brake fluid Hyundai Coupe 2003 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Coupe, Model: Hyundai Coupe 2003Pages: 310, PDF Size: 2.87 MB

Page 268 of 310

APPEARANCE CARE

4-2

oxidization of the aluminium wheel will occur, spoiling the appearance.The use of an a toothbrush will facilitate cleaningbetween the wheel "spokes". SE040B1-E STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be difficult to remove from the paint film, turpentineor a proprietary paint cutting compound may beused. Ensure that the area to be cleaned is notrubbed intensively to prevent breaking throughthe colour coat and exposing the under coat. SE040C1-E POLISHING The exterior paint work should be polished with a proprietary wax polish when water no longercollects in bead form on the paint work. Theinstructions of the product manufacturer shouldbe adhered to. SE040E1-E BUMPER MAINTENANCEThe special material from which the bumpers are manufactured warrants special attention to pre-serve the appearance of the bumpers. Avoidcontact with battery electrolyte or brake fluid andensure that accidental spillages are immediatelyflushed with water.Do not use abrasive cleaning materials whichmay damage the bumpers.

SE040F1-E ACCIDENT REPAIRSIn the event of the body work sustaining damage, the following points should be noted prior torepairs being undertaken.If body panels are replaced or repaired, anticorrosion treatment must be applied to the repairarea. The product used must be compatible withthose used in manufacture. It is recommendedthat repairs are entrusted to a Hyundai dealer toensure that replacement parts used are of thesame high quality as those used in manufactureof the vehicle and that the correct repair methodsand materials will ensure adequate levels ofcorrosion protection and the continued validity ofthe Anti Perforation Warranty. SE050A1-E INTERIOR During the winter period, it is possible that the passenger compartment flooring may becomewet from damp footwear or quantities of snowadhering to footwear. The carpet should not beallowed to remain in this condition since thecarpet may begin to create musty smells and willpromote corrosion of the floor pan in addition tothe carpet and under felt beginning to rot. SE050C1-E INTERIOR VALETINGThe soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavysoiling should be removed with a dry cleaningagent recommended for this purpose followingthe instructions of the product manufacturer.Paint thinner, solvents or other such cleaningmaterials should not be used since damage tothe upholstery may result.

SE050D1-E SEAT BELTSSeat belts should be cleaned only with a mild soap solution. Strong detergents, solvens orbleaches may damage the belt webbing andtherefore reduce the effectiveness of the belt.Belts which display signs of fraying, wear of cutshould be replaced. SE050E1-E WINDOWSA proprietary glass cleaner should be used to clean the inside of the windows. However, therear heated windscreen must only be cleanedusing a light horizontal cleaning action. Careshould be exercised to avoid the use of abrasivecleaners or contact with items of jewellery whichmay damage the heating elements.

Avoid subjecting the bumpers to high tempera-tures such as may be encountered in high bakepaint ovens.

Page 269 of 310

VEHICLE MAINTENANCE REQUIREMENTS 5-1

SF020A1-E MAINTENANCE AND SERVICINGREQUIREMENTS To ensure the continued reliability and safety ofthe vehicle, certain routine maintenance opera-tions are required at specific mileage or timeintervals.It is the responsibility of the vehicle owner toensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.The new vehicle warranty may be invalidated ifthe routine maintenance operations are not per-formed in line with the recommendations outlinedand the safety and durability of the vehicle ad-versely affected.It is recommended that all maintenance opera-tions with the exception of the daily operatingchecks are entrusted to a Hyundai dealer toensure that the latest repair and maintenanceprocedures and specialized servicing tools areemployed. In addition, the use of genuine Hyundaireplacement parts will ensure that the vehiclesafety and performance will not be compro-mised.

