check engine Hyundai Matrix 2004 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Matrix, Model: Hyundai Matrix 2004Pages: 317, PDF Size: 5.12 MB

Page 151 of 317

DO-IT-YOURSELF MAINTENANCE 6-17

G140B01A-AAT

Checking the Air Conditioning Operation

1. Start the engine and let it run at a fast idle for

several minutes with the air conditioning set at the maximum cold setting.

2. If the air coming out of the in-dash vents is not cold, have the air conditioning systeminspected by your Hyundai dealer.

CAUTION: Running the air conditioning system for extended periods of time with a low refriger-ant level may damage the compressor. G140C01A-AAT

Lubrication To lubricate the compressor and the seals in the system, the air conditioning should be runfor at least 10 minutes each week. This isparticularly important during cool weather whenthe air conditioning system is not otherwise inuse.

G150A01A-GAT

CHECKING STEERING WHEEL FREEPLAY

To check the steering wheel freeplay, stop the

car with the wheels pointed straight ahead and gently move the steering wheel back and forth.Use very light finger pressure and be sensitiveto changes in resistance that mark the limits ofthe freeplay. If the freeplay is greater thanspecified, have it inspected by your Hyundaidealer and adjusted or repaired if necessary.

G150A01FC

G140D01S-GAT

Checking the Compressor Drive Belt

When the air conditioning is being used regular- ly, the compressor drive belt tension should bechecked at least once a month. To check the drive belt tension, press down on the belt halfway between the engine crankshaftand compressor pulleys. Pressing with yourfinger, you should not be able to deflect this beltanymore than 8.0 mm. If you have the instru-ments to check it with a force of 98N (22 lb.),the deflection should be approx. 8.0 mm (0.315in.). If the belt is too loose, have it adjusted byyour Hyundai dealer.

G140D01A

A/C

CRANK PULLEY

TENSION PULLEY

30 mm (1.18 in.)

8mm(0.315 in.)

Page 152 of 317

DO-IT-YOURSELF MAINTENANCE

6-18 G180A01A-GAT

CHECKING BRAKE PEDAL CLEARANCE

You need a helper to check the brake pedal

clearance. With the engine running, have your helper press down on the brake pedal severaltimes and then hold it down with a force of about490N (50 kg, 110 lbs). The brake pedal clear-ance is the distance from the top surface of thebrake pedal to the asphalt sheeting under thefloor mat. If the brake pedal clearance is notwithin the limits specified in the illustration, haveit inspected by your Hyundai dealer and adjust-ed or repaired if necessary.

SSA6180A

45.1 mm (1.78 in.)

G170A01A-GAT

CHECKING BRAKE PEDAL FREE-PLAY

With the engine off, press down on the brake

pedal several times to reduce the vacuum in the brake booster.

Then, using your hand, press down slowly on

the brake pedal until you feel a change inresistance. This is the brake pedal freeplay.The freeplay should be within the limits speci-fied in the illustration. If it is not, have it inspect-ed by your Hyundai dealer and adjusted orrepaired if necessary.

SSA6170A

3 ~ 8 mm (0.12 ~ 0.31 in.)

G160A01A-GAT

CHECKING CLUTCH PEDAL FREE-PLAY

With the engine off, press lightly on the clutch

pedal until you feel a change in resistance. This is the clutch pedal freeplay. The freeplay shouldbe within the limits specified in the illustration. Ifit is not, have it inspected by your Hyundaidealer and adjusted or repaired if necessary.

G160A01E

6 ~ 13 mm (0.24 ~ 0.51 in.)

