cooling HYUNDAI ELANTRA SPORT 2019 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: ELANTRA SPORT, Model: HYUNDAI ELANTRA SPORT 2019Pages: 534, PDF Size: 51.51 MB

Page 434 of 534

7-9

7

Maintenance

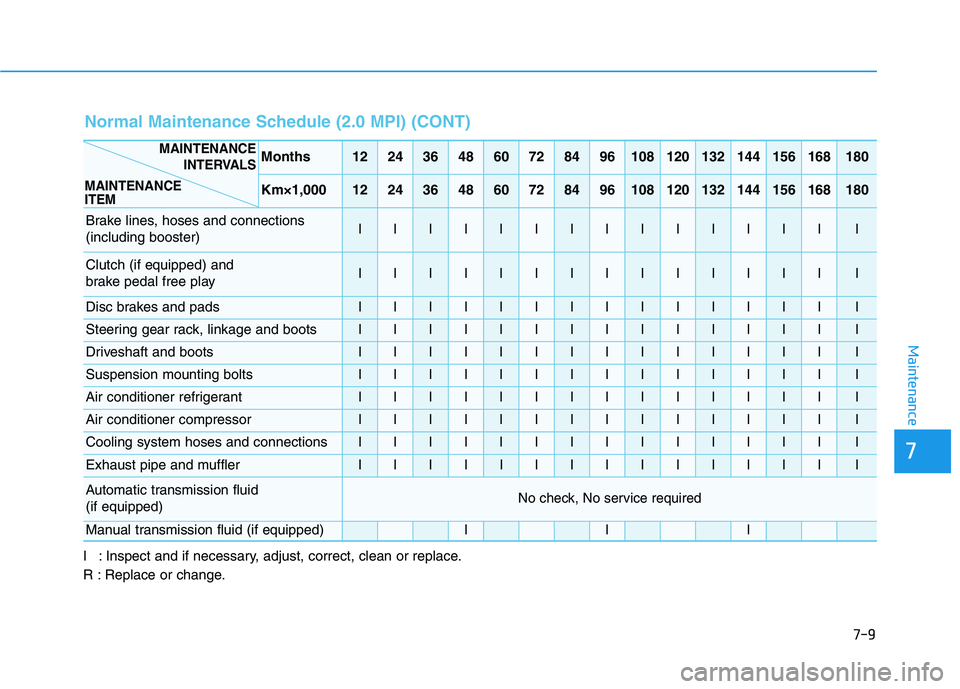

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

Normal Maintenance Schedule (2.0 MPI) (CONT)

Months1224364860728496108120132144156168180

Km×1,0001224364860728496108120132144156168180

Brake lines, hoses and connections (including booster)IIIIIIIIIIIIIII

Clutch (if equipped) and

brake pedal free playIIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Cooling system hoses and connections IIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

