heating Hyundai Atos 2002 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2002, Model line: Atos, Model: Hyundai Atos 2002Pages: 249, PDF Size: 3.11 MB

Page 204 of 249

3-3

WHAT TO DO IN AN EMERGENCY

ZD050B1-E

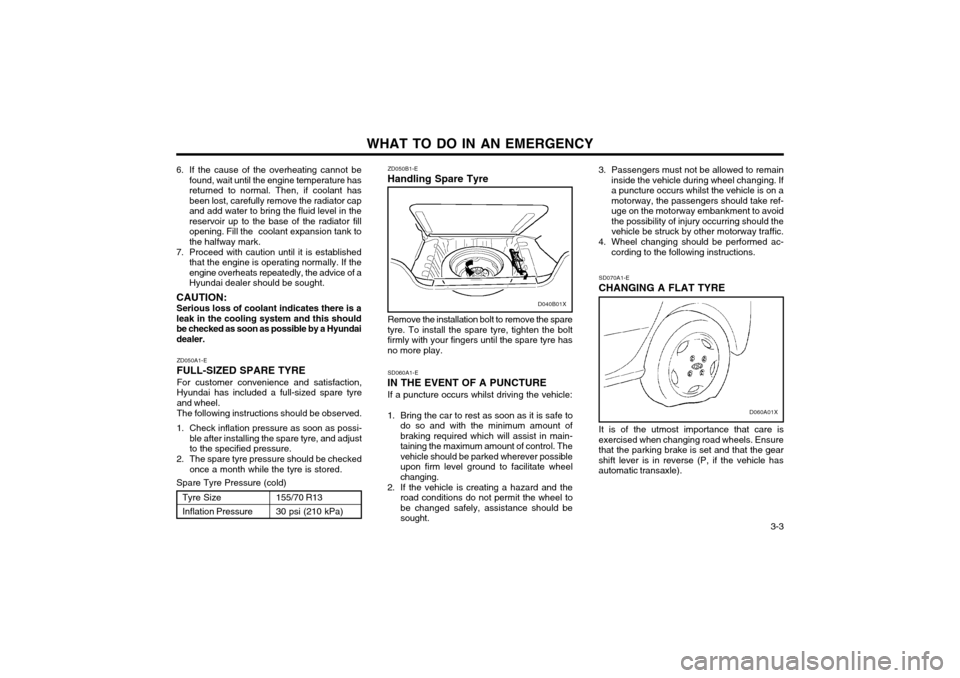

Handling Spare Tyre

6. If the cause of the overheating cannot be

found, wait until the engine temperature has returned to normal. Then, if coolant hasbeen lost, carefully remove the radiator capand add water to bring the fluid level in thereservoir up to the base of the radiator fill

opening. Fill the coolant expansion tank tothe halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice of aHyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there is aleak in the cooling system and this shouldbe checked as soon as possible by a Hyundaidealer. 3. Passengers must not be allowed to remain

inside the vehicle during wheel changing. Ifa puncture occurs whilst the vehicle is on amotorway, the passengers should take ref-uge on the motorway embankment to avoidthe possibility of injury occurring should thevehicle be struck by other motorway traffic.

4. Wheel changing should be performed ac- cording to the following instructions.

ZD050A1-E

FULL-SIZED SPARE TYRE For customer convenience and satisfaction,Hyundai has included a full-sized spare tyreand wheel. The following instructions should be observed.

1. Check inflation pressure as soon as possi- ble after installing the spare tyre, and adjust to the specified pressure.

2. The spare tyre pressure should be checked once a month while the tyre is stored.

Spare Tyre Pressure (cold)

D040B01X

Remove the installation bolt to remove the spare

tyre. To install the spare tyre, tighten the bolt firmly with your fingers until the spare tyre hasno more play.

SD060A1-E

IN THE EVENT OF A PUNCTURE

If a puncture occurs whilst driving the vehicle:

1. Bring the car to rest as soon as it is safe to do so and with the minimum amount ofbraking required which will assist in main-taining the maximum amount of control. Thevehicle should be parked wherever possibleupon firm level ground to facilitate wheelchanging.

