Hyundai Getz 2004 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2004, Model line: Getz, Model: Hyundai Getz 2004Pages: 445, PDF Size: 12.16 MB

Page 371 of 445

3- 8 WHAT TO DO IN AN EMERGENCY

HTB149

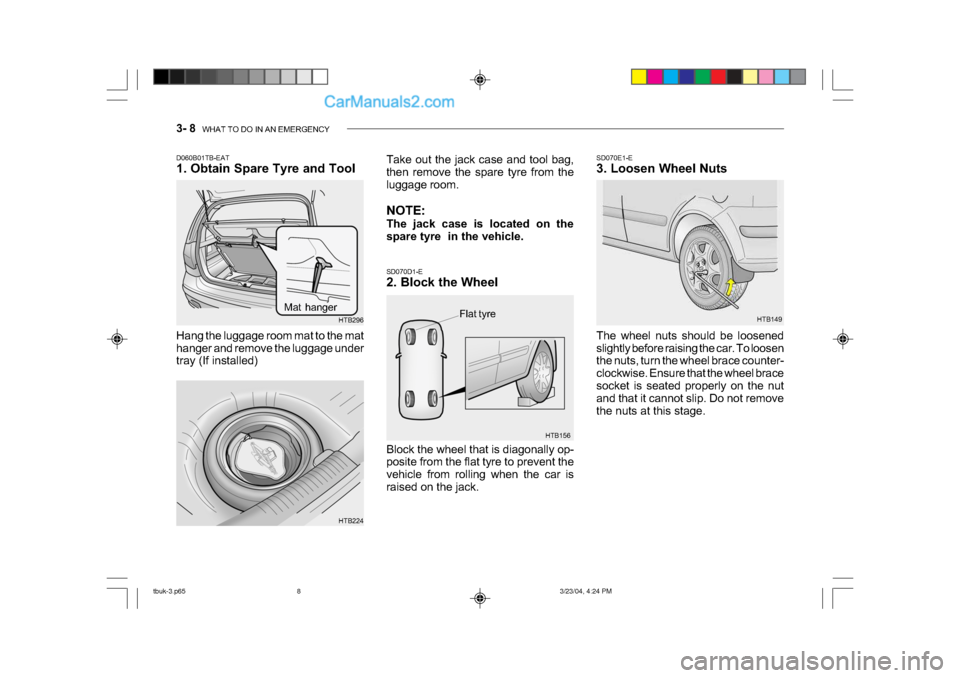

SD070E1-E

3. Loosen Wheel Nuts

The wheel nuts should be loosened

slightly before raising the car. To loosen

the nuts, turn the wheel brace counter-

clockwise. Ensure that the wheel brace

socket is seated properly on the nut

and that it cannot slip. Do not remove

the nuts at this stage.Flat tyre

HTB156

SD070D1-E

2. Block the Wheel

Block the wheel that is diagonally op-

posite from the flat tyre to prevent the

vehicle from rolling when the car is

raised on the jack.

Take out the jack case and tool bag,

then remove the spare tyre from the

luggage room.

NOTE:

The jack case is located on the

spare tyre in the vehicle.

Hang the luggage room mat to the mat

hanger and remove the luggage under

tray (If installed)

D060B01TB-EAT

1. Obtain Spare Tyre and Tool

HTB224

HTB296

Mat hanger

tbuk-3.p65

3/23/04, 4:24 PM

8

Page 372 of 445

WHAT TO DO IN AN EMERGENCY 3- 9

!

