maintenance schedule Hyundai Matrix 2003 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 273 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 6ZF060D2-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. 6ZF060E1-A

o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation andreplace if necessary. Drive belts should bechecked periodically for proper tension andadjusted as necessary.

6ZF060C1-A

o Fuel filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 274 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/ parking brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake pads, calipers and rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust pipe and muffler Visually inspect the exhaust pipes, mufflerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range

of the dipstick, after engine and transaxle areat normal operating temperature. Check theAutomatic Transaxle Fluid level with the en-gine running and the transaxle in neutral, withthe parking brake properly applied. Use DIA-MOND ATF SP- III or SK ATF SP- III when

adding or changing fluid. 6ZF070F1-A

o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling system Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N01E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Valve Clearance

Intake valves: 0.0067 ~ 0.0091 in. (0.17 ~ 0.23mm)

Exhaust valves: 0.0098 ~ 0.0122 in. (0.25 ~ 0.31mm)

Page 281 of 312

OWNER MAINTENANCE

6-6 the level again, allow several minutes for the oil to drain into the sump. Replace the oil fillercap rotating it in a clockwise direction untiltight. The quantity of oil required to raise the level from the minimum to maximum level is approx-imately 1 litre. The distance between the "F" and "L" marks is equal to about 1 liter(Gasoline Engine)/1.2liter(Diesel Engine) of oil.

o The engine oil consumption is strongly

effected by the viscosity and quality of oil,engine rpm and driving condition etc. The engine oil is more consumed under severe driving conditions such as highspeeds and frequent acceleration and de-celeration than normal driving condition.

ZG030E1-A

ENGINE OIL CONSUMPTION Function of engine oil

Engine oil has the primary function of lubricat-

ing and cooling the inside of the engine. Engine oil consumption

It is normal that an engine should consume

some engine oil while normal driving. The cause of oil consumption in a normal engine are asfollows;

o Engine oil is used to lubricate pistons, piston rings and cylinders. A thin film of oil is left on the cylinder wallwhen a piston moves downwards in thecylinder. High negative pressure generatedduring engine operation sucks some of theoil into the combustion chamber. This oil with some oil of the cylinder wall is burned by the high temperature combustiongases during the combustion process. SG040A1-E

ENGINE OIL AND FILTER

REPLACEMENT

SSA6040A

Oil filler cap

Drain plug

Oil filter The engine oil and filter must be changed at

the time or mileage interval specified in the maintenance schedule. If the vehicle is oper-ated under severe or adverse conditions, theoil and filter must be replaced more frequently.

To replace the oil and filter, proceed as fol-

lows:

1. Ensure that the engine is at normal operat- ing temperature and park the vehicle on level ground with the parking brake se-curely applied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plugfrom the sump.

CAUTION: The oil being drained from the engine will

be hot. Care should be exercised to pre- vent scalding.

Diesel engine

Gasoline engine Drain plug

Oil filter

KCHB001A-1

Page 282 of 312

OWNER MAINTENANCE 6-7

SG050A1-E

ENGINE COOLANT CHECKING AND REPLACING WARNING: Do not remove the radiator cap when the

engine is hot, since the system is pressur- ized and coolant may be ejected from theradiator resulting in scalding.

SG050B1-E

Coolant recommendations

G050B01FC

G050B02FC

Gasoline engine Diesel engine

Only ethylene glycol based coolant with a

corrosion inhibitor suited to aluminium alloy engine components should be used in thecooling system. No further additives or inhibi- tors should be used. The coolant specific gravity should be checked as prescribed inthe maintenance schedule to ensure adequatefrost and corrosion protection. In addition, theengine coolant must be replaced at the speci-fied interval since the corrosion inhibitor prop-erties deteriorate with time.

It is important to note that whilst an increase

in the concentration of anti freeze gives anincrease in the level of frost protection, asolution which is in excess of 65% anti freezewill result in reduced frost protection andengine overheating. Therefore the recom-mended concentration of 50% should not beexceeded for general use.

The use of methanol based anti freeze com-

pounds may result in engine overheating andwill invalidate the vehicle warranty.

4. When the oil has drained from the sump,

replace the drain plug using a new washerensuring that the plug is not over tight-ened.

