power steering fluid HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 36 of 1681

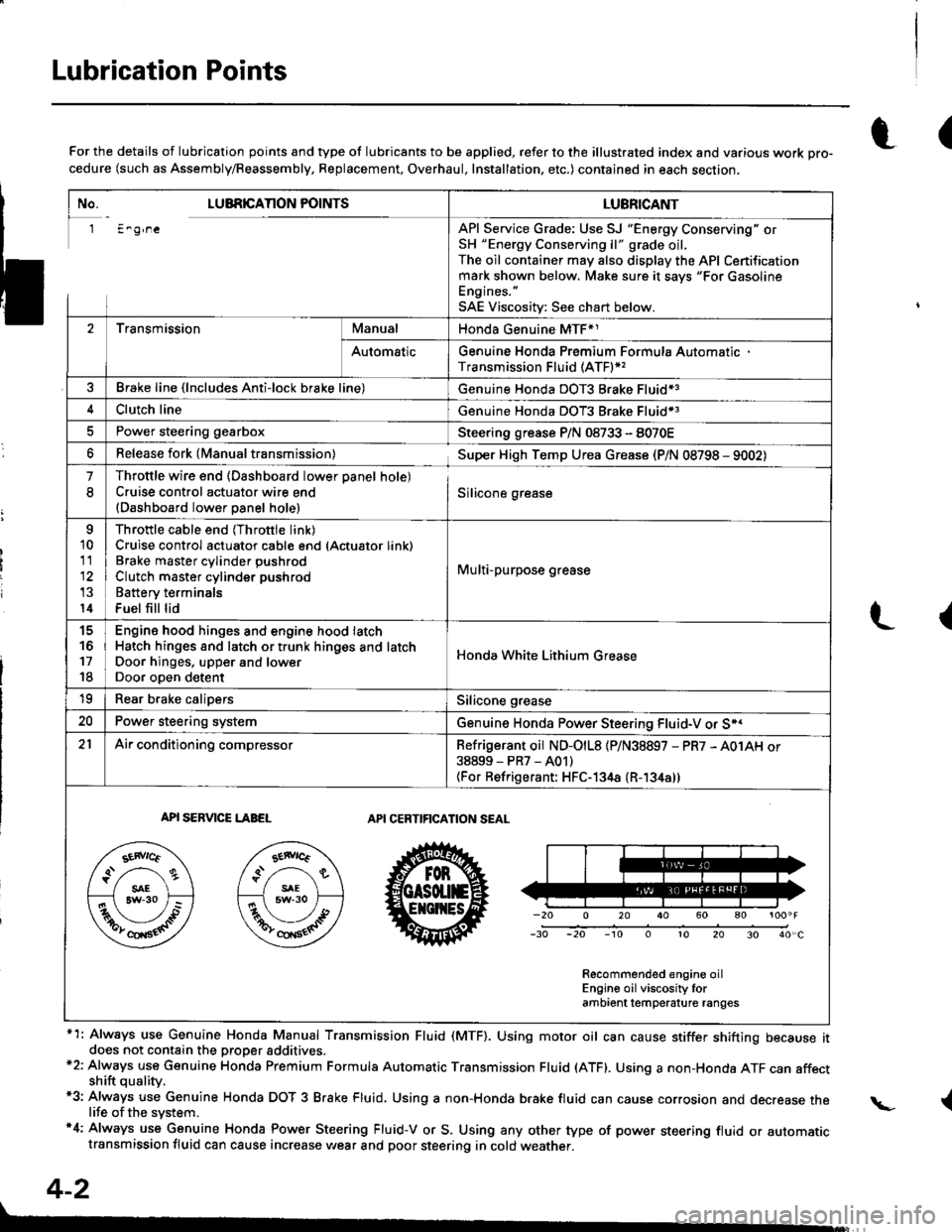

Lubrication Points

No. LUBRICAnON POINTSLUBRICANT

1 E^g,neAPI Service Grade: Use SJ "Energy Conserving" orSH "Energy Conserving ll" grade oil,The oil container may also display the API Certificationmark shown below. Make sure it savs "For GasolineEngines. "

SAE Viscositv: See chart below.

2TransmissionManualHonda Genuine MTF*1

AutomaticGenuine Honda Premium Formula AutomaticTransmission Fluid (ATF)*,

Brake line (lncludes Anti-lock brake line)Genuine Honda DOT3 Brake Fluid13

Clutch lineGenuine Honda DOT3 Brake Fluid*3

Power steering gearboxSteering grease P/N 08733 - 8070E

Release fork lManual transmission)Sup€r High Temp Urea Grease (P/N 08798 - 9002)

1

8

Throttle wire end (Dashboard lower oanel hole)Cruise control actuator wire end(Dashboard lower Danel hole)Silicone grease

o

10

11

14

Throttle cable end (Throttle link)Cruise control actuator cable end (Actuator link)Brake master cvlinder oushrodClutch master cylinder pushrod

Battery terminals

Fuel fill lid

Multi-purpose grease

to

17

18

Engin6 hood hinges and engine hood latchHatch hinges 8od latch or trunk hinges and latchDoor hjnges, upper and lowerDoor ooen detent

Honda White Lithium Grease

19Rear b.ake calipersSilicone grease

20Power steering systemGenuine Honda Power Steering Fluid-V or S*.

21Ai|' conditioning compressorRefrigerant oii ND-O|L8 {P/N38897 - PR7 - A01AH or38899-PR7-A01)(For Refrigerant: HFC-134a (R- 134a))

API SERVICE LABELAPI CERTIFICATION SEAL

Recommended engine oilEngin€ oil viscosity lorambrent lemperature ranges

r(For the details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work Dro-cedure (such as Assembly/Reassembly, Replacement, Overhaul, Installation. etc.) contained in each section,

*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because itdoes not contain the proper addtuves.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affectshift quality.*3: Always use Genuine Honda DOT 3 B.ake Fluid, Using a non-Honda brake fluid can cause corrosion and decrease thelife of the system.'4: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatictransmission fluid can cause increase v,/ear and poor steering in cold weather.