Page 153 of 317

DO-IT-YOURSELF MAINTENANCE 6-19

G190A01A-GAT

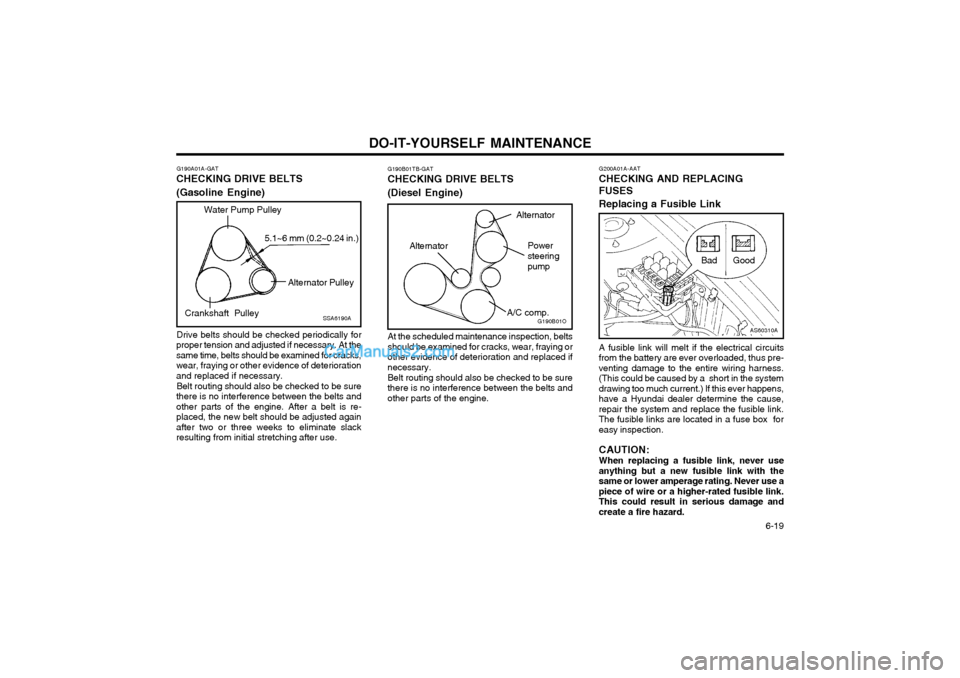

CHECKING DRIVE BELTS (Gasoline Engine)

Drive belts should be checked periodically for

proper tension and adjusted if necessary. At the same time, belts should be examined for cracks,wear, fraying or other evidence of deteriorationand replaced if necessary.

Belt routing should also be checked to be sure

there is no interference between the belts andother parts of the engine. After a belt is re-placed, the new belt should be adjusted againafter two or three weeks to eliminate slackresulting from initial stretching after use.

SSA6190A

Water Pump Pulley

Alternator Pulley

Crankshaft Pulley 5.1~6 mm (0.2~0.24 in.)

G200A01A-AAT

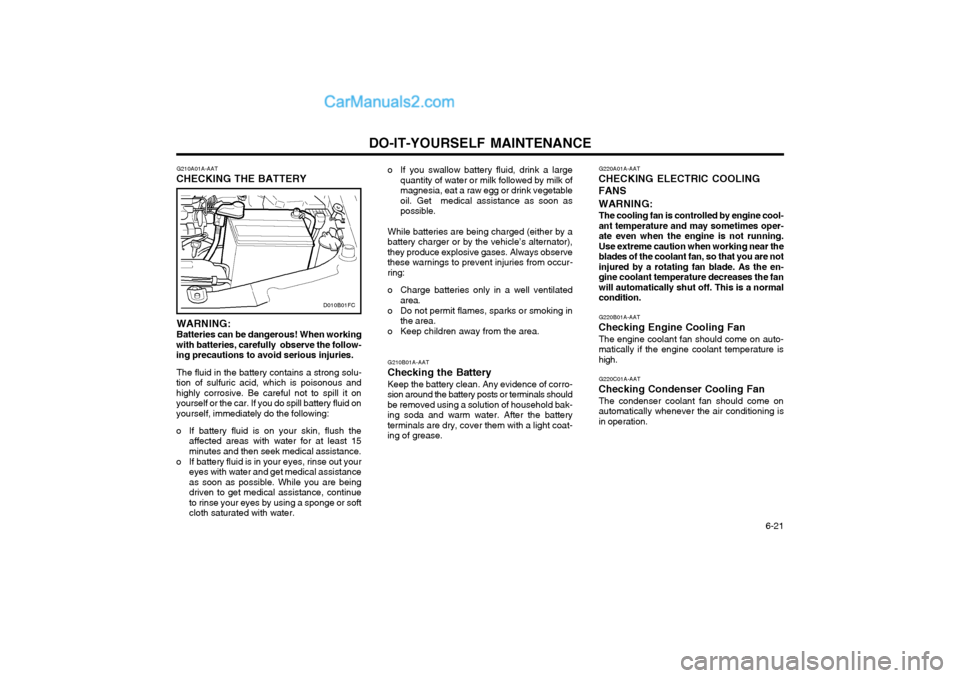

CHECKING AND REPLACING FUSES Replacing a Fusible Link

A fusible link will melt if the electrical circuits

from the battery are ever overloaded, thus pre- venting damage to the entire wiring harness.(This could be caused by a short in the systemdrawing too much current.) If this ever happens,have a Hyundai dealer determine the cause,repair the system and replace the fusible link.The fusible links are located in a fuse box foreasy inspection.

