fuel HYUNDAI IX35 2015 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2015, Model line: IX35, Model: HYUNDAI IX35 2015Pages: 550, PDF Size: 9.92 MB

Page 435 of 550

613

What to do in an emergency

TYRE PRESSURE MONITORING SYSTEM (TPMS, IF EQUIPPED) (TYPE B)(1) Low tyre pressure telltale / TPMS malfunction indicator

(2) Low tyre pressure position tell- tale Each tyre, including the spare (if pro-

vided), should be checked monthly

when cold and inflated to the inflation

pressure recommended by the vehi-

cle manufacturer on the vehicle plac-

ard or tyre inflation pressure label. (If

your vehicle has tyres of a different

size than the size indicated on the

vehicle placard or tyre inflation pres-

sure label, you should determine the

proper tyre inflation pressure for

those tyres.)

As an added safety feature, your

vehicle has been equipped with a

tyre pressure monitoring system

(TPMS) that illuminates a low tyre

pressure telltale when one or more

of your tyres is significantly under-

inflated. Accordingly, when the low

tyre pressure telltale illuminates, you

should stop and check your tyres as

soon as possible, and inflate them to

the proper pressure. Driving on a sig-

nificantly under-inflated tyre causes

the tyre to overheat and can lead to

tyre failure. Under-inflation also

reduces fuel efficiency and tyre tread

life, and may affect the vehicle’s han-

dling and stopping ability. Please note that the TPMS is not a

substitute for proper tyre mainte-

nance, and it is the driver’s responsi-

bility to maintain correct tyre pres-

sure, even if under-inflation has not

reached the level to trigger illumina-

tion of the TPMS low tyre pressure

telltale.

Your vehicle has also been equipped

with a TPMS malfunction indicator to

indicate when the system is not

operating properly. The TPMS mal-

function indicator is combined with

the low tyre pressure telltale. When

the system detects a malfunction,

the telltale will flash for approximate-

ly one minute and then remain con-

tinuously illuminated. This sequence

will continue upon subsequent vehi-

cle start-ups as long as the malfunc-

tion exists. When the malfunction

indicator is illuminated, the system

may not be able to detect or signal

low tyre pressure as intended. TPMS

malfunctions may occur for a variety

of reasons, including the installation

of replacement or alternate tyres or

wheels on the vehicle that prevent

the TPMS from functioning properly.

OEL063012R

WEL-1001/OLM043504N

■

Type A

■Type B

EL(FL) UK 6.QXP 12/16/2014 8:12 PM Page 13

Page 461 of 550

Maintenance

7

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-7• Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . 7-7

• Owner maintenance precautions . . . . . . . . . . . . . . . . 7-7

• Engine compartment precautions (Diesel engine) . . . 7-8Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-9• Owner maintenance schedule. . . . . . . . . . . . . . . . . . . . 7-9Scheduled maintenance service . . . . . . . . . . . . . . . 7-11

Explanation of scheduled maintenance items . . . 7-12

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15• Checking the engine oil level . . . . . . . . . . . . . . . . . . . 7-15

• Changing the engine oil and filter . . . . . . . . . . . . . . . 7-16Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16• Checking the coolant level . . . . . . . . . . . . . . . . . . . . . 7-17

• Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . 7-18Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19• Checking the brake/clutch fluid level . . . . . . . . . . . 7-19Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20• Checking the washer fluid level . . . . . . . . . . . . . . . . 7-20Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20• Check the parking brake . . . . . . . . . . . . . . . . . . . . . . 7-20Fuel Filter (For Diesel). . . . . . . . . . . . . . . . . . . . . . 7-21• Draining water from fuel filter . . . . . . . . . . . . . . . . . 7-21

• Extracting air from the fuel filter . . . . . . . . . . . . . . . 7-21

• Fuel filter cartridge replacement . . . . . . . . . . . . . . . . 7-22

Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23Climate control air filter . . . . . . . . . . . . . . . . . . . . 7-25• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

30• For best battery service . . . . . . . . . . . . . . . . . . . . . . . 7-30

• Battery capacity label . . . . . . . . . . . . . . . . . . . . . . . . 7-31

• Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

• Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32\

Tyres and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33• Tyre care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

