maintenance Hyundai Accent 2006 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Accent, Model: Hyundai Accent 2006Pages: 599, PDF Size: 17.59 MB

Page 554 of 599

6OWNER MAINTENANCE

12SPARKING PLUG REPLACEMENT

G060A01L Prior to installing a sparking plug, the gap between the centre and outer elec- trodes must be checked and adjusted as necessary.Adjustment is facilitated by bending the outer electrode towards or away from the centre electrode. Under no circum-stances should attempts be made to adjust the position of the centre elec- trode.

4. Insert the sparking plug into the cyl-

inder head and using a suitable plug socket, slowly rotate the sparkingplug, (being careful not to cross- thread), until the plug contacts the seating area. Tighten the plug withthe plug socket by a further 1/2 to 3/ 4 of a turn only.

3. Clean around the base of the plug to

be removed, and install the plugsocket ensuring that the ceramic insulator does not become damaged.Turn the socket counterclockwise to remove the plug.

CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment.Wire brushing may damage the cen- tre electrode insulator causing mis- firing to occur. Only the correct gradeof sparking plug should be used. Use of an incorrect grade may result in serious engine damage.

!

SG060A1-E (Petrol Engine Only) This operation should only be performed when the engine is cold.

1. Remove the centre cover from the

engine rocker cover (DOHC Engine only).

2. Remove plug lead from the sparking

plug to be replaced, pulling the leadby the rubber cap. (Pulling the lead may damage the carbon conductor.) 0.039~0.043 in. (1.0 ~ 1.1 mm )

G060C01A

HLC5023

Page 555 of 599

6

OWNER MAINTENANCE

13AIR CLEANER ELEMENT REPLACEMENT

CHAMPION NGKRC10YC4 BKR5ES-11

5. Replace the plug lead ensuring that

the cap is pushed firmly into place. Confirm that the cap is correctly seated by lightly pulling upon it.

NOTE: When replacing the spark plug, genu- ine Hyundai replacement parts are recommended. Recommended Spark Plugs :

G060C03A SG070A2-E To replace the air cleaner element, remove the air intake ducting from theair flow sensor body and unfasten the spring clips holding the air flow sensor top to the body. Lift out the air flowsensor followed by the air cleaner ele- ment. Replacement of the element is the reverse of the above.

!

CAUTION:

o The air flow sensor is a precision engineered electronic measuring device and therefore care should be exercised that the air flow sen-sor is not damaged during re- placement of the element.

o When removing the air cleaner element, be careful that dust ordirt does not enter the air intake. These may result in damage to theair cleaner element

To ensure maximum filtration perfor-mance and continued engine perfor- mance, only genuine Hyundai replace- ments should be used.

G070A01A-D

Page 556 of 599

6OWNER MAINTENANCE

14WINDSCREEN WIPER BLADES

CAUTION:

Engine coolant anti freeze must not be used in the windscreen washersystem since damage to the paintwork may result. Undiluted windscreen washer addi-tive must not be allowed to come into contact with the paintwork. If spillage occurs, flush the affectedarea immediately with water. Do not operate the windscreen washer for more than 15 seconds continuouslyor when the reservoir is empty since damage to the washer pump will result.

!