5. Remove the oil filter by rotating counter- clockwise, using a proprietary oil filter re-moval tool if necessary. Note that the oilfilter will contain approximately 0.5 litres ofoil and this should be collected in a suit-able receptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil and rotatingclockwise until the filter contacts the mount-ing and then a further one half turn. Do notover-tighten Tightening torque: 2.3 ~ 2.5 kgf.m

7. Pour the specified quantity of the recom- mended oil into the engine and replace the filler cap. Start the engine and ensure thatno oil leaks exist. Turn off the engine andafter a couple minutes, recheck the oillevel.

WARNING:Prolonged and repeated contact with used

engine oils may result in serious skin dis-orders including dermatitis and cancer.Avoid contact with skin as far as possibleand always wash thoroughly after any con-tact. Keep used oils out of reach of chil-dren. It is illegal to pollute drains, watercourses and soil. Use only authorized wastecollection facilities including civic amenity sites and garages for the disposal of usedoil and oil filters. If in doubt, contact thelocal authority for disposal instructions.

Page 283 of 312

OWNER MAINTENANCE

6-8 SG050C1-E

Engine Coolant Level

SG050D1-E

To Change the Engine Coolant The engine coolant should be changed at

those intervals specified in the vehicle main- tenance schedule in Section 5.

NOTE:Care should be taken to ensure that cool-

ant is not allowed to spill onto thepaintwork since the finish may becomedamaged. If coolant spillage occurs, theaffected area should be rinsed thoroughlywith water. The engine coolant level may be observed

through the side of the plastic coolant reservoir(expansion tank) when the engine is cold. If thelevel is below the "LOW" mark, add coolant ofthe correct concentration until the level is be-tween the "LOW" and "Full" marks. If the levelfalls below the "LOW" mark on a regular basisdespite being topped up, consult a Hyundaidealer. 1. Park the vehicle on level ground and en-

sure that the parking brake is firmly ap-plied, and the engine allowed to cool. DO NOT ATTEMPT THIS OPERATION WHILST THE ENGINE IS HOT SINCEBURNING OR SCALDING MAY RESULT.

2. Prepare a suitable receptacle to collect the displaced coolant and position this under theradiator drain tap.

3. With the heater temperature control set to the "HOT" position, remove the radiator capand open the radiator drain tap.

4. When the engine coolant has drained com- pletely, close the drain tap ensuring that thisis not over tightened.

5. Prepare a suitable quantity of new engine coolant (refer to section 9) and pour thisinto the radiator.

6. Start the engine with the radiator cap still removed and continue to add coolant as thelevel decreases as air is expelled from thesystem. When the level remains constant,replace the radiator cap and replenish thecoolant reservoir.

7. When the engine is hot, check to ensure that no coolant leaks are present.

WARNING: The cooling fan is controlled by engine coolant temperature and may sometimesoperate even when the engine is not run-ning. Use extreme caution when workingnear the blades of the cooling fan so that

G050C01FC

G050C02FC

Diesel engine

Gasoline engine

NOTE: It is imperative that vehicles fitted with an

air conditioning system have a coolant concentration of the recommended strengthat all times. The use of the air conditioningsystem when the cooling system is filledwith water only will result in the heatermatrix freezing and subsequently bursting.

Page 286 of 312

OWNER MAINTENANCE 6-11

specified in the maintenance schedule. Only those lubricants specified below should beused in order to prevent gear shifting difficul-ties or transaxle damage.

WARNING: The transaxle lubricant level should only

be checked when the engine is cold to preclude the possibility of personal injuryby contact with hot components. Recommended Oil

Use only the approved transaxle lubricant.

The recommended lubricants are complete in themselves and the use of additives is neitherrequired nor recommended. The use of addi-tives may invalidate the vehicle warranty. Transaxle Lubricant Level

Checking

SSA6100B

SG090A2-E

WINDSCREEN WASHER RESERVOIR REPLENISHMENT

and water. If the wipers continue to streak or smear the glass, replace them with genuineHyundai replacement.

CAUTION:

o Do not operate the wipers on dry glass since rapid wear and damage to thewindscreen glass may result.

o Keep the blade rubber out of contact with petroleum products such as en-gine oil, gasoline, etc.

The level of windscreen washer fluid available

should be checked on a daily basis. The levelof fluid will be visible through the side of thereservoir. When the fluid is to be replenished,only a proprietary screen wash additive shouldbe used and in the concentration recommended SG100A1-E

MANUAL TRANSAXLE LUBRICANT The manual transaxle lubricant must be

checked and or changed at the intervals

G110A01EDrain plug

Filler plug

HFC5010 by the manufacturer. The windscreen washer reservoir has a total capacity of 3 litres.

