brake Hyundai Kona 2018 Owner's Manual - RHD (UK, Australia)

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2018, Model line: Kona, Model: Hyundai Kona 2018Pages: 497, PDF Size: 11.7 MB

Page 476 of 497

7-69

7

MaintenanceHigh-pressure washing

• When using high-pressure washers,make sure to maintain sufficient dis-

tance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

• Do not spray the camera, sensors or its surrounding area directly with a

high pressure washer. Shock

applied from high pressure water

may cause the device to not operate

normally.

• Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

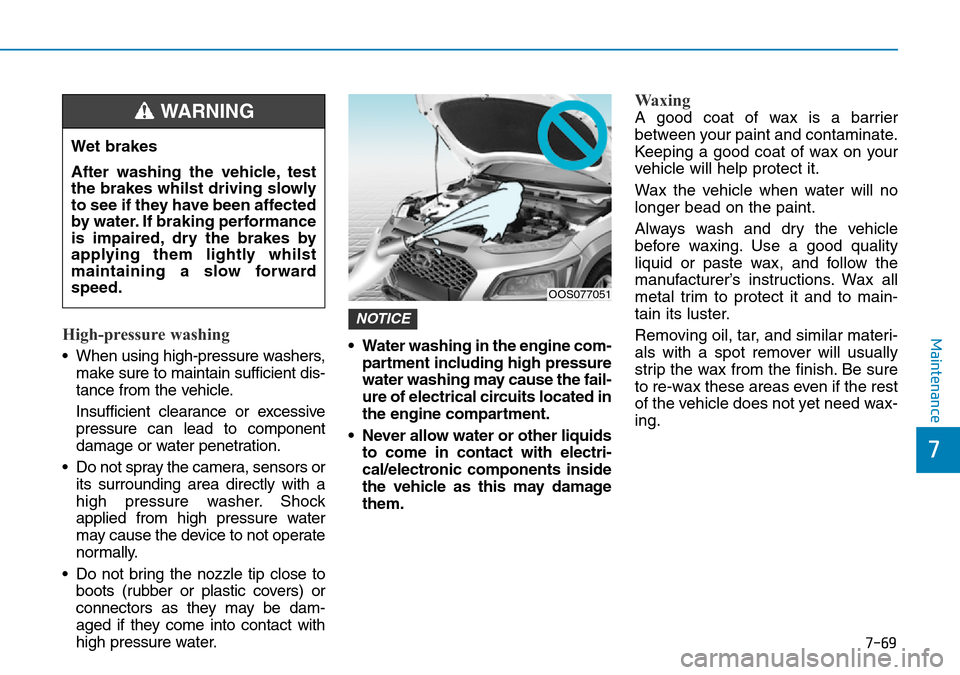

high pressure water. • Water washing in the engine com-

partment including high pressure

water washing may cause the fail-

ure of electrical circuits located in

the engine compartment.

• Never allow water or other liquids to come in contact with electri-

cal/electronic components inside

the vehicle as this may damage

them.

Waxing

A good coat of wax is a barrier

between your paint and contaminate.

Keeping a good coat of wax on your

vehicle will help protect it.

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-

ing.

NOTICE

Wet brakes

After washing the vehicle, test

the brakes whilst driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly whilst

maintaining a slow forward

speed.

WARNING

OOS077051

Page 477 of 497

7-70

Maintenance

• Wiping dust or dirt off the body with a dry cloth will scratch the

finish.

• Do not use steel wool, abrasive cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminium parts.

This may result in damage to the

protective coating and cause dis-

colouration or paint deteriora-

tion.

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body

shop applies anti-corrosion materi-

als to the parts repaired or replaced.

Bright-metal maintenance

• To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

• To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

• During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may

collect on the underbody. If these

materials are not removed, acceler-

ated rusting can occur on underbody

parts such as the fuel lines, frame,

floor pan and exhaust system, even

though they have been treated with

rust protection. Thoroughly flush the vehicle under-

body and wheel openings with luke-

warm or cold water once a month,

after off-road driving and at the end of

each winter. Pay special attention to

these areas because it is difficult to

see all the mud and dirt. It will do

more harm than good to wet down the

road grime without removing it. The

lower edges of doors, rocker panels,

and frame members have drain holes

that should not be allowed to clog with

dirt; trapped water in these areas can

cause rusting.

