pump Hyundai Matrix 2006 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 282 of 490

1CONTROLS AND EQUIPMENT

2

B010A03O-EAT PETROL ENGINES THIS VEHICLE MUST ONLY BE OP- ERATED WITH UNLEADED FUEL.SERIOUS DAMAGE WILL RESULT FROM THE USE OF LEADED FUEL. Unleaded fuel with a Research Octane Number (RON) of 91 or higher must be used in this vehicle.To prevent accidental charging of the fuel tank with leaded fuel, a small diameter filler neck along with arestrictor flap are fitted to ensure that only unleaded fuel pump nozzles may enter the filler neck. However, care must be exercised whenrefuelling the vehicle tank from jerrycans or by means of a funnel that the fuel being used is unleaded. The use of leaded fuel in this vehicle willresult in irreversible pollution of the catalyst element. Such pollution will prevent correct operation of the cata-lyst and give rise to increased operat- ing temperatures leading to the cata- lyst element melting and restricting theexhaust flow along with an increase in exhaust emission levels.

B010A02FC-D

FUEL RECOMMENDATIONS

!

CAUTION:

The vehicle warranty will not extend to damage arising from the use ofincorrect fuels. DIESEL ENGINES Diesel fuel of 52 to 54 cetane is used in Hyundai vehicle. If two types of dieselfuel are available, use summer or win- ter fuel properly according to the fol- lowing temperature conditions.

o Above 23°F (-5°C ) ... Summer type

diesel fuel.

o Below 23°F (-5°C) ... Winter type

diesel fuel.

Watch the fuel level in the tank very carefully: If the engine stops throughfuel failure, the circuits must be com- pletely purged to permit restarting.

CAUTION:

Do not let any petrol or water enter the tank. This would make it neces-sary to drain it out and to bleed the lines to avoid siezing the injection pump and damaging the engine.

!

UNLEADED FUEL ONLY

Page 326 of 490

1CONTROLS AND EQUIPMENT

46

SB2100I-EDoor Ajar Warning Light

The door ajar warning light indicates that a door is not correctly closed.Ensure that the light is extinguished prior to driving the vehicle.

CAUTION:

If the drive belt (generator belt) is loose, broken, or missing whilst thevehicle is driving, there may be a serious malfunction, engine could overheat because this belt also drivesthe water pump.! SB210P1-E

Low Fuel Level Warning Light

The low fuel warning light serves to warn the driver that the remaining fuelquantity is approximately 9 litres and that the vehicle should be refuelled. If the vehicle is driven for an extendedperiod with the low fuel warning light illuminated there exists a possibility that misfiring due to fuel shortage mayoccur. This situation must be avoided to prevent damage to the catalyst oc- curring.

SB210M1-E Charging System Warning Light

The charging system warning light should illuminate when the ignitionswitch is turned to the "ON" position and should be extinguished when the engine is started. If the light fails toilluminate when the ignition is turned "ON" or fails to extinguish after starting the engine, the nearest Hyundaiauthorised repairer should be contacted. If the light illuminates whilst the vehicle is being driven, stop the vehicle assoon as it is safe to do so and check the condition of the generator drive belt. If the belt is in place and the tension issatisfactory, the advice of a Hyundai authorised repairer should be sought.

SB210J1-E High Beam Indicator Light

The high beam indicator light will illumi- nate whenever the headlights are switched to high beam of flash position.

B260B01FC-EAT

Hatchback Door Open Warning

Light

The hatchback door open warning light indicates when hatchback door open isopen or is not fully closed. Ensure that the light has extinguished prior to driv- ing the vehicle.

SB210K1-E Oil Pressure Warning Light CAUTION:

If the oil pressure light illuminates when the engine is running, an in- sufficient oil pressure level for con- tinued safe operation of the engine exists. Continued operation of the engine in this condition may result in serious engine damage.

!

