cooling HYUNDAI IX35 2014 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: IX35, Model: HYUNDAI IX35 2014Pages: 1534, PDF Size: 39.76 MB

Page 300 of 1534

Maintenance

6

7

Engine compartment precautions (Diesel engine)

• The piezo injector operates at high

voltage (maximum 200v). Therefore,

the following accidents may occur.

- Direct contact with the injector or

injector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room whilst the engine is running.

- Do not touch the injector, injector

wirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector whilst the engine is running.

- People using pacemakers must not go near the engine whilst the engine

is starting or running.

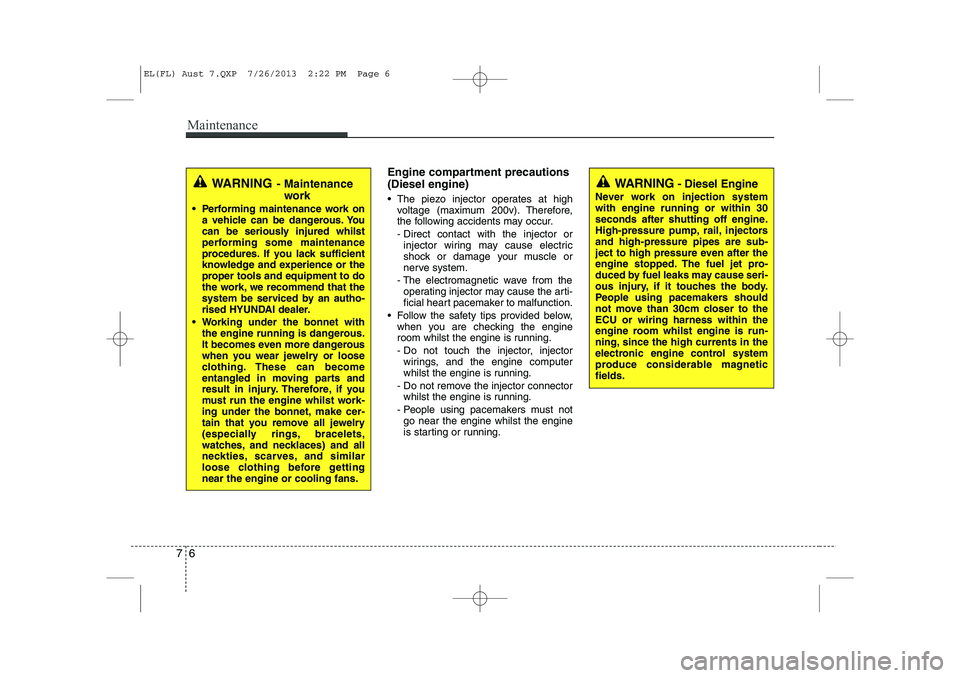

WARNING - Maintenance

work

Performing maintenance work on a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by an autho-

rised HYUNDAI dealer.

Working under the bonnet with the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before gettingnear the engine or cooling fans.WARNING - Diesel Engine

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectorsand high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

electronic engine control system

produce considerable magneticfields.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 6