L(

{

4-2

Page 650 of 1681

Steering

Componsnt Location

lndox

*Stooring Wheel

Removal ....

Disassombly/Ro8$.mbly

Disassombly ......

F08$€mbly

Powcr Stosring Gosrbox

R6moval

............................ 17-3

............. 17 -1

................ 17-16

............................. 17_25

17-30

17.31

.......17-21

Sy3tom DGcription

Fluid Flow Disgram

Steering Pump .............. 17-5

Stocring Goarbox ...17.8

Troublorhooting

Gonoral Troubleshooting .............................. 17.10

Noiso lnd Vibration ...... 17-1i[

Fluid Losk3

lnspoction

Installation

Powor Steering Hos6, Lino3

Roplacom€nt .................. 17.34

Powor Steoring Pump

RGplac6montlolpeqtion lnd Adiu3tm6nl

Stoo.ing Operation

Powor A$bi Chock

with v.hiclo Parked

Stcering Linkage 6nd Goarbox

Pump Bolt

17.18

17.18

17.19

17-20

17.35

t7-36

17 -37

r7-39

Inspoction

................... 17.41

Rack Guide Adiustmont ..........................-.-.-. 17 -21

Ffuid Rcplacemont ........17-21

Pump Prc&suro Chock ...,........................,..,..., 17 -22

Fluid Leakage Inrpection ............................... 17-23

Dissssembly

R€aEs€mbly

In3tallation........... 17_58

Ball Joint Boot Replacem.ni ........................ 17-61

17-U

17.49

J ,urrar*TNTAL REsrRArNr sysrEM (sRsr

The Integra SRS includes a driver's airbag located in the steering wheel hub and a passenger's airbag located inthe dashboard above the glove box,

Information necessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk(*) on the contents page include, or are located near, SRS components. Servicing, dissssembling or replacing

these items will require special pr6cautions and tools, and should therefore be done by an authorized Acura dealer.

. To avoid rondoring ths SRS inoparstivo. which could |rad to parsonal iniury or doath in the ov€nt of ! sev6.o

trontal collision, all SRS sarvice work must be perto.med by an authorizod Acura dsalor.. lmpropor 3orvic€ procadures, including inco[6ql rgmoval and inrtallation of the SRS, could l6ad to pgrsonal

iniury clus€d by unintentional doployment of the airbags,. Do nol bump tho SRS unh, (Xherwise, th6 3ystom may fail in cas€ ol a collision, or the airbags may d€ploy

when ths ignition switch is ON {ll).. All SRS electrical wiring harness€s aro covered with yallow insulation. Related component3 are located in ths

stcaring column. tront con3ol6, dashboard, d.shbolrd lower panel, and in the dashboard above ths glove box.

Do not u3o electrical test oquipm€nt on the3e circuii3.

NOTE: The original radio has a coded theft protection circuit. Be sure to get the customer's code number before- disconn€cting the battery.- removing the No. 47 (7.5 A) fuse from the under-hood fuse/relay box,- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

Page 653 of 1681

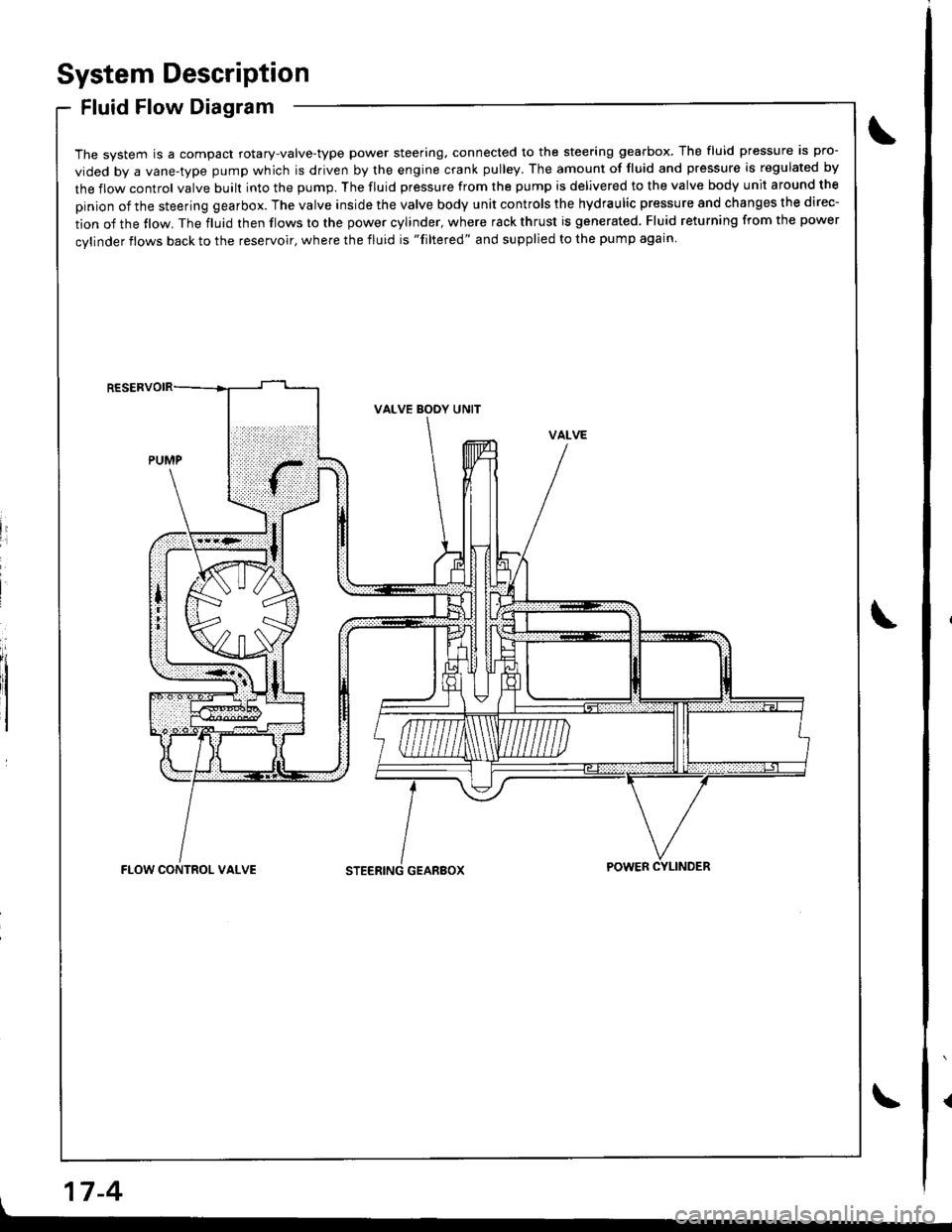

System Description

Fluid Flow Diagram

The system is a compact rotary-valve-type power steering, connected to the steering gearbox. The fluid pressure is pro-