33

• Recommended cold tyre inflation pressures . . . . . . 7-33

• Checking tyre inflation pressure . . . . . . . . . . . . . . . . 7-35

• Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

• Wheel alignment and tyre balance . . . . . . . . . . . . . 7-37

• Tyre replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

• Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

• Tyre traction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. 7-39

• Tyre maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

• Tyre sidewall labeling . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

• Low aspect ratio tyre . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 1

Page 465 of 550

75

Maintenance

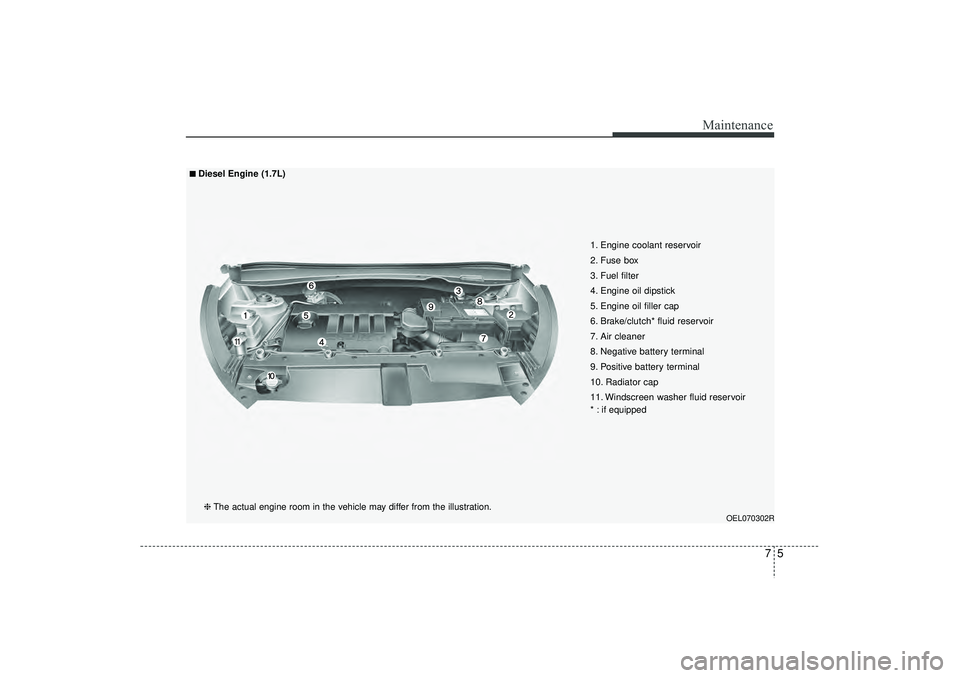

OEL070302R

1. Engine coolant reservoir

2. Fuse box

3. Fuel filter

4. Engine oil dipstick

5. Engine oil filler cap

6. Brake/clutch* fluid reservoir

7. Air cleaner

8. Negative battery terminal

9. Positive battery terminal

10. Radiator cap

11. Windscreen washer fluid reservoir* : if equipped

■ ■Diesel Engine (1.7L)❈ The actual engine room in the vehicle may differ from the illustration.

