ECU HYUNDAI IX35 2014 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: IX35, Model: HYUNDAI IX35 2014Pages: 1534, PDF Size: 39.76 MB

Page 1442 of 1534

What to do in an emergency

34

6

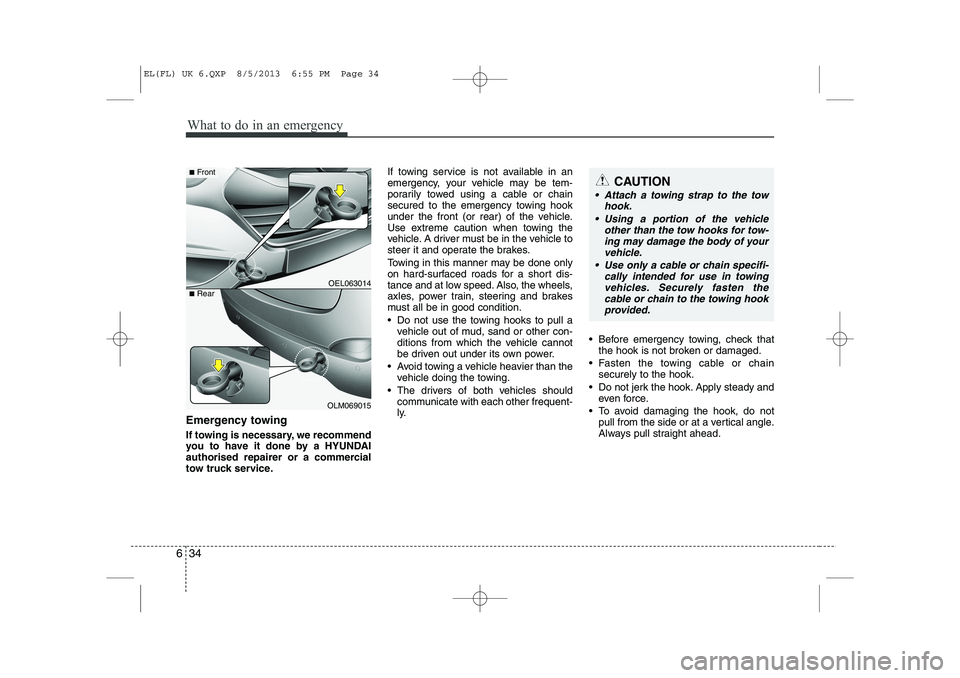

Emergency towing

If towing is necessary, we recommend

you to have it done by a HYUNDAI

authorised repairer or a commercial

tow truck service. If towing service is not available in an

emergency, your vehicle may be tem-

porarily towed using a cable or chain

secured to the emergency towing hook

under the front (or rear) of the vehicle.

Use extreme caution when towing the

vehicle. A driver must be in the vehicle to

steer it and operate the brakes.

Towing in this manner may be done only

on hard-surfaced roads for a short dis-

tance and at low speed. Also, the wheels,

axles, power train, steering and brakes

must all be in good condition.

Do not use the towing hooks to pull a

vehicle out of mud, sand or other con-

ditions from which the vehicle cannot

be driven out under its own power.

Avoid towing a vehicle heavier than the vehicle doing the towing.

The drivers of both vehicles should communicate with each other frequent-

ly. Before emergency towing, check that

the hook is not broken or damaged.

Fasten the towing cable or chain securely to the hook.

Do not jerk the hook. Apply steady and even force.

To avoid damaging the hook, do not pull from the side or at a vertical angle.

Always pull straight ahead.

CAUTION

Attach a towing strap to the tow

hook.

Using a portion of the vehicle other than the tow hooks for tow-ing may damage the body of yourvehicle.

Use only a cable or chain specifi- cally intended for use in towingvehicles. Securely fasten thecable or chain to the towing hook provided.

OEL063014

OLM069015

■ Front

■Rear

EL(FL) UK 6.QXP 8/5/2013 6:55 PM Page 34

Page 1452 of 1534

Maintenance

8

7

Engine compartment precautions (Diesel engine)

• The piezo injector operates at high

voltage (maximum 200v). Therefore,

the following accidents may occur.

- Direct contact with the injector or

injector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room whilst the engine is running.

