HYUNDAI ELANTRA SPORT 2019 Owners Manual

Manufacturer: HYUNDAI, Model Year: 2019, Model line: ELANTRA SPORT, Model: HYUNDAI ELANTRA SPORT 2019Pages: 534, PDF Size: 51.51 MB

Page 441 of 534

7-16

Maintenance

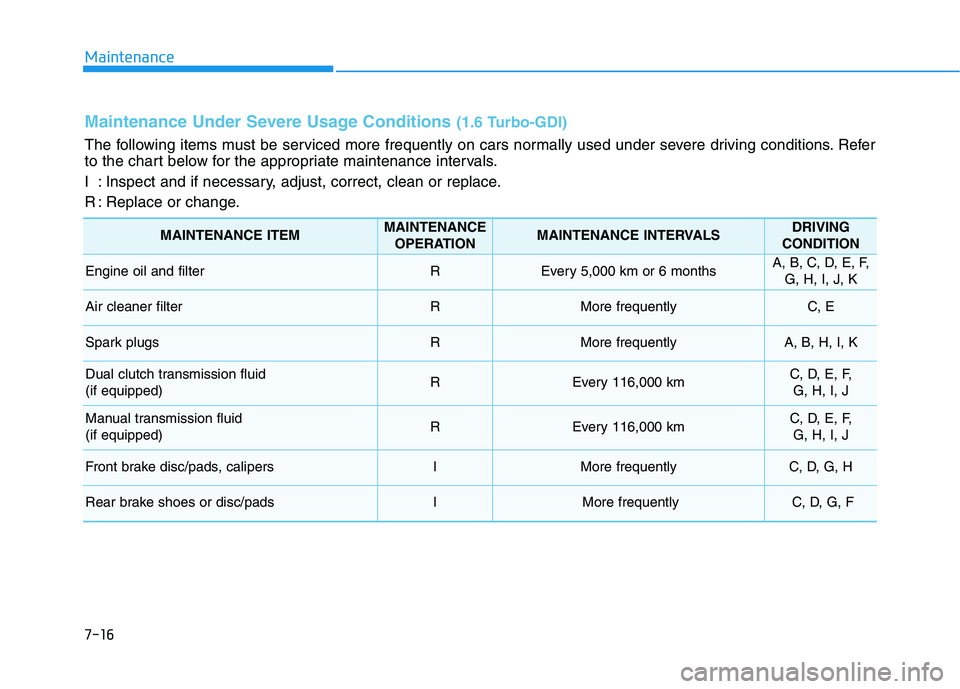

Maintenance Under Severe Usage Conditions (1.6 Turbo-GDI)

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING

CONDITION

Engine oil and filterREvery 5,000 km or 6 monthsA, B, C, D, E, F, G, H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyA, B, H, I, K

Dual clutch transmission fluid (if equipped)REvery 116,000 kmC, D, E, F, G, H, I, J

