lock HONDA RIDGELINE 2012 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2012, Model line: RIDGELINE, Model: HONDA RIDGELINE 2012 1.GPages: 429, PDF Size: 7.72 MB

Page 297 of 429

Your vehicle is equipped with disc

brakes at all f our wheels. A power

assist helps reduce the ef f ort needed

on the brake pedal. The emergency

brake assist system increases the

stopping f orce when you depress the

brake pedal hard in an emergency

situation. The anti-lock brake system

(ABS) helps you retain steering

control when braking very hard.

Resting your f oot on the pedal keeps

the brakes applied lightly, builds up

heat, reduces their ef f ectiveness and

reduces brake pad lif e. In addition,

f uel economy can be reduced. It also

keeps your brake lights on all the

time, conf using drivers behind you.Constant application of the brakes

when going down a long hill builds

up heat and reduces their ef f ective-

ness. Use the engine to assist the

brakes by taking your f oot of f the

accelerator and downshif ting to a

lower gear.

Check the brakes after driving

through deep water. Apply the

brakes moderately to see if they f eel

normal. If not, apply them gently and

f requently until they do. Be extra

cautious and alert in your driving.

The hydraulic system that operates

the brakes has two separate circuits.

Each circuit works diagonally across

the vehicle (the lef t-f ront brake is

connected with the right-rear brake,

etc.). If one circuit should develop a

problem, you will still have braking

at two wheels.

If the brake pads need replacing, you

will hear a distinctive, metallic

screeching sound when you apply

the brake pedal. If you do not have

the brake pads replaced, they will

screech all the time. It is normal f or

the brakes to occasionally squeal or

squeak when you apply them.

Braking System Design

Brake Pad Wear Indicators

Braking System

290

Main MenuTable of Contents

Page 298 of 429

The anti-lock brake system (ABS)

helpspreventthewheelsfrom

locking up, and helps you retain

steering control by pumping the

brakes rapidly, much f aster than a

person can do it.

The electronic brake distribution

(EBD) system, which is part of the

ABS, also balances the f ront-to-rear

braking distribution according to

vehicle loading.If this indicator comes on, the anti-

lock f unction of the braking system

has shut down. The brakes still work

like a conventional system, but

without anti-lock. You should have

your dealer inspect your vehicle as

soon as possible.

You will f eel a pulsation in the brake

pedal when the ABS activates, and

you may hear some noise. This is

normal: it is the ABS rapidly

pumpingthebrakes.Ondry

pavement, you will need to press on

thebrakepedalveryhardbeforethe

ABS activates. However, you may

feel the ABS activate immediately if

you are trying to stop on snow or ice.

Let the ABS work f or you by always

keeping f irm, steady pressure on the

brake pedal. This is sometimes

ref erred to as ‘‘stomp and steer.

Page 299 of 429

Always steer moderately

when you are braking hard. Severe

or sharp steering wheel movement

can still cause your vehicle to veer

into oncoming traffic or off the road. such as trying to take a

corner too f ast or making a sudden

lane change. Always drive at a safe

speed f or the road and weather

conditions. It only helps with the

steering control during braking.

If the ABS indicator and the brake

system indicator come on together,

and the parking brake is f ully

released, the EBD system may also

be shut down.

Test your brakes as instructed on

page . If the brakes f eel normal,

drive slowly and have your vehicle

repaired by your dealer as soon as

possible. Avoid sudden hard braking

which could cause the rear wheels to

lock up and possibly lead to a loss of

control.