- Do not touch the injector, injector

wirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector whilst the engine is running.

- People using pacemakers must not go near the engine whilst the engine

is starting or running.

WARNING - Maintenance

work

Performing maintenance work on a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by a

HYUNDAI authorised repairer.

Working under the bonnet with the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before gettingnear the engine or cooling fans.WARNING - Diesel Engine

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectorsand high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

electronic engine control system

produce considerable magneticfields.

EL(FL) UK 7.QXP 8/5/2013 7:02 PM Page 8

Page 1456 of 1534

Maintenance

12

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically forproper tension and adjusted as neces-

sary. Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by a HYUNDAI

authorised repairer.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by a

HYUNDAI authorised repairer.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

Common Rail system produce con-

siderable magnetic fields.

EL(FL) UK 7.QXP 8/5/2013 7:02 PM Page 12

Page 1457 of 1534

713

Maintenance

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.Air cleaner filter

We recommend that you use air cleaner

filter for replacement from a HYUNDAI

authorised repairer.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range. Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts. Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, we recommend

that the fluid be changed by a HYUNDAI

authorised repairer in accordance to thescheduled maintenance at the beginning

of this chapter.

✽✽

NOTICE

Automatic transaxle fluid colour is basi-

cally red. As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.It is normal condition and you should

not judge the need to replace the fluid

based upon the changed colour.

EL(FL) UK 7.QXP 8/5/2013 7:02 PM Page 13

Page 1465 of 1534

721

Maintenance

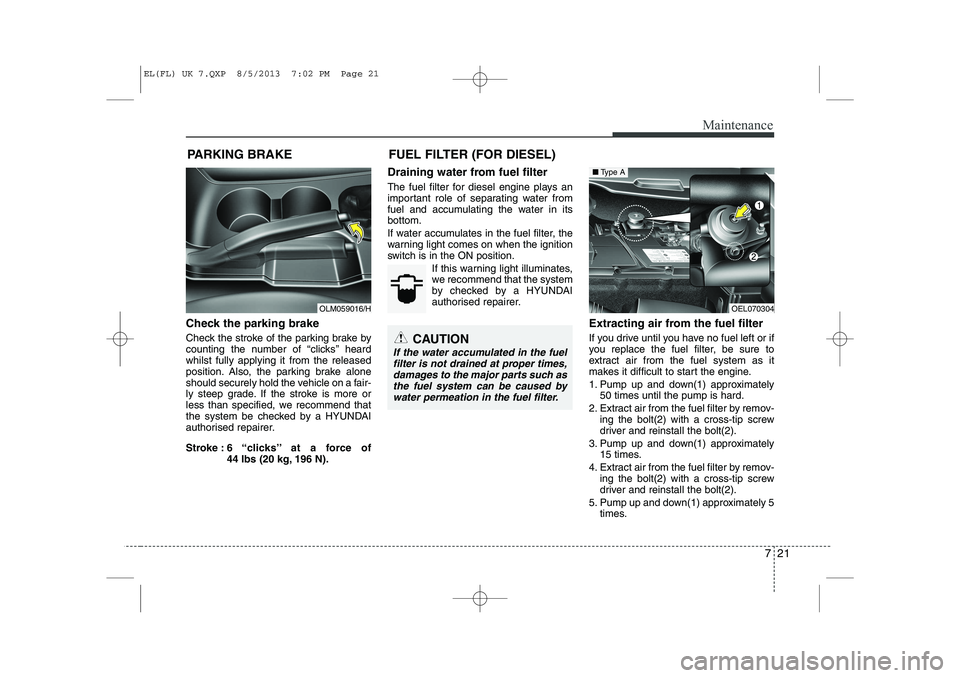

PARKING BRAKE

Check the parking brake

Check the stroke of the parking brake by

counting the number of “clicks’’ heardwhilst fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade. If the stroke is more or

less than specified, we recommend that

the system be checked by a HYUNDAI

authorised repairer.

Stroke : 6 “clicks’’ at a force of 44 lbs (20 kg, 196 N). Draining water from fuel filter

The fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in itsbottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position.

If this warning light illuminates,

we recommend that the system

by checked by a HYUNDAI

authorised repairer.