vided by a vane-type pump which is driven by the engine crank pulley. The amount of fluid and pressure is regulated by

the flow control valve built into the pump. The fluid pressure from the pump is delivered to the valve body unit around the

pinion of the steering gearbox. The valve inside the valve body unit controls the hydraulic pressure and changes the direc-

tion of the tlow. The fluid then flows to the power cylinder, where rack thrust is generated. Fluid returning from the power

cylinder flows back to the reservoir, where the fluid is "filtered" and supplied to the pump again

li

I

VALVE BODY UNIT

GEARBOXFLOW CONTROL VALVEPOWER CYLINDER

17-4

Page 657 of 1681

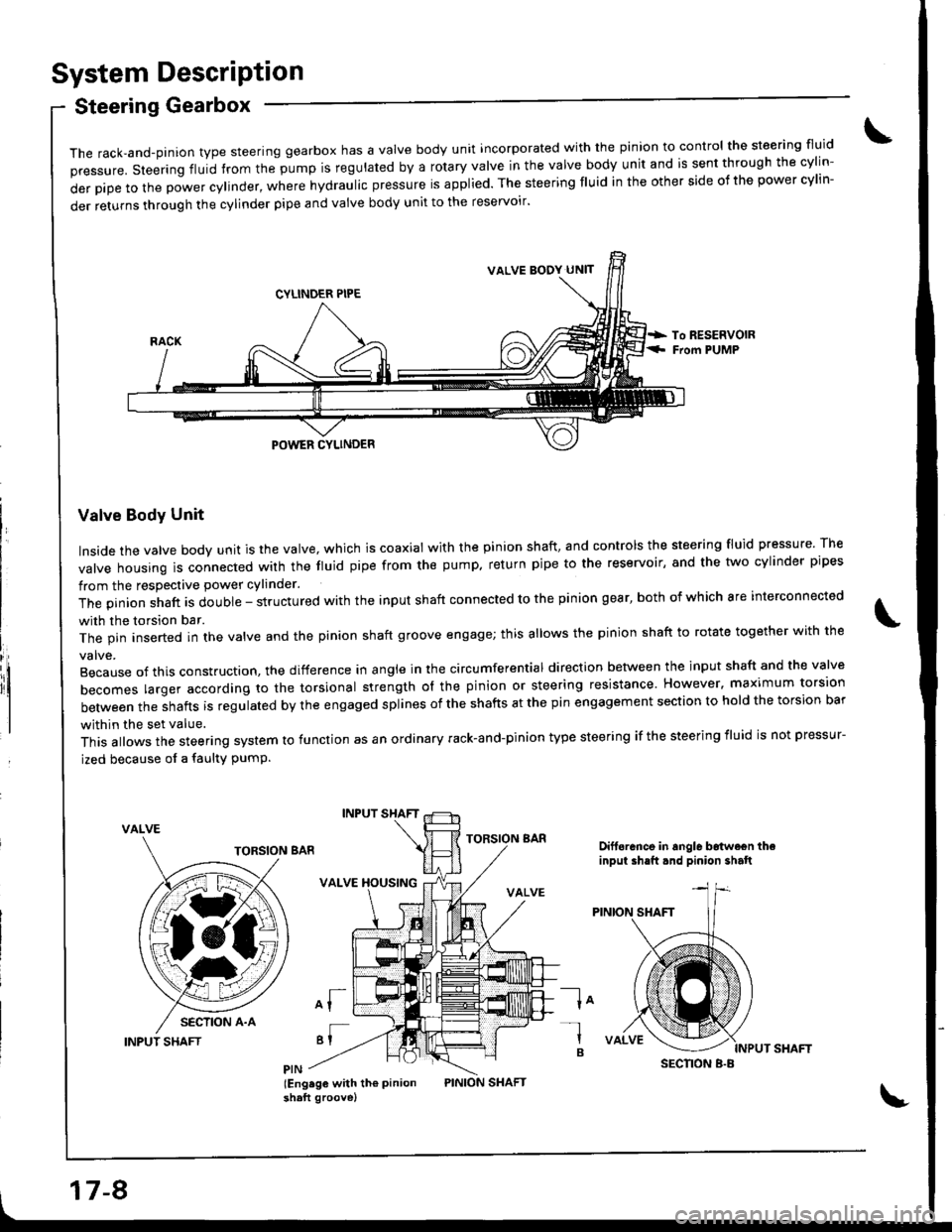

System DescriPtion

Steering Gearbox

it

The rack,and-pinion type steering gearbox has a Valve body unit incorporated with the pinion to control the steering fluid

pressure. steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin-

derpipetothepowercy|inder,wherehydrauIicpressureisapp|ied.Thesteeringf|Uidintheothersideofthepowercy|in-

der returns through the cylinder pipe and valve body unit to the reservoir'

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure The

valve housing ls connected wirh the fluid pipe from the pump. return pipe to the reservoir, and the two cylinder pipes

from the respective power cylinder.

The pinion shaft is double - structured with the input shaft connected to the pinion gear, both of which are interconnected

with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with the

Because of this construction. the difference in angle in the circumferential direction between the input shaft and the valve

becomes larger according ro the torsional strength ol the pinion or steering resistance. However. maximum torsion

between the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion bar

within the set value.