Manual transmission fluid (if equipped)REvery 116,000 kmC, D, E, F, G, H, I, J

Front brake disc/pads, calipersIMore frequentlyC, D, G, H

Rear brake shoes or disc/padsIMore frequentlyC, D, G, F

Page 442 of 534

7-17

7

Maintenance

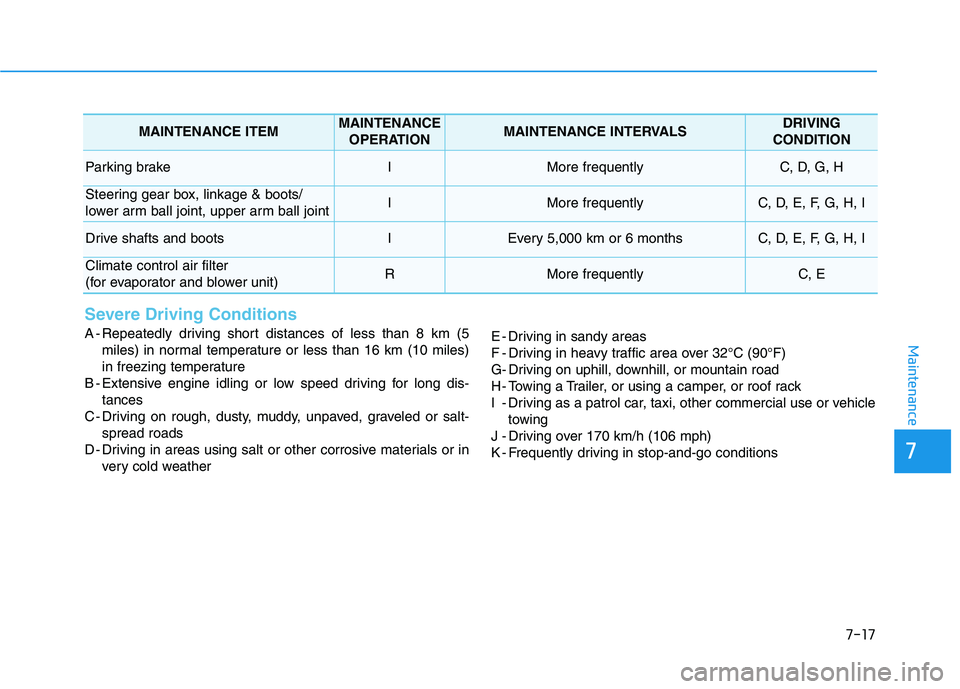

Severe Driving Conditions

A - Repeatedly driving short distances of less than 8 km (5miles) in normal temperature or less than 16 km (10 miles)

in freezing temperature

B - Extensive engine idling or low speed driving for long dis- tances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C (90°F)

G- Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle

towing

J - Driving over 170 km/h (106 mph)

K - Frequently driving in stop-and-go conditions

MAINTENANCE ITEMMAINTENANCE OPERATIONMAINTENANCE INTERVALSDRIVING

CONDITION

Parking brakeIMore frequentlyC, D, G, H

Steering gear box, linkage & boots/

lower arm ball joint, upper arm ball jointIMore frequentlyC, D, E, F, G, H, I

Drive shafts and bootsIEvery 5,000 km or 6 monthsC, D, E, F, G, H, I

Climate control air filter

(for evaporator and blower unit)RMore frequentlyC, E

Page 443 of 534

7-18

MaintenanceE

E XX PPLLAA NN AATTIIOO NN OO FF SS CC HH EEDD UU LLEE DD MM AAIINN TTEENN AANN CCEE IITT EEMM SS

Engine Oil and Filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,more frequent oil and filter changesare required.

Drive Belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel Filter

A clogged-up fuel filter may limit the

vehicle driving speed, damage theemission system, and cause the

hard starting. When a considerable

amount of foreign substances are

accumulated in the fuel tank, the fuelfilter should be replaced. Upon installing a new fuel filter, oper-

ate the engine for several minutes,

and check the connections for any

leakages. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

Fuel Lines, Fuel Hoses and Connections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized HYUNDAI

dealer replace any damaged or leak-

ing parts immediately.

Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure a new vaporhose or fuel filler cap is correctlyreplaced.

Vacuum Crankcase Ventilation Hoses (if equipped)

Inspect the surface of hoses for evi- dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component whichmight cause heat damage or

mechanical wear.

Inspect all hose connections, such

as clamps and couplings, to make

sure they are secure, and that no

leaks are present. Hoses should be

replaced immediately if there is any

evidence of deterioration or damage.

Page 444 of 534

Air Cleaner Filter

A genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

Cooling System

Check cooling system components,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Engine Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Automatic Transmission Fluid (if equipped)

Automatic transmission fluid should

not be checked under normal usage

conditions. But in severe conditions,the fluid should be changed at an

authorized HYUNDAI dealer inaccordance to the scheduled mainte-nance at the beginning of this chap-

ter.

Automatic transmission fluid

color is basically red.

As the vehicle is driven, the auto- matic transmission fluid will begin

to look darker. This is a normal

condition and you should not

judge the need to replace the fluid

based upon the changed color.

NOTICE

7-19

7

Maintenance

The use of a non-specified fluid could result in transmission

malfunction and failure. Use

only the specified automatic

transmission fluid (refer to"Recommended Lubricants and

Capacities" in chapter 8).