Page 329 of 490

1

CONTROLS AND EQUIPMENT

49

SB215B1-E ENGINE COOLANT TEMPERA- TURE GAUGE

HFC2045 HFC2101

INSTRUMENT CLUSTER

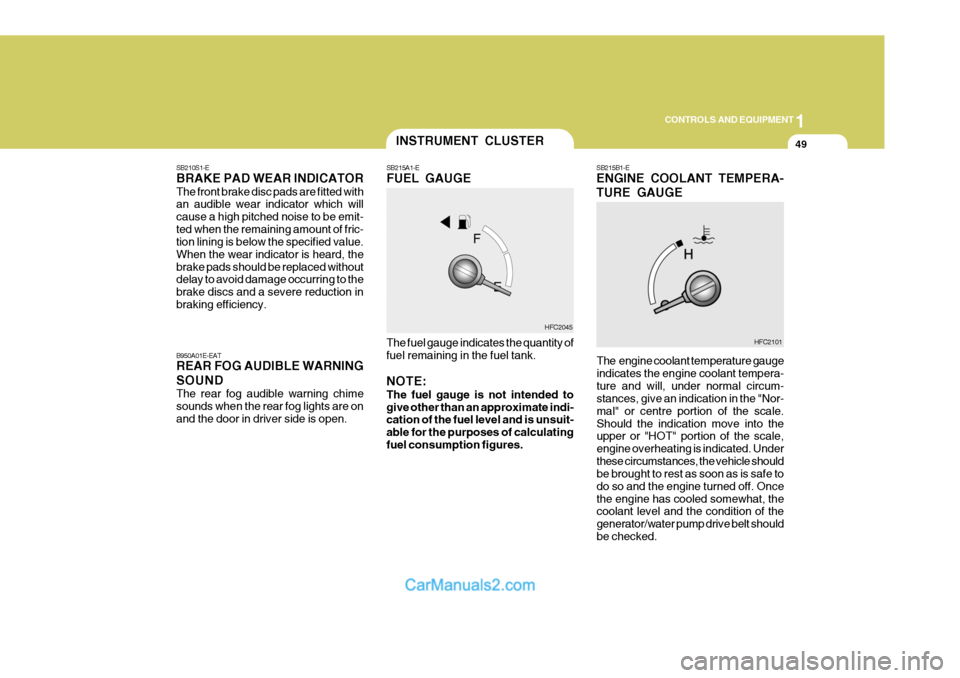

SB215A1-E FUEL GAUGE The fuel gauge indicates the quantity of fuel remaining in the fuel tank. NOTE: The fuel gauge is not intended to give other than an approximate indi- cation of the fuel level and is unsuit- able for the purposes of calculatingfuel consumption figures.

SB210S1-E BRAKE PAD WEAR INDICATOR The front brake disc pads are fitted with an audible wear indicator which will cause a high pitched noise to be emit-ted when the remaining amount of fric- tion lining is below the specified value. When the wear indicator is heard, thebrake pads should be replaced without delay to avoid damage occurring to the brake discs and a severe reduction inbraking efficiency. B950A01E-EAT REAR FOG AUDIBLE WARNING SOUND The rear fog audible warning chime sounds when the rear fog lights are onand the door in driver side is open.

The engine coolant temperature gaugeindicates the engine coolant tempera-ture and will, under normal circum- stances, give an indication in the "Nor- mal" or centre portion of the scale.Should the indication move into the

upper or "HOT" portion of the scale, engine overheating is indicated. Underthese circumstances, the vehicle should be brought to rest as soon as is safe to do so and the engine turned off. Oncethe engine has cooled somewhat, the coolant level and the condition of the generator/water pump drive belt shouldbe checked.

Page 402 of 490

3 IN CASE OF EMERGENCY

2IF THE ENGINE WILL NOT START

SD020B1-E If the Engine Cannot be Cranked

1. If the vehicle is fitted with manualtransaxle, ensure that the clutch pedal is depressed whilst cranking the engine. If the vehicle is fitted with automatic transaxle, ensure that the transaxle

selector is at the "P" or "N" position.

2. Check the battery terminals and con-

nections to ensure that these areclean and also tight.

3. If the ignition warning lights dim when

the engine is cranked and the batteryterminals have been checked, a dis- charged battery is indicated.

4. Do not attempt to push or tow start

the vehicle, refer to "Jump Starting"for information regarding engine start- ing when the battery is discharged. D010C02A-EAT If Engine Turns Over Normally but Does Not Start

D010B01FC 1. Check fuel level.

2. With the key in the "OFF" position,check all connectors at ignition coilsand spark plugs(For Petrol Engine)or check all connectors at glow plug and glow plug relay(For Diesel En- gine). Reconnect any that may bedisconnected or loose.

3. Check fuel line in the engine com-

partment.

4. If engine still refuses to start, call a Hyundai authorised repairer or seekother qualified assistance. SSA3020C

!

SD020A1-E Seek assistance from the nearest Hyundai authorised repairer with regardto the method of ignition and fuel sys- tem diagnosis.

CAUTION:

If the engine refuses to start, noattempt should be made to push or tow start the vehicle. Vehicles withautomatic transaxle or fuel injection will not be able to be started in this manner since no drive is transmittedthrough the automatic transaxle whilst the engine is not running, and in the case of fuel injected deriva-tives, the fuel pump will not operate under tow start conditions. In addi- tion, if the vehicle is equipped withan exhaust catalyst, damage to the catalyst may result if the vehicle is tow started.

Page 404 of 490

3 IN CASE OF EMERGENCY

4IF THE ENGINE OVERHEATS

SD040A2-E If the temperature gauge indicates over- heating:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P" (automatic) or neutral (manual transaxle) and set the parking brake.If the air conditioning is on, turn it off.

