automatic transmission fluid HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 36 of 1681

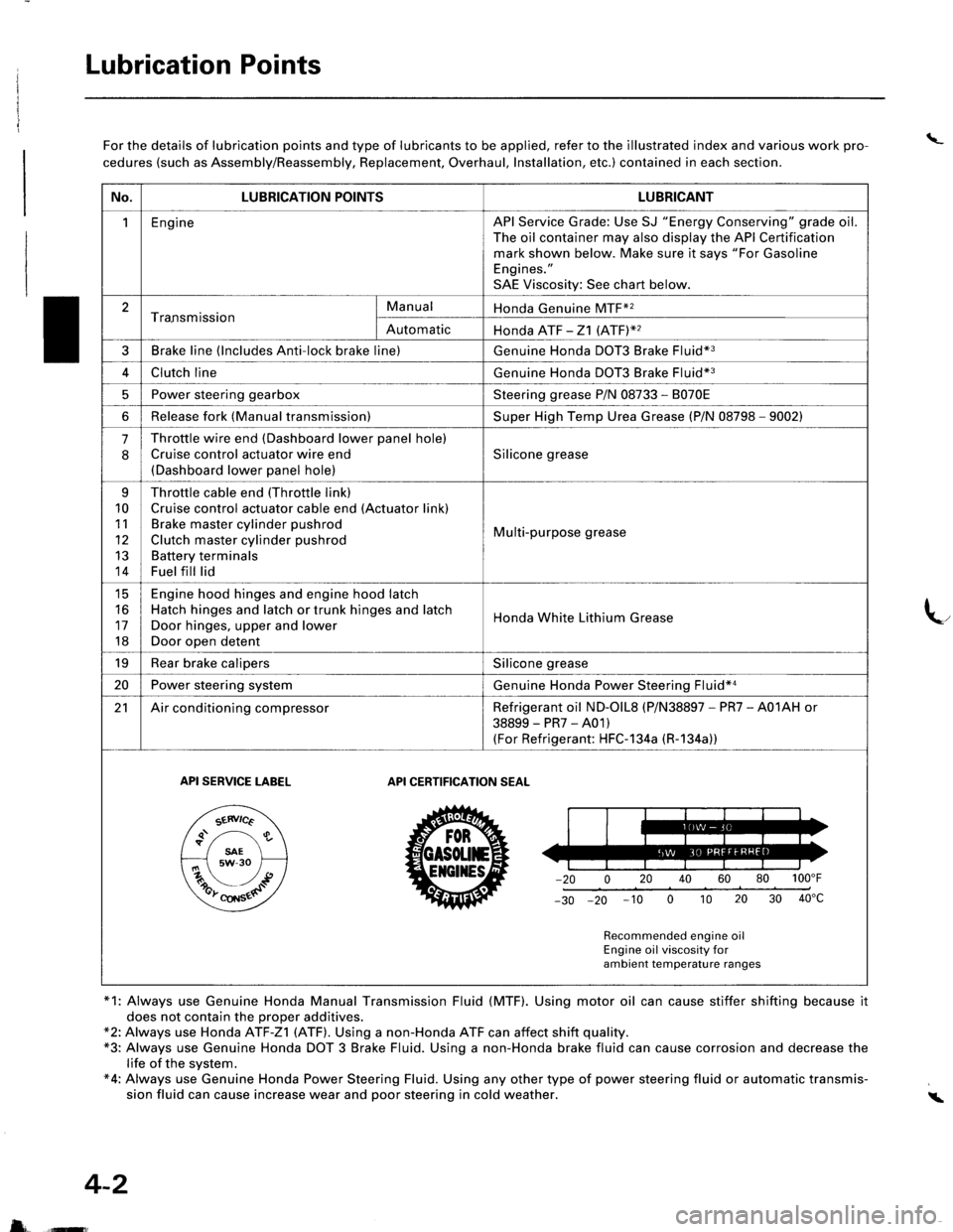

Lubrication Points

No. LUBRICAnON POINTSLUBRICANT

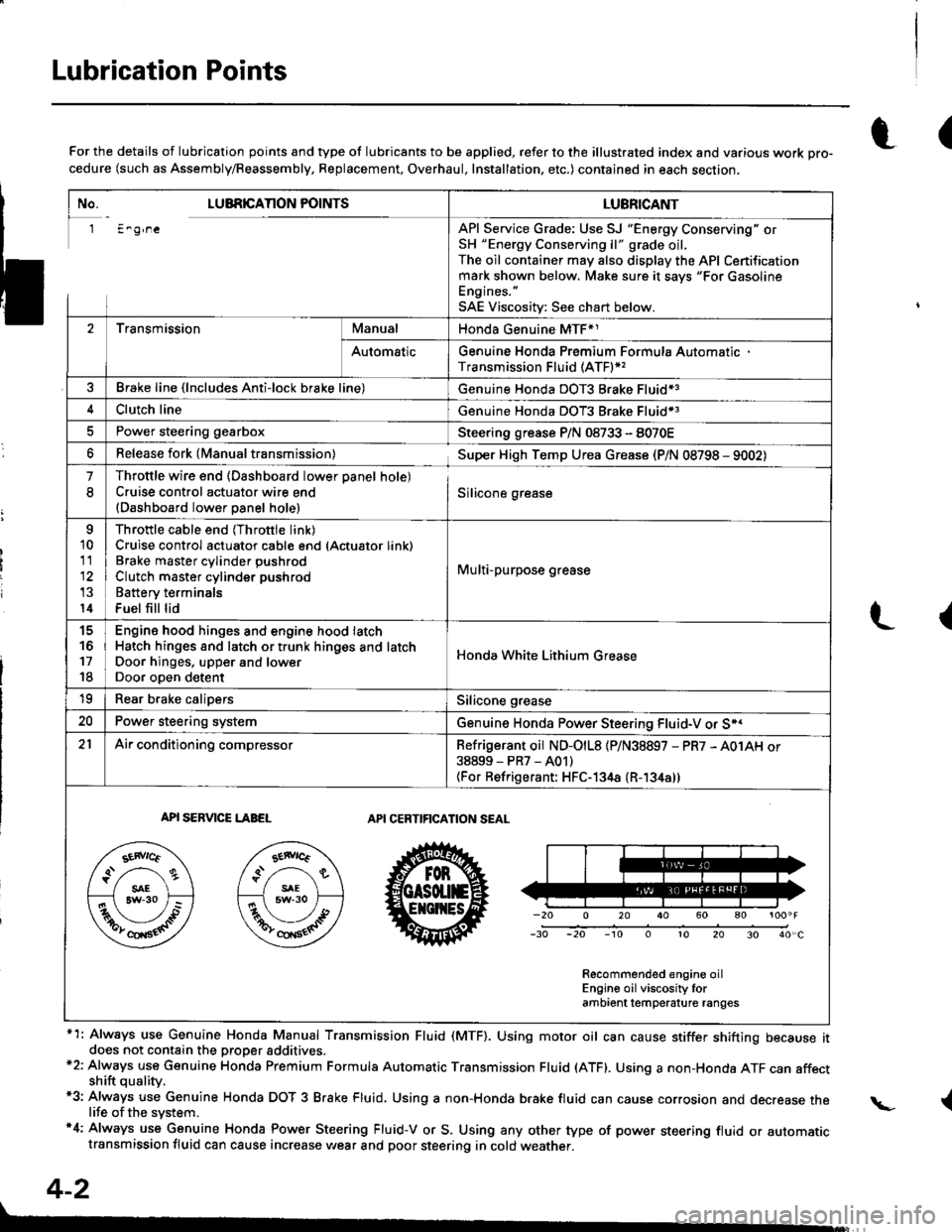

1 E^g,neAPI Service Grade: Use SJ "Energy Conserving" orSH "Energy Conserving ll" grade oil,The oil container may also display the API Certificationmark shown below. Make sure it savs "For GasolineEngines. "

SAE Viscositv: See chart below.

2TransmissionManualHonda Genuine MTF*1

AutomaticGenuine Honda Premium Formula AutomaticTransmission Fluid (ATF)*,

Brake line (lncludes Anti-lock brake line)Genuine Honda DOT3 Brake Fluid13

Clutch lineGenuine Honda DOT3 Brake Fluid*3

Power steering gearboxSteering grease P/N 08733 - 8070E

Release fork lManual transmission)Sup€r High Temp Urea Grease (P/N 08798 - 9002)

1

8

Throttle wire end (Dashboard lower oanel hole)Cruise control actuator wire end(Dashboard lower Danel hole)Silicone grease

o

10

11

14

Throttle cable end (Throttle link)Cruise control actuator cable end (Actuator link)Brake master cvlinder oushrodClutch master cylinder pushrod

Battery terminals

Fuel fill lid

Multi-purpose grease

to

17

18

Engin6 hood hinges and engine hood latchHatch hinges 8od latch or trunk hinges and latchDoor hjnges, upper and lowerDoor ooen detent

Honda White Lithium Grease

19Rear b.ake calipersSilicone grease

20Power steering systemGenuine Honda Power Steering Fluid-V or S*.

21Ai|' conditioning compressorRefrigerant oii ND-O|L8 {P/N38897 - PR7 - A01AH or38899-PR7-A01)(For Refrigerant: HFC-134a (R- 134a))

API SERVICE LABELAPI CERTIFICATION SEAL

Recommended engine oilEngin€ oil viscosity lorambrent lemperature ranges

r(For the details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work Dro-cedure (such as Assembly/Reassembly, Replacement, Overhaul, Installation. etc.) contained in each section,

*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because itdoes not contain the proper addtuves.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affectshift quality.*3: Always use Genuine Honda DOT 3 B.ake Fluid, Using a non-Honda brake fluid can cause corrosion and decrease thelife of the system.'4: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatictransmission fluid can cause increase v,/ear and poor steering in cold weather.