Automatic transmission fluid (if equipped)No check, No service required

Manual transmission fluid (if equipped)III

MAINTENANCEINTERVALS

MAINTENANCE ITEM

Page 439 of 534

7-14

Maintenance

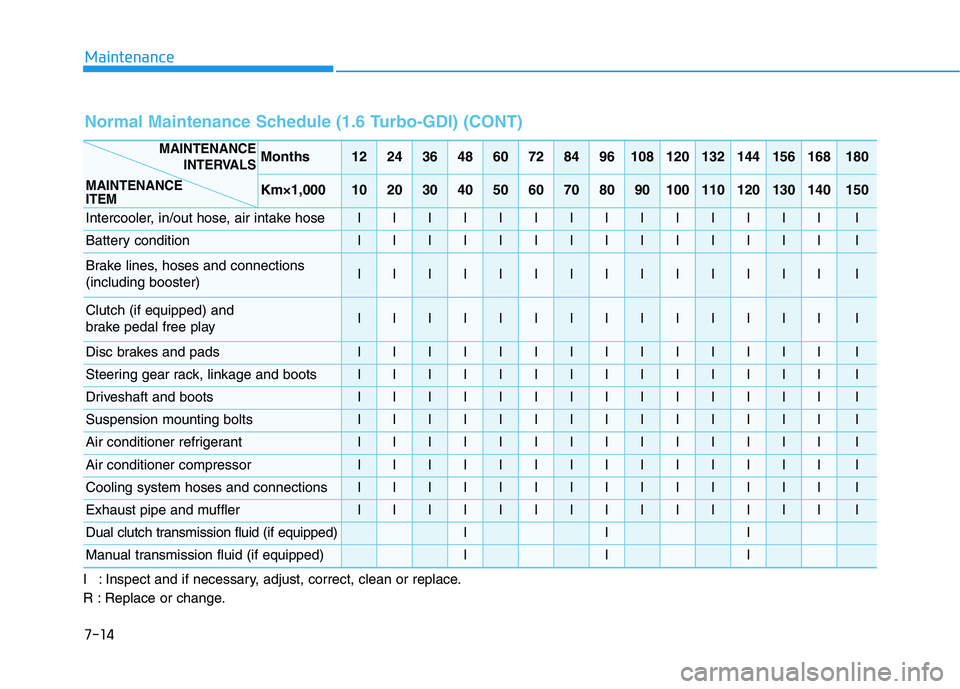

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

Normal Maintenance Schedule (1.6 Turbo-GDI) (CONT)

Months1224364860728496108120132144156168180

Km×1,000102030405060708090100110120130140150

Intercooler, in/out hose, air intake hoseIIIIIIIIIIIIIII

Battery conditionIIIIIIIIIIIIIII

Brake lines, hoses and connections (including booster)IIIIIIIIIIIIIII

Clutch (if equipped) and

brake pedal free playIIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Cooling system hoses and connections IIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

Dual clutch transmission fluid (if equipped)III

Manual transmission fluid (if equipped)III

MAINTENANCEINTERVALS

MAINTENANCE ITEM

Page 444 of 534

Air Cleaner Filter

A genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

Cooling System

Check cooling system components,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Engine Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Automatic Transmission Fluid (if equipped)

Automatic transmission fluid should

not be checked under normal usage

conditions. But in severe conditions,the fluid should be changed at an

authorized HYUNDAI dealer inaccordance to the scheduled mainte-nance at the beginning of this chap-

ter.

Automatic transmission fluid

color is basically red.

As the vehicle is driven, the auto- matic transmission fluid will begin

to look darker. This is a normal

condition and you should not

judge the need to replace the fluid

based upon the changed color.

NOTICE

7-19

7

Maintenance

The use of a non-specified fluid could result in transmission

malfunction and failure. Use

only the specified automatic

transmission fluid (refer to"Recommended Lubricants and

Capacities" in chapter 8).