SF000A1-E

5. VEHICLE MAINTE-

NANCE REQUIRE- MENTS NOTE: The inspection and testing of certain elec-tronic fuel injection/engine management andautomatic transmission control systems re-quire specialised electronic equipment spe-cifically designed for Hyundai vehicles. Theuse of general purpose electrical test equip-ment may result in damage to the control unitmicroprocessors. SF020C1-E Specified Scheduled Procedures

The Specified scheduled procedures are listed

in the maintenance charts beginning at page 5- 2. The operations specified must be performedat the time or mileage intervals shown irrespec-tive of whether the mileage interval has beenreached before the specified time interval.

Certain lubricants and components degrade

with both time and mileage (e.g. engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended that themaintenance operations are performed by thefactory-trained or distributor-trained techniciansat your Hyundai dealer because of the need forspecialized knowledge and tooling and to en-sure that no possibility of invalidating the man-ufacturers warranty exists.

The maintenance schedules relate to vehicles

operated under normal conditions, vehicles which are operated under adverse conditionswill require more frequent maintenance which isdescribed at page 5-4. SF030B1-E SERVICE HISTORY It is important that all scheduled maintenance services are recorded in the warranty and ser-vice passport to ensure that proof of mainte-nance is available when warranty service isrequired.

5

Page 271 of 310

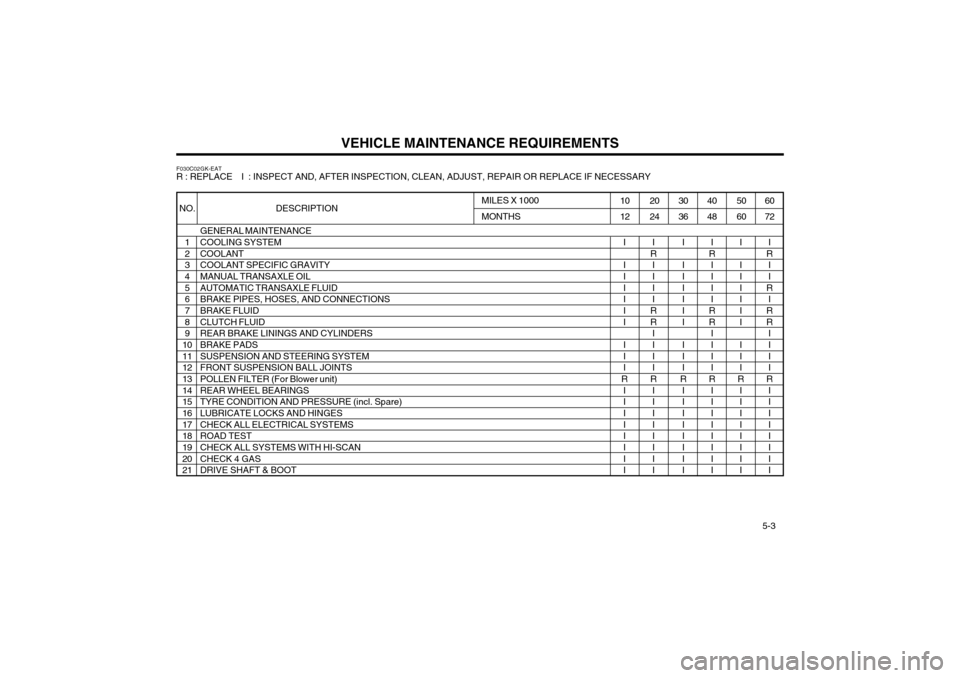

VEHICLE MAINTENANCE REQUIREMENTS 5-3

I I I I II I I I I

R

III I II I I

F030C02GK-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEM COOLANT COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID BRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUID CLUTCH FLUID REAR BRAKE LININGS AND CYLINDERSBRAKE PADS SUSPENSION AND STEERING SYSTEM FRONT SUSPENSION BALL JOINTSPOLLEN FILTER (For Blower unit) REAR WHEEL BEARINGS TYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGES CHECK ALL ELECTRICAL SYSTEMS ROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN CHECK 4 GAS DRIVE SHAFT & BOOT