If this happens, you will also see the

‘‘CHECK ABS SYSTEM

Page 339 of 429

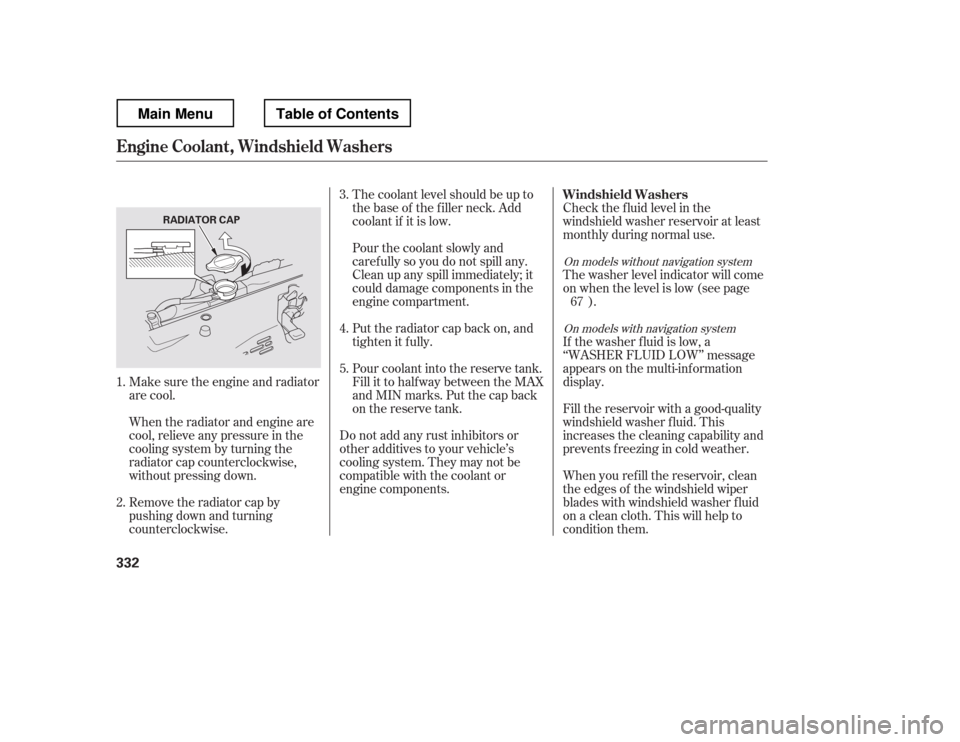

Make sure the engine and radiator

are cool.

When the radiator and engine are

cool, relieve any pressure in the

cooling system by turning the

radiator cap counterclockwise,

without pressing down.

Remove the radiator cap by

pushing down and turning

counterclockwise.The coolant level should be up to

the base of the f iller neck. Add

coolant if it is low.

Pourthecoolantslowlyand

caref ully so you do not spill any.

Clean up any spill immediately; it

could damage components in the

engine compartment.

Put the radiator cap back on, and

tighten it fully.

Pour coolant into the reserve tank.

Fill it to half way between the MAX

and MIN marks. Put the cap back

on the reserve tank.

Do not add any rust inhibitors or

other additives to your vehicle

Page 343 of 429

Pour the f luid slowly and caref ully so

you do not spill any. Clean up any

spill immediately; it could damage

components in the engine

compartment.

A low power steering f luid level can

indicate a leak in the system. Check

the f luid level f requently, and have

the system inspected as soon as

possible.

Always use Honda Power Steering

Fluid. You may use another power

steering f luid as an emergency

replacement, but have the power

steering system f lushed and ref illed

with Honda PSF as soon as possible.

If you are not sure how to add f luid,

contact your dealer.