CAUTION

Page 448 of 534

7-23

7

Maintenance

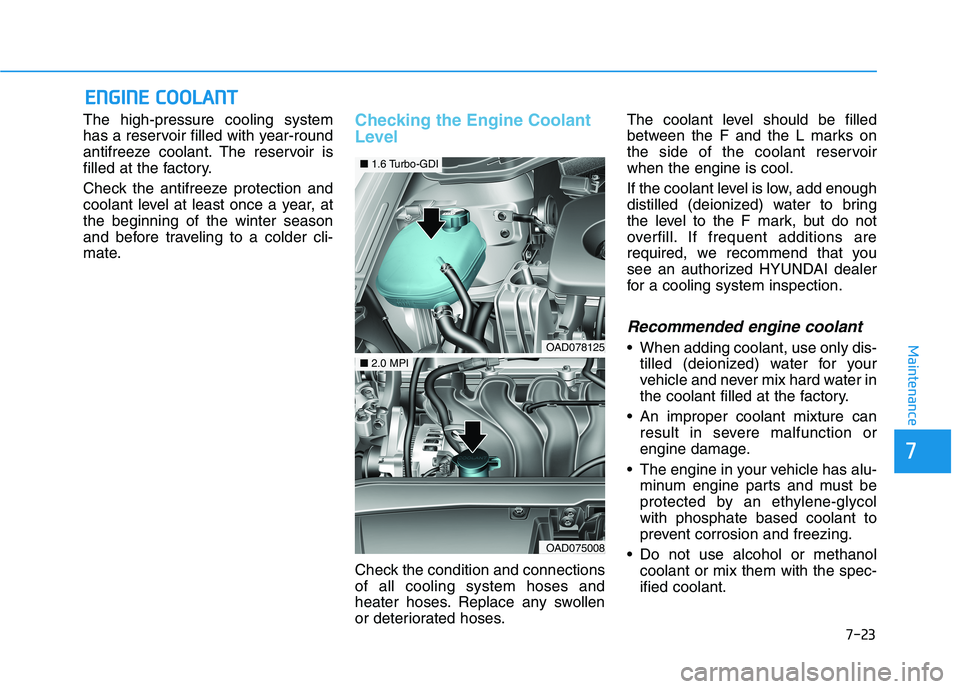

EENN GGIINN EE CC OO OOLLAA NN TT

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, atthe beginning of the winter season

and before traveling to a colder cli-

mate.Checking the Engine Coolant

Level

Check the condition and connections of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses. The coolant level should be filled

between the F and the L marks on

the side of the coolant reservoirwhen the engine is cool.

If the coolant level is low, add enough

distilled (deionized) water to bring

the level to the F mark, but do not

overfill. If frequent additions are

required, we recommend that you

see an authorized HYUNDAI dealer

for a cooling system inspection.

Recommended engine coolant

When adding coolant, use only dis-

tilled (deionized) water for your

vehicle and never mix hard water in

the coolant filled at the factory.

An improper coolant mixture can result in severe malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycolwith phosphate based coolant to

prevent corrosion and freezing.

Do not use alcohol or methanol coolant or mix them with the spec-ified coolant.OAD078125

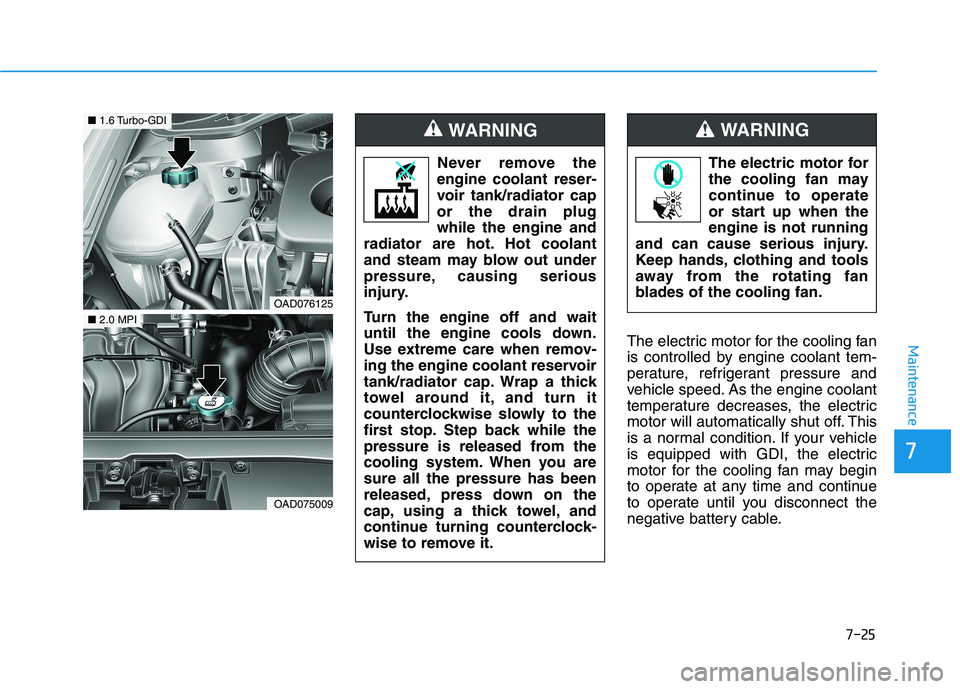

■1.6 Turbo-GDI

OAD075008

■2.0 MPI

Page 450 of 534

The electric motor for the cooling fan

is controlled by engine coolant tem-

perature, refrigerant pressure and

vehicle speed. As the engine coolant

temperature decreases, the electric

motor will automatically shut off. This

is a normal condition. If your vehicle

is equipped with GDI, the electric

motor for the cooling fan may begin

to operate at any time and continue

to operate until you disconnect the

negative battery cable.7-25

7

Maintenance

The electric motor for

the cooling fan may

continue to operate

or start up when theengine is not running

and can cause serious injury.