MILES X 1000 MONTHS

NO. DESCRIPTION1 2 34 5 67 8 9

10 11 1213 14 1516 17 1819 20 21I I I I II I I I I

R

III I II I I

10 12 202430364048 50606072

I

R I I I I

R R I I I I

R

III I II I II

R I I I I

R R I I I I

R

III I II I I I I I I II I I I I

R

III I II I I I

R II

R I

R R I I I I

R

III I II I I

Page 272 of 310

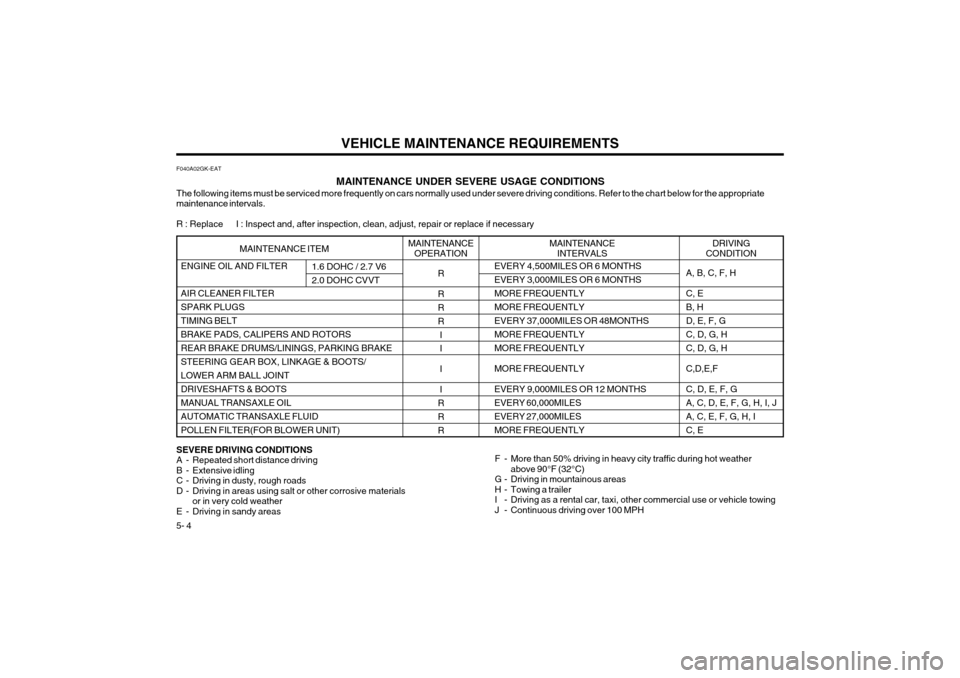

VEHICLE MAINTENANCE REQUIREMENTS

5- 4 MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

F040A02GK-EAT

DRIVING

CONDITION

R R RR

I I II

R RR

MAINTENANCE ITEM MAINTENANCE

OPERATION MAINTENANCE

INTERVALS

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGSTIMING BELTBRAKE PADS, CALIPERS AND ROTORSREAR BRAKE DRUMS/LININGS, PARKING BRAKESTEERING GEAR BOX, LINKAGE & BOOTS/LOWER ARM BALL JOINTDRIVESHAFTS & BOOTSMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(FOR BLOWER UNIT) EVERY 4,500MILES OR 6 MONTHSEVERY 3,000MILES OR 6 MONTHSMORE FREQUENTLYMORE FREQUENTLYEVERY 37,000MILES OR 48MONTHSMORE FREQUENTLYMORE FREQUENTLY MORE FREQUENTLYEVERY 9,000MILES OR 12 MONTHS EVERY 60,000MILESEVERY 27,000MILESMORE FREQUENTLY

A, B, C, F, H C, E B, HD, E, F, GC, D, G, HC, D, G, H C,D,E,FC, D, E, F, G A, C, D, E, F, G, H, I, JA, C, E, F, G, H, IC, E

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas F - More than 50% driving in heavy city traffic during hot weather

above 90°F (32°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving as a rental car, taxi, other commercial use or vehicle towing