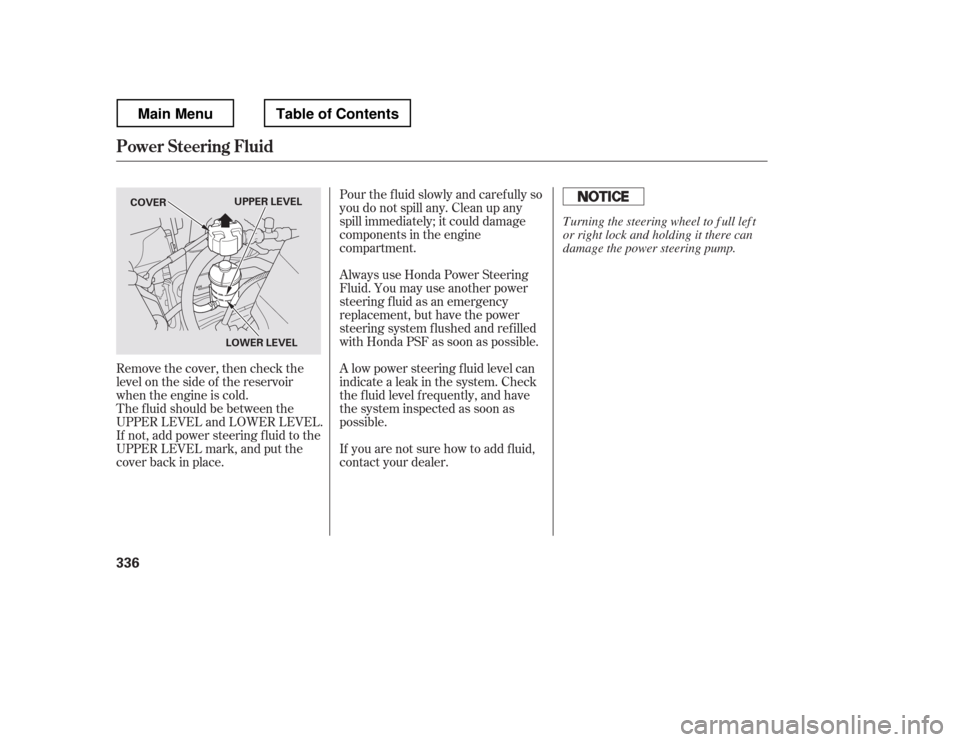

Remove the cover, then check the

level on the side of the reservoir

when the engine is cold.

The f luid should be between the

UPPER LEVEL and LOWER LEVEL.

If not, add power steering f luid to the

UPPER LEVEL mark, and put the

cover back in place.

Power Steering Fluid

336

LOWER LEVEL

COVER

UPPER LEVEL

T urning the steering wheel to f ull lef t

or right lock and holding it there can

damage the power steering pump.

Main MenuTable of Contents

Page 346 of 429

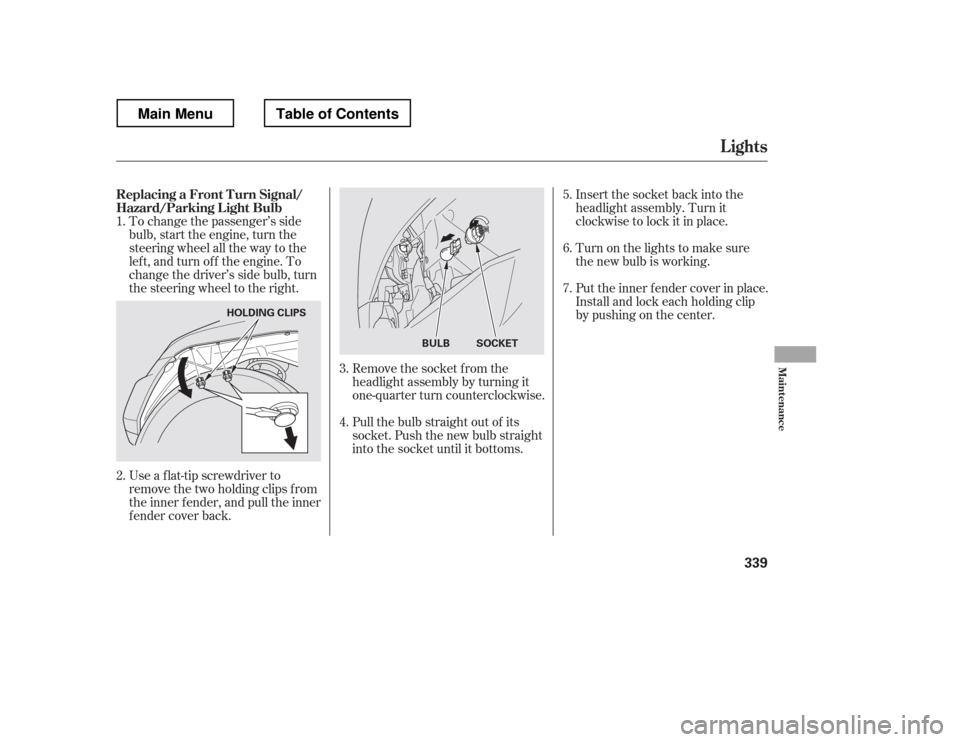

Remove the socket from the

headlight assembly by turning it

one-quarter turn counterclockwise.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.Turn on the lights to make sure

the new bulb is working.

Put the inner f ender cover in place.

Install and lock each holding clip

bypushingonthecenter.

Insert the socket back into the

headlight assembly. Turn it

clockwise to lock it in place.