2. If the vehicle is creating a hazard and the road conditions do not permit the wheel tobe changed safely, assistance should besought. SD070A1-E

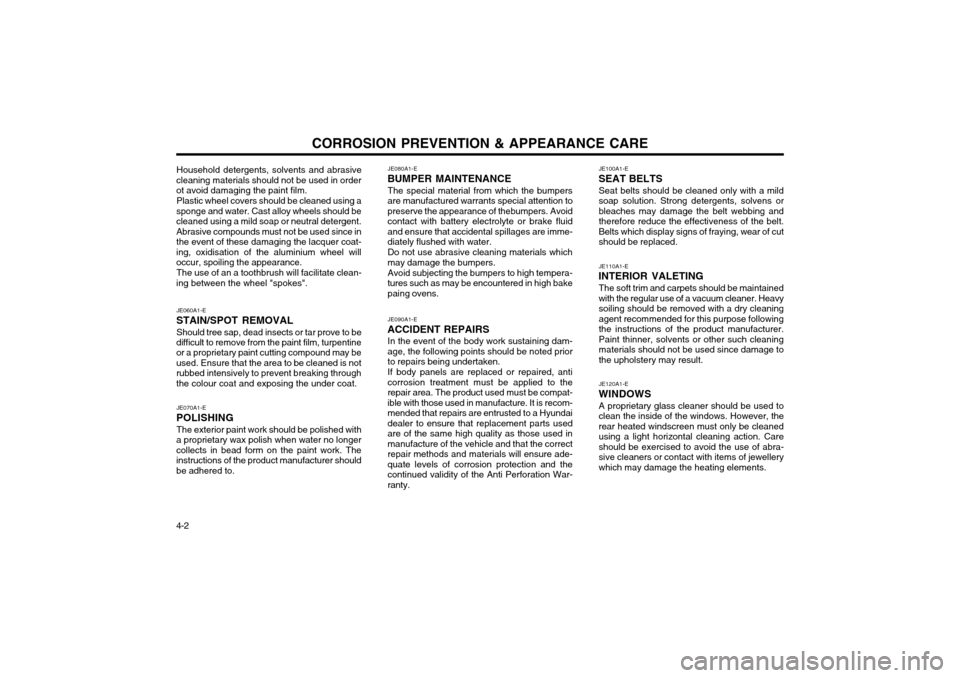

CHANGING A FLAT TYRE

D060A01X

It is of the utmost importance that care is

exercised when changing road wheels. Ensure that the parking brake is set and that the gearshift lever is in reverse (P, if the vehicle hasautomatic transaxle).

Tyre Size Inflation Pressure 155/70 R1330 psi (210 kPa)

Page 211 of 249

CORROSION PREVENTION & APPEARANCE CARE

4-2 Household detergents, solvents and abrasive

cleaning materials should not be used in order ot avoid damaging the paint film.

Plastic wheel covers should be cleaned using a

sponge and water. Cast alloy wheels should becleaned using a mild soap or neutral detergent.Abrasive compounds must not be used since inthe event of these damaging the lacquer coat-ing, oxidisation of the aluminium wheel willoccur, spoiling the appearance.

The use of an a toothbrush will facilitate clean-

ing between the wheel "spokes". JE080A1-E

BUMPER MAINTENANCE

The special material from which the bumpersare manufactured warrants special attention topreserve the appearance of thebumpers. Avoidcontact with battery electrolyte or brake fluidand ensure that accidental spillages are imme-diately flushed with water. Do not use abrasive cleaning materials which may damage the bumpers. Avoid subjecting the bumpers to high tempera- tures such as may be encountered in high bakepaing ovens.

JE060A1-E

STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be

difficult to remove from the paint film, turpentineor a proprietary paint cutting compound may beused. Ensure that the area to be cleaned is notrubbed intensively to prevent breaking throughthe colour coat and exposing the under coat.