SD070H1-E

6. Changing Wheels

HTB157

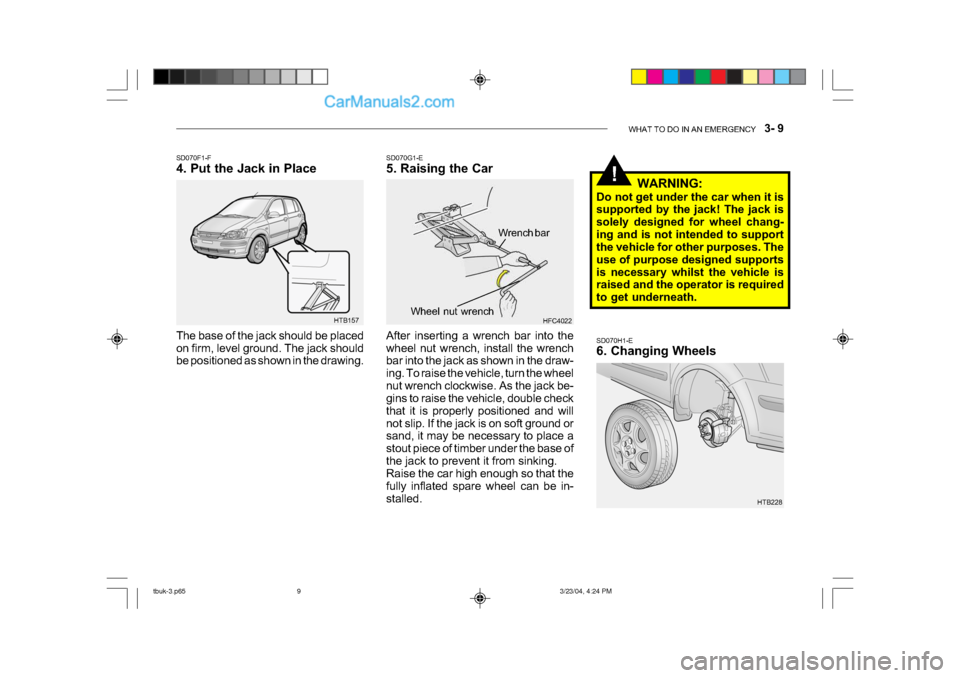

SD070F1-F

4. Put the Jack in Place

The base of the jack should be placed

on firm, level ground. The jack should

be positioned as shown in the drawing.

SD070G1-E

5. Raising the Car

After inserting a wrench bar into the

wheel nut wrench, install the wrench

bar into the jack as shown in the draw-

ing. To raise the vehicle, turn the wheel

nut wrench clockwise. As the jack be-

gins to raise the vehicle, double check

that it is properly positioned and will

not slip. If the jack is on soft ground or

sand, it may be necessary to place a

stout piece of timber under the base of

the jack to prevent it from sinking.

Raise the car high enough so that the

fully inflated spare wheel can be in-

stalled. HFC4022

Wrench bar

Wheel nut wrench

WARNING:

Do not get under the car when it is

supported by the jack! The jack is

solely designed for wheel chang-

ing and is not intended to support

the vehicle for other purposes. The

use of purpose designed supports

is necessary whilst the vehicle is

raised and the operator is required

to get underneath.

HTB228

tbuk-3.p65 3/23/04, 4:24 PM

9

Page 373 of 445

3- 10 WHAT TO DO IN AN EMERGENCY

!