J - Continuous driving over 100 MPH

1.6 DOHC / 2.7 V6 2.0 DOHC CVVT

Page 274 of 310

VEHICLE MAINTENANCE REQUIREMENTS

5- 6

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to the maintenance schedule. NOTE: If the oil level is low, check for possible leaksbefore adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/

parking brake

Check the rear brake drums and linings for scoring, burning, leaking fluid, broken parts, andexcessive wear. Inspect the parking brake sys-tem including the parking brake lever and cables.For detailed service procedures, refer to theShop Manual. 6ZF070J1-A

o Brake pads, calipers and rotorsCheck the pads for excessive wear, discs for run out and wear, and calipers for fluid leakage. 6ZF070K1-A

o Exhaust pipe and mufflerVisually inspect the exhaust pipes, muffler and hangers for cracks, deterioration, or damage.Start the engine and listen carefully for anyexhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070L1-A

o Suspension mounting bolts Check the suspension connections for loose- ness or damage. Retighten to the specified torque.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range of the dipstick, after engine and transaxle are at normaloperating temperature. Check the AutomaticTransaxle Fluid level with the engine running andthe transaxle in neutral, with the parking brakeproperly applied. Use DIAMOND ATF SP- III,

SK ATF SP- III when adding or changing fluid. 6ZF070M1-A

o Steering gear box, linkage & boots/

lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel.Check the linkage for bends or damage. Checkthe dust boots and ball joints for deterioration,cracks, or damage. Replace any damaged parts. 6ZF070N1-A

o Power steering pump, belt and hos-

es

Check the power steering pump and hoses for leakage and damage. Replace any damaged orleaking parts immediately. Inspect the powersteering belt for evidence of cuts, cracks, exces-sive wear, oiliness and proper tension. Replaceor adjust it if necessary.

6ZF070F1-A o Brake hoses and linesVisually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately. 6ZF070G2-A

o Brake fluidCheck brake fluid level in the brake fluid reser- voir. The level should be between "MIN" and"MAX" marks on the side of the reservoir. Useonly hydraulic brake fluid conforming to DOT 3 orDOT 4.

6ZF070B1-A

o Cooling systemCheck the cooling system part, such as radiator, coolant reservoir, hoses and connections forleakage and damage. Replace any damagedparts. 6ZF070C1-A

o Coolant The coolant should be changed at the intervals specified in the maintenance schedule.

Page 276 of 310

OWNER MAINTENANCE 6-1

CAUTION: When inspecting or servicing the engine, youshould handle tools and other heavy objectscarefully so that the plastic rocker cover ofthe engine is not damaged.

SG000A1-E

6. OWNER MAINTENANCE

6

G010A01GK-EAT ENGINE COMPARTMENT (1.6 DOHC)

1. Clutch fluid reservoir (Not all models)

2. Engine oil filler cap

3. Brake Booster

4. Brake fluid reservoir

5. Relay box

6. Windscreen washer fluid reservoir cap

7. Power steering fluid reservoir

8. Engine coolant reservoir

9. Engine oil level dipstick

10. Radiator cap11. Automatic transaxle fluid level dipstick

(Not all models)

12. Air cleaner

13. Battery HGK238-D

1

2

345

6 7 8 9 10 11 12 13

Page 277 of 310

OWNER MAINTENANCE

6-2

G010A01GK-EAT ENGINE COMPARTMENT (2.0 DOHC CVVT) HGK059-D

CAUTION: When inspecting or servicing the engine, youshould handle tools and other heavy objectscarefully so that the plastic rocker cover ofthe engine is not damaged.