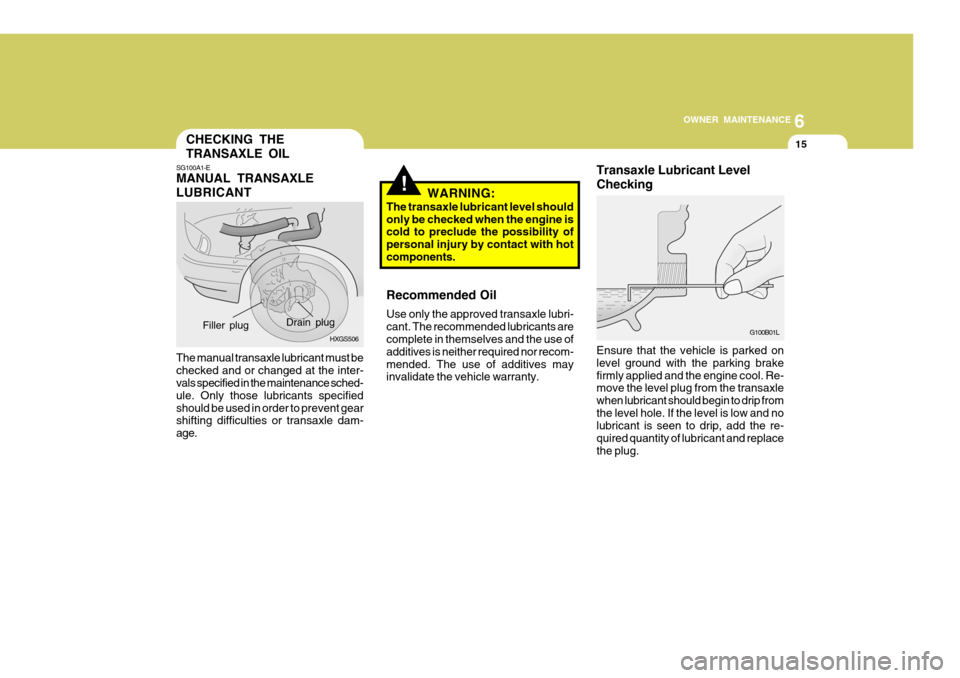

The level of windscreen washer fluid available should be checked on a daily basis. The level of fluid will be visible through the side of the reservoir. Whenthe fluid is to be replenished, only a proprietary screen wash additive should be used and in the concentration rec-ommended by the manufacturer. The windscreen washer reservoir has a total capacity of 3 litres.

SG090A2-E

G080A01A-EAT The wiper blades should be carefully inspected from time to time and cleanedto remove accumulations of road film or other debris. To clean the wiper blades and arms, use a clean sponge or clothwith a mild soap or detergent and water. If the wipers continue to streak or smear the glass, replace them with genuineHyundai replacement. NOTE:

o Do not operate the wipers on dry

glass since rapid wear and damage to the windscreen glass may result.

o Keep the blade rubber out of con-

tact with petroleum products suchas engine oil, petrol, etc.

HEF119 HLC5007

WINDSCREEN WASHER RES- ERVOIR REPLENISHMENT

Page 557 of 599

6

OWNER MAINTENANCE

15CHECKING THE TRANSAXLE OIL

!