CAUTION: When replacing a fusible link, never use

anything but a new fusible link with the same or lower amperage rating. Never use apiece of wire or a higher-rated fusible link.This could result in serious damage andcreate a fire hazard.

AS60310A

Bad Good

G190B01TB-GAT

CHECKING DRIVE BELTS (Diesel Engine)

At the scheduled maintenance inspection, belts should be examined for cracks, wear, fraying orother evidence of deterioration and replaced ifnecessary. Belt routing should also be checked to be sure there is no interference between the belts andother parts of the engine.G190B01O

Power steeringpump

A/C comp.

Alternator

Alternator

Page 155 of 317

DO-IT-YOURSELF MAINTENANCE 6-21

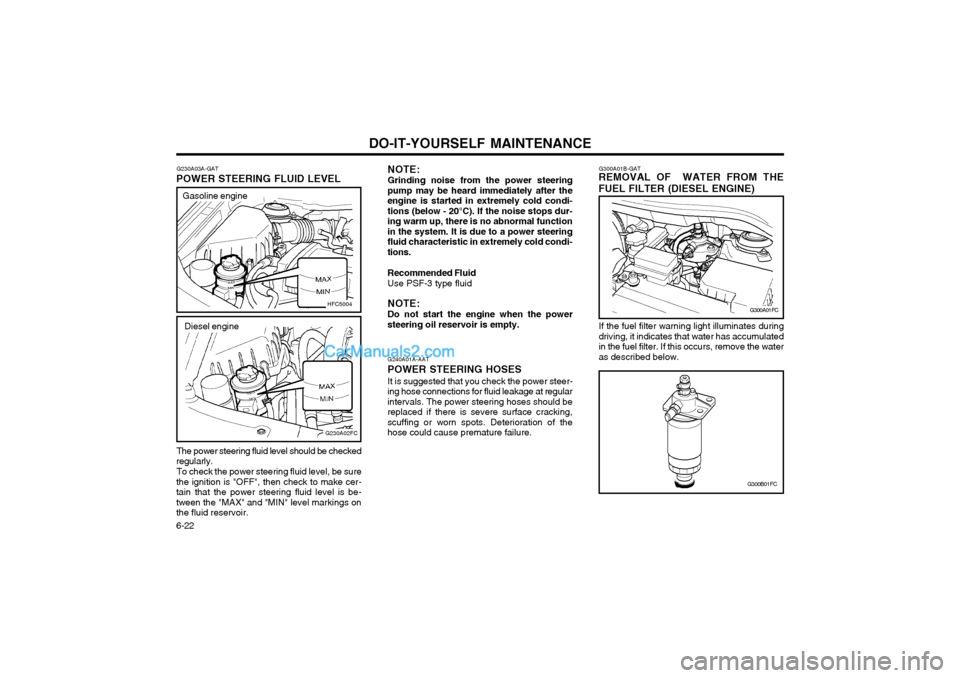

G210A01A-AAT

CHECKING THE BATTERY

WARNING: Batteries can be dangerous! When working

with batteries, carefully observe the follow- ing precautions to avoid serious injuries.

The fluid in the battery contains a strong solu-

tion of sulfuric acid, which is poisonous andhighly corrosive. Be careful not to spill it onyourself or the car. If you do spill battery fluid onyourself, immediately do the following:

o If battery fluid is on your skin, flush the affected areas with water for at least 15 minutes and then seek medical assistance.

o If battery fluid is in your eyes, rinse out your eyes with water and get medical assistanceas soon as possible. While you are beingdriven to get medical assistance, continueto rinse your eyes by using a sponge or softcloth saturated with water.

D010B01FC

G220A01A-AAT

CHECKING ELECTRIC COOLING FANS WARNING: The cooling fan is controlled by engine cool- ant temperature and may sometimes oper-ate even when the engine is not running.Use extreme caution when working near theblades of the coolant fan, so that you are notinjured by a rotating fan blade. As the en-gine coolant temperature decreases the fanwill automatically shut off. This is a normalcondition. G220B01A-AAT

Checking Engine Cooling Fan The engine coolant fan should come on auto- matically if the engine coolant temperature ishigh. G220C01A-AAT

Checking Condenser Cooling Fan The condenser coolant fan should come on automatically whenever the air conditioning isin operation.