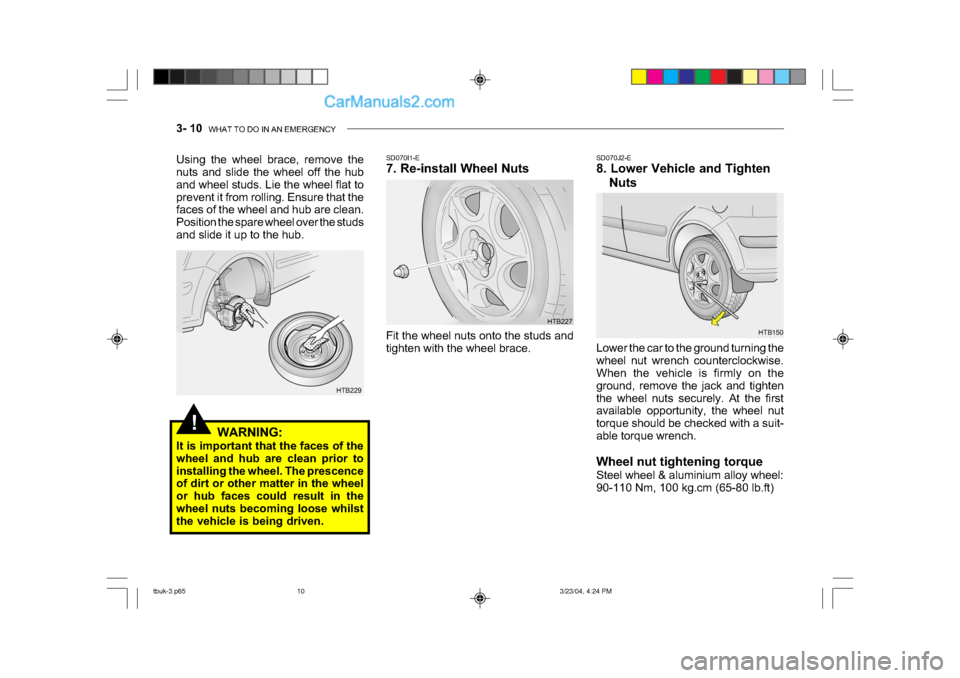

HTB150

SD070J2-E

8. Lower Vehicle and Tighten

Nuts

Lower the car to the ground turning the

wheel nut wrench counterclockwise.

When the vehicle is firmly on the

ground, remove the jack and tighten

the wheel nuts securely. At the first

available opportunity, the wheel nut

torque should be checked with a suit-

able torque wrench.

Wheel nut tightening torque

Steel wheel & aluminium alloy wheel:

90-110 Nm, 100 kg.cm (65-80 lb.ft)

SD070I1-E

7. Re-install Wheel NutsFit the wheel nuts onto the studs and

tighten with the wheel brace.

HTB227

Using the wheel brace, remove the

nuts and slide the wheel off the hub

and wheel studs. Lie the wheel flat to

prevent it from rolling. Ensure that the

faces of the wheel and hub are clean.

Position the spare wheel over the studs

and slide it up to the hub.

HTB229

WARNING:

It is important that the faces of the

wheel and hub are clean prior to

installing the wheel. The prescence

of dirt or other matter in the wheel

or hub faces could result in the

wheel nuts becoming loose whilst

the vehicle is being driven.