3. If coolant is running out under the car

or steam is coming out from underthe bonnet stop the engine. Do not open the bonnet until the coolant has stopped running or the steaming hasstopped. If there is no visible loss of coolant and no steam, leave the engine running and check to be surethe engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is broken. If it is not broken,check to see that it is tight.If the drive belt seems to be satisfac- tory, check for coolant leaking from the radiator, hoses or under the car.(If the air conditioning had been in use, it is normal for cold water to be draining from it).

4. Connect the red jump cable to the

positive (+) terminal of the boosterbattery and the other end to the positive (+) terminal of the discharged battery.

5. Attach the black jump cable to the negative (-) terminal of the boosterbattery, and the other end to a groundpoint within the engine compartment of the vehicle with the flat battery. Do not connect to the negative batteryterminal of the flat battery since sparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flatbattery.

7. Switch "ON" the main beam

headlamps before carefully remov-ing the jumper cables in the reverse order of attachment. Once the jumper cables have been removed, switch"OFF" the main beam headlamps. CAUTION:

If the jump cables are incorrectlyinstalled, damage to the vehicle elec- trical system may occur, in particu- lar the electronic components suchas the Fuel Injection system com- puter and the Automatic Transaxle computer. The battery must never bedisconnected whilst the engine is running.

!

Page 405 of 490

3

IN CASE OF EMERGENCY

5

!

!

!WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drive belts to prevent injury. 5. If the water pump drive belt is broken

or coolant is leaking out, stop theengine immediately and call the near- est Hyundai authorised repairer for assistance.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine. High pres-sure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.!

WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, care-fully remove the radiator cap and add water to bring the fluid level in the reservoir up to the base of the radia-tor fill opening. Fill the coolant ex- pansion tank to the halfway mark.

7. Proceed with caution until it is estab- lished that the engine is operatingnormally. If the engine overheats repeatedly, the advice of a Hyundaiauthorised repairer should be sought. CAUTION:

Serious loss of coolant indicatesthere is a leak in the cooling system and this should be checked as soon as possible by a Hyundai authorisedrepairer.

Page 422 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

3

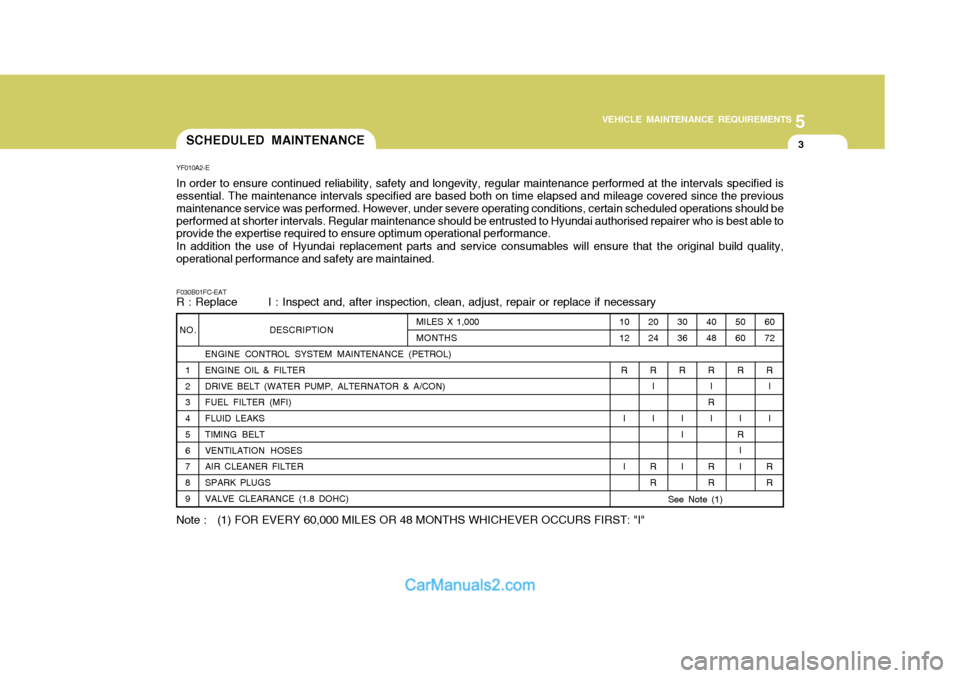

NO.

