maintenance schedule Hyundai Elantra 2009 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2009, Model line: Elantra, Model: Hyundai Elantra 2009Pages: 345, PDF Size: 19.91 MB

Page 271 of 345

No.1

2

3

4

5

6

7

8

9

10

79

Maintenance

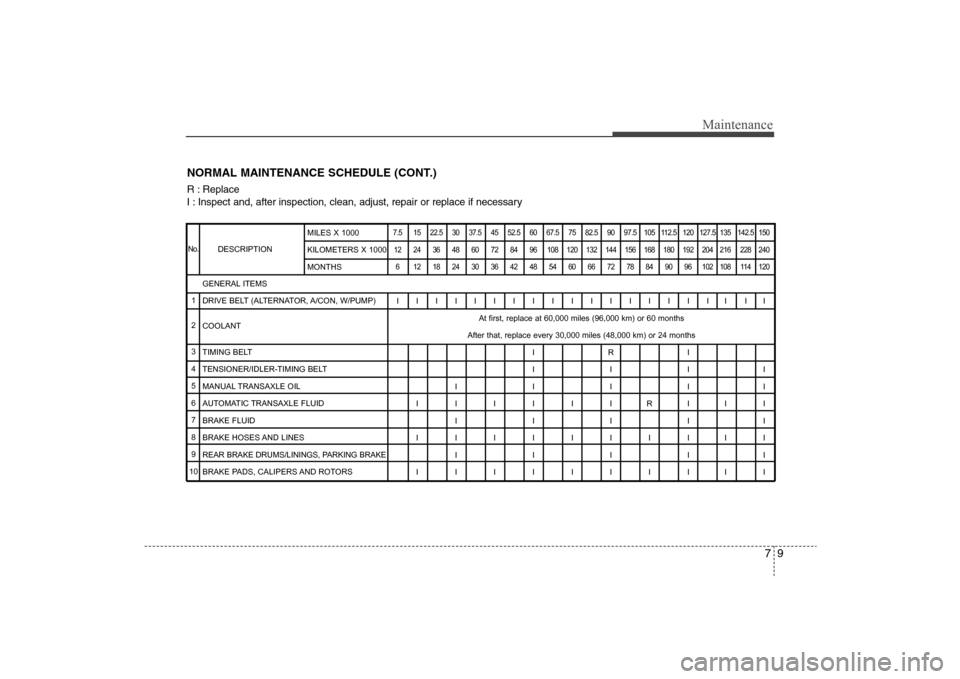

NORMAL MAINTENANCE SCHEDULE (CONT.)

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120IIIIIIIIIIIIIIIIII II

At first, replace at 60,000 miles (96,000 km) or 60 months

After that, replace every 30,000 miles (48,000 km) or 24 months

IRI

IIII

IIIII

IIIIIIRIII

IIIII

IIIIIIIIII

IIIII

IIIIIIIIII GENERAL ITEMS

DRIVE BELT (ALTERNATOR, A/CON, W/PUMP)

COOLANT

TIMING BELT

TENSIONER/IDLER-TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORSMILES X 1000

KILOMETERS X 1000

MONTHS

R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 272 of 345

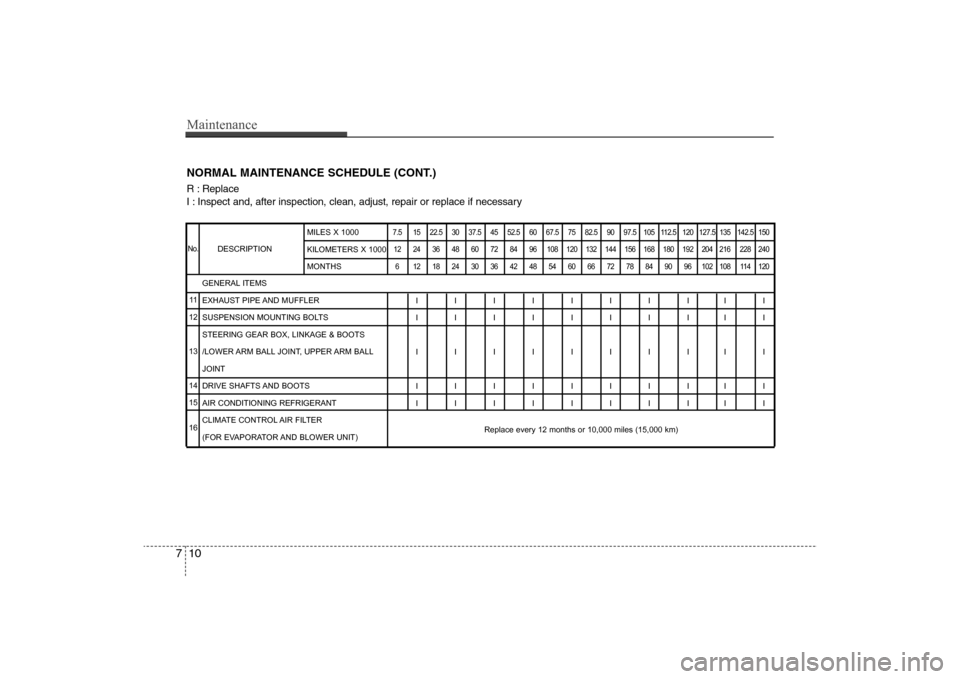

Maintenance10 7NORMAL MAINTENANCE SCHEDULE (CONT.)R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