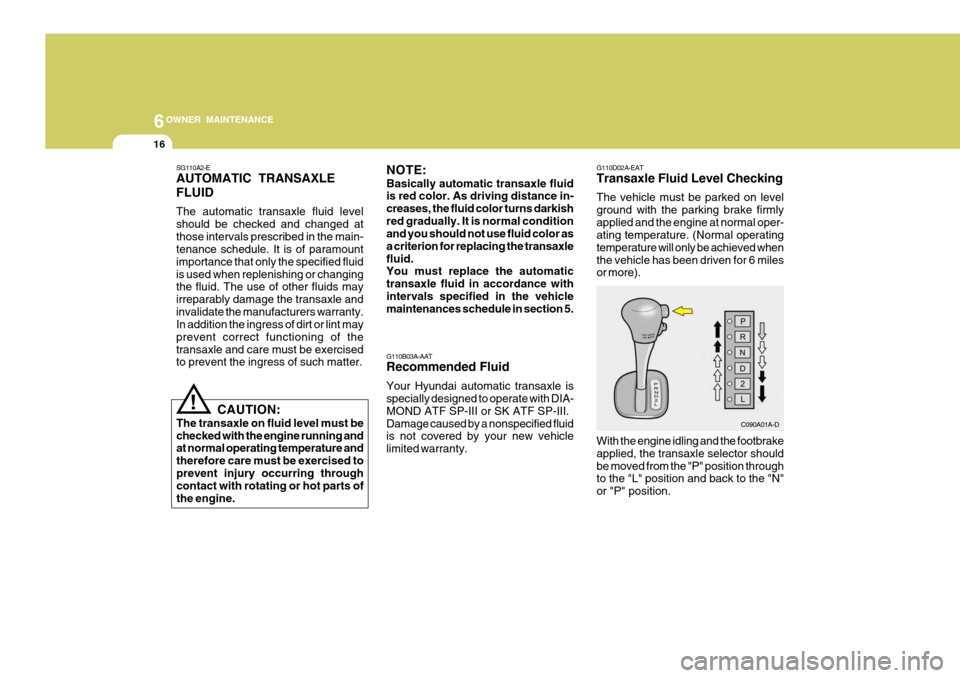

SG100A1-E MANUAL TRANSAXLE LUBRICANT The manual transaxle lubricant must be checked and or changed at the inter- vals specified in the maintenance sched- ule. Only those lubricants specifiedshould be used in order to prevent gear shifting difficulties or transaxle dam- age. WARNING:

The transaxle lubricant level shouldonly be checked when the engine is cold to preclude the possibility of personal injury by contact with hotcomponents.

HXGS506

Drain plug

Filler plug

Recommended Oil Use only the approved transaxle lubri- cant. The recommended lubricants are complete in themselves and the use of additives is neither required nor recom-mended. The use of additives may invalidate the vehicle warranty. Ensure that the vehicle is parked on level ground with the parking brakefirmly applied and the engine cool. Re- move the level plug from the transaxle when lubricant should begin to drip fromthe level hole. If the level is low and no lubricant is seen to drip, add the re- quired quantity of lubricant and replacethe plug.

Transaxle Lubricant Level Checking

G100B01L

Page 558 of 599

6OWNER MAINTENANCE

16

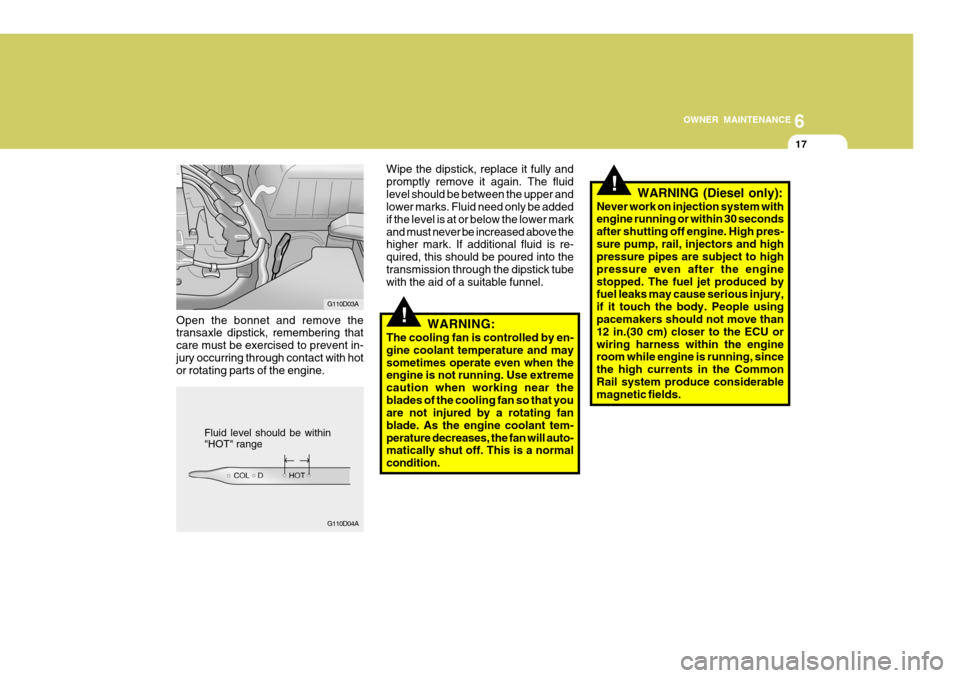

G110D02A-EAT Transaxle Fluid Level Checking The vehicle must be parked on level ground with the parking brake firmlyapplied and the engine at normal oper- ating temperature. (Normal operating temperature will only be achieved whenthe vehicle has been driven for 6 miles or more). With the engine idling and the footbrake applied, the transaxle selector shouldbe moved from the "P" position through to the "L" position and back to the "N" or "P" position.