L(

{

4-2

Page 196 of 1681

lllustrated Index

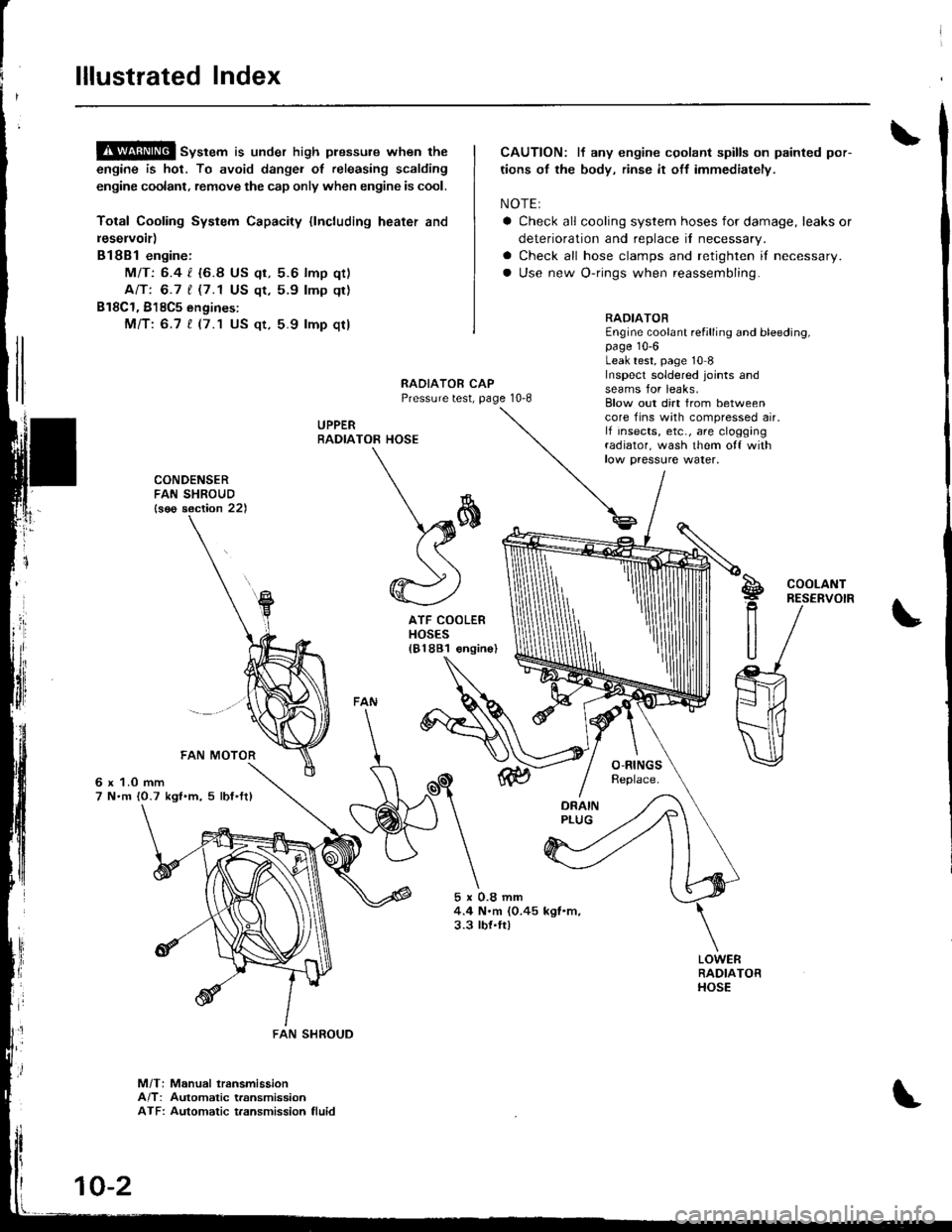

!$!!@ sv"t"m is under high plessure when the

engine is hot, To avoid dangei of releasing scalding

engine coolant, remove the cap only when engine is cool.

Total Cooling System Capacity {lncluding heater and

leservoir)

Bl8Bl engine:

MIT: 6.4 l. {6.8 US qt, 5.6 lmp qt)

Ant 6.7 t (7.1 US qt,5.9 lmp qt)

B18C1, 818C5 engines:

Mfi:6.7 t (7.1 US qt, 5.9 lmp qt)

CAUTION: lf any engine cgolant spills on painted por-

tions of the body, rinse it off immediately.

NOTE:

a Check all cooling system hoses for damage, leaks or

deterioration and replace il necessary.

a Check all hose clamps and retighten if necessary.

a Use new O-rings when reassembling.

RADIATOREngine coolant refilling and bleeding,page 10-6Leak test, page 10 8Inspecl soldered joints andseams for leaks,RAOIATOR CAPPressure test, page 10-8

UPPERRADIA

rl

]

CONDENSERFAN SHROUD{s€o section 22)

6 x 1.0 mm7 N.m {0.7 kgl.m, 5 lbf'ftl

5x0.8mm4.4 N.m (0.45 kgl.m,3.3 tbt.ft)

Blow out dirt from betweencore fins with compressed air.lf insects, etc., are cloggingradiator, wash them o{f withlow paessure water,

TOR HOSE

\*

\sffi((

@)

ATF COOLERHOSES181881 €ngin

S!g

R

U

COOLANTRESERVOIR

M/T: Manual lransmissionA/T: Automatic transmissionATF: Automatic t.ansmission fluid

FAN SHROUD

10-2

Page 418 of 1681

Automatic Transmission

Special Tools ................ '14-2

Descraption .................... 14-3

Clutches ............ ...... 14-6

Power Flow ..,........... 14-8

Electronic Control System ..................... 1 4-1 8

Hydraulic Control ...... 14-23

Hydraulic Flow .........- 14-28

Lock-up System ........ 14-38

Electrical System

Component Location -................................ 1 4-45

Circuit Diagram ............. 14-46

TCM Terminal Voltage/

Measuring Conditions ......,.................... 1 4-48

Troubleshooting Procedures .. . ... ........ ...... ... 14-50

Symptom-to-Component Chart

Electrical System ...... 14-54

Electrical Troubleshooting

Troubleshooting Flowcharts .......... ... ...,.. 14-56

Lock-up Control Solenoid Valve A/B Assembly

Test .................. ...... 14-A7

Replacement ............. 14-a7

Shilt Control Solenoid Valve A/B Assembly

Test .................. ...... '14-88

Replacement .,..,........ 14-88

lvlainshaf t/Countershaft Speed Sensors

Replacement ....-......,. 14-89

Transmission Control Module (TCM)

Replacement ............. 14-89

Hydraulic System

Symptom-to-Component Chart

Hydraulic System ...... 14-90

Road Test ,................... 14-94

Stall Speed

Test .................. ...... 14-97

Fluid Level

Checking/Changing .... 14-98

Pressure Testing ........... 14-99

Transmission

Transmission

Removal ............. ...... 14-10�4

lllustrated lndex

Transmission/Right Side Cover ............... 1 4-1 08

Transmission Housin9 ................,..,....... 1 4-1'1 O

Torque Converter Housing/ValveBody .................. .. 14-112

Right Side Cover

Removal ............. ...... 14-114

Transmission Housing

Removal ............. ...... 14-1 l6

Torque Converter Housing/Valve Body

Removal ............. ...... l4-1 18

Valve Caps

Description ...........-... 14-120

Valve Body

Repair ................ ...... 14-12'l

Valve

Assembly

ATF Pump

Inspeclton

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly

Secondary Valve Body

Disassembly/lnspection/Reassembly

Servo Body

....... 14-124

....... 14-126

....... 14-127

....... 14 124

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection/Reassembly .......

