cont'd)

l,'a

15-21

Page 619 of 1681

Limited Slip Differential (B18C5 engine)

Description (cont'd)

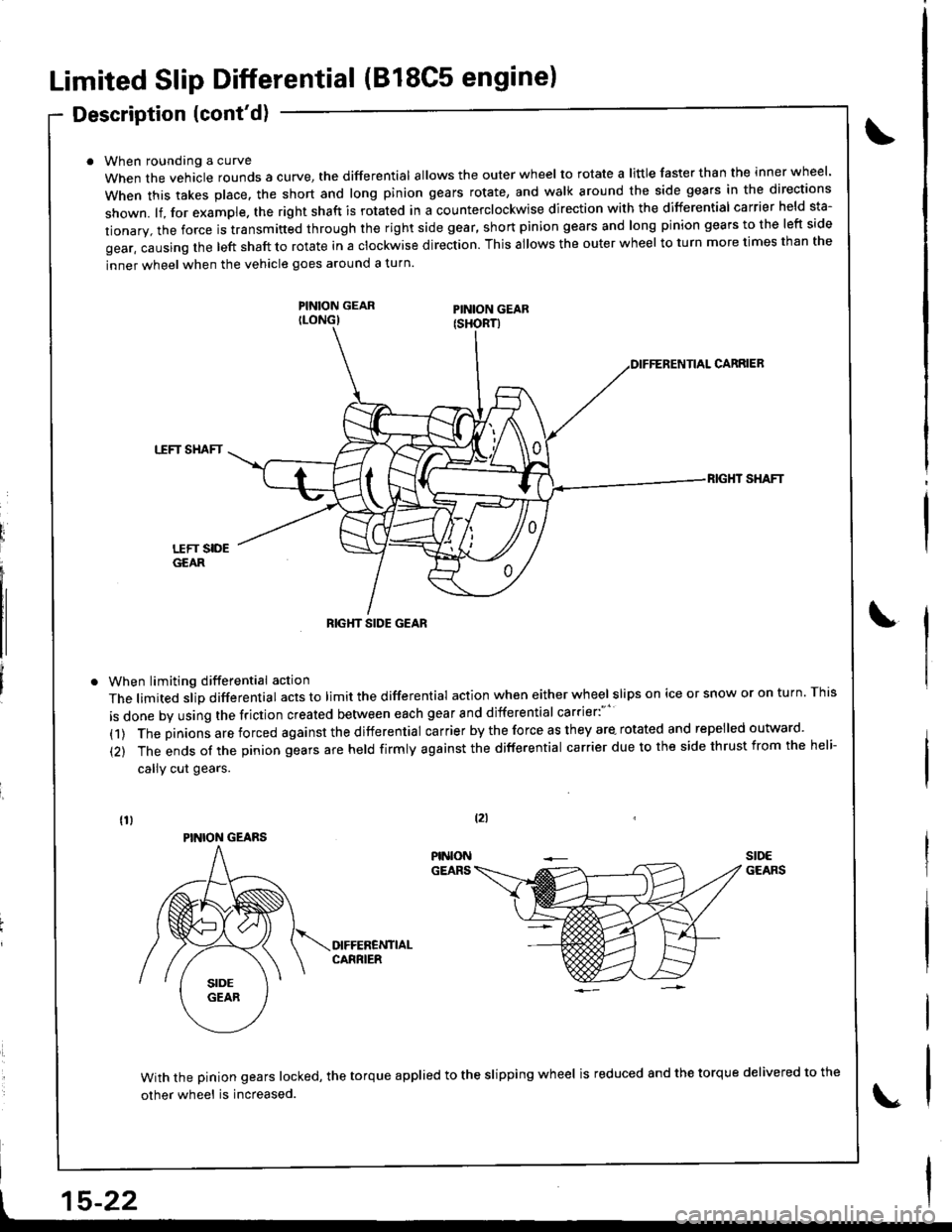

When roundang a curve

When the vehacle rounds a curye, tne differential allows the outer wheel to rotate a little faster than the inner wheel.

when this takes p|ace. the short and |ong pinion gears rotate, and wa|k around the side gears in the directions

shown. lf, for example. the right shaft is rotated in a counterclockwise direction with the differential carrier held sta-

tionary, the force is transmitted through the right side gear, short pinion gears and long pinion gears to the left side

gear, causing the left shaft to rotate in a clockwise direction. This allows the outer wheel to turn more times than the

inner wheel when the vehicle goes around a turn.

PINION GEARILONG)

When limiting differential action

The limited slip differential acts to limit the differential action when either wheel slips on ice or snow or on turn. This

is done by using the friction created between each gear and differential carrier:"''

(1) The pinions are forced against the differential carrier by the force as they are- rotated and repelled outward.

(2) The ends of the pinion gears are held firmly against the differential carrier due to the side thrust from the heli-

callY cut gears.

CARRIEB

TTFT SHAFT

RIG}IT SHAFT

With the pinion gears locked, the torque applied to the slipping wheel is reduced 8nd the torque delivered to the

other wheel is increased.

tzl

t15-22

RIGHT SIDE GEAR

PINION GEARS