SG110A2-E AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should be checked and changed atthose intervals prescribed in the main- tenance schedule. It is of paramount importance that only the specified fluidis used when replenishing or changing the fluid. The use of other fluids may irreparably damage the transaxle andinvalidate the manufacturers warranty. In addition the ingress of dirt or lint may prevent correct functioning of thetransaxle and care must be exercised to prevent the ingress of such matter.

CAUTION:

The transaxle on fluid level must be checked with the engine running and at normal operating temperature and therefore care must be exercised toprevent injury occurring through contact with rotating or hot parts of the engine.

! G110B03A-AAT Recommended Fluid Your Hyundai automatic transaxle is specially designed to operate with DIA- MOND ATF SP-III or SK ATF SP-III.Damage caused by a nonspecified fluid is not covered by your new vehicle limited warranty.

NOTE: Basically automatic transaxle fluid is red color. As driving distance in- creases, the fluid color turns darkishred gradually. It is normal condition and you should not use fluid color as a criterion for replacing the transaxlefluid. You must replace the automatic transaxle fluid in accordance withintervals specified in the vehicle maintenances schedule in section 5.

C090A01A-D

Page 559 of 599

6

OWNER MAINTENANCE

17

!Open the bonnet and remove the transaxle dipstick, remembering that care must be exercised to prevent in-jury occurring through contact with hot or rotating parts of the engine. WARNING:

The cooling fan is controlled by en- gine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near theblades of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant tem-perature decreases, the fan will auto- matically shut off. This is a normal condition.

Wipe the dipstick, replace it fully andpromptly remove it again. The fluidlevel should be between the upper and lower marks. Fluid need only be added if the level is at or below the lower markand must never be increased above the higher mark. If additional fluid is re- quired, this should be poured into thetransmission through the dipstick tube with the aid of a suitable funnel.

G110D03A

G110D04A

Fluid level should be within "HOT" range

!WARNING (Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine. High pres-sure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People usingpacemakers should not move than 12 in.(30 cm) closer to the ECU or wiring harness within the engine room while engine is running, since the high currents in the CommonRail system produce considerable magnetic fields.