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering iluid is not pressur-

ized because of a faulty PumP.

VALVE

INPUT SHAFT

INPUT SHAFT

VALVE XOUSING

of

'I

lEng.ge with th€ Pinionshaft groove)

TORSION BARDift6rance in angle b6twe€n theinput ih.ft.nd pinion shalt

la-l

B

VALVE BODY UN]T

SECNON B.B

17-8

Page 658 of 1681

INPUT SHAFT

High assist at lower speedsl

When steering resistance is high, such as when driving at low speed, or when turning the wheel with the car stopped, the

diiference in angle created between the input shaft and the valve opens the tluid passage on one side, and closes the fluidpassage on the other side, at each pair of orifices. The fluid pressure lncreases in the side of the power cylinder fed by thelarger fluid passage. This increased pressure pushes on the rack piston, allowing the steering wheel to be turned with light

effon. On the other side of the power cylinder, the return passage opens allowing the steering fluid to return through theinput shaft to the reservoir. The fluid passages to the power cylinder automatically change in size, increasing as the steer-ing resistance increases. In other words, the passages become larger and power assist increases when the steering effort

would normally be high, (for example, when parking or making low speed turns), and the passages become smaller andpower assist decreases when the steering effort would normally be low, (for example, when driving at high speeds or

straight ahead).

FLUIO PASSAGE TOPOWER CYLINDER

Ce) r.r;

VK

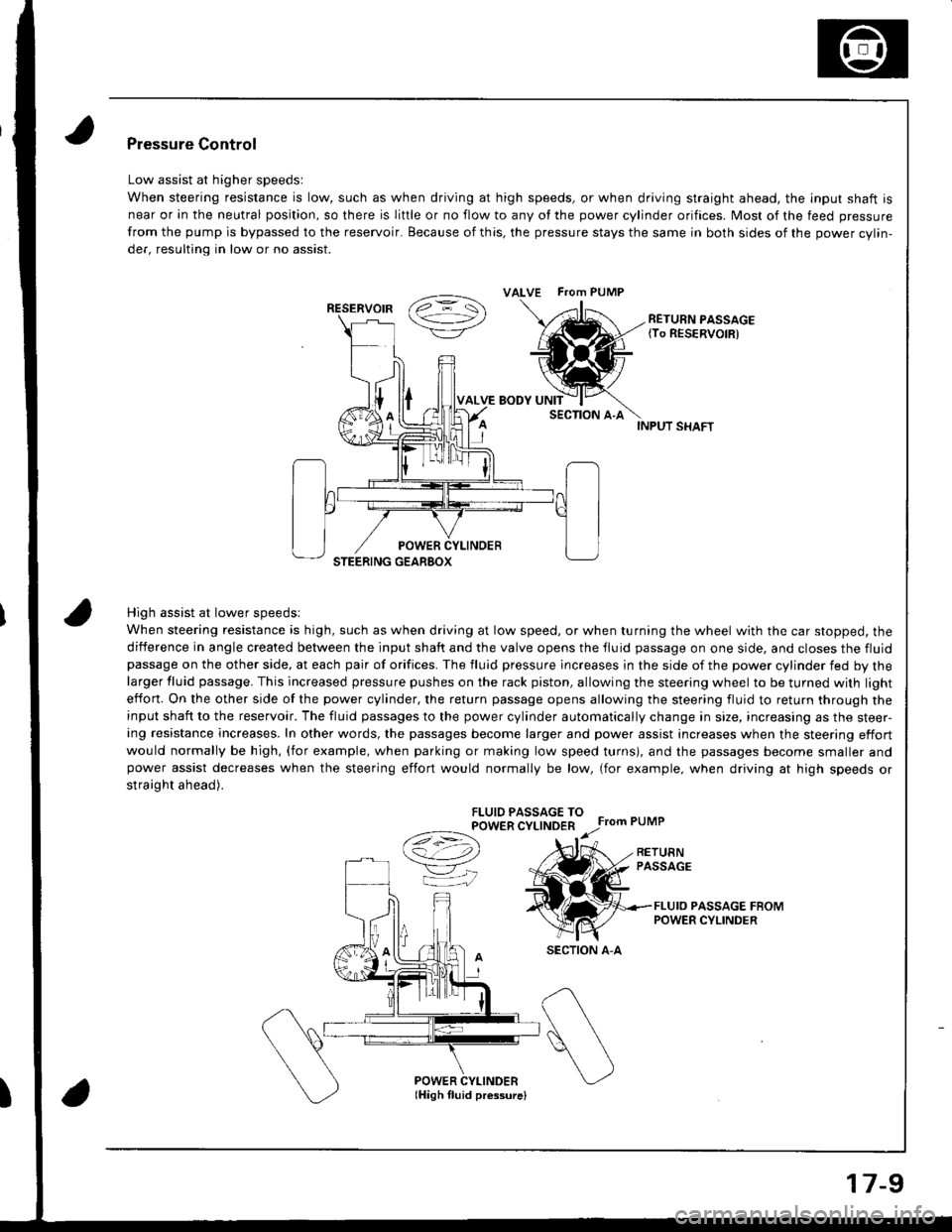

Pressure Control

Low assist at higher speedsl

When steering resistance is low, such as when driving at high speeds, or when driving straight ahead. the lnput shaft is

near or in the neutral position, so there is liftle or no flow to any of the power cylinder orifices. Most of the feed pressure

from the pump is bypassed to the reservoir. Because of this, the pressure stays the same in both sides of the power cvlin-

der, resulting in low or no assist.