CAUTION

Page 445 of 534

7-20

Maintenance

Dual Clutch Transmission Fluid (if equipped)

Inspect the dual clutch transmission fluid according to the maintenance

schedule.

Manual Transmission Fluid (if equipped)

Inspect the manual transmission fluid according to the maintenance

schedule.

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake/Clutch Fluid

Check brake/clutch fluid level in the

brake/clutch fluid reservoir. The level

should be between the MIN and the

MAX marks on the side of the reser-

voir. Use only hydraulic brake/clutch

fluid conforming to DOT 3 or DOT 4specification.

Parking Brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

engine off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 446 of 534

7-21

7

Maintenance

EENN GGIINN EE OO IILL

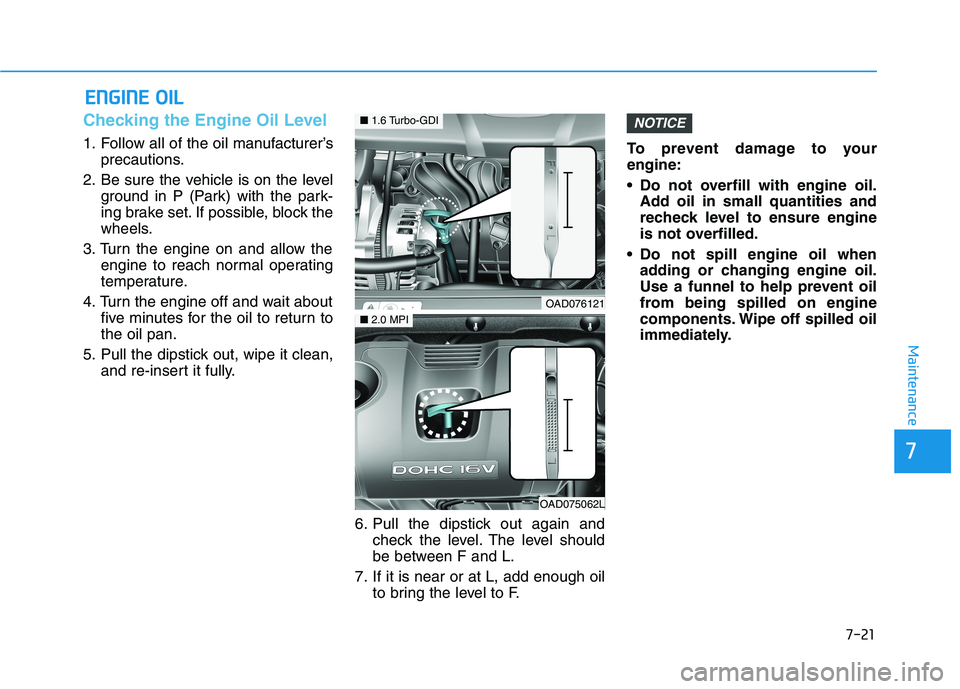

Checking the Engine Oil Level

1. Follow all of the oil manufacturer’s

precautions.

2. Be sure the vehicle is on the level ground in P (Park) with the park-

ing brake set. If possible, block the

wheels.

3. Turn the engine on and allow the engine to reach normal operating

temperature.

4. Turn the engine off and wait about five minutes for the oil to return tothe oil pan.

5. Pull the dipstick out, wipe it clean, and re-insert it fully.

6. Pull the dipstick out again andcheck the level. The level should

be between F and L.

7. If it is near or at L, add enough oil to bring the level to F. To prevent damage to yourengine:

Do not overfill with engine oil.

Add oil in small quantities and

recheck level to ensure engine

is not overfilled.

Do not spill engine oil when adding or changing engine oil.

Use a funnel to help prevent oil

from being spilled on engine

components. Wipe off spilled oil

immediately.

NOTICE

OAD076121

■1.6 Turbo-GDI

OAD075062L

■2.0 MPI

Page 447 of 534

7-22

Maintenance

Use only the specified engine oil

(refer to "RecommendedLubricants and Capacities" in

chapter 8).