tbuk-3.p65 3/23/04, 4:24 PM

10

Page 374 of 445

WHAT TO DO IN AN EMERGENCY 3- 11

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE

WITH NO DAMAGE HTB208

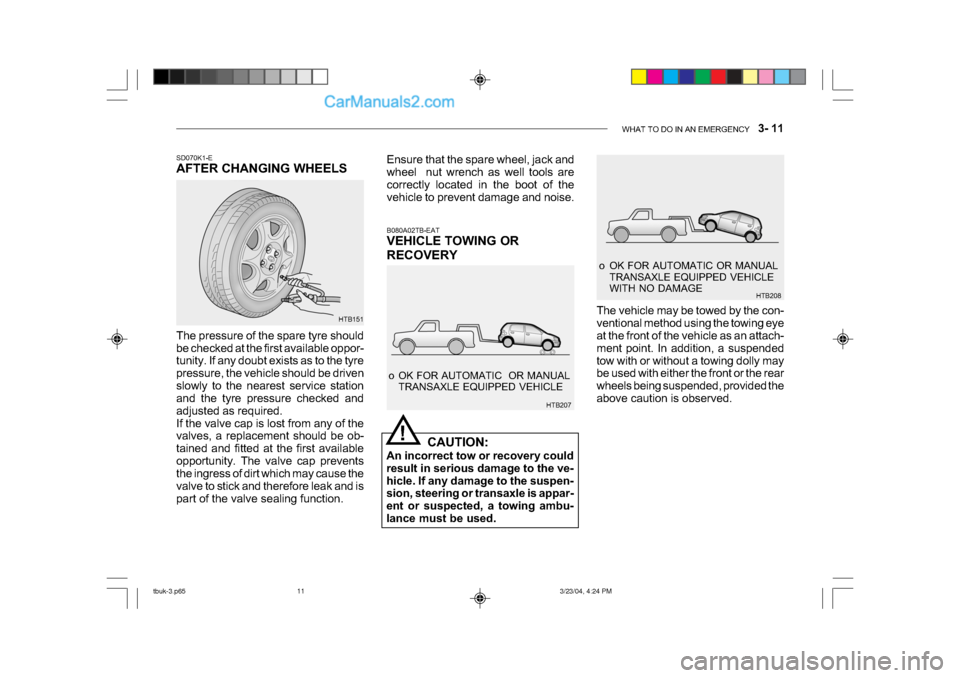

HTB151B080A02TB-EAT

VEHICLE TOWING OR

RECOVERY

CAUTION:

An incorrect tow or recovery could

result in serious damage to the ve-

hicle. If any damage to the suspen-

sion, steering or transaxle is appar-

ent or suspected, a towing ambu-

lance must be used. o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE

HTB207

!

SD070K1-E

AFTER CHANGING WHEELS

The pressure of the spare tyre should

be checked at the first available oppor-

tunity. If any doubt exists as to the tyre

pressure, the vehicle should be driven

slowly to the nearest service station

and the tyre pressure checked and

adjusted as required.

If the valve cap is lost from any of the

valves, a replacement should be ob-

tained and fitted at the first available

opportunity. The valve cap prevents

the ingress of dirt which may cause the

valve to stick and therefore leak and is

part of the valve sealing function. Ensure that the spare wheel, jack and

wheel nut wrench as well tools are

correctly located in the boot of the

vehicle to prevent damage and noise.

The vehicle may be towed by the con-

ventional method using the towing eye

at the front of the vehicle as an attach-

ment point. In addition, a suspended

tow with or without a towing dolly may

be used with either the front or the rear

wheels being suspended, provided the

above caution is observed.

tbuk-3.p65 3/23/04, 4:24 PM

11

Page 375 of 445

3- 12 WHAT TO DO IN AN EMERGENCY

!

CAUTION:

The following restriction must be

observed in order to avoid serious

damage to the transaxle .

The vehicle must never be towed

from the rear with the front wheels

on the ground.

The vehicle must not be towed until

transaxle fluid has been added to

bring the level up to the "HOT"

marking on the dipstick. (The level

will need to be reduced again after

towing).

The vehicle must not be towed at

speeds faster than 25 mph. or dis-

tances greater than fifty miles. The

general points regarding the steer-

ing lock etc. described in the pre-

ceding section (Manual transaxle

vehicle) should be observed.