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 5

Page 466 of 550

Maintenance67

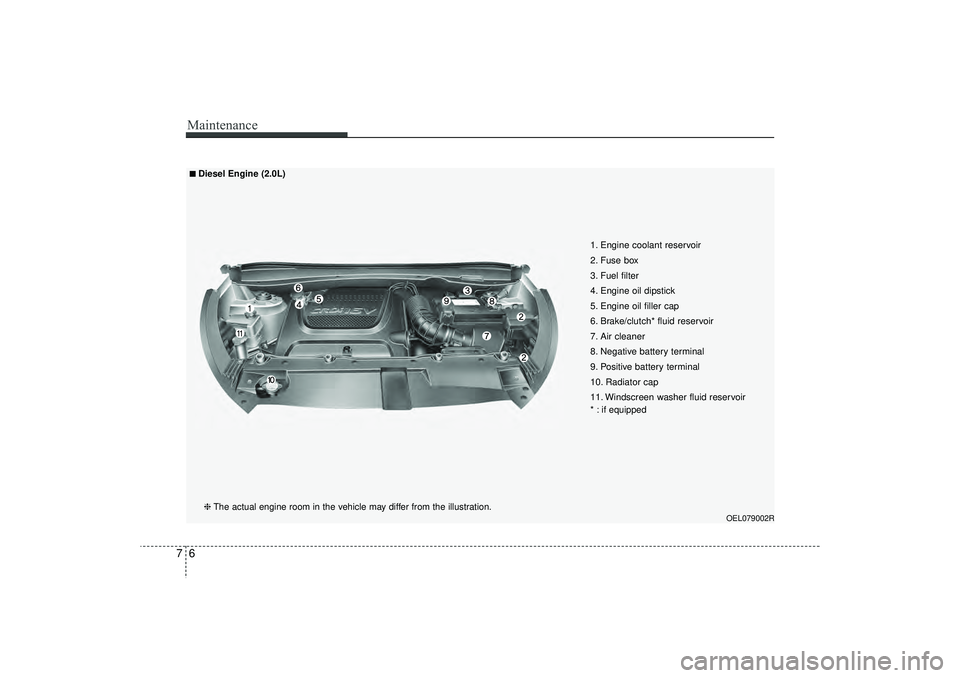

OEL079002R

1. Engine coolant reservoir

2. Fuse box

3. Fuel filter

4. Engine oil dipstick

5. Engine oil filler cap

6. Brake/clutch* fluid reservoir

7. Air cleaner

8. Negative battery terminal

9. Positive battery terminal

10. Radiator cap

11. Windscreen washer fluid reservoir* : if equipped

■ ■Diesel Engine (2.0L)❈The actual engine room in the vehicle may differ from the illustration.

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 6

Page 468 of 550

Maintenance87

Engine compartment precautions

(Diesel engine)• The piezo injector operates at highvoltage (maximum 200v). Therefore,

the following accidents may occur.

- Direct contact with the injector orinjector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room whilst the engine is running.

- Do not touch the injector, injectorwirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector whilst the engine is running.

- People using pacemakers must not go near the engine whilst the engine

is starting or running.

WARNING

- Maintenance work

Performing maintenance work on

a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by a

HYUNDAI authorised repairer.

Working under the bonnet with the engine running is dangerous.

It becomes even more dangerous

when you wear jewellery or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewellery

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before getting

near the engine or cooling fans.

CAUTION

Do not put heavy objects or apply excessive force on top of theengine cover (if equipped) or fuel related parts.

When you inspect the fuel system (fuel lines and fuel injectiondevices), we recommend that you contact a HYUNDAI authorisedrepairer.

Do not drive long time with the engine cover (if equipped)removed.

When checking the engine room, do not go near fire.

Fuel, washer fluid, etc. are flam-mable oils that may cause fire.

Before touching the battery, igni- tion cables and electrical wiring,you should disconnect the bat-tery "-" terminal. You may get an electric shock from the electriccurrent.

When you remove the interior trim cover with a flat bed (-) driv-er, be careful not to damage thecover.

Be careful when you replace and clean bulbs to avoid burns orelectrical shock.

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 8

Page 469 of 550

79

Maintenance

The following lists are vehicle checks and

inspections that should be performed at

the frequencies indicated to help ensure

safe, dependable operation of your vehi-

cle. If you have any question, we recom-

mend that you consult a HYUNDAI

authorised repairer.

These Owner Maintenance Checks are

generally not covered by warranties and

you may be charged for labour, parts and

lubricants used.

Owner maintenance schedule When you stop for fuel: Check the engine oil level.

Check coolant level in coolant reser-voir.

Check the windscreen washer fluid level.

Look for low or under-inflated tyres.

WARNING

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot coolant

and steam may blow out under

pressure. This could cause burns

or other serious injury.

WARNING

- Diesel Engine

Never work on injection system

with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectors

and high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move than 30cm closer to the

ECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

electronic engine control system

produce considerable magnetic

fields.

OWNER MAINTENANCE

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 9

Page 472 of 550

Maintenance12

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMSEngine oil and filterThe engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.Drive beltsInspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filter (cartridge)A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by a HYUNDAI

authorised repairer.

Fuel lines, fuel hoses and con-

nectionsCheck the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by a

HYUNDAI authorised repairer.

WARNING -

Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectors

and high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move than 30cm closer to the

ECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

Common Rail system produce con-

siderable magnetic fields.

CAUTION

When you are inspecting the belt,

place the ignition switch in theLOCK/OFF or ACC position.