Page 307 of 1534

713

Maintenance

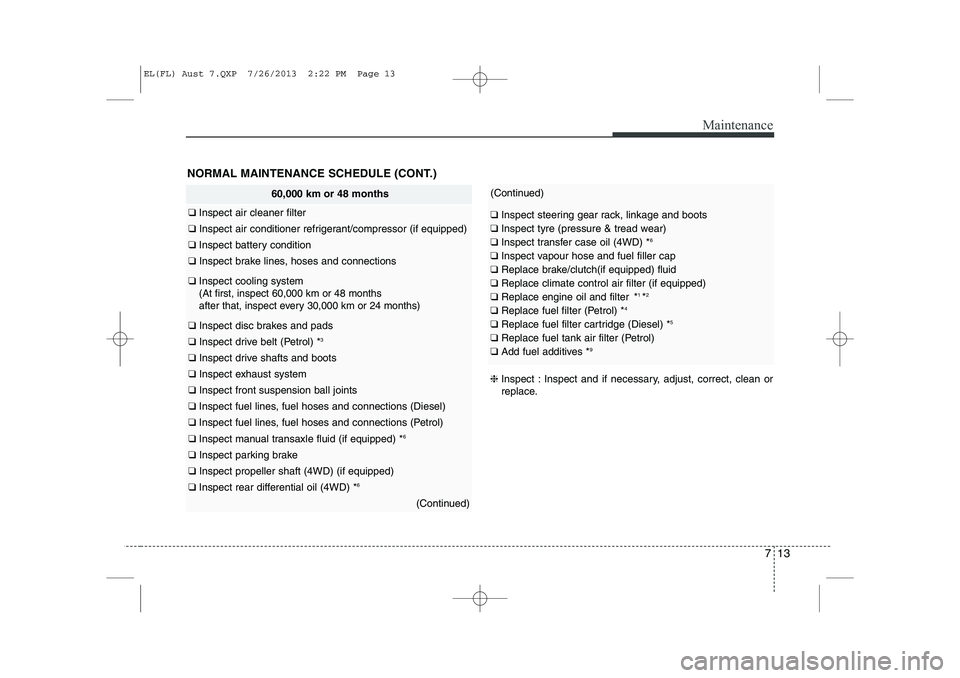

NORMAL MAINTENANCE SCHEDULE (CONT.)

60,000 km or 48 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel lines, fuel hoses and connections (Petrol)

❑ Inspect manual transaxle fluid (if equipped) * 6

❑

Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect rear differential oil (4WD) * 6

(Continued)

(Continued)

❑

Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect transfer case oil (4WD) * 6

❑ Inspect vapour hose and fuel filler cap

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Replace fuel filter (Petrol) * 4

❑ Replace fuel filter cartridge (Diesel) * 5

❑ Replace fuel tank air filter (Petrol)

❑ Add fuel additives * 9

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 13

Page 308 of 1534

Maintenance

14

7

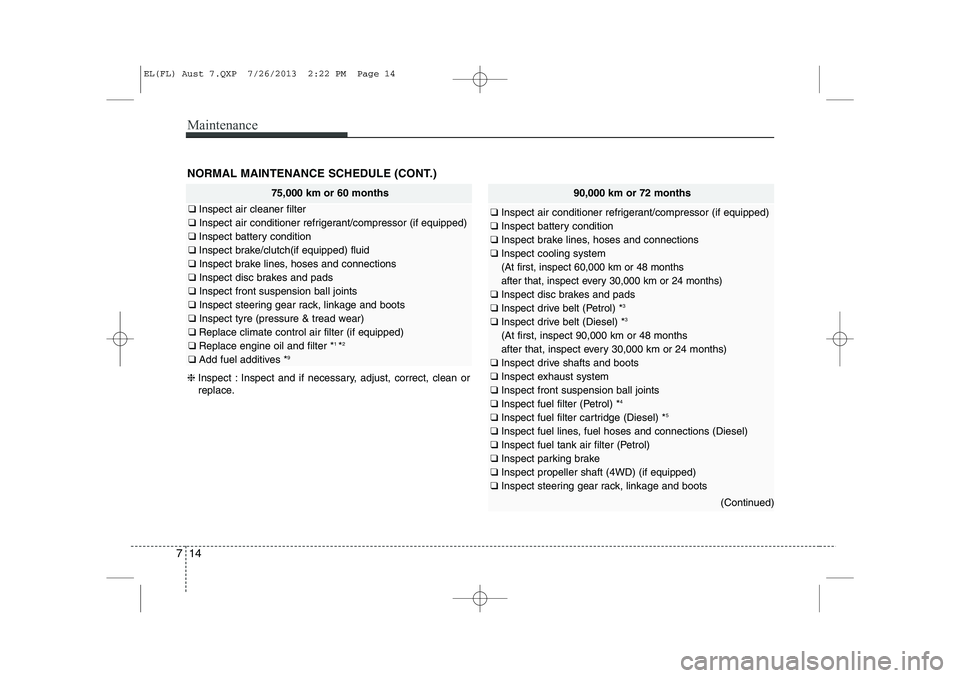

NORMAL MAINTENANCE SCHEDULE (CONT.)