G210B01A-AAT

Checking the Battery Keep the battery clean. Any evidence of corro-

sion around the battery posts or terminals shouldbe removed using a solution of household bak-ing soda and warm water. After the batteryterminals are dry, cover them with a light coat-ing of grease.

o If you swallow battery fluid, drink a large

quantity of water or milk followed by milk ofmagnesia, eat a raw egg or drink vegetableoil. Get medical assistance as soon aspossible.

While batteries are being charged (either by abattery charger or by the vehicle’s alternator),they produce explosive gases. Always observethese warnings to prevent injuries from occur-ring:

o Charge batteries only in a well ventilated area.

o Do not permit flames, sparks or smoking in the area.

o Keep children away from the area.

Page 156 of 317

DO-IT-YOURSELF MAINTENANCE

6-22

G240A01A-AAT

POWER STEERING HOSES

It is suggested that you check the power steer-

ing hose connections for fluid leakage at regular intervals. The power steering hoses should bereplaced if there is severe surface cracking,scuffing or worn spots. Deterioration of thehose could cause premature failure. NOTE: Grinding noise from the power steering

pump may be heard immediately after the engine is started in extremely cold condi-tions (below - 20°C). If the noise stops dur-ing warm up, there is no abnormal functionin the system. It is due to a power steeringfluid characteristic in extremely cold condi-tions.

Recommended Fluid Use PSF-3 type fluid NOTE: Do not start the engine when the power

steering oil reservoir is empty. G300A01B-GAT

REMOVAL OF WATER FROM THE FUEL FILTER (DIESEL ENGINE)

If the fuel filter warning light illuminates during driving, it indicates that water has accumulatedin the fuel filter. If this occurs, remove the wateras described below.

G300A01FC

G300B01FC

G230A03A-GAT

POWER STEERING FLUID LEVEL

HFC5004

Gasoline engine

The power steering fluid level should be checked

regularly.

To check the power steering fluid level, be sure

the ignition is "OFF", then check to make cer- tain that the power steering fluid level is be-tween the "MAX" and "MIN" level markings onthe fluid reservoir.

G230A02FC

Diesel engine

Page 157 of 317

DO-IT-YOURSELF MAINTENANCE 6-23

G260A03A-GAT

REPLACING HEADLIGHT BULBS Before attempting to replace a headlight bulb,

be sure the switch is turned to the "OFF" position.

The next paragraph shows how to reach the

headlight bulbs so they may be changed. Besure to replace the burned-out bulb with one ofthe same number and wattage rating.

CAUTION: Keep the lamps out of contact with petro-

leum products, such as oil, gasoline, etc.

1. Loosen the drain plug at the bottom of the

fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine isstarted. If in doubt, consult your nearest authorized HYUNDAI dealer.

WARNING: Be sure to carefully wipe away any water

drained out in this manner, because the fuelmixed in the water might be ignited andresult in a fire. 5. Push the bulb spring for removing the head-

light bulb.

6. Remove the protective cap from the replace- ment bulb and install the new bulb by match-ing the plastic base with the headlight hole.Install the dust cover after retightening thebulb spring and reconnect the power cord.

7. Use the protective cap and carton to dis- pose of the old bulb.

8. Check for proper headlight aim.

WARNING The halogen bulb contains gas under pres-

sure and if impacted could shatter, resulting in flying fragments. Always wear eye pro-tection when servicing the bulb. Protect thebulb against abrasions or scratches andagainst liquids when lighted. Turn on thebulb only when installed in a headlight. Re-place the headlight if damaged or cracked.Keep the bulb out of the reach of childrenand dispose of the used bulb with care.

G270A02FC

G270A02A-GAT

HEADLIGHT BULB Replacement instructions:

G270A01FC

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its plastic base, avoid touching the glass.