Replace every 12 months or 10,000 miles (15,000 km) GENERAL ITEMS

EXHAUST PIPE AND MUFFLER

SUSPENSION MOUNTING BOLTS

STEERING GEAR BOX, LINKAGE & BOOTS

/LOWER ARM BALL JOINT, UPPER ARM BALL

JOINT

DRIVE SHAFTS AND BOOTS

AIR CONDITIONING REFRIGERANT

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)MILES X 1000

KILOMETERS X 1000

MONTHS

No.11

12

13

14

15

16

Page 274 of 345

Maintenance12 7EXPLANATION OF SCHEDULED MAINTENANCE ITEMSEngine oil and filterThe engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.Drive beltsInspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filterA clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by trained technicians.

Fuel lines, fuel hoses and con-

nectionsCheck the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

a trained technician replace any dam-

aged or leaking parts immediately.

Page 275 of 345

713

Maintenance

Timing beltInspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.Vapor hose and fuel filler capThe vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hosesInspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filterA Genuine Hyundai air cleaner filter is

recommended when the filter is

replaced.Spark plugsMake sure to install new spark plugs of

the correct heat range.Valve clearanceInspect excessive valve noise and/or

engine vibration and adjust if necessary.

A qualified technician should perform the

operation.Cooling systemCheck the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 276 of 345

Maintenance14 7Manual transaxle fluid

(if equipped)Inspect the manual transaxle fluid

according to the maintenance schedule.✽ ✽

NOTICEIf the oil level is low, check for possible

leaks before adding oil. Do not overfill.Automatic transaxle fluid

(if equipped)The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.Brake hoses and linesVisually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake fluidCheck brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4

specification.Rear disc brake / linings, parking

brakeCheck the rear disc brake and linings for

scoring, burning, leaking fluid, broken

parts, and excessive wear. Inspect the

parking brake system including the park-

ing brake lever and cables.Brake pads, calipers and rotorsCheck the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.Exhaust pipe and mufflerVisually inspect the exhaust pipes, muf-

fler and hangers for cracks, deterioration,

or damage. Start the engine and listen

carefully for any exhaust gas leakage.

Tighten connections or replace parts as

necessary.

Suspension mounting boltsCheck the suspension connections for

looseness or damage. Retighten to the

specified torque.Steering gear box, linkage &

boots/lower arm ball jointWith the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.Drive shafts and bootsCheck the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.Air conditioning refrigerant

(if equipped)Check the air conditioning lines and con-

nections for leakage and damage.