75,000 km or 60 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect brake lines, hoses and connections

❑ Inspect disc brakes and pads

❑ Inspect front suspension ball joints

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

❈

Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

90,000 km or 72 months

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑ Inspect drive belt (Diesel) * 3

(At first, inspect 90,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Petrol) * 4

❑ Inspect fuel filter cartridge (Diesel) * 5

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel tank air filter (Petrol)

❑ Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect steering gear rack, linkage and boots

(Continued)

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 14

Page 310 of 1534

Maintenance

16

7

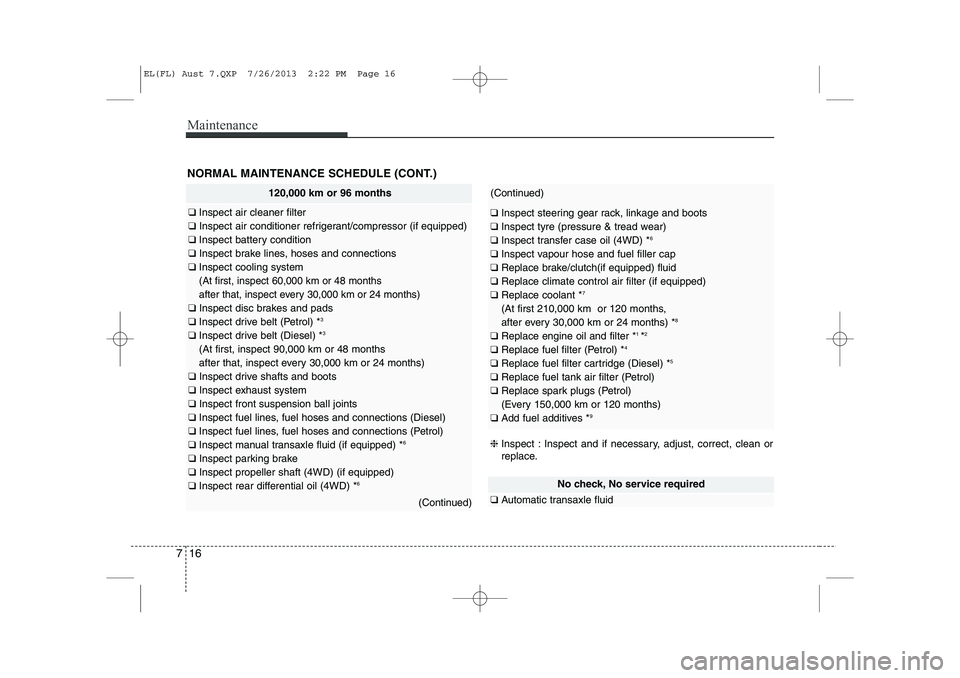

NORMAL MAINTENANCE SCHEDULE (CONT.)

120,000 km or 96 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑ Inspect drive belt (Diesel) * 3

(At first, inspect 90,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel lines, fuel hoses and connections (Petrol)

❑ Inspect manual transaxle fluid (if equipped) * 6

❑ Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect rear differential oil (4WD) * 6

(Continued)

(Continued)

❑

Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect transfer case oil (4WD) * 6

❑ Inspect vapour hose and fuel filler cap

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace coolant * 7

(At first 210,000 km or 120 months,

after every 30,000 km or 24 months) * 8

❑ Replace engine oil and filter * 1

*2

❑ Replace fuel filter (Petrol) * 4

❑ Replace fuel filter cartridge (Diesel) * 5

❑ Replace fuel tank air filter (Petrol)

❑ Replace spark plugs (Petrol)

(Every 150,000 km or 120 months)

❑ Add fuel additives * 9

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

No check, No service required

❑Automatic transaxle fluid

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 16

Page 314 of 1534

Maintenance

20

7

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage. Air cleaner filter

We recommend that you use air cleaner

filter for replacement from an authorised

HYUNDAI dealer.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range. Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts. Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, we recommend

that the fluid be changed by an autho-

rised HYUNDAI dealer in accordance tothe scheduled maintenance at the begin-

ning of this chapter.

✽✽

NOTICE

Automatic transaxle fluid colour is basi-

cally red. As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.It is normal condition and you should

not judge the need to replace the fluid

based upon the changed colour.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 20

Page 317 of 1534

723

Maintenance

ENGINE COOLANT

Changing the engine oil and filter

We recommend that the engine oil and

filter be replaced by an authorised

HYUNDAI dealer. The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant concentration level at least once

a year, at the beginning of the winter sea-

son, and before travelling to a colder cli-

mate.

