ECU Hyundai Matrix 2006 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 426 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive Belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil contamination and replace if neces- sary. Drive belts should be checkedperiodically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.After installing a new filter, run theengine for several minutes, and checkfor leaks at the connections.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.

6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately.

Page 427 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060H1-A

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when filter is replaced.

6ZF060J1-A

o Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ining those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-AAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-sary. A qualified technician should perform the operation.

Page 438 of 490

6

OWNER MAINTENANCE

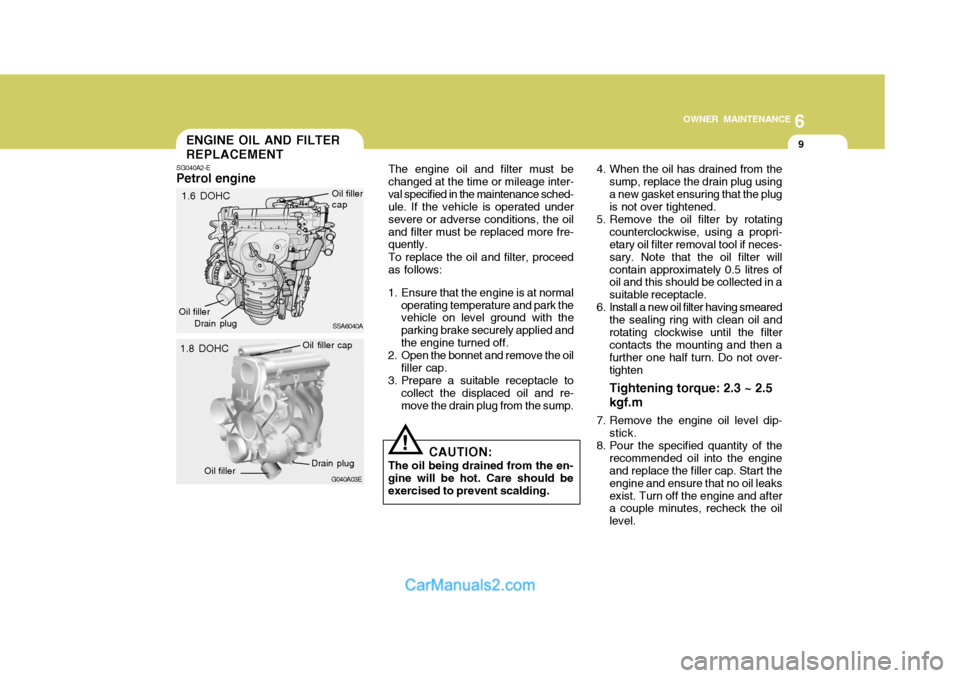

9ENGINE OIL AND FILTER REPLACEMENT

SSA6040A

1.6 DOHC

Oil filler cap

Drain plug

Oil filler

G040A03E

Oil filler cap

Drain plug

Oil filler

1.8 DOHC

SG040A2-E

Petrol engine The engine oil and filter must be changed at the time or mileage inter-val specified in the maintenance sched- ule. If the vehicle is operated under severe or adverse conditions, the oiland filter must be replaced more fre- quently. To replace the oil and filter, proceed as follows:

1. Ensure that the engine is at normal operating temperature and park the vehicle on level ground with the parking brake securely applied andthe engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and re-move the drain plug from the sump.

CAUTION:

The oil being drained from the en-gine will be hot. Care should beexercised to prevent scalding. 4. When the oil has drained from the

sump, replace the drain plug usinga new gasket ensuring that the plug is not over tightened.

5. Remove the oil filter by rotating counterclockwise, using a propri-etary oil filter removal tool if neces- sary. Note that the oil filter willcontain approximately 0.5 litres of oil and this should be collected in a suitable receptacle.

6. Install a new oil filter having smeared

the sealing ring with clean oil androtating clockwise until the filter contacts the mounting and then a further one half turn. Do not over-tighten Tightening torque: 2.3 ~ 2.5 kgf.m

7. Remove the engine oil level dip- stick.

8. Pour the specified quantity of the

recommended oil into the engine and replace the filler cap. Start the engine and ensure that no oil leaksexist. Turn off the engine and after a couple minutes, recheck the oil level.

!

Page 451 of 490

6 OWNER MAINTENANCE

22

!

!

BRAKE SYSTEM CHECKING

Fluid level should be within this range

C090A03FC

WARNING:

The cooling fan is controlled by engine coolant temperature and may sometimes operate even when the engine is not running. Use extremecaution when working near the blades of the cooling fan so that you are not injured by a rotating fanblade. As the engine coolant tem- perature decreases, the fan will au- tomatically shut off. This is a nor-mal condition. WARNING (Diesel only):

Never work on injection system with

engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body.

People using pacemakers should

ensure that they keep a distance of30cm from the ECU or wiring har- ness within the engine room whilst engine is running, since the highcurrents in the Common Rail sys- tem produce considerable magnetic fields. SG120A1-E

CAUTION:

Correct operation of the braking

system is essential to the safe op-eration of the vehicle and therefore, any maintenance operations other than those listed below should beentrusted to a Hyundai authorised repairer.

!

SG120C2-E

Brake Fluid Recommendations

Only brake fluid conforming to DOT 3

or DOT 4 specifications or higher may be used in the braking system. Care should be taken to observe the in- structions and precautions printed uponthe container.