CAUTION: Engine coolant anti freeze must not be

used in the windscreen washer system since damage to the paintwork may result.

Undiluted windscreen washer additive must

not be allowed to come into contact with thepaintwork. If spillage occurs, flush the af-fected area immediately with water. Do notoperate the windscreen washer for morethan 15 seconds continuously or whenthe reservoir is empty since damage tothe washer pump will result.

Page 287 of 312

OWNER MAINTENANCE

6-12 SG110D2-E

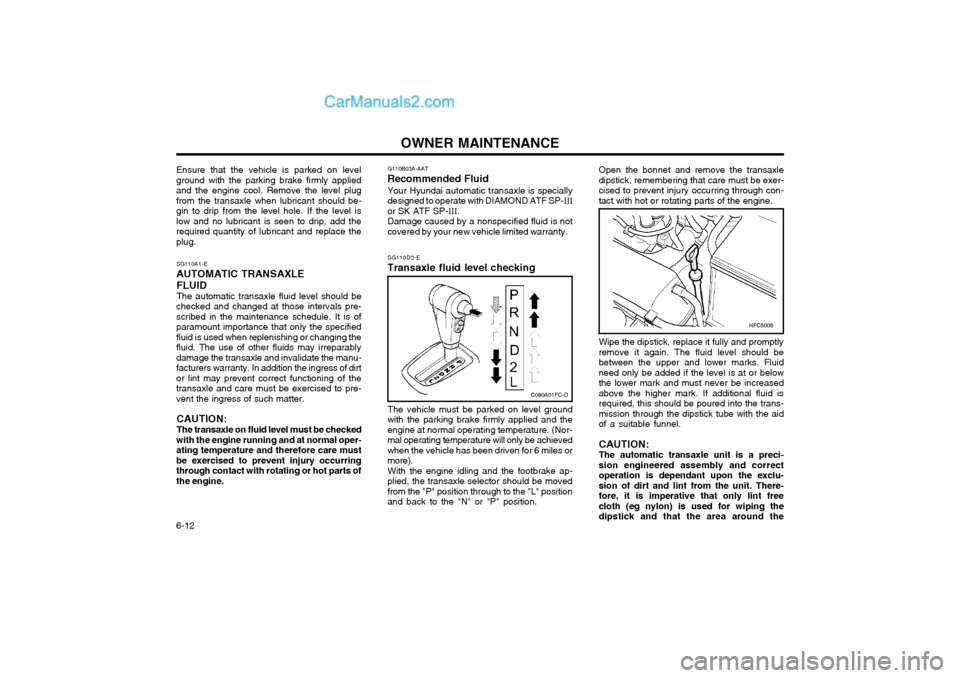

Transaxle fluid level checking

The vehicle must be parked on level ground

with the parking brake firmly applied and the engine at normal operating temperature. (Nor-mal operating temperature will only be achievedwhen the vehicle has been driven for 6 miles ormore). With the engine idling and the footbrake ap-

plied, the transaxle selector should be movedfrom the "P" position through to the "L" positionand back to the "N" or "P" position.

C090A01FC-D

SG110A1-E

AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should be

checked and changed at those intervals pre- scribed in the maintenance schedule. It is ofparamount importance that only the specifiedfluid is used when replenishing or changing thefluid. The use of other fluids may irreparablydamage the transaxle and invalidate the manu-facturers warranty. In addition the ingress of dirtor lint may prevent correct functioning of thetransaxle and care must be exercised to pre-vent the ingress of such matter.

CAUTION: The transaxle on fluid level must be checked

with the engine running and at normal oper- ating temperature and therefore care mustbe exercised to prevent injury occurringthrough contact with rotating or hot parts ofthe engine. G110B03A-AAT

Recommended Fluid Your Hyundai automatic transaxle is specially designed to operate with DIAMOND ATF SP- III

or SK ATF SP- III.

Damage caused by a nonspecified fluid is notcovered by your new vehicle limited warranty.

Wipe the dipstick, replace it fully and promptlyremove it again. The fluid level should bebetween the upper and lower marks. Fluidneed only be added if the level is at or belowthe lower mark and must never be increasedabove the higher mark. If additional fluid isrequired, this should be poured into the trans-mission through the dipstick tube with the aidof a suitable funnel. CAUTION: The automatic transaxle unit is a preci-sion engineered assembly and correctoperation is dependant upon the exclu-sion of dirt and lint from the unit. There-fore, it is imperative that only lint freecloth (eg nylon) is used for wiping thedipstick and that the area around the

HFC5008

Ensure that the vehicle is parked on level ground with the parking brake firmly appliedand the engine cool. Remove the level plugfrom the transaxle when lubricant should be-gin to drip from the level hole. If the level islow and no lubricant is seen to drip, add therequired quantity of lubricant and replace theplug. Open the bonnet and remove the transaxledipstick, remembering that care must be exer-cised to prevent injury occurring through con-tact with hot or rotating parts of the engine.