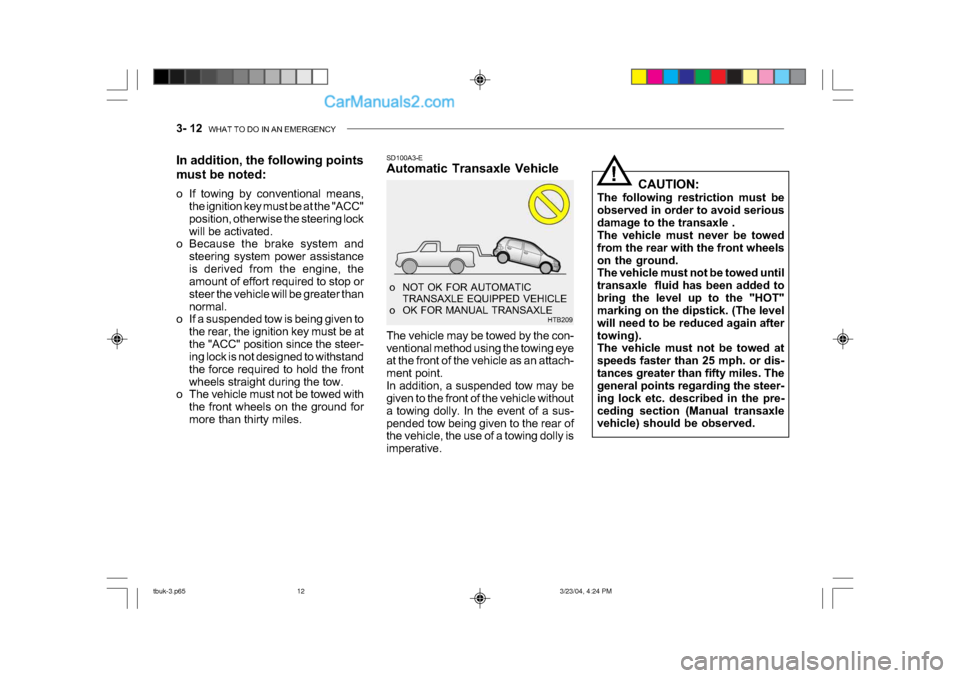

SD100A3-E

Automatic Transaxle Vehicle

The vehicle may be towed by the con-

ventional method using the towing eye

at the front of the vehicle as an attach-

ment point.

In addition, a suspended tow may be

given to the front of the vehicle without

a towing dolly. In the event of a sus-

pended tow being given to the rear of

the vehicle, the use of a towing dolly is

imperative.

o NOT OK FOR AUTOMATIC

TRANSAXLE EQUIPPED VEHICLE

o OK FOR MANUAL TRANSAXLE HTB209

In addition, the following points

must be noted:

o If towing by conventional means,

the ignition key must be at the "ACC"

position, otherwise the steering lock

will be activated.

o Because the brake system and

steering system power assistance

is derived from the engine, the

amount of effort required to stop or

steer the vehicle will be greater than

normal.

o If a suspended tow is being given to

the rear, the ignition key must be at

the "ACC" position since the steer-

ing lock is not designed to withstand

the force required to hold the front

wheels straight during the tow.

o The vehicle must not be towed with

the front wheels on the ground for

more than thirty miles.

tbuk-3.p65 3/23/04, 4:24 PM

12

Page 376 of 445

WHAT TO DO IN AN EMERGENCY 3- 13

D120A01A-EAT

IF YOU LOSE YOUR KEYS

Information about the key of immobi-

lizer system will be found on page 1-4.CAUTION:

If the car is being towed with all

four wheels on the ground, it can

be towed only from the front. Be

sure that the transaxle is in neu-

tral. Do not tow at speeds greater

than 30 mph (50 km/h) and for more

than 15 miles(25 km).

Be sure the steering is unlocked by

placing the key in the "ACC" posi-

tion. A driver must be in the towed

vehicle to operate the steering and

brakes.

!