Page 560 of 599

6OWNER MAINTENANCE

18BRAKE SYSTEM CHECKING

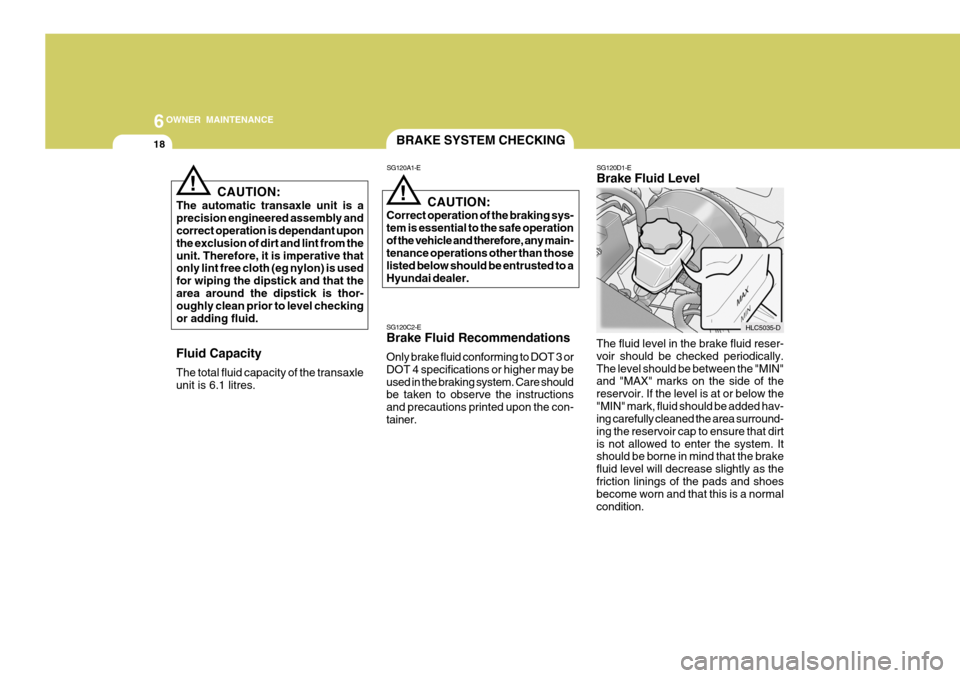

SG120D1-E Brake Fluid Level

The fluid level in the brake fluid reser- voir should be checked periodically.The level should be between the "MIN" and "MAX" marks on the side of the reservoir. If the level is at or below the"MIN" mark, fluid should be added hav- ing carefully cleaned the area surround- ing the reservoir cap to ensure that dirtis not allowed to enter the system. It should be borne in mind that the brake fluid level will decrease slightly as thefriction linings of the pads and shoes become worn and that this is a normal condition.

! CAUTION:

The automatic transaxle unit is a precision engineered assembly and correct operation is dependant upon the exclusion of dirt and lint from theunit. Therefore, it is imperative that only lint free cloth (eg nylon) is used for wiping the dipstick and that thearea around the dipstick is thor- oughly clean prior to level checking or adding fluid.

Fluid Capacity The total fluid capacity of the transaxle unit is 6.1 litres. SG120A1-E

SG120C2-E Brake Fluid Recommendations Only brake fluid conforming to DOT 3 or DOT 4 specifications or higher may beused in the braking system. Care should be taken to observe the instructions and precautions printed upon the con-tainer.! CAUTION:

Correct operation of the braking sys- tem is essential to the safe operationof the vehicle and therefore, any main- tenance operations other than those listed below should be entrusted to aHyundai dealer.

HLC5035-D

Page 561 of 599

6

OWNER MAINTENANCE

19CHECKING THE CLUTCH FLUID

!

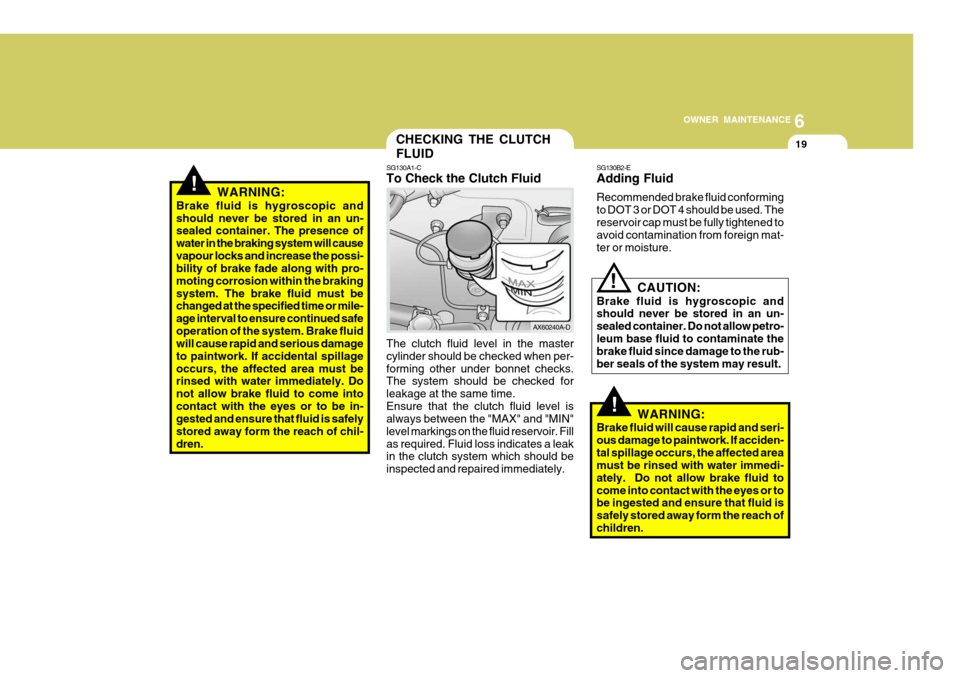

SG130A1-C To Check the Clutch Fluid The clutch fluid level in the master cylinder should be checked when per-forming other under bonnet checks. The system should be checked for leakage at the same time.Ensure that the clutch fluid level is always between the "MAX" and "MIN" level markings on the fluid reservoir. Fillas required. Fluid loss indicates a leak in the clutch system which should be inspected and repaired immediately.