Extracting air from the fuel filter

If you drive until you have no fuel left or if

you replace the fuel filter, be sure to

extract air from the fuel system as it

makes it difficult to start the engine.

1. Pump up and down(1) approximately50 times until the pump is hard.

2. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

3. Pump up and down(1) approximately 15 times.

4. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

5. Pump up and down(1) approximately 5 times.

CAUTION

If the water accumulated in the fuel

filter is not drained at proper times,

damages to the major parts such asthe fuel system can be caused by water permeation in the fuel filter.

OEL070304

■ Type A

OLM059016/H FUEL FILTER (FOR DIESEL)

EL(FL) UK 7.QXP 8/5/2013 7:02 PM Page 21

Page 1474 of 1534

Maintenance

30

7

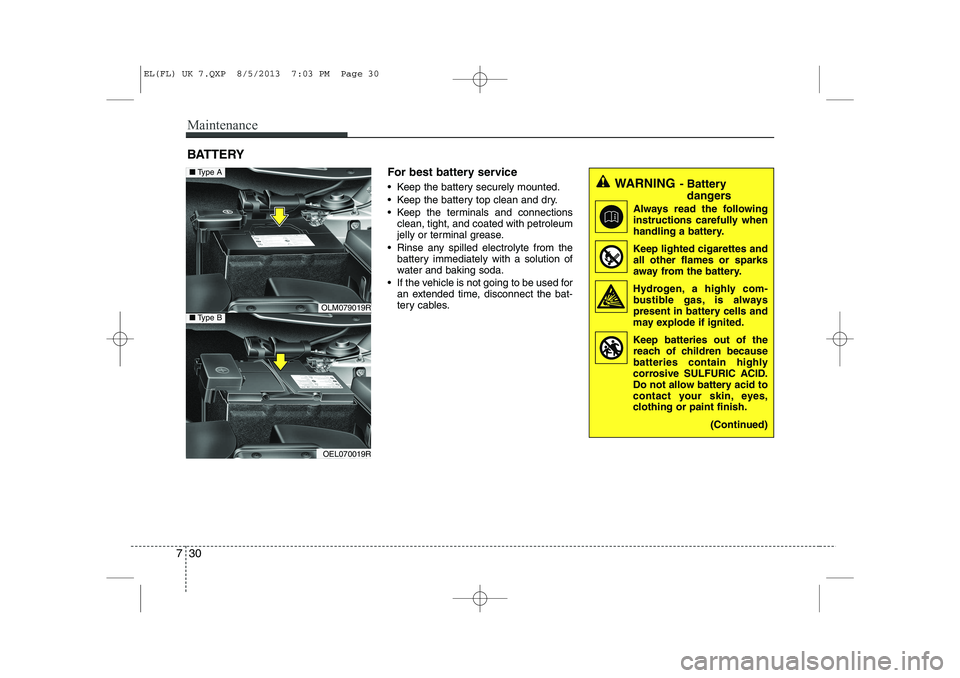

BATTERY

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connectionsclean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

WARNING - Battery

dangers

Always read the following

instructions carefully when

handling a battery.

Keep lighted cigarettes and all other flames or sparks

away from the battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells and

may explode if ignited.

Keep batteries out of the

reach of children because

batteries contain highly

corrosive SULFURIC ACID.

Do not allow battery acid to

contact your skin, eyes,

clothing or paint finish.

(Continued)