NOTICE

NOTICE

After washing the vehicle, test

the brakes whilst driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly whilst

maintaining a slow forward

speed.

WARNING

Page 493 of 497

8-8

Specifications & Consumer information

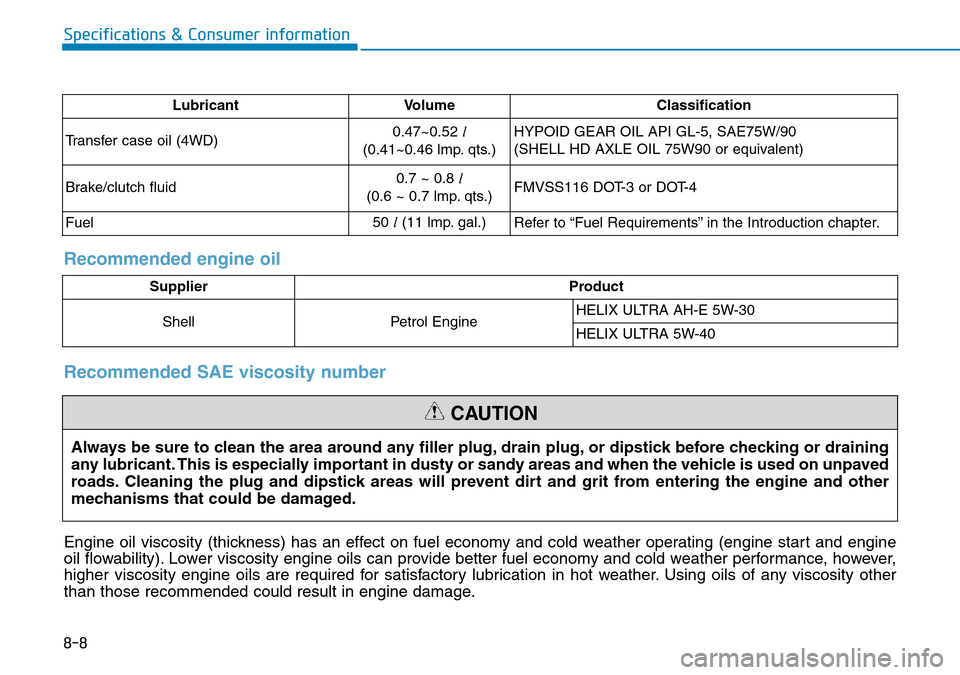

LubricantVolume Classification

Transfer case oil (4WD) 0.47~0.52

l

(0.41~0.46 lmp. qts.) HYPOID GEAR OIL API GL-5, SAE75W/90

(SHELL HD AXLE OIL 75W90 or equivalent)

Brake/clutch fluid 0.7 ~ 0.8 l

(0.6 ~ 0.7 lmp. qts.) FMVSS116 DOT-3 or DOT-4

Fuel 50

l(11 lmp. gal.)

Refer to “Fuel Requirements” in the Introduction chapter.

Recommended engine oil

Supplier Product

Shell Petrol EngineHELIX ULTRA AH-E 5W-30

HELIX ULTRA 5W-40

Always be sure to clean the area around any filler plug, drain plug, or dipstick before checking or draining

any lubricant. This is especially important in dusty or sandy areas and when the vehicle is used on unpaved

roads. Cleaning the plug and dipstick areas will prevent dirt and grit from entering the engine and other

mechanisms that could be damaged.

CAUTION

Recommended SAE viscosity number

Engine oil viscosity (thickness) has an effect on fuel economy and cold weather operating (engine start and engine

oil flowability). Lower viscosity engine oils can provide better fuel economy and cold weather performance, however,

higher viscosity engine oils are required for satisfactory lubrication in hot weather. Using oils of any viscosity other

than those recommended could result in engine damage.