WARNING:

Brake fluid is hygroscopic andshould never be stored in an un- sealed container. The presence of water in the braking system will causevapour locks and increase the possi- bility of brake fade along with pro- moting corrosion within the brakingsystem. The brake fluid must be changed at the specified time or mile- age interval to ensure continued safeoperation of the system. Brake fluid will cause rapid and serious damage to paintwork. If accidental spillageoccurs, the affected area must be rinsed with water immediately. Do not allow brake fluid to come intocontact with the eyes or to be in- gested and ensure that fluid is safely stored away form the reach of chil-dren.

AX60240A-D

!

SG130B2-E Adding Fluid Recommended brake fluid conforming to DOT 3 or DOT 4 should be used. Thereservoir cap must be fully tightened to avoid contamination from foreign mat- ter or moisture.

! CAUTION:

Brake fluid is hygroscopic and should never be stored in an un- sealed container. Do not allow petro-leum base fluid to contaminate the brake fluid since damage to the rub- ber seals of the system may result.

WARNING:

Brake fluid will cause rapid and seri-ous damage to paintwork. If acciden-tal spillage occurs, the affected area must be rinsed with water immedi- ately. Do not allow brake fluid tocome into contact with the eyes or to be ingested and ensure that fluid is safely stored away form the reach ofchildren.

Page 562 of 599

6OWNER MAINTENANCE

20

CRANK PULLEY

G140D01A

TENSION PULLEY

A/C

AIR CONDITIONING SYSTEM MAINTENANCE

SG140C2-E Checking the Refrigerant

1. Start the engine and run at idle for

several minutes with the refrigera- tion system running at the coldest setting.

2. If the air coming out of the in-dash vents is not cold, have the air condi-tioning system inspected by your Hyundai dealer.

! CAUTION:

Running the air conditioning system for extended periods of time with a low refrigerant level may damage thecompressor.

SG140A1-E Condenser Ensure that the condenser is periodi- cally inspected and that accumulationsof dirt, dead insects and leaves etc, are removed to ensure that the efficiency of the system is not impaired. Care mustbe exercised to ensure that the con- denser fins are not damaged during cleaning.