1 2 3 4 5 6 7 8 9 DESCRIPTION

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)ENGINE OIL & FILTER DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON) FUEL FILTER (MFI) FLUID LEAKS TIMING BELT VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS VALVE CLEARANCE (1.8 DOHC)

YF010A2-E In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should be

performed at shorter intervals. Regular maintenance should be entrusted to Hyundai authorised repairer who is best able to provide the expertise required to ensure optimum operational performance. In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality, operational performance and safety are maintained. F030B01FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary60 72

R I I

R R

50 60

R

I

R II

4048

R I

R I

R R

30 36

R

II I

20 24

R I I

R R

10 12

R

I I

MILES X 1,000 MONTHS

See Note (1)

Note : (1) FOR EVERY 60,000 MILES OR 48 MONTHS WHICHEVER OCCURS FIRST: "I" SCHEDULED MAINTENANCE

Page 423 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

4

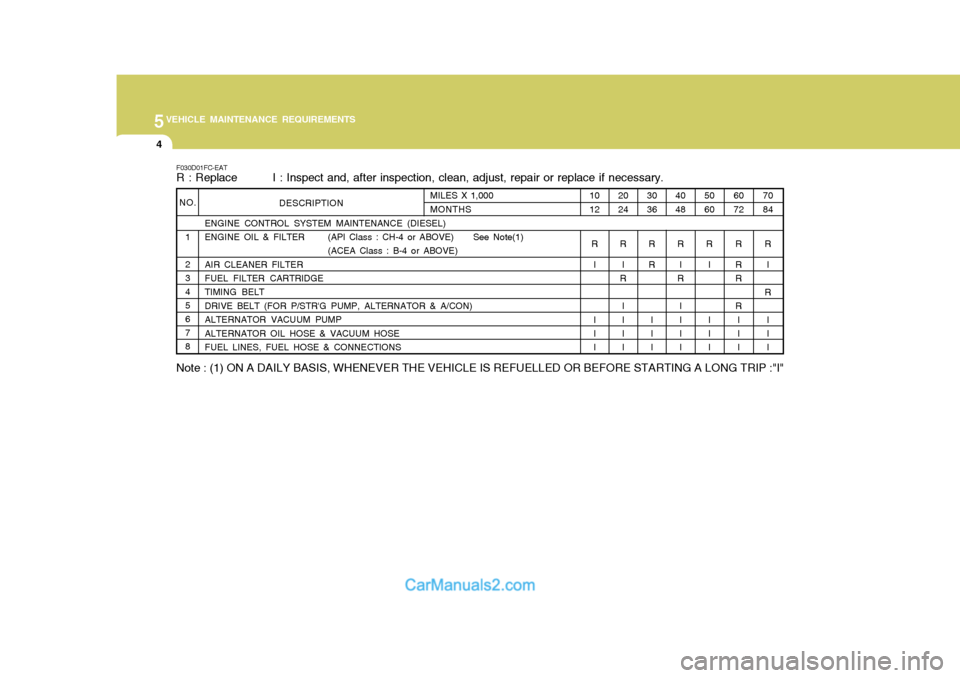

NO.1 2 345678 ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class : CH-4 or ABOVE) See Note(1)

(ACEA Class : B-4 or ABOVE)

AIR CLEANER FILTER FUEL FILTER CARTRIDGE TIMING BELTDRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR & A/CON)ALTERNATOR VACUUM PUMPALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

F030D01FC-EAT

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary.

70 84

R I

R II I

60 72

R R R R I I I

50 60

R I I I I

40 48

R I

R

III I

30 36

R R

I I I

20 24

R I

R

III I

10 12

R I I I I

MILES X 1,000 MONTHSDESCRIPTION

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

Page 426 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive Belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil contamination and replace if neces- sary. Drive belts should be checkedperiodically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.After installing a new filter, run theengine for several minutes, and checkfor leaks at the connections.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.

6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately.

Page 429 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

10

6ZF070L1-A

o Suspension Mounting Bolts Check the suspension connections for looseness or damage. Retighten to thespecified torque.6ZF070J1-A

o Brake Pads, Calipers and Rotors

Check the pads for excessive wear,

discs for run out and wear, and cali- pers for fluid leakage.

6ZF070K1-A

o Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

silencer and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070M1-A

o Steering Gear Box, Linkage &

Boots/Lower arm Ball Joint

With the vehicle stopped and engine

off, check for excessive freeplay in the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and balljoints for deterioration, cracks, or dam- age. Replace any damaged parts.

6ZF070N1-A

o Power Steering Pump, Belt

and Hoses

Check the power steering pump and

hoses for leakage and damage. Re- place any damaged or leaking parts immediately. Inspect the power steer-ing belt for evidence of cuts, cracks, excessive wear, oil contamination and proper tension. Replace or adjust it ifnecessary. 6ZF070P1-A

o Driveshafts and Boots

Check the drive shafts, boots andclamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease. 6ZF070Q1-A

o Air conditioning Refrigerant

Check the air conditioning lines and connections for leakage and damage.Check air conditioning performance according to the relevant shop manual if necessary.