JE070A1-E

POLISHING The exterior paint work should be polished with

a proprietary wax polish when water no longercollects in bead form on the paint work. Theinstructions of the product manufacturer shouldbe adhered to. JE090A1-E

ACCIDENT REPAIRS In the event of the body work sustaining dam-age, the following points should be noted priorto repairs being undertaken. If body panels are replaced or repaired, anti corrosion treatment must be applied to therepair area. The product used must be compat-ible with those used in manufacture. It is recom-mended that repairs are entrusted to a Hyundaidealer to ensure that replacement parts usedare of the same high quality as those used inmanufacture of the vehicle and that the correctrepair methods and materials will ensure ade-quate levels of corrosion protection and thecontinued validity of the Anti Perforation War-ranty. JE100A1-E

SEAT BELTS

Seat belts should be cleaned only with a mildsoap solution. Strong detergents, solvens orbleaches may damage the belt webbing andtherefore reduce the effectiveness of the belt.Belts which display signs of fraying, wear of cutshould be replaced. JE110A1-E

INTERIOR VALETING

The soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavysoiling should be removed with a dry cleaningagent recommended for this purpose followingthe instructions of the product manufacturer.Paint thinner, solvents or other such cleaningmaterials should not be used since damage tothe upholstery may result. JE120A1-E

WINDOWS

A proprietary glass cleaner should be used to clean the inside of the windows. However, therear heated windscreen must only be cleanedusing a light horizontal cleaning action. Careshould be exercised to avoid the use of abra-sive cleaners or contact with items of jewellerywhich may damage the heating elements.

Page 220 of 249

DO-IT-YOURSELF MAINTENANCE

6-2 ZG020B1-E

GENERAL CHECKS Engine Compartment

The following should be checked regularly:

o Engine oil level and condition

o Transaxle fluid level and condition

o Brake reservoir fluid level

o Engine coolant level

o Windscreen washer fluid level

o Accessory drive belt condition

o Coolant hose condition

o Fluid leaks (on or below components)

o Power steering fluid level

o Tyre pressure and condition (including spare)

o Battery condition ZG020C1-A

Vehicle Exterior

The following should be checked monthly:

o Overall appearance and condition

o Wheel condition and wheel nut tightness

o Exhaust system condition

o Light condition and operation

o Windscreen glass condition

o Wiper blade condition

o Paint condition and corrosion

o Fluid leaks

o Door and hood lock condition o Air filter element condition G020C02X-GAT

Vehicle Interior

The following should be checked each time

when the vehicle is driven:

o Lights operation

o Windscreen wipers operation

o Horn operation

o Defroster, heating system operation (and air conditioning, if installed)

o Steering operation and condition

o Mirror condition and operation

o Turn signal operation

o Accelerator pedal operation

o Brake operation, including parking brake

o Manual transaxle operation, including clutch operation

o Automatic transaxle operation, including "Park" mechanism operation

o Seat control condition and operation

o Seat belt condition and operation

o Sunvisor operation

If you notice anything that does not operate

correctly or appear to be functioning correctly, inspect it carefully and seek assistance fromyour Hyundai dealer if service is needed. ZG030A1-A