To change the passenger

Page 347 of 429

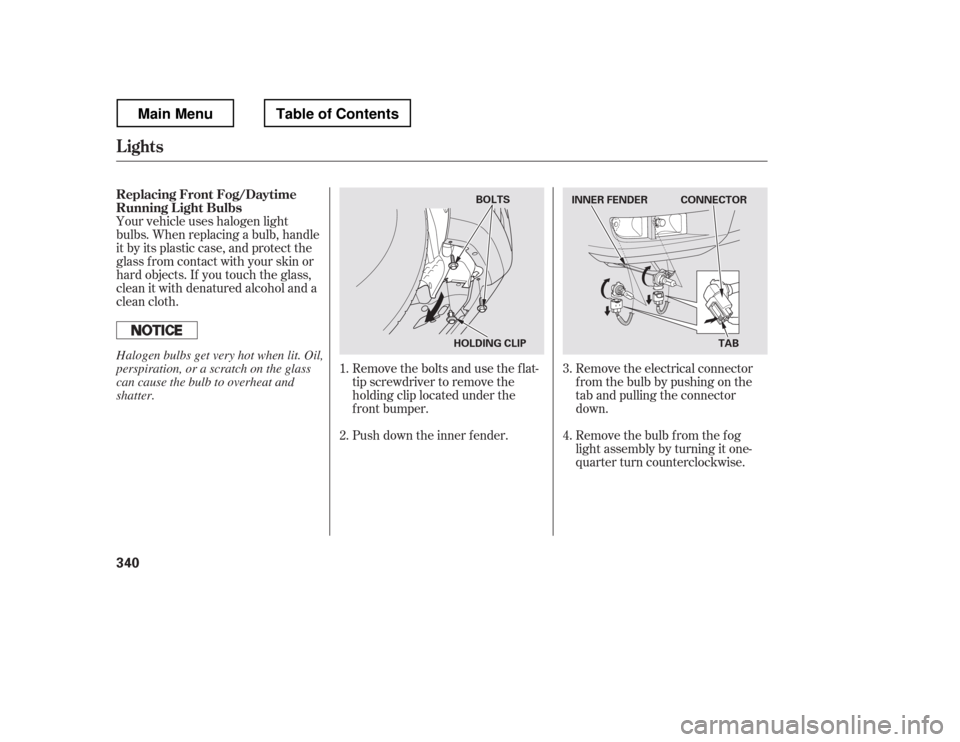

Your vehicle uses halogen light

bulbs. When replacing a bulb, handle

it by its plastic case, and protect the

glass from contact with your skin or

hard objects. If you touch the glass,

clean it with denatured alcohol and a

clean cloth.Push down the inner f ender.Remove the electrical connector

f rom the bulb by pushing on the

tab and pulling the connector

down.

Remove the bulb f rom the f og

light assembly by turning it one-

quarter turn counterclockwise.

Remove the bolts and use the flat-

tip screwdriver to remove the

holding clip located under the

f ront bumper.

2. 3. 4.

1.

Replacing Front Fog/Daytime

Running L ight Bulbs

Lights

340

BOLTS

INNER FENDER

TAB

HOLDING CLIP CONNECTOR

Halogen bulbs get very hot when lit. Oil,

perspiration, or a scratch on the glass

can cause the bulb to overheat and

shatter.