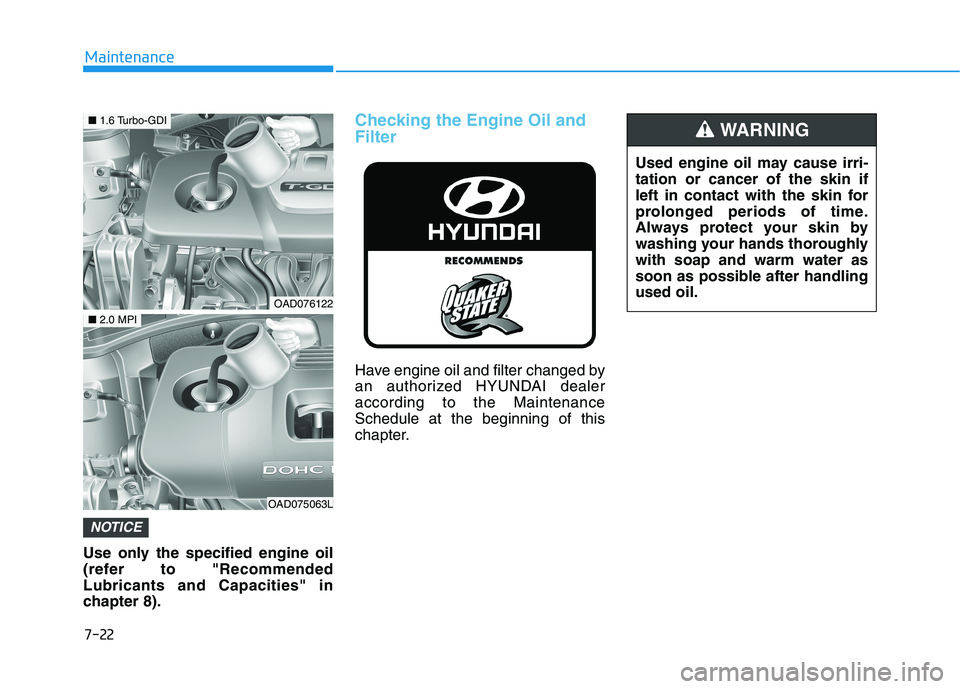

Checking the Engine Oil and Filter

Have engine oil and filter changed by

an authorized HYUNDAI dealeraccording to the MaintenanceSchedule at the beginning of this

chapter.

NOTICE

Used engine oil may cause irri- tation or cancer of the skin if

left in contact with the skin for

prolonged periods of time.

Always protect your skin by

washing your hands thoroughlywith soap and warm water as

soon as possible after handlingused oil.