RETURN PASSAGE{To RESERVOIR)

POWER CYLINDERlHigh fluid pressurelI

ALVE FTom PUMP

RESERVOIR

SECTION A-A

17-9

Page 659 of 1681

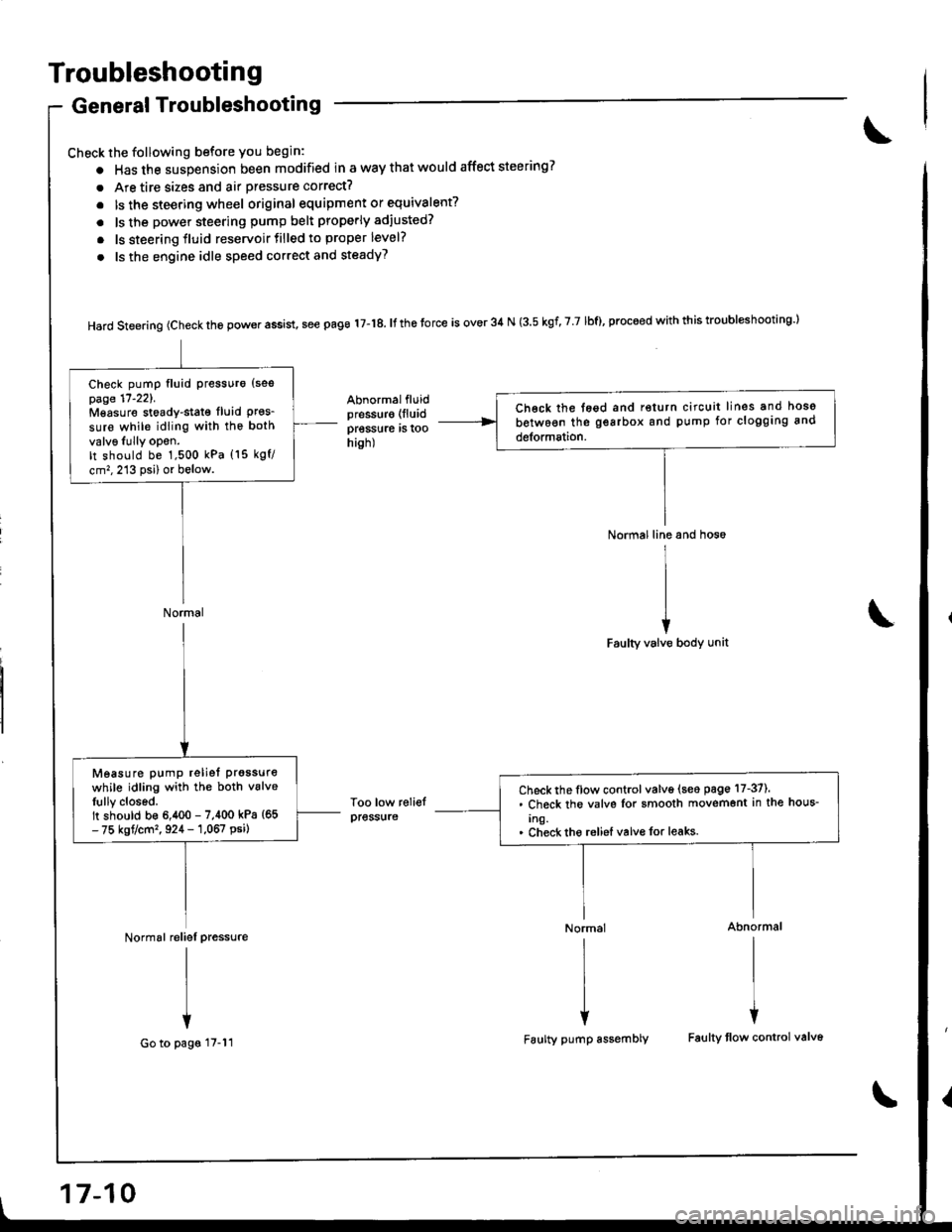

Troubleshooting

General Troubleshooting

Check the following before you begin:

o Has the suspension been modified in a way that would affect steering?

. Are tire sizes and air pressure correct?

. lsthe steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adiusted?

. ls steering fluid reservoirtilled to proper level?

. ls the engine idle speed correct and steadyT

Hard steering (check the power assist, see page 17-18. It the torce is over 34 N (3.5 kgf, 7 7 lbf), proceed with this troubl*hooting l

Abnormalfluidpressur€ (lluid

pressure rs roohish)

Too low reliefpress{ire

Normal line and hos6

I

II

iFaulty valve body unit

Normal Abnormal

rlrl

l{

Faulty pump assembly Faulty tlow control valv6

Ch€ck the tegd and return circuit lines and hoso

between the gearbox and pump for clogging and

detormation.

Check pump fluid Pressuro {sespage 17'221.Mgasure stoady-stat€ fluid Pres_sure while idling with the both

valv6Iully opon.It should be 1,500 kPa (15 kgf/

cm,,213 psi) or below.

Normal

Check the flow control valve (seo page 17-37).. Check the valvs Ior smooth movemont in the hous-

Ing.. Check tho reliel valvo for leaks.

Measure pump reliet prgssure

while idling with the both vslveIully closed.It should b€ 6,400 - 7,400 kPa {65- 75 kgt/cm'�, 924 - 1,067 psi)