Keep hands, clothing and tools

away from the rotating fan

blades of the cooling fan.

WARNING

OAD076125

■ 1.6 Turbo-GDI

OAD075009

■2.0 MPI Never remove the

engine coolant reser-

voir tank/radiator capor the drain plugwhile the engine and

radiator are hot. Hot coolant

and steam may blow out under

pressure, causing serious

injury.

Turn the engine off and wait

until the engine cools down.

Use extreme care when remov-

ing the engine coolant reservoir

tank/radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning counterclock-

wise to remove it.

WARNING

Page 488 of 534

7-63

7

Maintenance

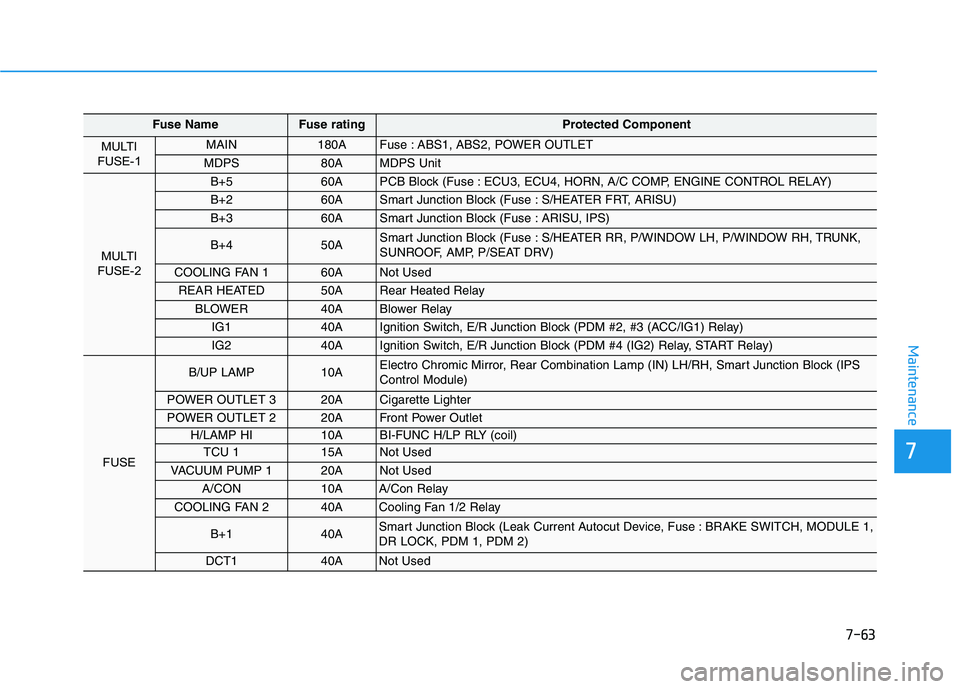

Fuse NameFuse rating Protected Component

MULTI

FUSE-1 MAIN 180A Fuse : ABS1, ABS2, POWER OUTLET

MDPS 80A MDPS Unit

MULTI

FUSE-2

B+5 60A PCB Block (Fuse : ECU3, ECU4, HORN, A/C COMP, ENGINE CONTROL RELAY)

B+2 60A Smart Junction Block (Fuse : S/HEATER FRT, ARISU)

B+3 60A Smart Junction Block (Fuse : ARISU, IPS)

B+4 50A Smart Junction Block (Fuse : S/HEATER RR, P/WINDOW LH, P/WINDOW RH, TRUNK,

SUNROOF, AMP, P/SEAT DRV)

COOLING FAN 1 60A Not Used

REAR HEATED 50A Rear Heated Relay

BLOWER 40A Blower Relay

IG1 40A Ignition Switch, E/R Junction Block (PDM #2, #3 (ACC/IG1) Relay)

IG2 40A Ignition Switch, E/R Junction Block (PDM #4 (IG2) Relay, START Relay)

FUSE

B/UP LAMP 10A Electro Chromic Mirror, Rear Combination Lamp (IN) LH/RH, Smart Junction Block (IPS Control Module)