Main MenuTable of Contents

Page 348 of 429

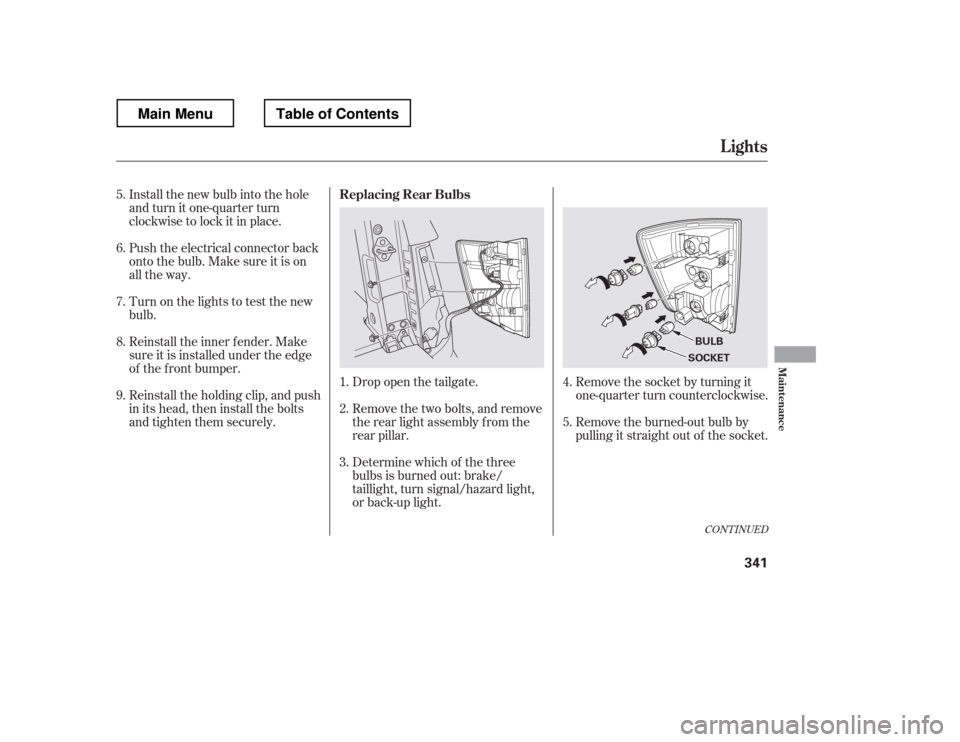

Remove the socket by turning it

one-quarter turn counterclockwise.

Remove the burned-out bulb by

pulling it straight out of the socket.

Drop open the tailgate.

Remove the two bolts, and remove

the rear light assembly f rom the

rear pillar.

Determine which of the three

bulbs is burned out: brake/

taillight, turn signal/hazard light,

or back-up light.

Install the new bulb into the hole

and turn it one-quarter turn

clockwise to lock it in place.

Push the electrical connector back

onto the bulb. Make sure it is on

all the way.

Turn on the lights to test the new bulb.

Reinstall the inner f ender. Make

sure it is installed under the edge

of the f ront bumper.

Reinstall the holding clip, and push

in its head, then install the bolts

and tighten them securely.

1. 2. 3. 4. 5.

5. 6. 7. 8. 9.

CONT INUED

Replacing Rear Bulbs

Lights

Maint enance

341

BULB

SOCKET

Main MenuTable of Contents

Page 349 of 429

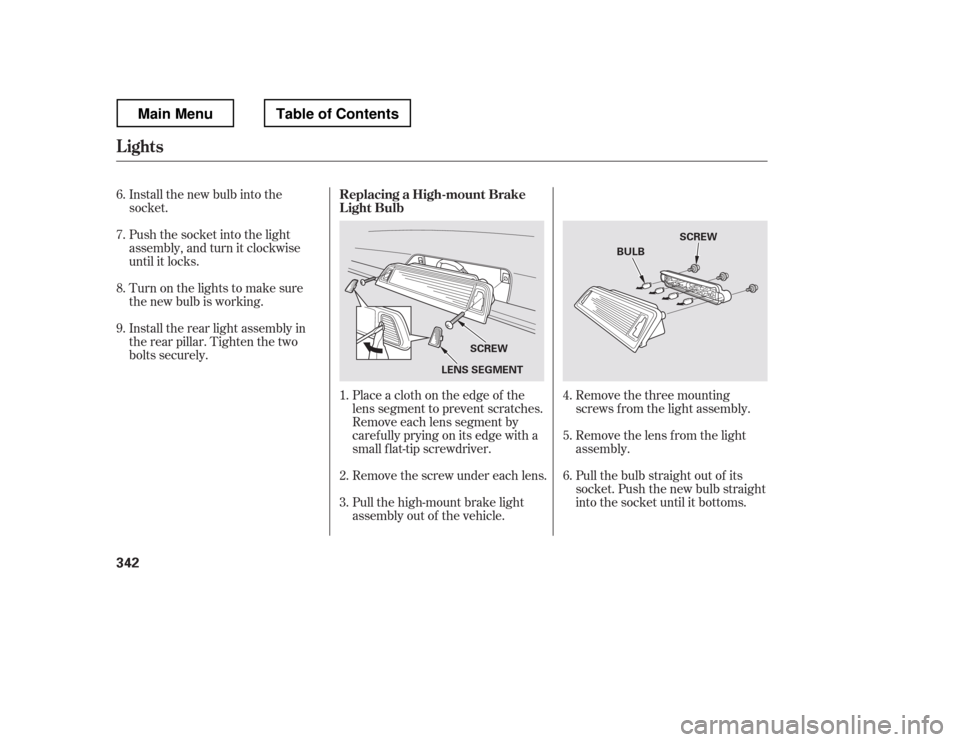

Remove the three mounting

screws f rom the light assembly.