WARNING

OAD076122

■1.6 Turbo-GDI

OAD075063L

■2.0 MPI

Page 448 of 534

7-23

7

Maintenance

EENN GGIINN EE CC OO OOLLAA NN TT

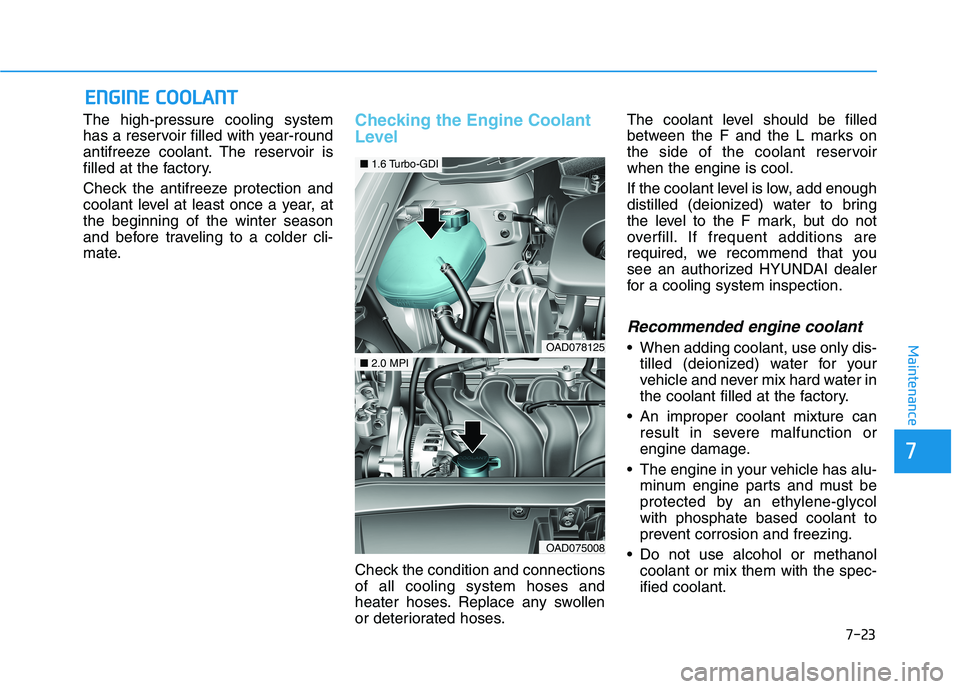

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, atthe beginning of the winter season

and before traveling to a colder cli-

mate.Checking the Engine Coolant

Level

Check the condition and connections of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses. The coolant level should be filled

between the F and the L marks on

the side of the coolant reservoirwhen the engine is cool.

If the coolant level is low, add enough

distilled (deionized) water to bring

the level to the F mark, but do not

overfill. If frequent additions are

required, we recommend that you

see an authorized HYUNDAI dealer

for a cooling system inspection.

Recommended engine coolant

When adding coolant, use only dis-

tilled (deionized) water for your

vehicle and never mix hard water in

the coolant filled at the factory.

An improper coolant mixture can result in severe malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycolwith phosphate based coolant to

prevent corrosion and freezing.

Do not use alcohol or methanol coolant or mix them with the spec-ified coolant.OAD078125

■1.6 Turbo-GDI

OAD075008

■2.0 MPI

Page 449 of 534

7-24

Maintenance

Do not use a solution that containsmore than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of thesolution.

For mixing percentage, refer to the

following table:

Information

If in doubt about the mix ratio, a 50%

water and 50% antifreeze mix is the

easiest to mix together as it will be the

same quantity of each. It is suitable to

use for most temperature ranges of

-35°C (-31°F) and higher.

i

Ambient

Temperature Mixture Percentage

(volume)

Antifreeze Water

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

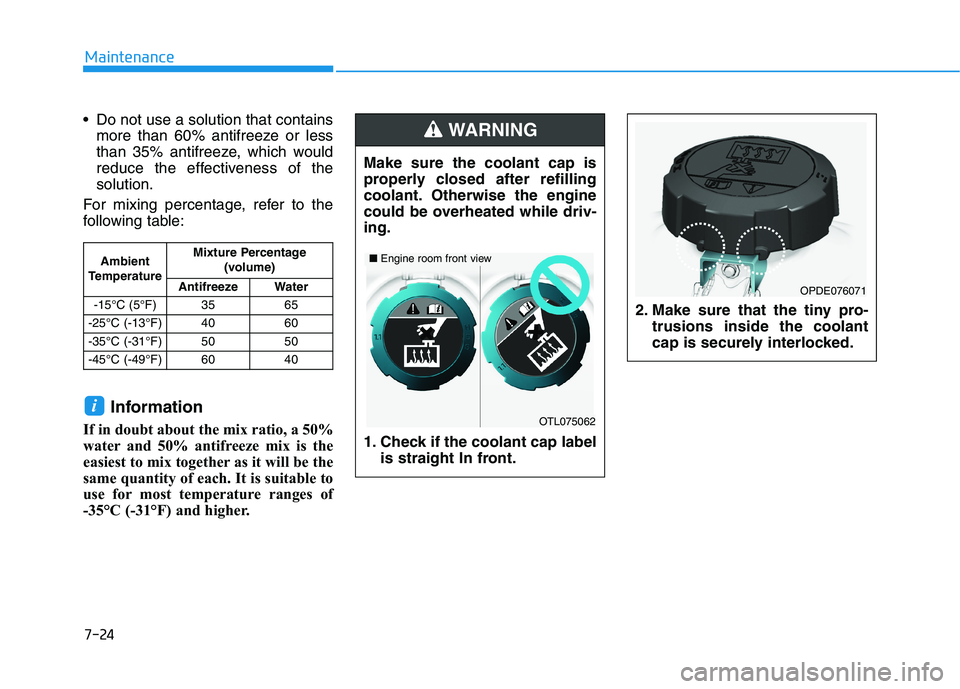

Make sure the coolant cap is

properly closed after refilling

coolant. Otherwise the engine

could be overheated while driv-ing.