POWER OUTLET 3 20A Cigarette Lighter

POWER OUTLET 2 20A Front Power Outlet

H/LAMP HI 10A BI-FUNC H/LP RLY (coil)

TCU 1 15A Not Used

VACUUM PUMP 1 20A Not Used

A/CON 10A A/Con Relay

COOLING FAN 2 40A Cooling Fan 1/2 Relay

B+1 40A Smart Junction Block (Leak Current Autocut Device, Fuse : BRAKE SWITCH, MODULE 1, DR LOCK, PDM 1, PDM 2)

DCT1 40A Not Used

Page 489 of 534

7-64

Maintenance

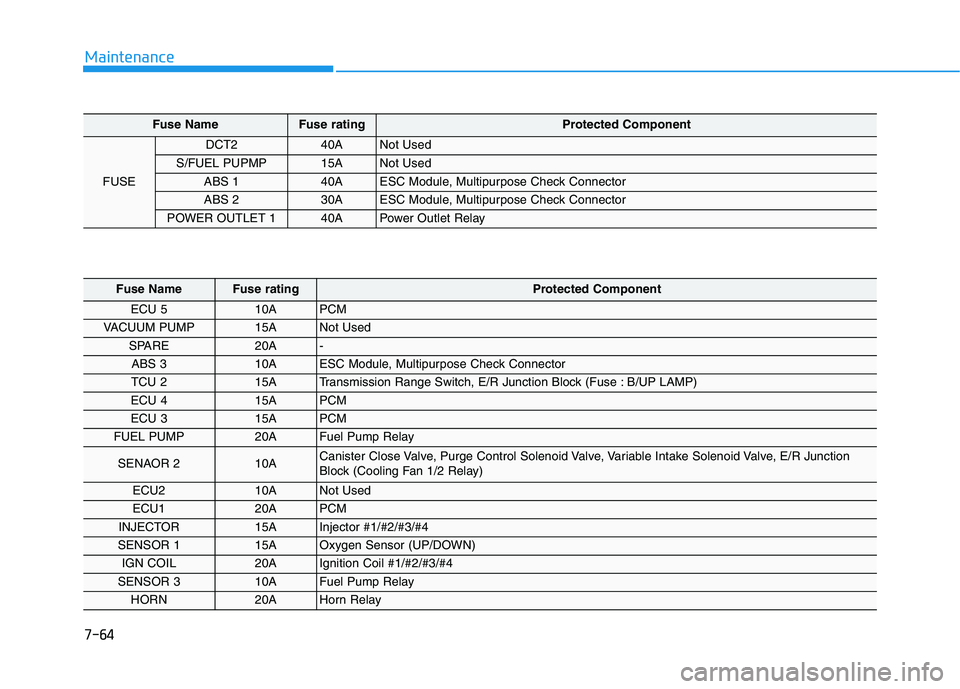

Fuse NameFuse rating Protected Component

FUSE

DCT2 40A Not Used

S/FUEL PUPMP 15A Not Used

ABS 1 40A ESC Module, Multipurpose Check Connector

ABS 2 30A ESC Module, Multipurpose Check Connector

POWER OUTLET 1 40A Power Outlet Relay

Fuse Name Fuse rating Protected Component

ECU 5 10A PCM

VACUUM PUMP 15A Not Used

SPARE 20A -

ABS 3 10A ESC Module, Multipurpose Check Connector

TCU 2 15A Transmission Range Switch, E/R Junction Block (Fuse : B/UP LAMP)

ECU 4 15A PCM

ECU 3 15A PCM

FUEL PUMP 20A Fuel Pump Relay

SENAOR 2 10A Canister Close Valve, Purge Control Solenoid Valve, Variable Intake Solenoid Valve, E/R Junction

Block (Cooling Fan 1/2 Relay)

ECU2 10A Not Used

ECU1 20A PCM

INJECTOR 15A Injector #1/#2/#3/#4

SENSOR 1 15A Oxygen Sensor (UP/DOWN)

IGN COIL 20A Ignition Coil #1/#2/#3/#4

SENSOR 3 10A Fuel Pump Relay

HORN 20A Horn Relay