Mainsha{t

14-130

14-132

Disassembly/lnspection/Reassembly ....... 14-133

Inspection ................. 14-134

Countershaft

Disassembly/lnspection/Reassembly,..,.., l4-136

Disassembly/Reassembly ..,...,..,.........,,.. 1 4-1 37

Inspection ......,...,..,... 14-138

One-way Clutch

Disassembly/lnspection/Reassembly ....,.. 14-141

Sub-shaft

Disassembly/lnspection/Reassembly ...,,..'14-142

Disassembly/Reassembly ....................... 1 4- l 43

Sub-shaft Bearings

Replacement ,..,,.,,..,.. 14-144

Clutch

lllustrated Index ................................... I 4-1 45

Disassembly ............. 14-144

Reassembly .............. 14-150

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Replacement ......... 14-154

Countershaft Bearing Replacement ......... 1 4- 1 55

Transmission Housing Bearings

Mainshaft/Countershaft BearingReplacement ......,.. 14-'156

Sub-shaft Bearing Replacement .,............ 1 4-1 57

Reverse ldler Gear

Installation .........-..... 14-158

Parking Brake Stop

Inspection/Adjustment .......................... 1 4-1 58

Transmission

Reassembly .............. 14-160

Torque Converler/Drive Plate ..............,.,,.,, 1 4-1 67

Transmission

Installation ............... 14-168

Cooler Flushing ......... 14-172

ATF Cooler Hoses

Connection ,..,,,....,,.,, '14-'174

*shift cable

Removal/lnstallation . . .. .... ... .... ... .... .. . ... .. 14-'l75

Adjustment ,..,...,,,,.,, 14-'116*Shilt lever

Disassembly/Reassembly ....................... 1 4-'17 7'Shift Indicator Panel

Adjustment .............. 14-178

\l

)g

Page 420 of 1681

Description

\J

t{

{

14-3

The automatic transmission is a combination of a 3-element torque converter and triple-shalt electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engrne.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in sigle unit. The torque converter is connected to

the engine crankshaft so they turn torether as a unit as the engine turns. Around the outside of the torque convener is a

ring gear which meshes with the starter pinion when the engine is being started. The entire torque converter assembly

serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts; the mainshaft. the countershaft, and the sub shaft. The mainshaft is in-line with

the engine crankshaft.

The mainshaft includes the 1st, and 2ndl4th clutches,and gear for 3rd, 2nd, 4th, reverse, and 1st. (3rd gear is integral with

the mainshaft, while reverse gear is integral with the 4th gear.)

The countershaft includes the 3rd clutch and gears for 3rd,2nd, 4th, reverse, 1st, and parking. Reverse and 4th gears can

be loched to the countershaft at its center,providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the 1st-hold clutch and gears fo 1st and 4th.

The gears on the mainshaft are in constant mesh with those on the countersahft and sub-shaft.When certain combinations

of gears in the transmission are engaged by clutches. power in transmitted from the mainshaft to the countershaft via the

sub-shaft to orovude oil, lo'1. E, E. and E.

Electronic Control

The electronic control svstem consists of the Transmission Control Module (TCM), sensors, and four solenoid valves.

Shilting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the lelt side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the serbvo body, and

the lock-up valve body, through the respective separator plates, They are bolted to the torque converter housing,

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shitt valve, the Clutch Pressure Control

lCPC) valve, the 4th exhaust valve, the reliel valve, and the ATF pump gears.

The secondary valve body contains the 4-3 kick-down valve, the 3-2 kick-down valve, the 2-3 orifice control valve, the

3-4 shift valve, the orilice control valve, the modulator valve, and the servo control valve.

The regulator valve body contains the pressure regulator valve, the lock-up control valve, the torque converter check

valve, and the cooler check valve.

The servo body contains the servo valve, which is integrated with shift fork shaft, the throttle valve B, and the accumula-

tors.

The lock-up valve body contains the lock-up shift valve and the lock-up timing B valve, and is bolted to the regulator valve

ooqy.

Fluid from the regulator passes through the manual valve to the various control valves.

Shift Control Mechanism

Input to the TCM from various sensors located throughout the car determines which shift control solenoid valve should

be activated. Activating a shitt control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one ol the clutches, engaging that clutch and its corresponding gear.

Lock-uD Mechanism

In @ position, in 2nd, 3rd and 4th, and @ position in 3rd, pressurized fluid can be drained lrom the back oI the tor-

que converter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this

takes place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM

optimizes the timing of the lock-up mechanism.

The lock-up valves controlthe range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