3. Disconnect the power cord from the bulb base in the back of the headlight.

4. Remove the dust cover.

Page 158 of 317

DO-IT-YOURSELF MAINTENANCE

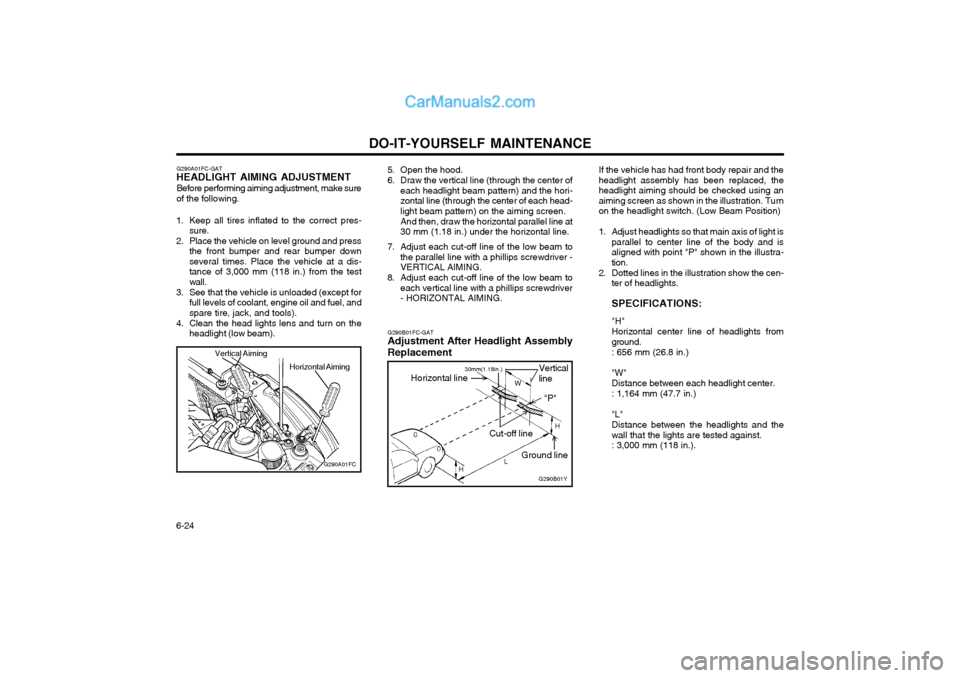

6-24 If the vehicle has had front body repair and the headlight assembly has been replaced, theheadlight aiming should be checked using anaiming screen as shown in the illustration. Turnon the headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of light is

parallel to center line of the body and is aligned with point "P" shown in the illustra-tion.

2. Dotted lines in the illustration show the cen- ter of headlights. SPECIFICATIONS: "H" Horizontal center line of headlights from ground. : 656 mm (26.8 in.) "W" Distance between each headlight center.: 1,164 mm (47.7 in.) "L" Distance between the headlights and the wall that the lights are tested against.: 3,000 mm (118 in.).

5. Open the hood.

6. Draw the vertical line (through the center of

each headlight beam pattern) and the hori- zontal line (through the center of each head-light beam pattern) on the aiming screen. And then, draw the horizontal parallel line at 30 mm (1.18 in.) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver -VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screwdriver- HORIZONTAL AIMING.

G290B01FC-GAT

Adjustment After Headlight Assembly Replacement

G290B01Y

Vertical line

Cut-off line Ground line

Horizontal line

LW

H

H "P"30mm(1.18in.)

G290A01FC-GAT

HEADLIGHT AIMING ADJUSTMENT

Before performing aiming adjustment, make sure of the following.

1. Keep all tires inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper and rear bumper downseveral times. Place the vehicle at a dis-tance of 3,000 mm (118 in.) from the testwall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, andspare tire, jack, and tools).