OLM079019R

OEL070019R

■Type A

■Type B

EL(FL) UK 7.QXP 8/5/2013 7:03 PM Page 30

Page 1491 of 1534

747

Maintenance

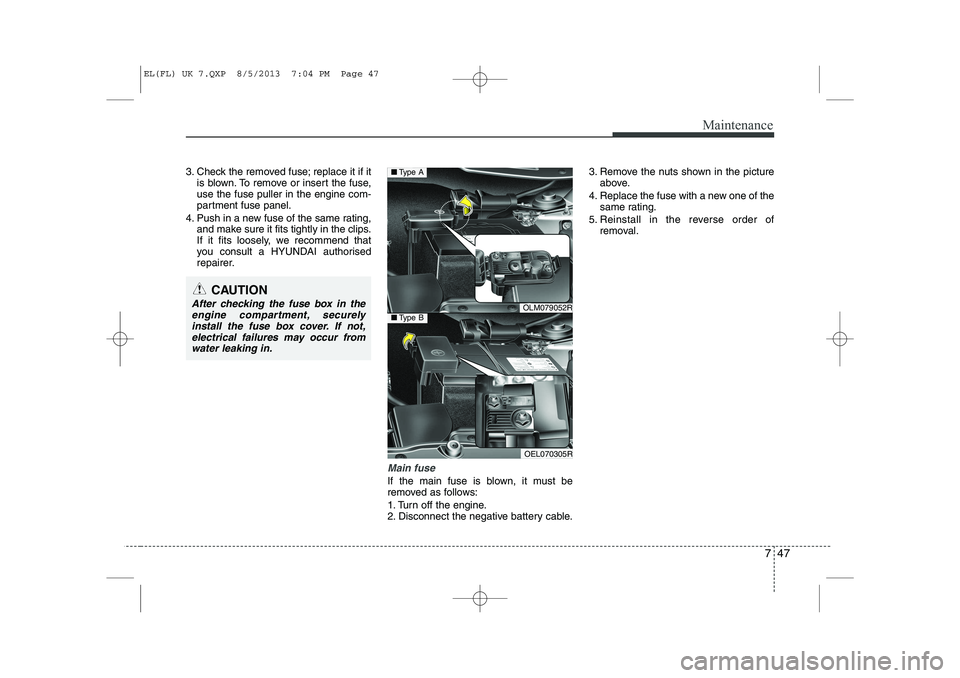

3. Check the removed fuse; replace it if itis blown. To remove or insert the fuse, use the fuse puller in the engine com-

partment fuse panel.

4. Push in a new fuse of the same rating, and make sure it fits tightly in the clips.

If it fits loosely, we recommend that

you consult a HYUNDAI authorised

repairer.

Main fuse

If the main fuse is blown, it must be

removed as follows:

1. Turn off the engine.

2. Disconnect the negative battery cable. 3. Remove the nuts shown in the picture

above.

4. Replace the fuse with a new one of the same rating.

5. Reinstall in the reverse order of removal.

CAUTION

After checking the fuse box in the

engine compartment, securelyinstall the fuse box cover. If not,electrical failures may occur from

water leaking in.OLM079052R

OEL070305R

■ Type A

■Type B

EL(FL) UK 7.QXP 8/5/2013 7:04 PM Page 47

Page 1498 of 1534

Maintenance

54

7

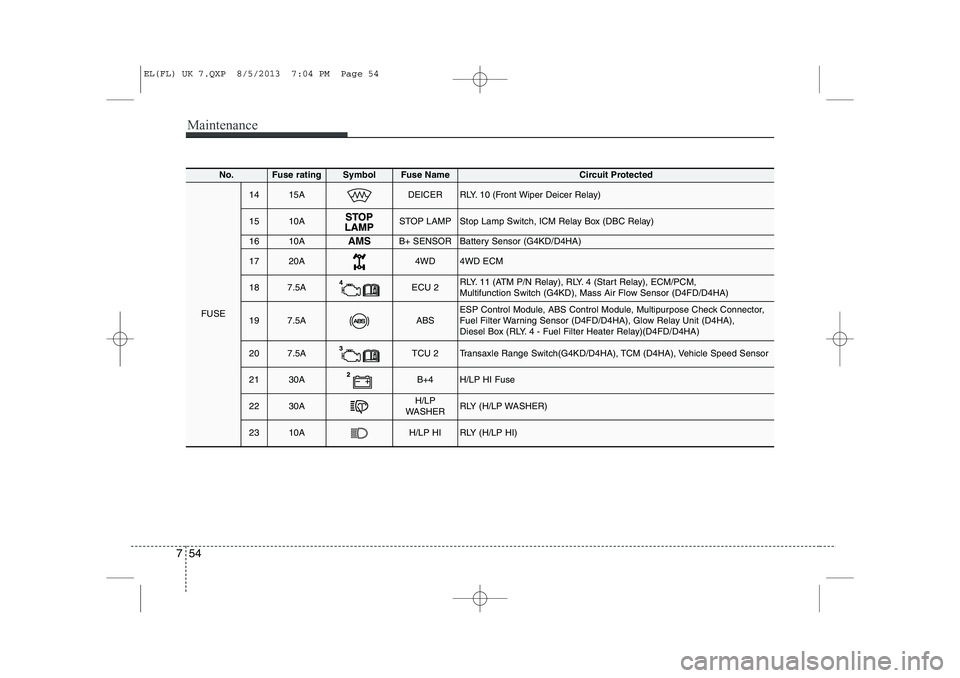

No.Fuse ratingSymbolFuse Name Circuit Protected

FUSE

1415ADEICERRLY. 10 (Front Wiper Deicer Relay)