Normal reliel pressure

I

I

+

Go to pags 17-11

17-10

Page 662 of 1681

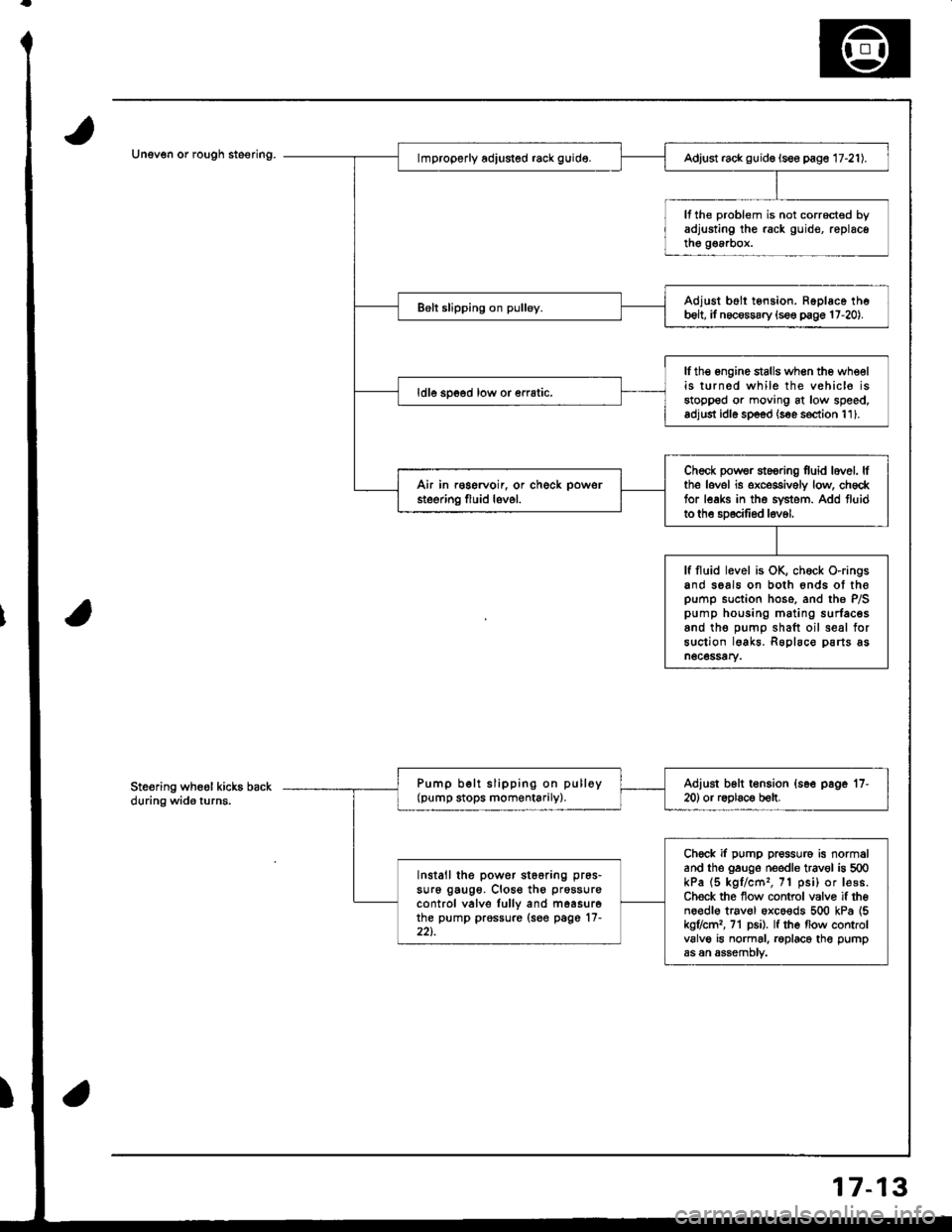

Unev€n or rough steering.Adjust rack guid€ (see page 17-21).

It the problem is not corrocted byadjusting the rack guid€, replacethe g€a.box.

Adjust b6ll tension. Ropl6ce theb6lt, it necossary {s€e p€ge 17-20).

lfth€ engine stalls when the wheelis turned while the vehic16 isstopped or moving at low speed.adjust idl6 sp6od (s€e s€ction 111.

ldle spoed low or €rratic.

Check powsr st6oring fuid lovel. lfthe lovel is exceggively low, ch6cktor leaks in the svstem. Add fluidto the sD6cilied l6v6l,

Air in r€gervoir, or check powsr

steering fluid lovel.

lf fluid level is OK, chock O-ringsand seals on both 6nds ot thepump suction hose. and the P/Spump housing mating surfacesand tho oumo shaft oil seal forsuction lgakr. Roplaco parts asn6c6ssary.

Pump b€lt slipping on pulloy(pump stops momentarily).Adiust b6lt t€nsion {s6e page '17-

20) or r6olac€ b€lt.

Chock if pump pressure is normaland the gauge needle trav€l is 500kPa (5 kgl/cm'�, 71 psi) or lesB.Ch€ck the flow control valvo if theno€dl€ trav€l oxco€ds 500 kPa {5kg7cml, 71 p6i). lf the flow controlvalve is normal. roplace the pumpas an assemDtv.

Install the power st66ring pr6s-

su16 gaug6. Close th6 prossure

control valve lully and m6asurethe pump prossure (see page'17-22t.

Ste€ring wheol kicks backduring wide turns.