1. Check if the coolant cap label is straight In front.

WARNING

OTL075062

■Engine room front view

2. Make sure that the tiny pro-trusions inside the coolant

cap is securely interlocked.

OPDE076071

Page 450 of 534

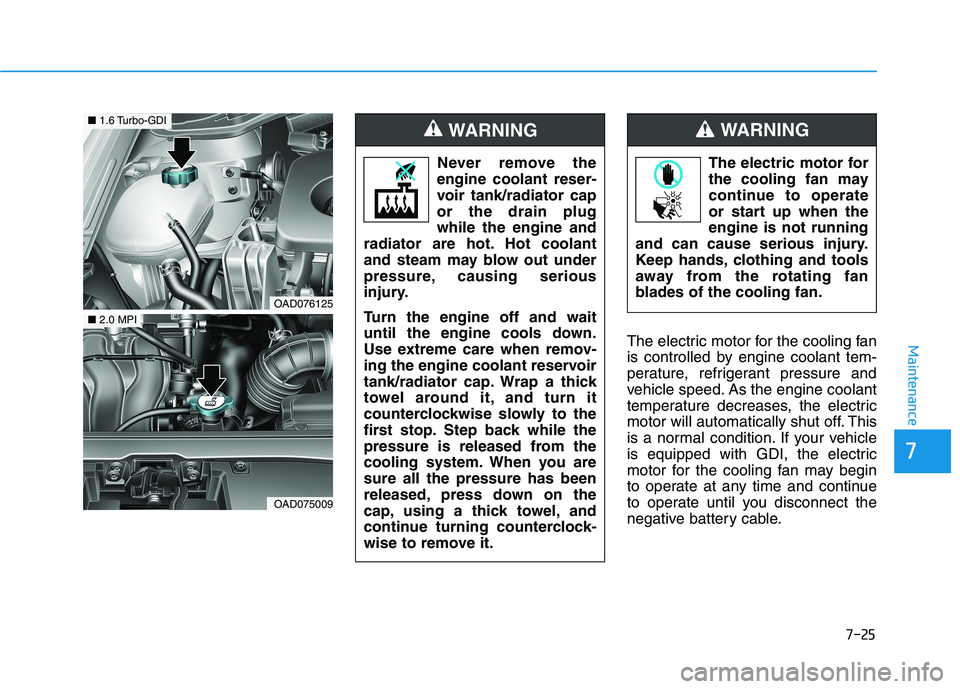

The electric motor for the cooling fan

is controlled by engine coolant tem-

perature, refrigerant pressure and

vehicle speed. As the engine coolant

temperature decreases, the electric

motor will automatically shut off. This

is a normal condition. If your vehicle

is equipped with GDI, the electric

motor for the cooling fan may begin

to operate at any time and continue

to operate until you disconnect the

negative battery cable.7-25

7

Maintenance

The electric motor for

the cooling fan may

continue to operate

or start up when theengine is not running

and can cause serious injury.

Keep hands, clothing and tools

away from the rotating fan

blades of the cooling fan.

WARNING

OAD076125

■ 1.6 Turbo-GDI

OAD075009

■2.0 MPI Never remove the

engine coolant reser-

voir tank/radiator capor the drain plugwhile the engine and

radiator are hot. Hot coolant

and steam may blow out under

pressure, causing serious

injury.

Turn the engine off and wait

until the engine cools down.

Use extreme care when remov-

ing the engine coolant reservoir

tank/radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning counterclock-

wise to remove it.

WARNING