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 12

Page 473 of 550

713

Maintenance

Vapour hose and fuel filler capThe vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuel

filler cap is correctly replaced.Vacuum crankcase ventilation

hoses (if equipped)Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filterWe recommend that you use air cleaner

filter for replacement from a HYUNDAI

authorised repairer.Spark plugs (for petrol engine)Make sure to install new spark plugs of

the correct heat range.Cooling systemCheck the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid

(if equipped)Inspect the manual transaxle fluid

according to the maintenance schedule.Automatic transaxle fluid

(if equipped)Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, we recommend

that the fluid be changed by a HYUNDAI

authorised repairer in accordance to the

scheduled maintenance at the beginning

of this chapter.✽ ✽NOTICEAutomatic transaxle fluid colour is basi-

cally red.

As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.

It is normal condition and you should

not judge the need to replace the fluid

based upon the changed colour.

WARNING

Do not disconnect and inspect

spark plugs when the engine is hot.

You may burn yourself.

EL(FL) UK 7.QXP 3/4/2015 9:04 PM Page 13

Page 481 of 550

721

Maintenance

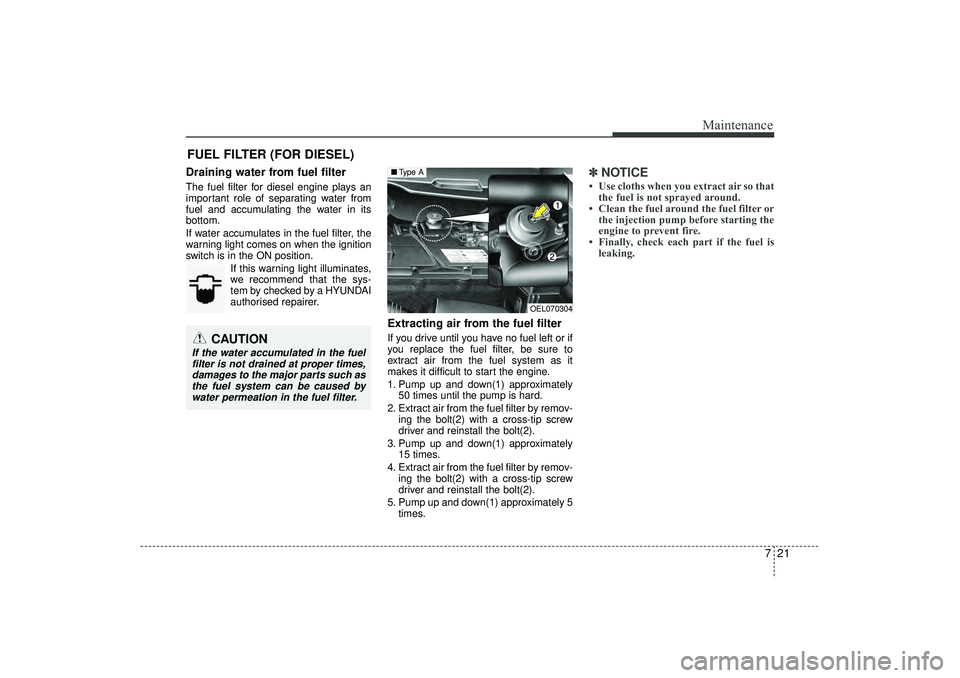

FUEL FILTER (FOR DIESEL)Draining water from fuel filterThe fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in its

bottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position.If this warning light illuminates,

we recommend that the sys-

tem by checked by a HYUNDAI

authorised repairer.

Extracting air from the fuel filterIf you drive until you have no fuel left or if

you replace the fuel filter, be sure to

extract air from the fuel system as it

makes it difficult to start the engine.

1. Pump up and down(1) approximately50 times until the pump is hard.

2. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

3. Pump up and down(1) approximately 15 times.

4. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

5. Pump up and down(1) approximately 5 times.

✽ ✽NOTICE• Use cloths when you extract air so that

the fuel is not sprayed around.

• Clean the fuel around the fuel filter or the injection pump before starting the

engine to prevent fire.

• Finally, check each part if the fuel is leaking.

CAUTION

If the water accumulated in the fuel

filter is not drained at proper times,damages to the major parts such as the fuel system can be caused bywater permeation in the fuel filter.

OEL070304

■ Type A

EL(FL) UK 7.QXP 3/4/2015 9:05 PM Page 21

Page 482 of 550

Maintenance22

7Fuel filter cartridge replacement✽

✽

NOTICEWhen replacing the fuel filter cartridge,

we recommend that you use parts for

replacement from a HYUNDAI autho-

rised repairer.

OLM079011

■ Type B

EL(FL) UK 7.QXP 3/4/2015 9:05 PM Page 22