Checking the coolant level

WARNING

Removing radiatorcap

Never attempt to remove the radi- ator cap whilst the engine is

operating or hot. Doing so mightlead to cooling system and

engine damage and could result

in serious personal injury fromescaping hot coolant or steam.

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop.

(Continued)

(Continued)Step back whilst the pressure is

released from the cooling sys-

tem. When you are sure all thepressure has been released,

press down on the cap, using a

thick towel, and continue turning

counterclockwise to remove it.

Even if the engine is not operat- ing, do not remove the radiatorcap or the drain plug whilst the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

WARNING

Used engine oil may cause irrita- tion or cancer of the skin if left in

contact with the skin for prolonged

periods of time. Used engine oil

contains chemicals that have

caused cancer in laboratory ani-

mals. Always protect your skin by

washing your hands thoroughlywith soap and warm water as soon

as possible after handling used oil.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 23

Page 318 of 1534

Maintenance

24

7

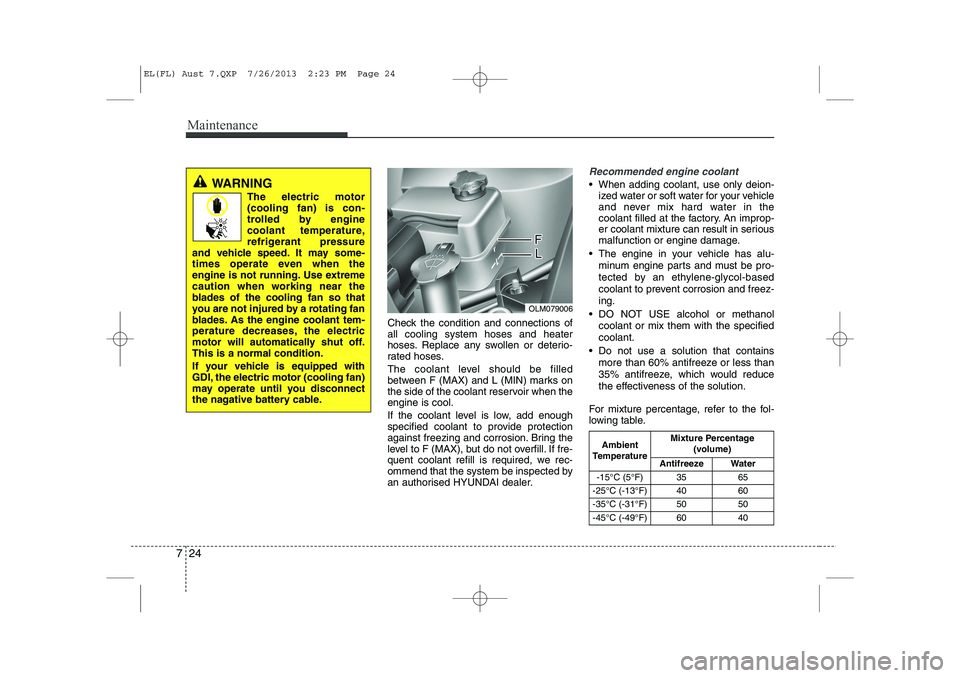

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F (MAX) and L (MIN) marks on

the side of the coolant reservoir when theengine is cool.

If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F (MAX), but do not overfill. If fre-

quent coolant refill is required, we rec-

ommend that the system be inspected by

an authorised HYUNDAI dealer.

Recommended engine coolant

When adding coolant, use only deion-

ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

The engine in your vehicle has alu- minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-ing.

DO NOT USE alcohol or methanol coolant or mix them with the specifiedcoolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.

For mixture percentage, refer to the fol-

lowing table.

OLM079006

Ambient

Temperature Mixture Percentage

(volume)

Antifreeze Water

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

WARNING The electric motor (cooling fan) is con-

trolled by engine

coolant temperature,

refrigerant pressure

and vehicle speed. It may some-

times operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that

you are not injured by a rotating fan

blades. As the engine coolant tem-

perature decreases, the electric

motor will automatically shut off.This is a normal condition.

If your vehicle is equipped with

GDI, the electric motor (cooling fan)

may operate until you disconnect

the nagative battery cable.