Page 446 of 1681

I

I

I

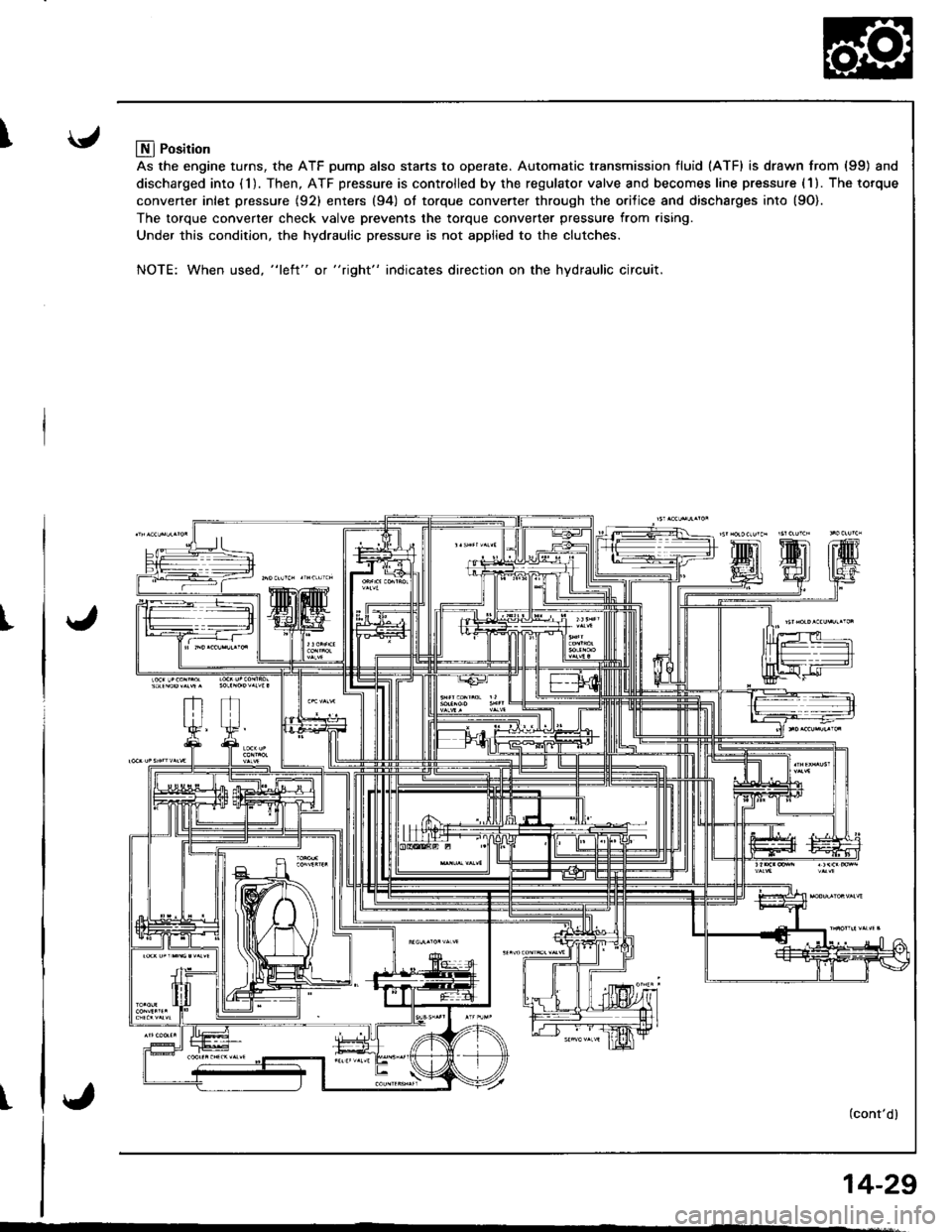

Llfl Position

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and

discharged into (1). Then, ATF pressure is controlled by the regulator valve and becomes line pressure (1). The torque

converter inlet pressure {92} enters (94) ol torque converter through the orilice and discharges into {9O).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches.

NOTE: When used, "l€ft" or "right" indicates direction on the hydraulic circuit.