Page 277 of 345

715

Maintenance

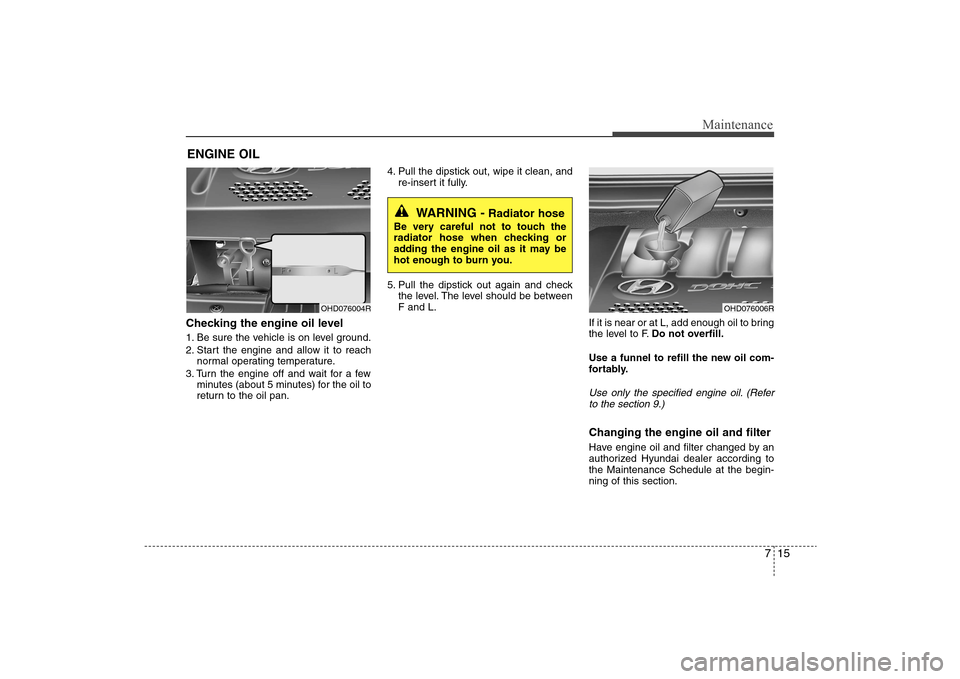

ENGINE OILChecking the engine oil level 1. Be sure the vehicle is on level ground.

2. Start the engine and allow it to reach

normal operating temperature.

3. Turn the engine off and wait for a few

minutes (about 5 minutes) for the oil to

return to the oil pan.4. Pull the dipstick out, wipe it clean, and

re-insert it fully.

5. Pull the dipstick out again and check

the level. The level should be between

F and L.

If it is near or at L, add enough oil to bring

the level to F.Do not overfill.

Use a funnel to refill the new oil com-

fortably.

Use only the specified engine oil. (Refer

to the section 9.)Changing the engine oil and filterHave engine oil and filter changed by an

authorized Hyundai dealer according to

the Maintenance Schedule at the begin-

ning of this section.

WARNING -

Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may be

hot enough to burn you.

OHD076004R

OHD076006R

Page 280 of 345

Maintenance18 7Changing the coolantHave coolant changed by an authorized

Hyundai dealer according to the

Maintenance Schedule at the beginning

of this section.

WARNING -

Radiator cap

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot coolant and

steam may blow out under pres-

sure causing serious injury.

OHD076009

WARNING -

Coolant

Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

Radiator coolant can severely

obscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

Windshield Washer fluid agents

contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allow

sparks or flame to contact the

washer fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

Windshield washer fluid is poi-

sonous to humans and animals.

Do not drink and avoid contact-

ing windshield washer fluid.

Serious injury or death could

occur.

Page 283 of 345

721

Maintenance

✽ ✽

NOTICE“COLD” range is for reference only and

should NOT be used to determine

transaxle fluid level.

✽ ✽

NOTICENew automatic transaxle fluid should be

red. The red dye is added so the assem-

bly plant can identify it as automatic

transaxle fluid and distinguish it from

engine oil or antifreeze. The red dye,

which is not an indicator of fluid quali-

ty, is not permanent. As the vehicle is

driven, the automatic transaxle fluid

will begin to look darker. The color may

eventually appear light brown.

Therefore, have an authorized Hyundai

dealer change the automatic transaxle

fluid according to the Scheduled

Maintenance at the beginning of this

section.Use only the specified automatic

transaxle fluid. (Refer to the section 9.)Changing the automatic transaxle

fluidHave automatic transaxle fluid changed

by an authorized Hyundai dealer accord-

ing to the Maintenance Schedule at the

beginning of this section.

WARNING -

Transaxle fluid

The transaxle fluid level should be

checked when the engine is at nor-

mal operating temperature. This

means that the engine, radiator,

radiator hose and exhaust system

etc., are very hot. Exercise great

care not to burn yourself during

this procedure.

WARNING

- Parking brake

To avoid sudden movement of the

vehicle, apply parking brake and

depress the brake pedal before

moving the shift lever.

CAUTION

Low fluid level causes transaxle

slippage. Overfilling can cause

foaming, loss of fluid and transaxle

malfunction.

The use of a non-specified fluid

could result in transaxle malfunc-

tion and failure.

Page 286 of 345

Maintenance24 7Replace the filter according to the

Scheduled Maintenance Section.If the vehicle is operated in extremely

dusty or sandy areas, replace the ele-

ment more often than the usual recom-

mended intervals. (Refer to

“Maintenance under severe usage condi-

tions” in this section.)

CAUTION

Do not drive with the air cleaner

removed; this will result in exces-

sive engine wear.

When removing the air cleaner fil-

ter, be careful that dust or dirt

does not enter the air intake, or

damage may result.

Use a Hyundai genuine part. Use

of nongenuine parts could dam-

age the air flow sensor.

Page 327 of 345

765

Maintenance

EMISSION CONTROL SYSTEMThe emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Owner’s

Handbook & Warranty Information book-

let in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all emission

regulations.

There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized Hyundai dealer in accordance with

the maintenance schedule in this manu-

al.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com-

pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control

systemThe positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control

(including ORVR: Onboard

Refueling Vapor Recovery)

SystemThe Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be

loaded into a canister while refueling at

the gas station, preventing the escape of

fuel vapors into the atmosphere.)CanisterFuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.