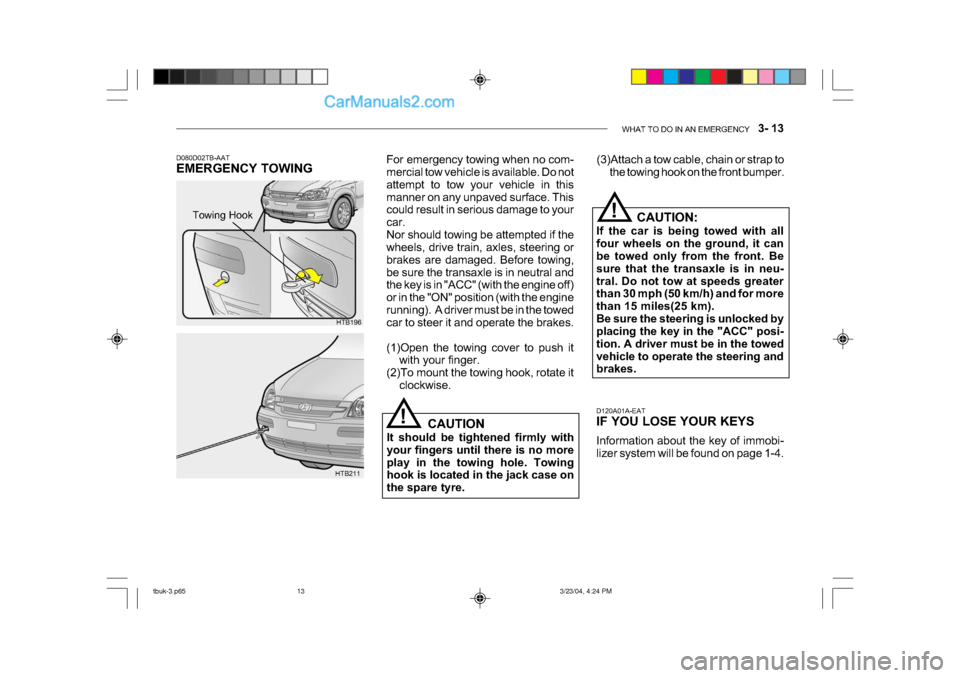

(3)Attach a tow cable, chain or strap to

the towing hook on the front bumper.

D080D02TB-AAT

EMERGENCY TOWING For emergency towing when no com-

mercial tow vehicle is available. Do not

attempt to tow your vehicle in this

manner on any unpaved surface. This

could result in serious damage to your

car.

Nor should towing be attempted if the

wheels, drive train, axles, steering or

brakes are damaged. Before towing,

be sure the transaxle is in neutral and

the key is in "ACC" (with the engine off)

or in the "ON" position (with the engine

running). A driver must be in the towed

car to steer it and operate the brakes.

(1)Open the towing cover to push it

with your finger.

(2)To mount the towing hook, rotate it clockwise.

HTB196

HTB211 CAUTION

It should be tightened firmly with

your fingers until there is no more

play in the towing hole. Towing

hook is located in the jack case on

the spare tyre.

!

Towing Hook

tbuk-3.p65

3/23/04, 4:24 PM

13

Page 377 of 445

4. CORROSION PREVENTION &APPEARANCE CARE

Protecting Your Hyundai From Corrosion ...................................... 4-2

Underbody coatings ........................................................................ 4-2Polishing ......................................................................................... 4-3

Interior Valeting ............................................................................... 4-4

4

tbuk-4.p65 7/3/2008, 4:09 PM

1

Page 378 of 445

4- 2 CORROSION PREVENTION AND APPEARANCE CARE

SE020A1-E PROTECTING YOUR HYUNDAI FROM CORROSION By using the most advanced design and construction practices, every Hyundai is built to retain the originalfactory finish for many years. How- ever, long term durability is also greatly dependant upon maintaining the vari-ous protection systems and coatings used in manufacture since constant, exposure to the elements will result ina breakdown and loss of effective- ness. The following suggestions are made to assist in the maintenance ofthe vehicle bodywork. SE030A1-E UNDERBODY COATINGS Every Hyundai passenger car receives a full underbody and cavity injectiontreatment during production. In order that this treatment may retain maxi- mum effectiveness it is recommendedthat the underbody receives a power wash and a thorough inspection after each winter season. In doing so anyaccumulations of mud, which act as moisture traps and combine with road salts to accelerate corrosion will beremoved. In order to maintain the Anti Perforation Warranty, the requirements regarding the retreatment programmemust be observed in accordance with the Terms and Conditions outlined in the separate Anti Perforation WarrantyBooklet. NOTE: The underbody should never be steam cleaned since the underbodycoating may be removed by this process. During the interim period betweenpower washing the underbody, the more vulnerable areas such as wheel arches should be hosed off particularly during the winter sea- son to prevent prolonged contact with road salts.Ensure that the various drain points located at the bottom of the door panels and sills are kept clear toprevent water from becoming trapped within the cavities. Wher- ever possible, the parking of thevehicle in a confined, poorly venti- lated location (a garage for example) should be avoided when the ve-hicle is wet or is covered with snow or ice. Under these conditions, the internal cavities of the vehicle willremain damp for prolonged peri- ods of time which will encourage corrosion. Parking the vehiclewhere good ventilation exists (out- side for example) is preferable.