1510ASTOP LAMPStop Lamp Switch, ICM Relay Box (DBC Relay)

1610AAMSB+ SENSORBattery Sensor (G4KD/D4HA)

1720A4WD4WD ECM

187.5AECU 2RLY. 11 (ATM P/N Relay), RLY. 4 (Start Relay), ECM/PCM,

Multifunction Switch (G4KD), Mass Air Flow Sensor (D4FD/D4HA)

197.5AABSESP Control Module, ABS Control Module, Multipurpose Check Connector,

Fuel Filter Warning Sensor (D4FD/D4HA), Glow Relay Unit (D4HA),

Diesel Box (RLY. 4 - Fuel Filter Heater Relay)(D4FD/D4HA)

207.5ATCU 2Transaxle Range Switch(G4KD/D4HA), TCM (D4HA), Vehicle Speed Sensor

2130AB+4H/LP HI Fuse

2230AH/LP

WASHERRLY (H/LP WASHER)

2310AH/LP HIRLY (H/LP HI)

EL(FL) UK 7.QXP 8/5/2013 7:04 PM Page 54

Page 1512 of 1534

Maintenance

68

7

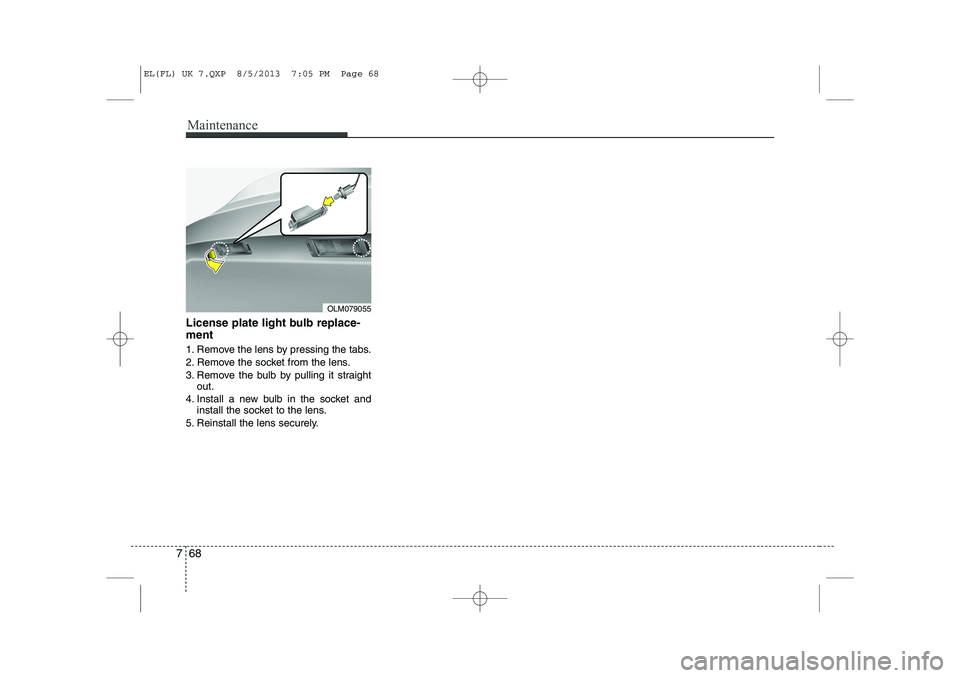

License plate light bulb replace- ment

1. Remove the lens by pressing the tabs.

2. Remove the socket from the lens.

3. Remove the bulb by pulling it straight

out.

4. Install a new bulb in the socket and install the socket to the lens.

5. Reinstall the lens securely.

OLM079055

EL(FL) UK 7.QXP 8/5/2013 7:05 PM Page 68