1. Clutch fluid reservoir (Not all models)

2. Engine oil filler cap

3. Brake Booster

4. Brake fluid reservoir

5. Relay box 6. Windscreen washer fluid reservoir cap

7. Power steering fluid reservoir

8. Engine coolant reservoir

9. Engine oil level dipstick

10. Radiator cap11. Automatic transaxle fluid level dipstick

(Not all models)

12. Air cleaner

13. Battery

1 23

45

6 7 8 9 10 11 12 13

Page 278 of 310

OWNER MAINTENANCE 6-3

G010B01GK-EAT ENGINE COMPARTMENT (2.7 V6) HGK209-D

1. Power steering fluid reservoir

2. Clutch fluid reservoir (Not all models)

3. Brake Booster

4. Brake fluid reservoir

5. Air filter element 6. Relay box

7. Windscreen washer fluid reservoir cap

8. Engine coolant reservoir

9. Engine oil level dipstick

10. Radiator cap11. Engine oil filler cap

12. Automatic transaxle fluid level dipstick

(Not all medels)

13. Battery

1 23 45

7 8 9 10 11 126

13CAUTION: When inspecting or servicing the engine, youshould handle tools and other heavy objectscarefully so that the plastic rocker cover ofthe engine is not damaged.

Page 279 of 310

OWNER MAINTENANCE

6-4

SG020B1-E DAILY OPERATING CHECKSThe following items should be checked on a daily basis or whenever the vehicle is refuelled, which-ever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all lighting equip-

ment.

o Windscreen wiper and washer operation.

o Horn operation.

o Warning lamp operation.

o Adjustment and cleanliness of mirrors.

o Seat and seat belt adjustment and operation.

o Fluid leakage. The vehicle must not be driven if the daily oper- ating checks indicate that any item of equipmentrelated to the safety or roadworthiness of thevehicle is not functioning correctly. SG030A1-E ENGINE OILThe correct engine oil level is of paramount importance. An excessively high or low oil levelmay result in irreparable damage being sus-tained by the engine. The engine oil level must bechecked on a daily basis or whenever the vehicleis refuelled, whichever occurs sooner.In addition, it is imperative that only an approvedgrade and specification of oil is used to avoid thepossibility of serious engine damage and prema-ture wear. The use of "budget price" oil is a falseeconomy that must be avoided if the maximumreliability and useful life is to be obtained from thevehicle.