4. Clean the head lights lens and turn on the headlight (low beam).

G290A01FC

Horizontal Aiming

Vertical Aiming

Page 169 of 317

VEHICLE SPECIFICATIONS

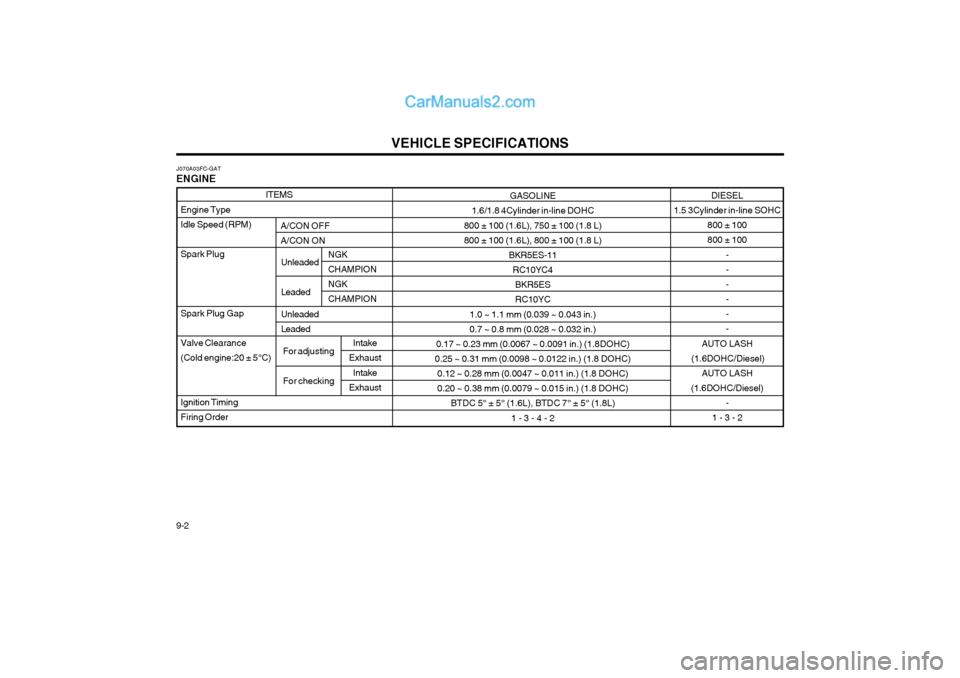

9-2 DIESEL

1.5 3Cylinder in-line SOHC 800 ± 100 800 ± 100

--- - --

AUTO LASH

(1.6DOHC/Diesel) AUTO LASH

(1.6DOHC/Diesel) -

1 - 3 - 2

GASOLINE

1.6/1.8 4Cylinder in-line DOHC

800 ± 100 (1.6L), 750 ± 100 (1.8 L)800 ± 100 (1.6L), 800 ± 100 (1.8 L) BKR5ES-11

RC10YC4BKR5ESRC10YC

1.0 ~ 1.1 mm (0.039 ~ 0.043 in.)0.7 ~ 0.8 mm (0.028 ~ 0.032 in.)

0.17 ~ 0.23 mm (0.0067 ~ 0.0091 in.) (1.8DOHC)

0.25 ~ 0.31 mm (0.0098 ~ 0.0122 in.) (1.8 DOHC)

0.12 ~ 0.28 mm (0.0047 ~ 0.011 in.) (1.8 DOHC)0.20 ~ 0.38 mm (0.0079 ~ 0.015 in.) (1.8 DOHC) BTDC 5° ± 5° (1.6L), BTDC 7° ± 5° (1.8L)

1 - 3 - 4 - 2

Intake

Exhaust

Intake

Exhaust

Engine Type Idle Speed (RPM) Spark Plug Spark Plug Gap Valve Clearance (Cold engine:20 ± 5°C) Ignition Timing Firing Order NGK CHAMPION NGKCHAMPION

Unleaded Leaded Unleaded Leaded

For adjusting For checking

J070A03FC-GAT ENGINE

ITEMS

A/CON OFF A/CON ON

Page 172 of 317

INDEX

10-2 Driving

Economical dr iving ........................................................................ 2-10

Smooth cornering .......................................................................... 2-10

Winter driving ................................................................................ 2-10

E Emissions Control Systems ................................................................ 7-1

Engine Before starting the engine ............................................................... 2-2Compartment .......................................................................... 6-1 ~ 6-3

Coolant ................................................................................. 6-8 ~ 6-10

Coolant temperature gauge ........................................................... 1-36

If the engine overheats ................................................................... 3-2

Number ............................................................................................ 8-1

Oil ........................................................................................... 6-4 ~ 6-5Starting ............................................................................................ 2-3

Engine Exhaust Can Be Dangerous ................................................... 2-1

FFold-up Tray ...................................................................................... 1-50

Front Fog Light Sw itch ...................................................................... 1-42

Front Seats Adjustable front seats ..................................................................... 1-9

Lumbar support control ................................................................. 1-10

Seat cushion height adjustment .................................................... 1-10

Fuel Capacity .......................................................................................... 9-1

Gauge ............................................................................................ 1-36

Recommendations ........................................................................... 1-1

Fuel Filler Lid

Remote release ............................................................................. 1-52