(cont'dl

14-29

Page 515 of 1681

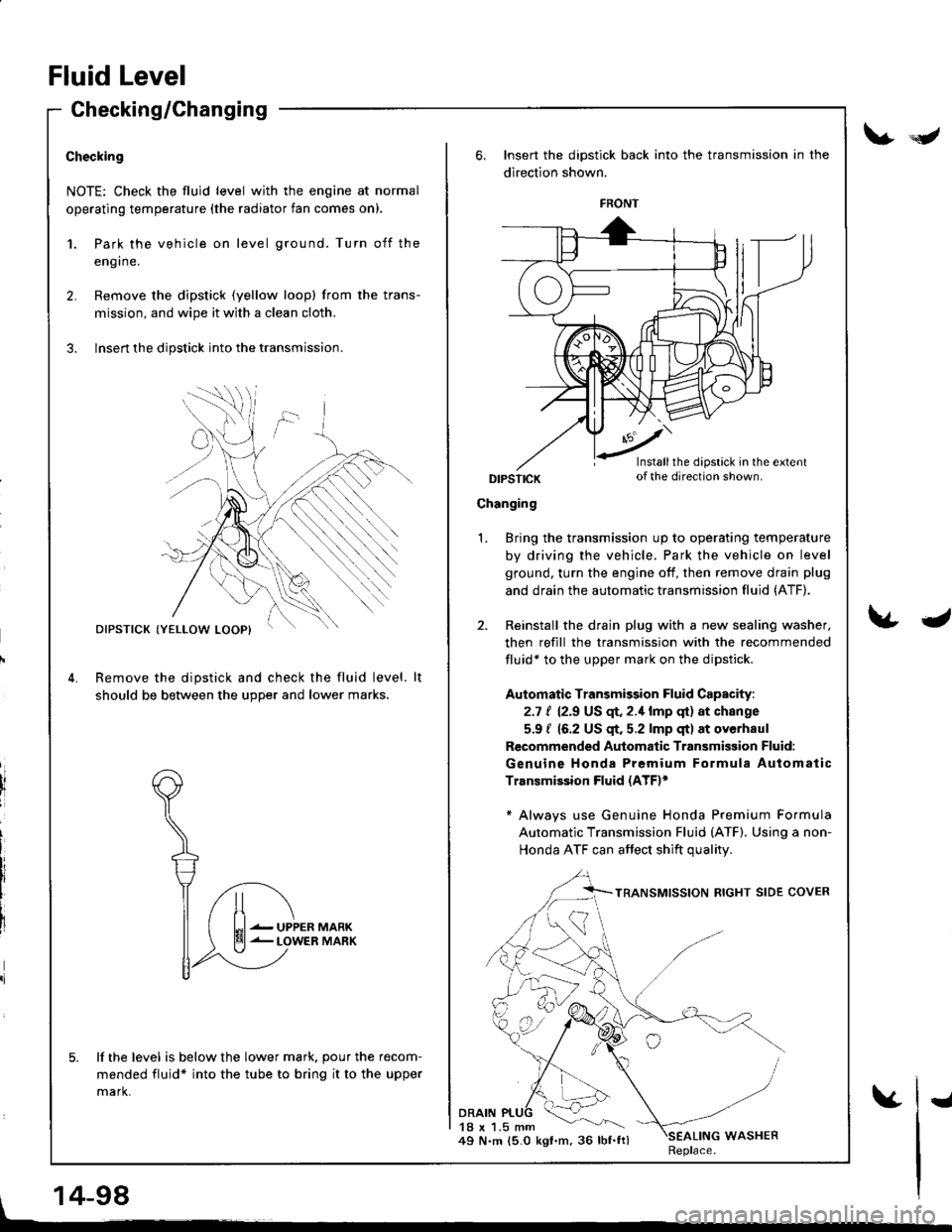

Checking/Changing

Checking

NOTE: Check the fluid level with the engine at normal

operating temperature (the radiator fan comes on).

1.

2.

Park the vehicle on level ground. Turn off the

eng I ne.

Remove the dipstick (yellow loopl from the trans-

mission, and wipe it with a clean cloth.

Insert the dipstick into the transmission.

Remove the dipstick and check the fluid level.

should be between the u9Der and lower marks.

lf the level is below the lower mark. pour the recom-

mended fluid* into the tube to bring it to the upper

mark.

DIPSTICK

UPPERLOWER

Insert the dipstick back into the transmission in the

direction shown.

DIPSTICK

Changing

DRAIN18 x 1.5 mm49 N.m 15.0 kgt.m, 36 lbf.ftl

Bring the transmission up to operating temperature

by driving the vehicle. Park the vehicle on level

ground, turn the engine off, then remove drain plug

and drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid* to the upper mark on the dipstick.

Automatic Transmission Fluid Capacity:

2.7 t 12.9 US qr,2.1lmp qt) at change

5.9 / 16.2 US $. 5.2 lmp qt) at overhaul

Recommended Automatic Transmisgion Fluid:

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATE*

* Always use Genuine Honda Premium Formula

Automatic Transmission Fluid (ATF). Using a non-

Honda ATF can affect shift qualitv

1.

WASHERReplace.

FRONT

Installthe dipstick in the extentof the direction shown.

Fluid Level

V*Y

\&J

, 14-98

vI

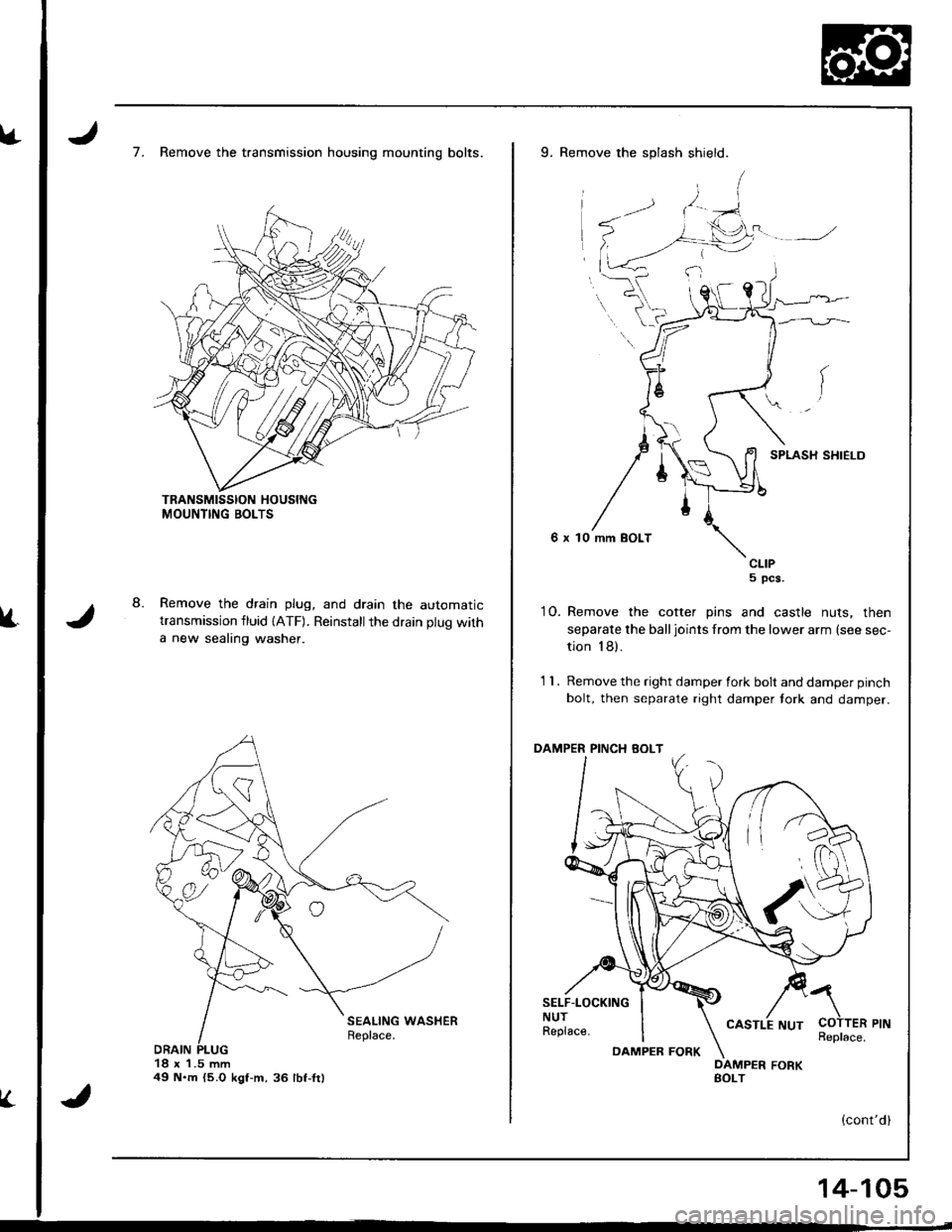

Page 522 of 1681

8.