EL(FL) Aust 7.QXP 7/26/2013 2:23 PM Page 24

Page 354 of 1534

Maintenance

60

7

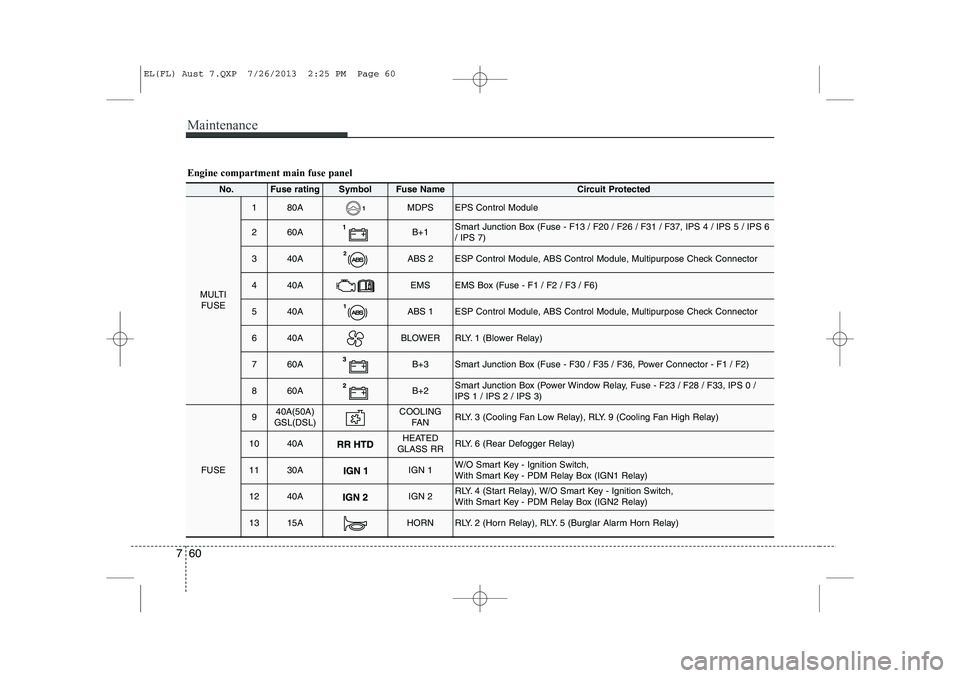

Engine compartment main fuse panel

No.Fuse ratingSymbolFuse Name Circuit Protected

MULTI

FUSE

180AMDPSEPS Control Module

260AB+1Smart Junction Box (Fuse - F13 / F20 / F26 / F31 / F37, IPS 4 / IPS 5 / IPS 6 / IPS 7)

340AABS 2ESP Control Module, ABS Control Module, Multipurpose Check Connector

440AEMSEMS Box (Fuse - F1 / F2 / F3 / F6)

540AABS 1ESP Control Module, ABS Control Module, Multipurpose Check Connector

640ABLOWERRLY. 1 (Blower Relay)

760AB+3Smart Junction Box (Fuse - F30 / F35 / F36, Power Connector - F1 / F2)

860AB+2Smart Junction Box (Power Window Relay, Fuse - F23 / F28 / F33, IPS 0 / IPS 1 / IPS 2 / IPS 3)

FUSE

940A(50A)

GSL(DSL)COOLING FA NRLY. 3 (Cooling Fan Low Relay), RLY. 9 (Cooling Fan High Relay)

1040AHEATED

GLASS RRRLY. 6 (Rear Defogger Relay)

1130AIGN 1W/O Smart Key - Ignition Switch,

With Smart Key - PDM Relay Box (IGN1 Relay)

1240AIGN 2RLY. 4 (Start Relay), W/O Smart Key - Ignition Switch,

With Smart Key - PDM Relay Box (IGN2 Relay)

1315AHORNRLY. 2 (Horn Relay), RLY. 5 (Burglar Alarm Horn Relay)

EL(FL) Aust 7.QXP 7/26/2013 2:25 PM Page 60

Page 400 of 1534

I3

Index

Battery ..............................................................................7-37

Battery saver function ......................................................4-88

Before driving ....................................................................5-4

Bonnet ..............................................................................4-25

Brake system ....................................................................5-31