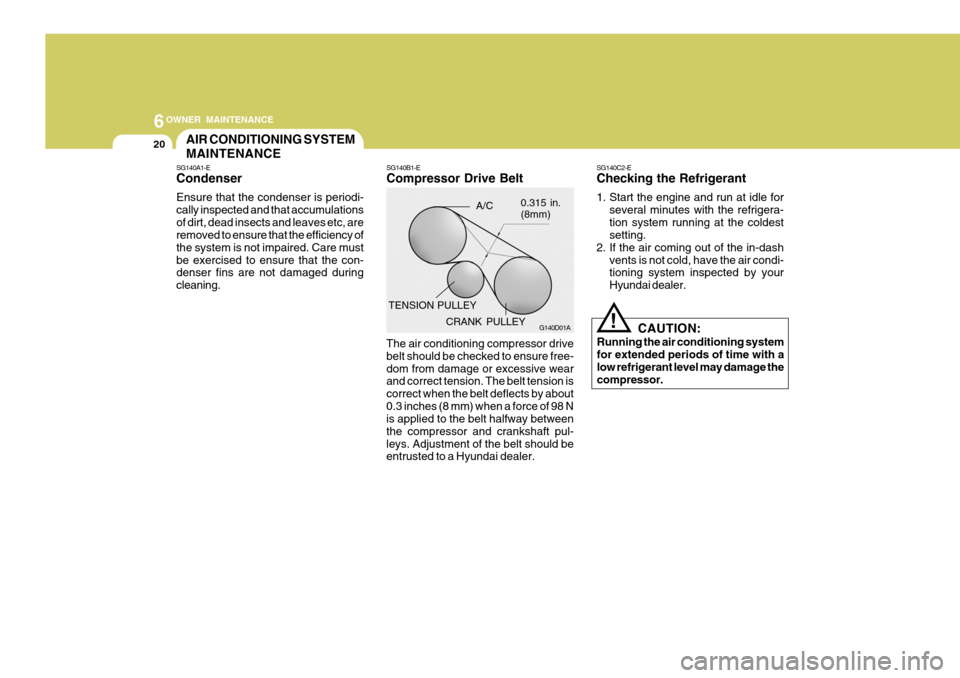

SG140B1-E Compressor Drive Belt

0.315 in. (8mm)

The air conditioning compressor drive belt should be checked to ensure free-dom from damage or excessive wear and correct tension. The belt tension is correct when the belt deflects by about0.3 inches (8 mm) when a force of 98 N is applied to the belt halfway between the compressor and crankshaft pul-leys. Adjustment of the belt should be entrusted to a Hyundai dealer.

Page 563 of 599

6

OWNER MAINTENANCE

21CHANGING THE POLLEN FILTER

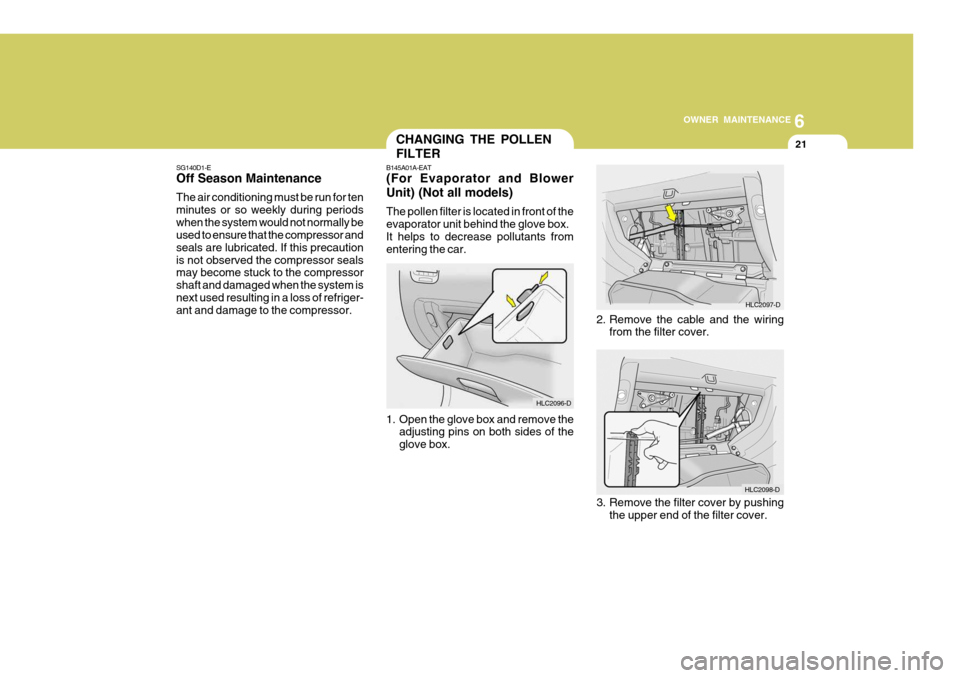

B145A01A-EAT

(For Evaporator and Blower

Unit) (Not all models) The pollen filter is located in front of the evaporator unit behind the glove box.It helps to decrease pollutants from entering the car.

1. Open the glove box and remove the

adjusting pins on both sides of the glove box. HLC2096-D

SG140D1-E Off Season Maintenance The air conditioning must be run for ten minutes or so weekly during periodswhen the system would not normally be used to ensure that the compressor and seals are lubricated. If this precautionis not observed the compressor seals may become stuck to the compressor shaft and damaged when the system isnext used resulting in a loss of refriger- ant and damage to the compressor.

2. Remove the cable and the wiring

from the filter cover.

3. Remove the filter cover by pushing the upper end of the filter cover. HLC2097-D

HLC2098-D