Fuse Panel Description .......................................................... 6-26 ~ 6-28

Fuses ...................................................................................... 6-19 ~6-20 GGeneral Checks

.................................................................................. 6-4

Glove box .......................................................................................... 1-47

H Hazard Warning System ................................................................... 1-41

Headlight Aiming Adjustment ........................................................... 6-24

Headlight Bulb ................................................................................... 6-23

Headlight Leveling Device System ........................................ 1-44 ~ 1-45

Heating and Ventilation

Air flow control .............................................................................. 1-58

Air intake control ........................................................................... 1-57

Bi-level heating .............................................................................. 1-59

Fan speed control ......................................................................... 1-57

Heating controls ............................................................................ 1-59

Temperature control ...................................................................... 1-59

High-mounted Rear Stoplight ............................................................ 1-50

Hood Release ................................................................................... 1-51

Horn .................................................................................................. 1-55

IIgnition Switch ..................................................................................... 2-2

Immobilizer System ............................................................................. 1-3

Instrument Cluster and Indicator ............................................ 1-31 ~ 1-35

Instruments and Controls .................................................................. 1-30

Interior Light Interior light ................................................................................... 1-47

Map light ........................................................................................ 1-46

Intermittent Wiper .............................................................................. 1-41

JJump Starting ...................................................................................... 3-1

Page 212 of 317

CONTROLS AND EQUIPMENT

1- 30 SB210E1-E

OVERDRIVE OFF INDICATOR LIGHT (Not all models)

When the overdrive (4th gear) switch is turned off and the operation of overdrive (4th gear) is cancelled, the overdrive warning light (O/D OFF) will be illuminated. When the switch is at the on position, the gearbox will operate in the normal fully automatic mode and the warning light will be extinguished.

B260P02Y-EAT

ABS SERVICE REMINDER INDICATOR (SRI)(Not all models)

When the key is turned to the "ON" position, the Anti-Lock Brake System SRI will come on and then go off in a few seconds. If the ABS SRI remains on, comes on while driving, or does not come on when the key is turned to the "ON" position, this indicates that there may be a problem with the ABS. If this occurs, have your vehicle checked by your Hyundai dealer as soon as possible. The normal braking system will still be operational, but without the assistance of the anti-lock brake system.

CAUTION: If the both ABS SRI and Parking Brake/Brake fluid level warning lights remain "ON" or come on while driving, there may be a

problem with E.B.D (Electronic Brake Force Distribution). If this occurs, avoid sudden stops and have your vehicle checked by your Hyundai dealer as soon as possible. SB210K1-E

OIL PRESSURE WARNING LIGHT

CAUTION: If the oil pressure light illuminates when the engine is running, an insufficient oil pressure level for continued safe opera- tion of the engine exists. Continued opera- tion of the engine in this condition may result in serious engine damage. Under normal circumstances, the light will illuminate when the ignition is turned "on" and will be extinguished when the engine is started.If the oil pressure warning light illuminates whilst the engine is running, stop the engine immediately and check the engine oil level. If the level is insufficient, add the required amount of oil as indicated by the engine oil dipstick. If the light fails to extinguish when the engine is restarted, do not continue to operate the ve- hicle. If the oil pressure light illuminates during nor-mal operation and the cause is not an insuffi- cient oil level, or the light fails to illuminate when the ignition is turned "on", contact the nearest Hyundai dealer before further operat- ing the vehicle.

SB210G1-E TURN SIGNAL INDICATOR LIGHT

Operation of a turn signal is indicated by the warning light located in the instrument cluster. If the light fails to illuminate or does not flash, a malfunction within the turn signal system is indicated.

SB210J1-E HIGH BEAM INDICATOR LIGHT

The high beam indicator light will illuminate whenever the headlights are switched to high beam of flash position.

SB210C1-F

SRS (Airbag) SERVICE REMINDER INDICATOR

The SRS service reminder indicator (SRI) comes on and flashes for about 6 seconds after the ignition key is turned to the "ON" position or after the engine is started, after which it will go out. This light also comes on when the SRS is not working properly. If the SRI does not come on, or continuously remains on after flashing for about 6 seconds when you turned the ignition key to the "ON" position or started the engine, or if it comes on while driving, have the SRS inspected by an authorized Hyundai Dealer.

fcuk-1.p65 3/6/2007, 9:58 AM

30