tbuk-4.p65

7/3/2008, 4:09 PM

2

Page 379 of 445

CORROSION PREVENTION AND APPEARANCE CARE 4- 3

SE040A1-E VALETING Regular cleaning of the exterior paintwork serves two important func-tions. Firstly, the removal of abrasive dirt and contaminants will maintain the lustre of the paintwork and will preventdiscolouration and dulling due to pro- longed contact. Secondly, the presence of damagethrough impact or abrasion will be ap- parent allowing early rectification to be made thus preventing corrosion frombecoming established and spreading beneath the paint film. To avoid "water spotting" the vehicle should not bewashed in direct sunlight particularly in the case of vehicles having dark body colours. The heat from the sun rays isabsorbed by the paint film increasing the surface temperature. This action causes water used for washing toevaporate quickly leaving behind the deposits from the water and the sham- poo used.Use only a shampoo intended for the purpose and ensure that the body work is thoroughly wetted to soften the dirtfilm prior to attempting to remove this. After removing the dirt film with a soft sponge, the body work should be thor- oughly rinsed and then dried with agood quality chamois leather to pre- vent streaking or spotting of the paint work.Household detergents, solvents and abrasive cleaning materials should not be used in order to avoid damaging thepaint film. Plastic wheel covers should be cleaned using a sponge and water. Cast alloywheels should be cleaned using a mild soap or neutral detergent. Abrasive compounds must not be used since inthe event of these damaging the lac- quer coating, oxidization of the alu- minium wheel will occur, spoiling theappearance. The use of an a toothbrush will facili- tate cleaning between the wheel"spokes".

SE040B1-E STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be difficult to remove from thepaint film, turpentine or a proprietary paint cutting compound may be used. Ensure that the area to be cleaned isnot rubbed intensively to prevent break- ing through the colour coat and expos- ing the under coat. SE040C1-E POLISHING The exterior paint work should be pol- ished with a proprietary wax polish when water no longer collects in bead form on the paint work. The instruc-tions of the product manufacturer should be adhered to.

tbuk-4.p65

7/3/2008, 4:09 PM

3

Page 380 of 445

4- 4 CORROSION PREVENTION AND APPEARANCE CARE

SE040E1-E BUMPER MAINTENANCE The special material from which the bumpers are manufactured warrantsspecial attention to preserve the ap- pearance of the bumpers. Avoid con- tact with battery electrolyte or brakefluid and ensure that accidental spill- ages are immediately flushed with water.Do not use abrasive cleaning materi- als which may damage the bumpers. Avoid subjecting the bumpers to hightemperatures such as may be encoun- tered in high bake paint ovens.

SE040F1-E ACCIDENT REPAIRS In the event of the body work sustain- ing damage, the following points should be noted prior to repairs being under- taken.If body panels are replaced or re- paired, anti corrosion treatment must be applied to the repair area. Theproduct used must be compatible with those used in manufacture. It is rec- ommended that repairs are entrustedto a Hyundai dealer to ensure that replacement parts used are of the same high quality as those used in manufac- ture of the vehicle and that the correctrepair methods and materials will en- sure adequate levels of corrosion pro- tection and the continued validity of theAnti Perforation Warranty. SE050A1-E INTERIOR During the winter period, it is possible that the passenger compartment floor- ing may become wet from damp foot- wear or quantities of snow adhering tofootwear. The carpet should not be allowed to remain in this condition since the carpet may begin to create mustysmells and will promote corrosion of the floor pan in addition to the carpet and under felt beginning to rot.

SE050C1-E INTERIOR VALETING The soft trim and carpets should be maintained with the regular use of avacuum cleaner. Heavy soiling should be removed with a dry cleaning agent recommended for this purpose follow-ing the instructions of the product manufacturer. Paint thinner, solvents or other such cleaning materials shouldnot be used since damage to the up- holstery may result. SE050D1-E SEAT BELTS Seat belts should be cleaned only with a mild soap solution. Strong deter- gents, solvens or bleaches may dam- age the belt webbing and thereforereduce the effectiveness of the belt. Belts which display signs of fraying, wear of cut should be replaced.

tbuk-4.p65

7/3/2008, 4:09 PM

4