Page 291 of 312

OWNER MAINTENANCE

6-16

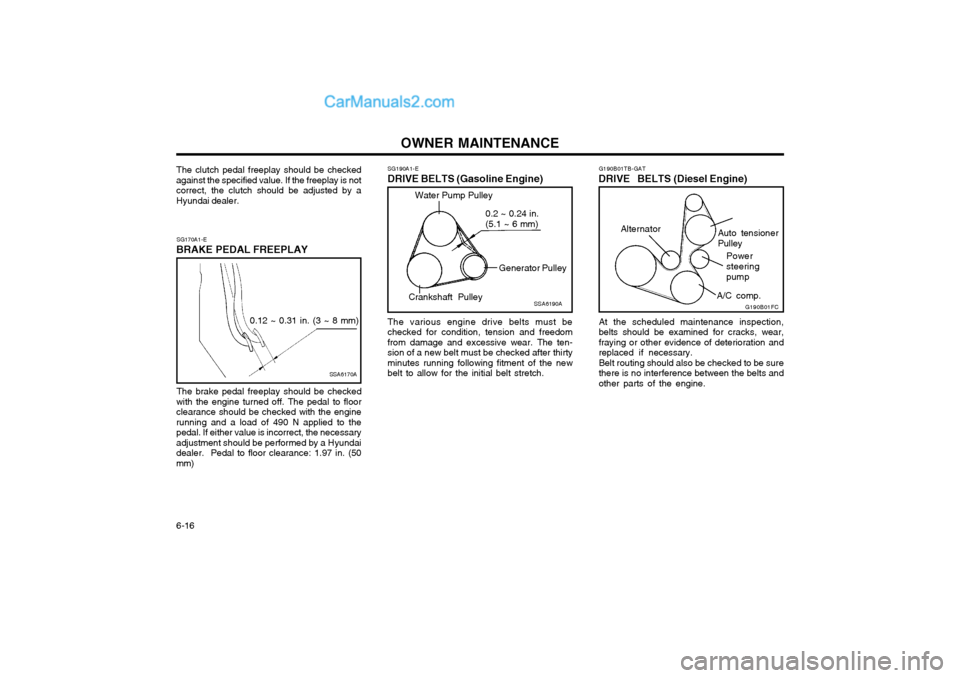

The clutch pedal freeplay should be checked against the specified value. If the freeplay is notcorrect, the clutch should be adjusted by aHyundai dealer.

SG170A1-E

BRAKE PEDAL FREEPLAY

SSA6170A

0.12 ~ 0.31 in. (3 ~ 8 mm)

The brake pedal freeplay should be checked

with the engine turned off. The pedal to floor clearance should be checked with the enginerunning and a load of 490 N applied to thepedal. If either value is incorrect, the necessaryadjustment should be performed by a Hyundaidealer. Pedal to floor clearance: 1.97 in. (50mm) SG190A1-E

DRIVE BELTS (Gasoline Engine)

SSA6190A

Water Pump Pulley

Generator Pulley

Crankshaft Pulley 0.2 ~ 0.24 in. (5.1 ~ 6 mm)

The various engine drive belts must be checked for condition, tension and freedomfrom damage and excessive wear. The ten-sion of a new belt must be checked after thirtyminutes running following fitment of the newbelt to allow for the initial belt stretch.

G190B01TB-GAT

DRIVE BELTS (Diesel Engine)

At the scheduled maintenance inspection, belts should be examined for cracks, wear,fraying or other evidence of deterioration andreplaced if necessary.Belt routing should also be checked to be surethere is no interference between the belts andother parts of the engine.

G190B01FC

Auto tensioner Pulley Powersteeringpump

A/C comp.