7. Remove the transmission housing mounting bolts.

Remove the drain plug, and drain the automatictransmission fluid {ATF). Reinstallthe drain plug with

a new sealing washer.

18 x 1.5 mm49 N.m {5.O kgt-m,36 lbf-fr)

V.

9. Remove the splash shield.

SPLASH SHIELD

6 x 10 mm BOLT

CLIP5 pcs.

10. Remove the cotter pins and castle nuts, then

separate the balljoints from the lower arm (see sec-

tion 18).

1 1 . Remove the right damper fork bolt and damper pinch

bolt, then separate right damper tork and damper.

PINCH BOLT

SELF.LOCKINGNUTReplace.

a

COTTER PINReplace.DAMPEB FORK

14-105

Page 1651 of 1681

I

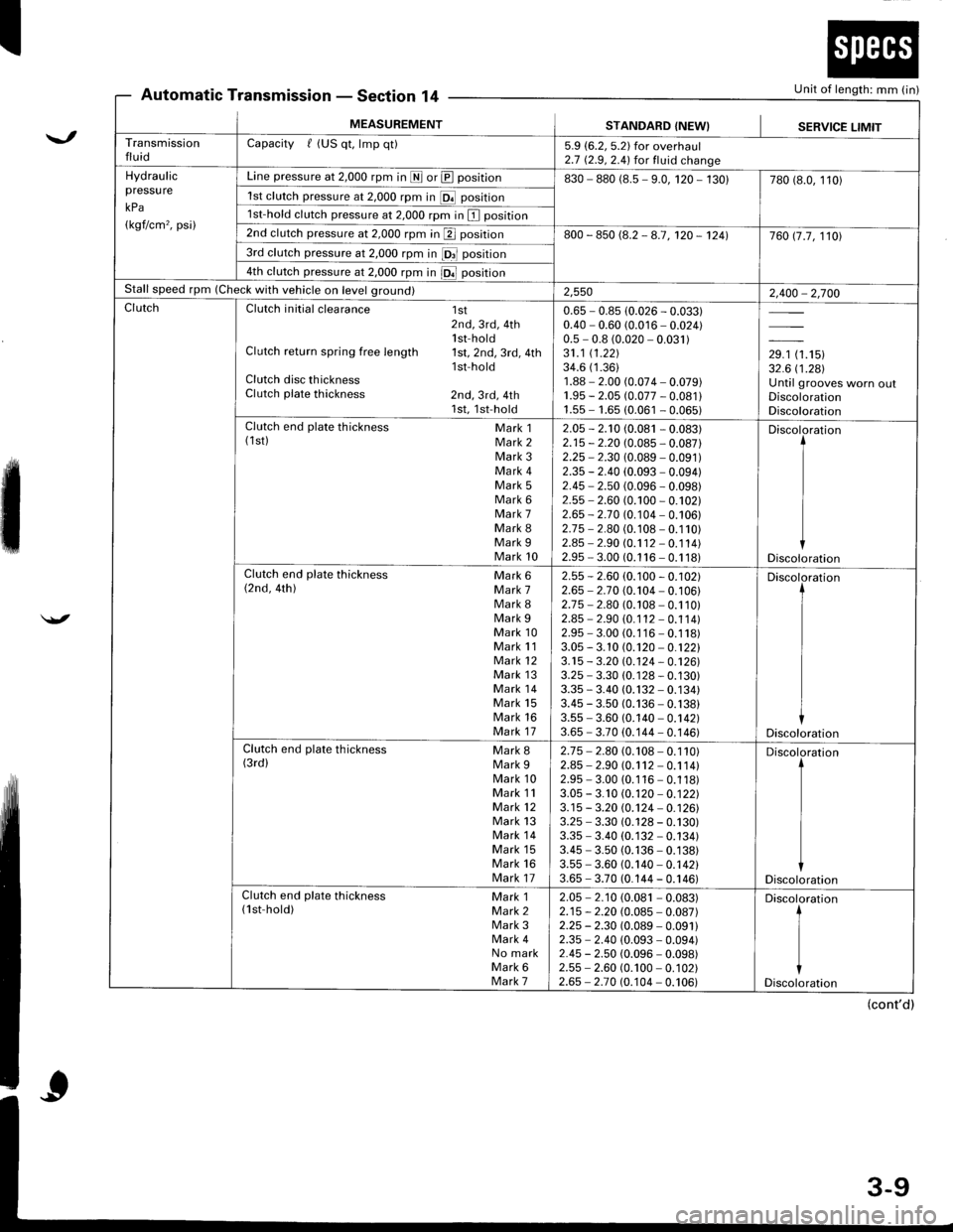

Automatic TransmissionSection 14

\.,

'

Unit of length: mm (in)- r;rEGl,l(tll I +

MEASUREMENTSTANDARD {NEW}SERVICE LIMITTransmissionfluidCapacity f (US qt, lmp qt)5.9 (6.2, 5.2) for overhaul2.7 (2.9,2.4) for fluid changeHydraulicpressu re

kPa

(kgf/cm'�, psi)

Line pressure at 2,000 rpm in I or @ position830 - 880 (8.5 - 9.0, 120 - 130)780 (8.0, 110)