Page 468 of 490

6

OWNER MAINTENANCE

39FUSE PANEL DESCRIPTION

G200C03FC-EAT

Engine Compartment (Petrol Engine)

G200C03FC

NOTE: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

PROTECTED COMPONENTS Generator (A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse Generator, Engine control relay, ECM Radiator fan relay Start relay, Ignition switch Blower relay Power window relay Condenser fan relay #1 ABS control module, ABS bleeding connector, ESP ABS control module, ABS bleeding connector, ESP Fuel pump relay Injector, lgnition coil MAP sensor, Oxygen sensor, CP sensor, Knock sensor, Throttle position sensor Audio, Room lamp, Overhead console lamp, lnstrument cluster DRL control module Horn relay A/C relay Front fog lamp relay ECM, TCM Tail lamp relay Left rear combi lamp, Left position lamp, Left License lamp Right rear combi lamp, Right position lamp, Right License lamp Left head lamp Right head lamp, (H/LP IND) Fuse

FUSE RATING

120A40A30A 20A 40A 40A 30A 20A 40A 40A 10A 15A 10A 10A 15A 10A 10A 15A 10A 20A 10A 10A 15A 15A

DESCRIPTION

ALT

B+

ECURAD IGN

BLR

P/WINCOND ABSABS

F/PUMP

INJ

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG ECU

LP

TAIL LH

TAIL RH H/LP LH

H/LP RH

Page 470 of 490

6

OWNER MAINTENANCE

41

ALT B+

ECU RAD IGN

BLR

P/WIN

COND

ABSABS

F/PUMP ECUECU

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG

ECULP

TAIL LH

TAIL RH H/LP LH

H/LP RH

PTC HTR 1 GLOW

PTC HTR 2 FFHS

PTC HTR 3 PROTECTED COMPONENTS

Generator(A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse, DeicerGenerator, Engine control relay, ECMRadiator fan relayStart relay, Ignition switchBlower relay Power window relay Condenser fan relay #1ABS control module, ABS bleeding connector, ESPABS control module, ABS bleeding connector, ESPFuel pump relayECM No.5 (Batt+) ECM No.4 (Batt+), Stop lamp switch, PTC heater relay #1 Glow plug relay, Assistor heater relay 1/2, Stop lamp switch,TDC sensor, EGR act, Throttle plate act, VGT vacuumAudio, Room lamp, Overhead console lamp, lnstrument cluster, ETACM, Luggage lampDRL control moduleHorn relayA/C relay Front fog lamp relay ECM, TCMTail lamp relayLeft rear combi lamp, Left position lamp, Left License lampRight rear combi lamp, Right position lamp, Right License lampLeft head lamp Right head lamp, (H/LP IND) Fuse PTC heater relay #1GLOW relayPTC heater relay #2FFHS relayPTC heater relay #3

FUSE RATING

140A40A 30A 30A40A40A30A30A 40A 40A10A30A10A 15A 10A 15A 10A10A15A10A20A 10A 10A15A15A40A80A 40A 30A40A

FUSE

FUSIBLE DESCRIPTION

Page 471 of 490

6 OWNER MAINTENANCE

42

G200D01FC-GAT Inner Panel

G200D01FCDESCRIPTION

H/LP IND

HTD IND

A/CON

RR HTD STOP

D/LOCK

HAZARD AUDIO

C/LIGHT A/B

A/B IND

T/SIG

ECU

ETACS

RR WPR

START

FRT WPR S/HTD

P/OUTLET

IG2

O/S MRR

PROTECTED COMPONENTS Head lamp indicator Defogger relay, Left(Right) outside mirror motor,Rear window motorA/C SwitchDefogger relayStop lamp switch, Power window relay Door lock(unlock) relay, ETACM, Sunroof relay Burglar alarm relay, Hazard relayAudioCigarette lighterSRS control moduleSRS IND. Hazard switch, Seat belt timer, Instrument cluster, ABS control module, Pre-excitation resistor, Washer motorECM, Vehicle speed sensor, TCM, Ignition coilETACM, A/T Shift leverRear wiper motor, Rear wiper relayStart relay Wiper relay, Washer motor, Wiper & Defogger timer Left (Right) front seat warmer switchFront (Rear) power outletETACM, Power window relay, Defogger relay, Sunroof relayHead lamp relay, Blower relayOutside mirror switch, Rear fog lamp relay

FUSE RATING

10A 10A 10A 30A10A15A 10A 10A15A10A10A 10A 15A 10A10A 10A 20A15A25A 10A 10A

Page 473 of 490

7EMISSION CONTROL SYSTEMS

2EMISSION CONTROL SYSTEMS

SH010A1-E

(Not all models)

Depending upon the market for which

the vehicle is destined, the emission control system will comprise one or more of the following emission control devices.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order that the proper functioning of

the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintained by an Hyundai authorised repairer inaccordance with the maintenance schedule in this manual. SH010B1-E

1. Crankcase Emission Control

System

The positive crankcase ventilation

system is employed to prevent air pollution caused by blow-by gasesbeing emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where this mixeswith blow-by gases and then passes through the PCV valve into the intake manifold from where it subsequentlyenters the combustion chamber and is burned.

SH010C1-E

2. Evaporative Emission Control

System

The Evaporative Emission Control Sys-

tem is designed to prevent fuel vapours from escaping into the atmosphere through the fuel tank ventilation sys- tem. Whilst the engine is not running, fuel

vapours generated inside the fuel tankare absorbed and stored in a charcoal canister. When the engine is started, the vapours

stored in the canister are drawn intothe induction system through the purge control solenoid valve and are subse-quently burned. The purge control solenoid valve is

controlled by the ECU; when the en- gine coolant temperature is low or the engine is idling, the purge control valveis closed and fuel vapours remain stored in the canister. Under normal running conditions when the engine iswarm, the valve opens and the vapours are drawn into the inlet tract and sub- sequently burned in the combustionchamber.

SH010D1-E

3. Exhaust Emission Con Trol

System

The exhaust emission control system

is a highly effective system whichcontrols exhaust emission whilst main-taining good vehicle performance.