Alternator

Page 301 of 312

EMISSION CONTROL SYSTEM 7-1

SH000A1-E

7. EMISSION

CONTROL SYSTEM

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the ve-hicle is destined, the emission control systemwill comprise one or more of the followingemission control devices. (1) Crankcase emission control system (2) Evaporative emission control system (3) Exhaust emission control system In order that the proper functioning of the emis- sion control systems may be ensured, it isrecommended that the vehicle is inspected andmaintained by an authorized Hyundai dealer inaccordance with the maintenance schedule inthis manual. SH010B1-E 1. CRANKCASE EMISSION CONTROL SYSTEM

The positive crankcase ventilation system is employed to prevent air pollution caused byblow-by gases being emitted from the crank-case by introducing fresh air to the crankcase through the air cleaner where this mixes withblow-by gases and then passes through thePCV valve into the intake manifold from whereit subsequently enters the combustion cham-ber and is burned.

SH010D1-E 3. EXHAUST EMISSION CONTROL SYSTEM The exhaust emission control system is a highlyeffective system which controls exhaust emis-sion while maintaining good vehicle perfor-mance.

SH010C1-E

2. EVAPORATIVE EMISSION

CONTROL SYSTEM

The Evaporative Emission Control System is designed to prevent fuel vapours from escap-ing into the atmosphere through the fuel tankventilation system.Whilst the engine is not running, fuel vapoursgenerated inside the fuel tank are absorbedand stored in a charcoal canister. When theengine is started, the vapours stored in thecanister are drawn into the induction systemthrough the purge control solenoid valve andare subsequently burned.The purge control solenoid valve is controlledby the ECU; when the engine coolant tempera-ture is low or the engine is idling, the purgecontrol valve is closed and fuel vapours remainstored in the canister. Under normal runningconditions when the engine is warm, the valveopens and the vapours are drawn into the inlettract and subsequently burned in the combus-tion chamber. SH020A1-E

Catalytic Convertor Operation Precautions; For a gasoline engine Hyundai Matrix models are fitted with catalytic convertors which require special operatingconsiderations. The catalytic convertor servesto oxidize certain noxious elements of theexhaust gases leaving the engine to reduce thelevel of pollutants emitted from the vehicle and,provided that care is exercised to prevent dam-age, the catalyst will operate efficiently for thelife of the vehicle.

7HFC5013

Catalytic Converter

Page 311 of 312

INDEX10-3

L LIGHTING SWITCH ....................................................................... 1-35LUGGAGE NET ............................................................................ 1-49 LUMBAR SUPPORT ADJUSTMENT ............................................... 1-9 M MAINTENANCE AND SERVICING REQUIREMENTS ..................... 5-1MAINTENANCE UNDER SEVERE USAGE CONDITIONS ............. 5-5MANUAL TRANSAXLE .................................................................... 2-5 MANUAL TRANSAXLE LUBRICANT ............................................. 6-11 MAP LIGHT ................................................................................... 1-43MULTI BOX ................................................................................... 1-44MULTI FUNCTION SWITCH .......................................................... 1-35 O OVERDRIVE SWITCH ..................................................................... 2-9 P PARKING BRAKE ......................................................................... 1-46POWER OUTLET .......................................................................... 1-47POWER STEERING FLUID LEVEL ............................................... 6-18 POWER STEERING HOSES ......................................................... 6-19 POWER WINDOW .......................................................................... 1-7PROTECTING YOUR HYUNDAI FROM CORROSION ................... 4-1

RREAR FOG AUDIBLE WARNING SOUND ................................... 1-32REAR FOG LIGHT SWITCH .......................................................... 1-38 REAR SEAT ARM REST ............................................................... 1-40 REAR SEAT WARNING ............................................................... 1-12RECOMMENDED SHIFT SPEEDS ................................................. 2-6REMOTE FUEL FILLER LID RELEASE .............................. 1-48 ~ 1-49REMOVAL OF WATER FROM THE FUEL FILTER ..................... 6-19REPLACING LIGHT BULBS ......................................................... 6-19 ROOF RACK ................................................................................ 1-50 RUNNING IN ................................................................................... 1-2 S SCHEDULED MAINTENANCE ........................................................ 5-2SEAT ADJUSTMENT .......................................................... 1-8 ~ 1-11 SEAT BELT PRECAUTIONS ......................................................... 1-13 SEAT BELTS ...................................................................... 1-14 ~ 1-16SEAT CUSHION HEIGHT ADJUSTMENT ....................................... 1-9SEAT WARMER ............................................................................ 1-12SERVICE HISTORY ........................................................................ 5-1SIDE VENTILATOR ....................................................................... 1-52 SMOOTH CORNERING ................................................................ 2-11 SNOW TYRES ................................................................................ 8-1SPARE WHEEL ............................................................................... 3-3SPARKING PLUG REPLACEMENT ................................................ 6-9