1st clutch pressure at 2,000 rpm in [Of position

1st-hold clutch pressure at 2,000 rpm in I position

2nd clutch pressure at 2,000 rpm in p position800 - 850 (8.2 - 8.7, 120 - 1241760 17.7, 1101

3rd clutch pressure at 2,000 rpm in fOrl position

4th clutch pressure at 2,000 rpm in iOl position

Stall speed rpm (Check with vehicle on level ground)2,5502,400 - 2,700ClutchClutch initial clearance 1st2nd, 3rd, 4th1 st-hol dClutch return spring free length 1st,2nd,3rd,4thlsf holdClutch disc thicknessClutch plate thickness 2nd, 3rd, 4th1st,1st-hold

0.65 - 0.85 (0.026 - 0.033)0.40 - 0.60 (0.016 - 0.024)0.5 - 0.8 (0.020 - 0.031)31.1 (1.221

34.6 (1.36)

1.88 - 2.00 (0.074 - 0.079)1.95 - 2.05 (0.077 - 0.081 l1.55 - 1.65 (0.061 - 0.065)

,r, tr.'tur32.6 i'1.281Until grooves worn oulDiscolorationDiscolorationClutch end plate thickness Mark 1(1st) Mark 2Mark 3Mark 4Mark 5Mark 6Mark 7Mark 8Mark 9Mark 10

2.05 - 2.'t0 (0.081 - 0.083)2.15 - 2.20 (0.085 - 0.087)2.25 - 2.30 (0.089 - 0.091)2.35 - 2.40 (0.093 - 0.094)2.45 - 2.50 (0.096 - 0.098)2.55 - 2.60 (0.100 - 0.102)2.65 - 2-70 (0.104 - 0.106)2.75 - 2.80 (0.108 - 0.110)2.45 - 2.90 (0.1 12 - 0.1 14)2.95 - 3.00 (0.1 16 - 0.1 18)

Discoloration

Discoloration

Clutch end plate thickness Mark 6(2nd, 4th) Mark 7Mark 8Mark 9Mark 10Mark 11Mark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.55 -2.60 (0.100 - 0.102)2.65 - 2.7 0 (0.104 - 0. 1 06)2.75 - 2.80 (0.108 - 0.110)2.85 - 2.90 (0. 1 12 - 0.1 1 4)2.95 - 3.00 (0.1 16 - 0.1 18)3.05 - 3. 10 (0.120 - 0.12213.15 - 3.20 10.124 - 0.12613.25 - 3.30 (0. 1 28 - 0.130)3.35 * 3.40 (0.132 - 0.134)3.45 - 3.50 (0.136 - 0.138)3.55 - 3.60 (0.140 - 0.142)3.65 - 3.70 (0.144 - 0.146)

Discoloration

Discoloration

Clutch end plate thickness Mark g(3rd) Mark 9Mark 10Mark 11Mark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.75 - 2.80 (0.108 - 0.110)2.85 - 2.90 (0.1 12 - 0.1 14)2.95 - 3.00 (0.116 - 0.118)3.05 - 3.10 (0.120 - 0.12213.15 - 3.20 @j24 - 0.12613.25 - 3.30 (0.128 - 0.130)3.35 - 3.40 (0. 132 - 0.134)3.45 - 3.50 (0.136 - 0.138)3.55 - 3.60 (0.140 - 0.142)3.65 - 3.70 (0.144 - 0.146)

Discoloration

Discoloration

Clutch end plate thickness Mark 1(lst-hold) Mark 2Mark 3Mark 4No markMark 6Mark 7

2.05 - 2.10 (0.081 - 0.083)2.15 - 2.20 (0.085 - 0.087)2.25 - 2.30 (0.089 - 0.09112.35 - 2.40 (0.093 - 0.094)2.45 - 2.50 (0.096 - 0.098)2.55 - 2.60 (0.100 - 0. 1 02)2.65 - 2.70 (0.104 - 0.106)

Discoloration

t

I

iDiscoloration

(cont'd)

Page 1664 of 1681

Lubrication Points

\_For the details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because it

does not contain the proper additives.*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift quality.*3: Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease thelife of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-sion fluid can cause increase wear and poor steering in cold weather.i

4-2

5 ffi

No.LUBRICATION POINTSLUBRICANT

1EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil.The oil container may also display the API Certificationmark shown below. Make sure it says "For GasolineEngines."

SAE Viscosity: See chart below.

2Tra.nsmissionManualHonda Genuine MTF*2

AutomaticHonda ATF -21 (ATFY2

3Brake line (lncludes Anti-lock brake line)Genuine Honda DOT3 Brake Fluid*3

4Clutch lineGenuine Honda DOT3 Brake Fluid*3

5Power steering gearboxSteering grease P/N 08733 - 8070E

6Release fork (Manual transmission)Super High Temp Urea Grease (P/N 08798 - 9002)

.J

Throttle wire end (Dashboard lower panel hole)

Cruise control actuator wire end(Dashboard lower panel hole)

Silicone grease

q

10

11

12

13

14

Throttle cable end (Throttle link)

Cruise control actuator cable end (Actuator link)Brake master cylinder pushrod

Clutch master cylinder pushrod

Battery terminalsFuel fill lid

Multi-purpose grease

tc

16

17

18

Engine hood hinges and engine hood latchHatch hinges and latch or trunk hinges and latch

Door hinges, upper and lower

Door open detent

Honda White Lithium Grease

19Rear brake calipersSilicone grease

20Power steering systemGenuine Honda Power Steering Fluid*a

21Air conditioning compressorRefrigerant oil ND-olL8 (P/N38897 - PR7 - A01AH or

38899-PR7-A01)(For Refrigerant: HFC-1 34a (R-1 34a))

API SERVICE TABELAPI CERTIFICATION SEAT

ZU30

Recommended engine oilEngine oil viscosity forambient temperature ranges