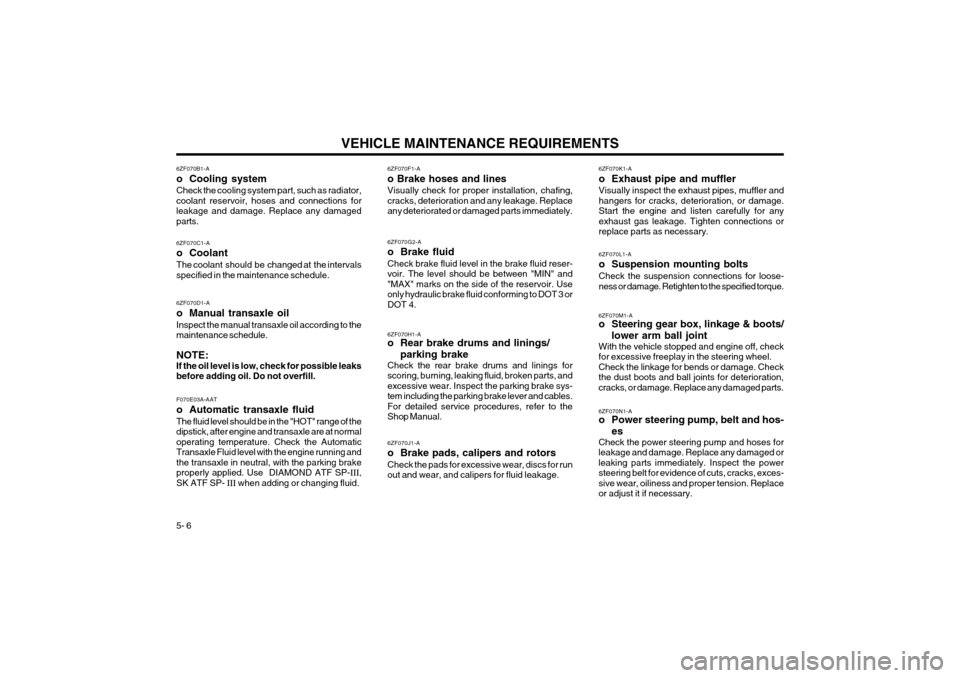

SG030B02GK-E Recommended Oil A multi grade oil having a specification which meets A.P.I. specification of SH, SG or above isrecommended. The oil viscosity should be se-lected according to the operating environment ofthe engine by means of the table shown below.The engine oil recommendations are complete inthemselves and the use of additives is neitherrequired nor recommended. The use of engineoil additives may result in invalidation of thevehicle warranty.