Anti-lock brake system (ABS) ..................................5-34

Downhill brake control (DBC) ..................................5-41

Electronic stability control (ESC) ..............................5-36

Emergency Stop Signal (ESS)....................................5-43

Hill-start assist control (HAC) ..................................5-41

Parking brake..............................................................5-32

Power brakes ..............................................................5-31

TSA (Trailer stability assist) ......................................5-43

Vehicle stability management ....................................5-39

Brake/clutch fluid ............................................................7-26

Bulb replacement ............................................................7-63

Bulb wattage ......................................................................8-3

Button start/stop, see engine start/stop button ..................5-9 Camera (Rear view) ........................................................4-87

Capacities (Lubricants) ......................................................8-6Care

Exterior care ..............................................................7-77

Interior care ................................................................7-82

Tyre care ....................................................................7-40

Cargo security screen ....................................................4-131

Centre console storage ..................................................4-123

Central door lock switch ..................................................4-16

Certification label ..............................................................8-9Chains Tyre chains ................................................................5-58

Checking tyre inflation pressure ......................................7-42

Child restraint system ......................................................3-31 ISOFIX system ..........................................................3-36

Seat belt ......................................................................3-33

Tether anchor system..................................................3-34

Child-protector rear door lock ........................................4-18

Cigarette lighter ............................................................4-126

Climate control air filter ..................................................7-32

Combined instrument, see instrument cluster..................4-46

Compact spare tyre replacement ......................................7-45

Compass with Electric chromic mirror ............................4-40

Cool box ........................................................................4-124

Coolant ............................................................................7-23

Cooling fluid, see engine coolant ....................................7-23

BC

EL(FL) Aust Index.qxp 7/26/2013 2:14 PM Page 3

Page 606 of 1534

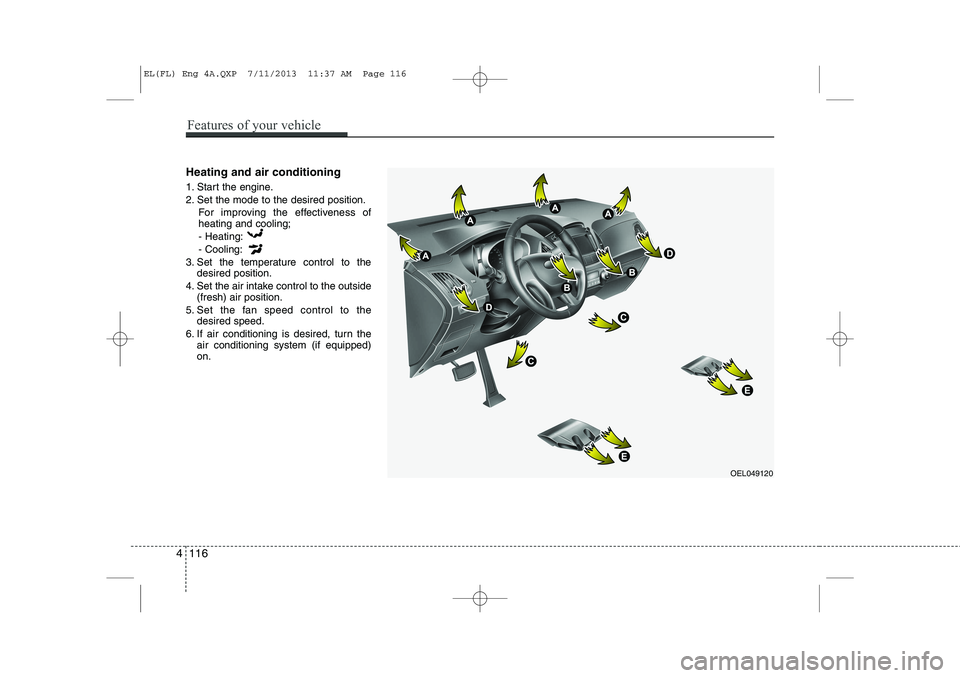

Heating and air conditioning

1. Start the engine.

2. Set the mode to the desired position.For improving the effectiveness of heating and cooling;- Heating: - Cooling:

3. Set the temperature control to the desired position.

4. Set the air intake control to the outside (fresh) air position.

5. Set the fan speed control to the desired speed.

6. If air conditioning is desired, turn the air conditioning system (if equipped) on.

OEL049120

4 116

Features of your vehicle

EL(FL) Eng 4A.QXP 7/11/2013 11:37 AM Page 116