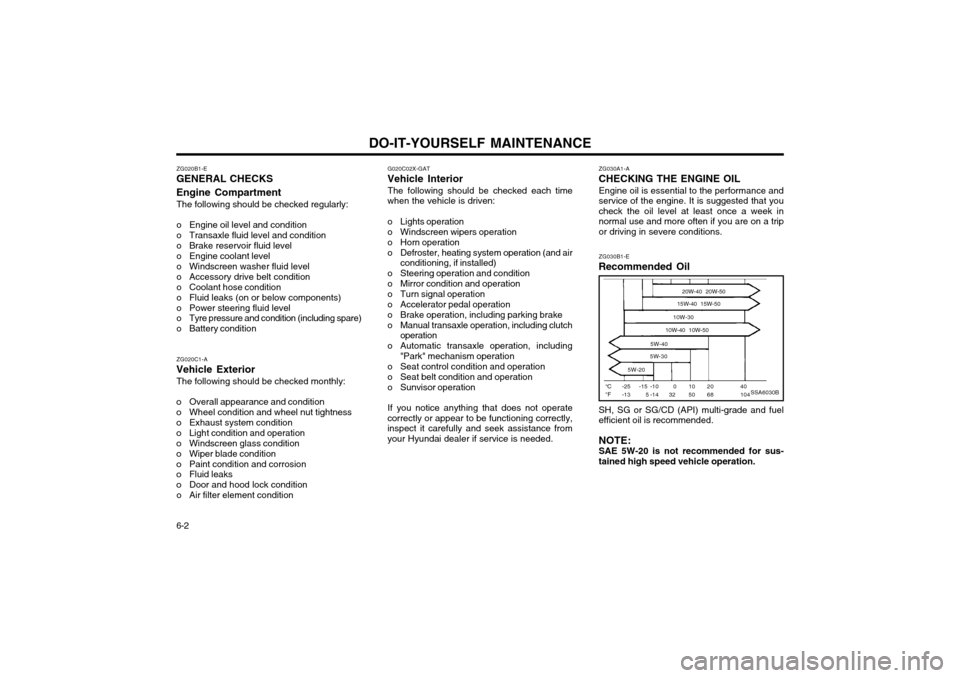

CHECKING THE ENGINE OIL

Engine oil is essential to the performance andservice of the engine. It is suggested that youcheck the oil level at least once a week innormal use and more often if you are on a tripor driving in severe conditions. ZG030B1-E

Recommended Oil

SSA6030B°C °F -25-13 20W-40 20W-50

15W-40 15W-50

10W-30

10W-40 10W-50

5W-40

5W-30

5W-20

40104

2068

1050

032

-15 5 -10-14

SH, SG or SG/CD (API) multi-grade and fuel efficient oil is recommended. NOTE: SAE 5W-20 is not recommended for sus-tained high speed vehicle operation.

Page 248 of 249

INDEX

10-2

FRONT FOG LIGHT

SWITCH ......................................................... 1-29

FUEL ECONOMY ............................................................................... 2-3

FUEL GAUGE .................................................................................. 1-20

FUEL RECOMMENDATIONS ........... ................................................. 1-1

FUSIBLE LINKS ............................................................................... 6-14

G GENERAL CHECKS .......................................................................... 6-2

H

HAZARD WARNING SYSTEM ........................................................ 1-24

HEADLIGHT BULB ........................................................................... 6-16

HEADLIGHT LEVELING DEVICE SYSTEM ....................................1-23

HEADRESTRAINT .............................................................................. 1-5

HEADLIGHT FLASH ER .................................................................... 1-22

HEADLIGHT SWITCH ...................................................................... 1-21

HEATED REAR WINDOW ................... ............................................1-24

HEATING AND VENTILATION ........................................................ 1-32

HIGH AND LOW BEAM ................................................................... 1-21

HIGH-MOUNTED REAR STOPLIGHT .............................................1-27

HORN ............................................................................................... 1-32

IIF THE ENGINE CANNOT BE CRANKED ........................................ 3-1

IF THE ENGINE OVERHEATS .......................................................... 3-2

IF THE ENGINE WILL NOT START .................................................. 3-1

IGNITION SWITCH ............................................................................. 2-2

IMMOBILIZER SYSTEM ..................................................................... 1-2INDIVIDUAL CIRCUIT FUSES ......................................................... 6-15

INSTRUMENT CLUSTER AND INDICATOR ..................................1-17INSTRUMENTS AND CONTROLS

..................................................1-16

INTERIOR LIGHT ............................................................................. 1-25

JJUMP STARTI NG ........................................................................ 3-1~3-2

KKEY POSITIONS ................................................................................ 2-2

KEYS .................................................................................................. 1-2 L LIGHT BULBS .................................................................................. 6-16

LIMP HOME PROCEDURES ............................................................. 1-2

LOW FUEL LEVEL WARNING LAMP .............................................1-19

M

MAINTENANCE AND SERVICING REQUIREMENTS ..................... 5-1

MAINTENANCE UNDER SEVERE USAGE CONDITIONS .............. 5-4

MANUAL TRANSAXLE LUBRICANT ................................................. 6-9

MANUAL TRANSAXLE ...................................................................... 2-4

MULTI FUNCTION SWITCH ................................. ...........................1-21

OODOMETER ..................................................................................... 1-21

OIL PRESSURE WARNING LIGHT ................................................. 1-18

OUTSIDE REAR VIEW MIRROR ....................................................1-25

PPARKING BRAKE ............................................................................ 1-26

POWER STEERING FLUID LEVEL ................................................. 6-16