7-13

Page 667 of 1681

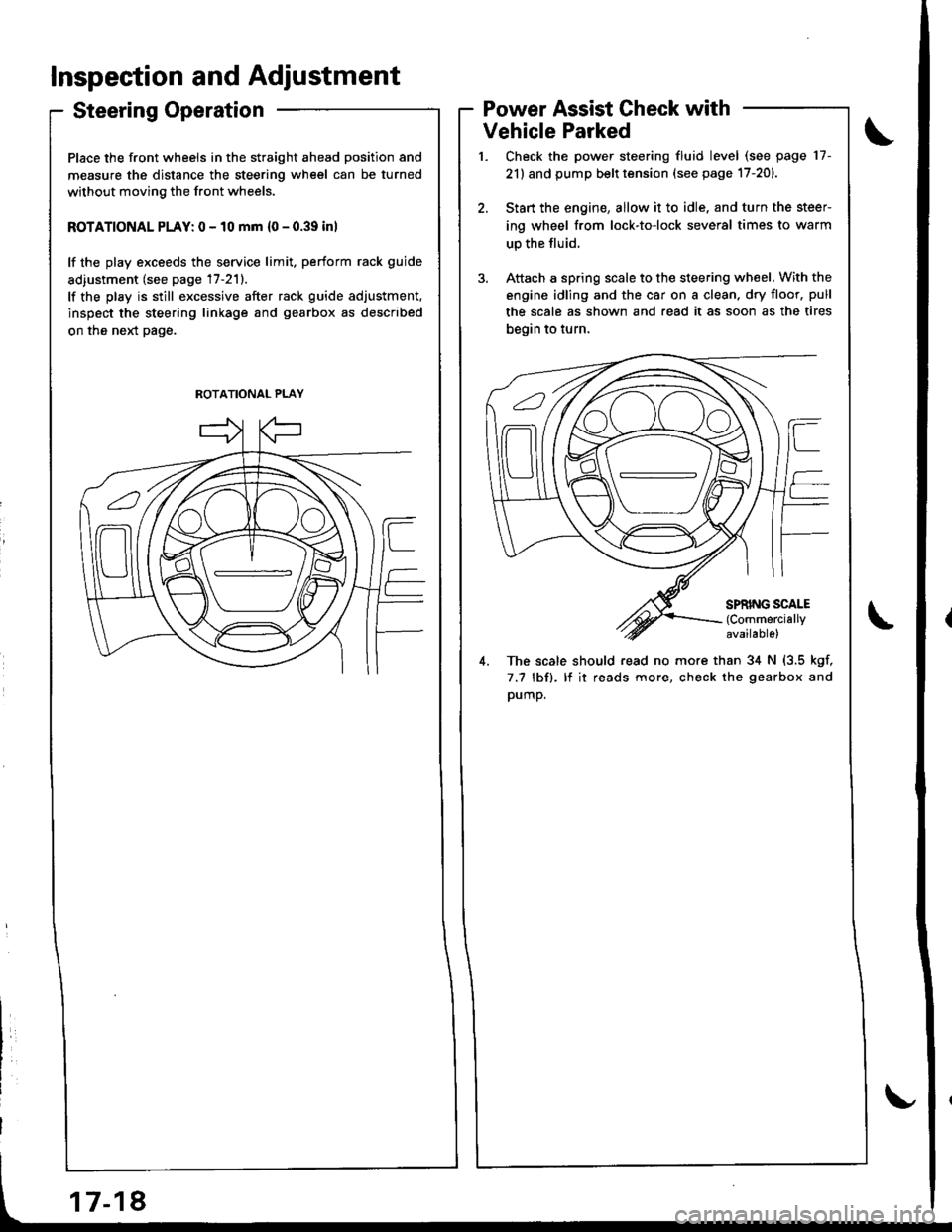

Inspection and Adjustment

Steering Operation

Place the front wheels in the straight ahead position and

measure the distance the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm {0 - 0.39 inl

lf the play exceeds the service limit. perform rack guide

adiustment (see page 17-211.

lf the play is still excessive after rack guide adjustment.

inspect the steering linkage and gearbox as described

on the neld page.

Power Assist Check with

Vehicle Parked

Check the power steering fluid level (see page 17-

21) and pump belt tension (see page 17-201.

Start the engine, allow it to idle. and turn the steer

ing wheel from lock-to-lock several times to warm

up the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean. dry floor. pull

the scale as shown and read it as soon as the tires

begin to turn,

4. The scale should read no more than 34 N (3.5 kgf,

7.7 lbf). lf it reads more, check the gearbox and

pump.

ROTATIONAL PLAY

Page 670 of 1681

Rack Guide AdjustmentFluid Replacement

Check the reservoir at regular intervals, and add fluid as

neceSsary.

CAUTION: Use only Genuine Honda Powel Ste€ring

Fluid-V. Using other fluids such as ATF or othor manu-

laclurer's power ste€ring fluid will damag€ the systom.

SYSTEM CAPACIW:

B18Gl ongine:

1.06lit€r (1.12 US. qt,0.93 lmp.qt)

Excopt 8l8Cl ongino:

1.0 lher (r.06 US. qt.0.88 imp.qtl

at disa$ombly

RESERVOIR CAPACITY:

0.,0 liter {0.42 US. qt, 0.35 lmp.qt}

LEVEL LINE

LEVEL LINE

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Take care not to spill thq fluid on lhe

body and parts. Wipe off any spilled fluid al onc€.

Start the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

2.

RETURN HOSE{From the oilcooler)

4. Reinstallthe return hose on the reservoir.

5. Fill the reservoir to the uDDer level line.

6. Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

from the system,

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not lill the reservoir boyond thc

upper level line.

J.

4.