SSA6030B°C °F

-25-13 20W-40 20W-50

15W-40 15W-50

10W-30

10W-40 10W-50

5W-40

5W-30

5W-2040

104

20 68

1050

032

-15 5 -10-14

1.6 DOHC 2.7 L V6

Page 286 of 310

OWNER MAINTENANCE 6-11

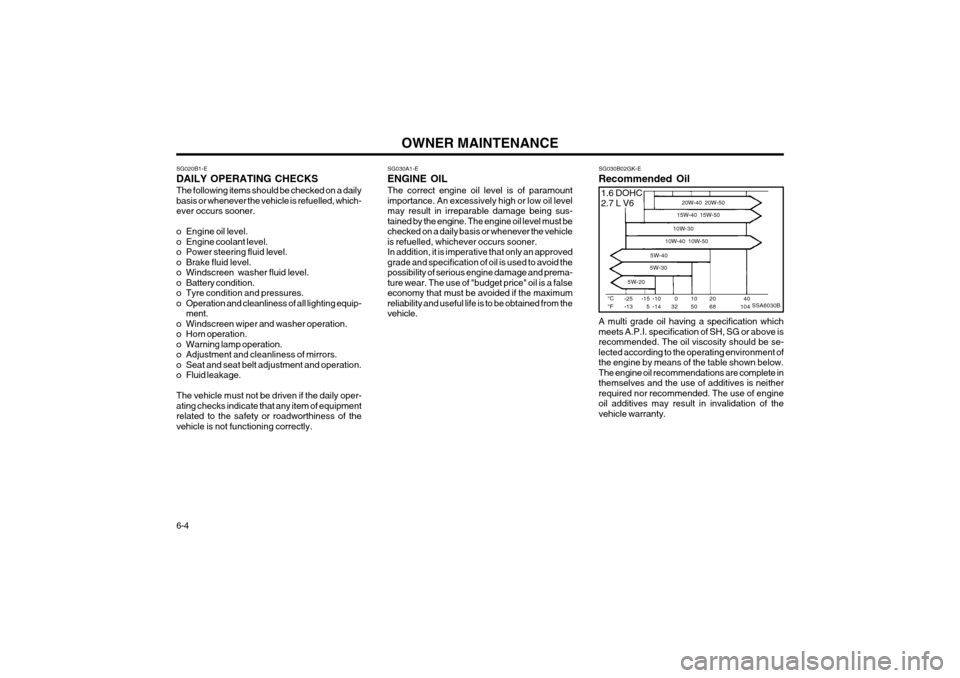

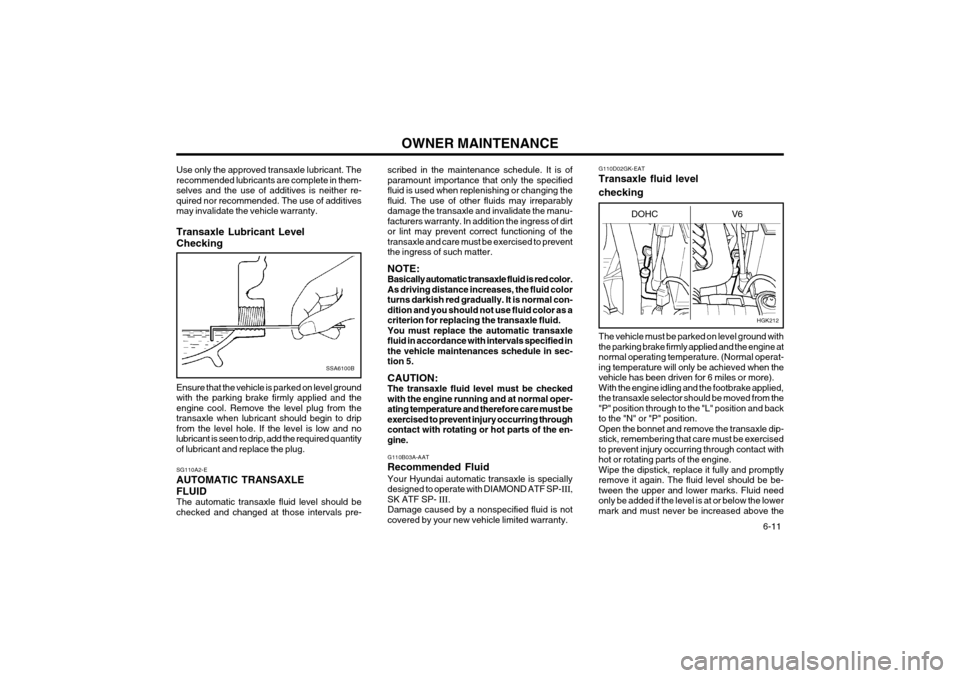

Ensure that the vehicle is parked on level ground with the parking brake firmly applied and theengine cool. Remove the level plug from thetransaxle when lubricant should begin to dripfrom the level hole. If the level is low and nolubricant is seen to drip, add the required quantityof lubricant and replace the plug. scribed in the maintenance schedule. It is ofparamount importance that only the specifiedfluid is used when replenishing or changing thefluid. The use of other fluids may irreparablydamage the transaxle and invalidate the manu-facturers warranty. In addition the ingress of dirtor lint may prevent correct functioning of thetransaxle and care must be exercised to preventthe ingress of such matter. NOTE: Basically automatic transaxle fluid is red color.As driving distance increases, the fluid colorturns darkish red gradually. It is normal con-dition and you should not use fluid color as acriterion for replacing the transaxle fluid.You must replace the automatic transaxlefluid in accordance with intervals specified inthe vehicle maintenances schedule in sec-tion 5. CAUTION: The transaxle fluid level must be checkedwith the engine running and at normal oper-ating temperature and therefore care must beexercised to prevent injury occurring throughcontact with rotating or hot parts of the en-gine. G110B03A-AAT Recommended FluidYour Hyundai automatic transaxle is specially designed to operate with DIAMOND ATF SP-

III,

SK ATF SP- III.

Damage caused by a nonspecified fluid is notcovered by your new vehicle limited warranty. G110D02GK-EAT Transaxle fluid level checking The vehicle must be parked on level ground with the parking brake firmly applied and the engine atnormal operating temperature. (Normal operat-ing temperature will only be achieved when thevehicle has been driven for 6 miles or more).With the engine idling and the footbrake applied,the transaxle selector should be moved from the"P" position through to the "L" position and backto the "N" or "P" position.Open the bonnet and remove the transaxle dip-stick, remembering that care must be exercisedto prevent injury occurring through contact withhot or rotating parts of the engine.Wipe the dipstick, replace it fully and promptlyremove it again. The fluid level should be be-tween the upper and lower marks. Fluid needonly be added if the level is at or below the lowermark and must never be increased above the

DOHC V6

HGK212

Use only the approved transaxle lubricant. The recommended lubricants are complete in them-selves and the use of additives is neither re-quired nor recommended. The use of additivesmay invalidate the vehicle warranty. Transaxle Lubricant Level Checking SG110A2-E AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should bechecked and changed at those intervals pre-

SSA6100B