Remove the lens f rom the light

assembly.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Place a cloth on the edge of the

lens segment to prevent scratches.

Remove each lens segment by

caref ully prying on its edge with a

small f lat-tip screwdriver.

Remove the screw under each lens.

Pull the high-mount brake light

assembly out of the vehicle.

Install the new bulb into the

socket.

Push the socket into the light

assembly, and turn it clockwise

until it locks.

Turn on the lights to make sure

the new bulb is working.

Install the rear light assembly in

the rear pillar. Tighten the two

bolts securely.

1. 2. 3. 4. 5. 6.

6.7. 8. 9.

Replacing a High-mount Brake

Light Bulb

Lights

342

LENS SEGMENT

SCREW SCREW

BULB

Main MenuTable of Contents

Page 350 of 429

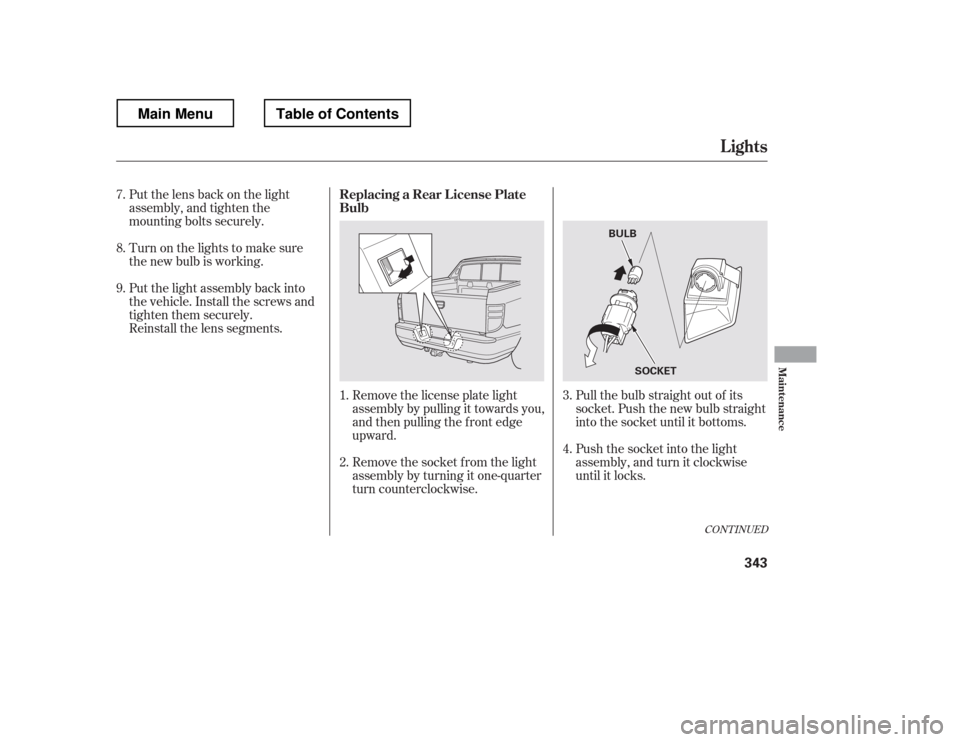

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Push the socket into the light

assembly, and turn it clockwise

until it locks.

Remove the license plate light

assembly by pulling it towards you,

and then pulling the f ront edge

upward.

Remove the socket f rom the light

assembly by turning it one-quarter

turn counterclockwise.

Put the lens back on the light

assembly, and tighten the

mounting bolts securely.

Turn on the lights to make sure

the new bulb is working.

Put the light assembly back into

the vehicle. Install the screws and

tighten them securely.

Reinstall the lens segments.

1. 2. 3. 4.

8.

7. 9.

CONT INUED

Replacing a Rear License Plate Bulb

Lights

Maint enance

343

BULB

SOCKET

Main MenuTable of Contents