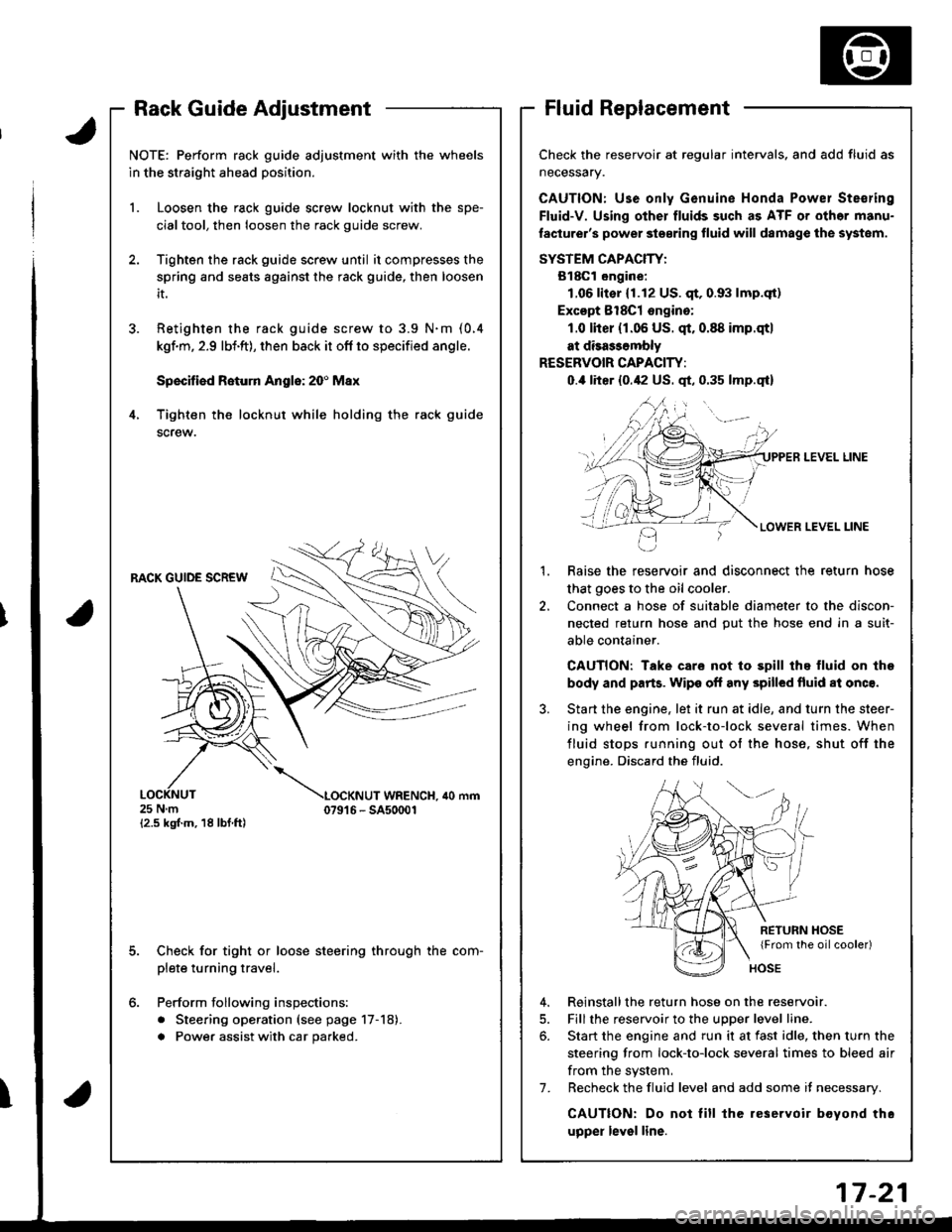

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

it.

Retighten ihe rack guide screw to 3.9 N.m (0.4

kgf.m, 2.9 lbi.ft), then back it ofl to specified angle.

Speciliad Roturn Anglo: 20' Max

Tighten th€ locknut while holding the rack guide

screw.

RACK GUIDE SCREW

25Nm{2.5 kgf.m, 18 lbf ft)

LOCKNUT WRENCH. ilo mm079't 6 - SA50001

E

6.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

a Power assist with car parked.

I

Page 671 of 1681

Inspection and Adjustment

Pump Pressure Check

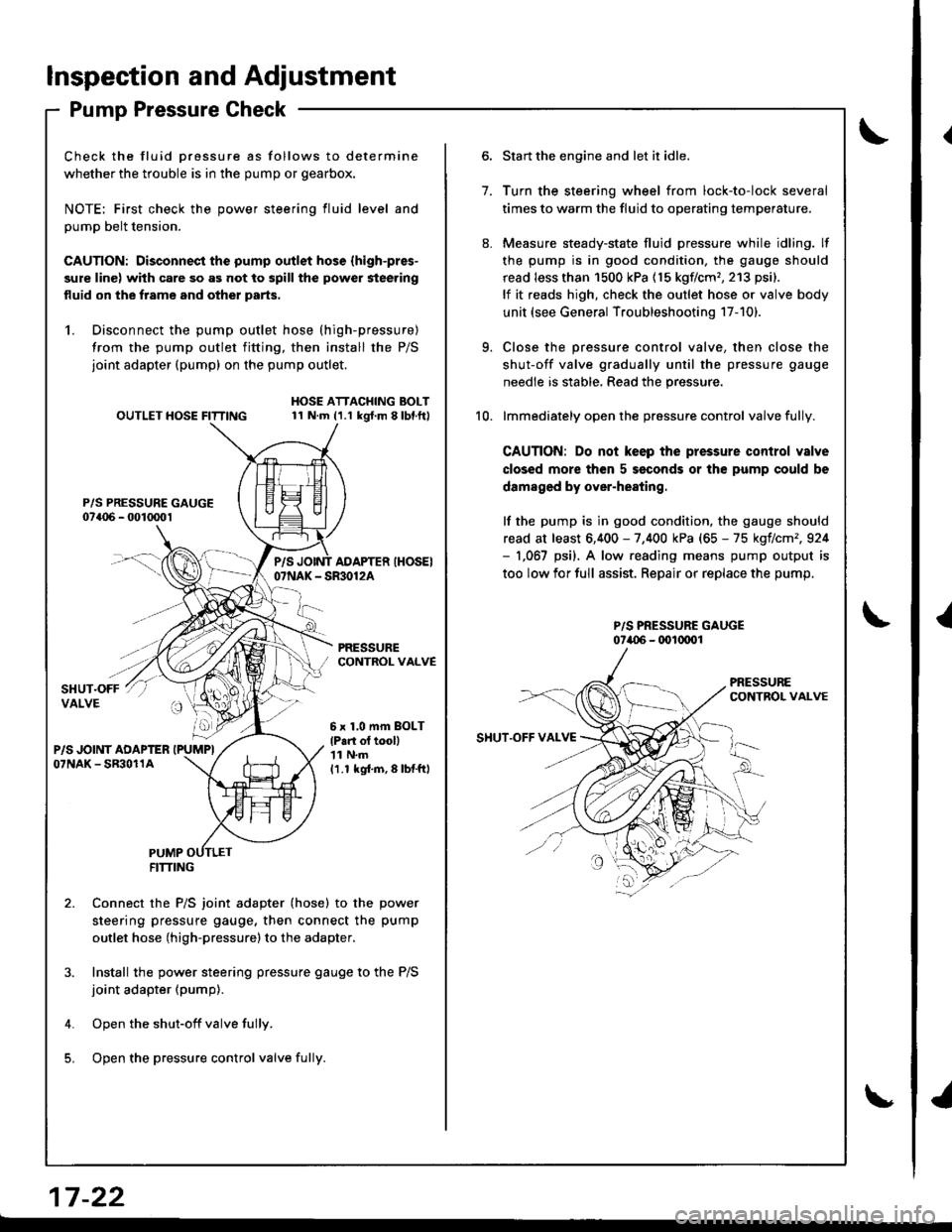

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I