tow Hyundai Matrix 2006 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 412 of 490

3 IN CASE OF EMERGENCY

12IF YOUR VEHICLE MUST BE TOWED

D080A01O-GAT If your vehicle has to be towed, it should be done by your Hyundai authorised repairer or a commercial tow truck ser- vice. This will help assure that yourvehicle is not damaged in towing. Also, professionals are generally aware of local laws governing towing. In anycase, rather than risk damage to your car, it is suggested that you show this information to the tow truck operator.Be sure that a safety chain system is used and that all local laws are ob- served.It is recommended that your vehicle be towed with a wheel lift and dollies or flatbed equipment with all the wheelsoff the ground.

! CAUTION:

o Your vehicle can be damaged if towed incorrectly!

o Be sure the transaxle is in neutral.

o When the engine will not start, be sure the steering is unlocked by placing the key in the "ACC" posi- tion. HFC005

1)

2)

3)

dolly

If the valve cap is lost from any of the valves, a replacement should be ob-tained and fitted at the first available opportunity. The valve cap prevents the ingress of dirt which may cause thevalve to stick and therefore leak and is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly located in the boot of thevehicle to prevent damage and noise.

D080B01O-GAT Towing the Vehicle Your vehicle can be towed by wheel lift type truck (1), (2) or flatbed equipment (3).

Page 413 of 490

3

IN CASE OF EMERGENCY

13

HFC004!

CAUTION:

o When towing the vehicle, take care not to cause damage to the bumper or underbody of the vehicle.

!

o Do not tow with sling type truck as this may cause damage to the bumper or underbody of the ve- hicle.

1) If the vehicle is being towed with the rear wheels on the ground, be sure the parking brake is released. NOTE: Before towing, check the level of the automatic transaxle fluid. If it is be- low the "HOT" range on the dipstick,add fluid. If you cannot add fluid, a towing dolly must be used.

2) If any of the loaded wheels or sus-

pension components are damaged or the vehicle is being towed with thefront wheels on the ground, use a towing dolly under the front wheels.

o Manual Transaxle: If you do not use a towing dolly, placethe ignition key in the "ACC" position and put the transaxle in "N (Neutral)".

HFC006

CAUTION:

Do not tow with the key removed or in the "LOCK" position when towingfrom the rear without a towing dolly.

o Automatic Transaxle: Be sure to use a towing dolly under the front wheels.

! CAUTION:

A vehicle with an automatic transaxle should never be towed from the rear with the front wheels on the ground. This can cause serious damage tothe transaxle.

3) It is recommended that your vehicle be towed with all the wheels off the ground.

Page 414 of 490

3 IN CASE OF EMERGENCY

14IF YOU LOSE YOUR KEYS

NOTE: Before towing, check the level of the automatic transaxle fluid. If it is be- low the "HOT" range on the dipstick,add fluid. If you cannot add fluid, a towing dolly must be used. D120A01A-EAT Information about the key of immobiliser system will be found on page 1-4.

!

EMERGENCY TOWING

D080D04A-EAT For emergency towing when no com- mercial tow vehicle is available, attach a tow cable, chain or strap to one of thetowing hooks under the front/rear of your vehicle. Do not attempt to tow your vehicle in this manner on any unpavedsurface. This could result in serious damage to your vehicle. Nor should towing be attempted if thewheels, drive train, axles, steering or brakes are damaged. Before towing, be sure the transaxle is in neutral and thekey is in "ACC" (with the engine off) or in the "ON" position (with the engine running). A driver must be in the towedvehicle to steer it and operate the brakes. D080D04FC

Front

Rear CAUTION:

If the car is being towed with all four wheels on the ground, it can be towed only from the front. Be sure that the transaxle is in neutral. Do not tow at speeds greater than 30 mph(50 km/h) and for more than 15 miles (25 km). Be sure the steering is unlocked byplacing the key in the "ACC" posi- tion. A driver must be in the towed vehicle to operate the steering andbrakes

Page 425 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

6

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADSREAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID POLLEN FILTER(IN FRONT OF BLOWER UNIT) A, B,C, D, E, F, G, H, I, KA, B, C, D, F, H, I, JC, EB, HD, E, F, G C, D, G, HC, D, G, HC, D, E, FA, C, D, E, F, G, H, I, JA, C, E, F, G, H, IC,E

R R RR

I I I

RRR DRIVING

CONDITION

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY

EVERY 37,000 MILES OR 48 MONTHSMORE FREQUENTLYMORE FREQUENTLYMORE FREQUENTLYEVERY 60,000 MILESEVERY 27,000 MILESMORE FREQUENTLY MAINTENANCE INTERVALS

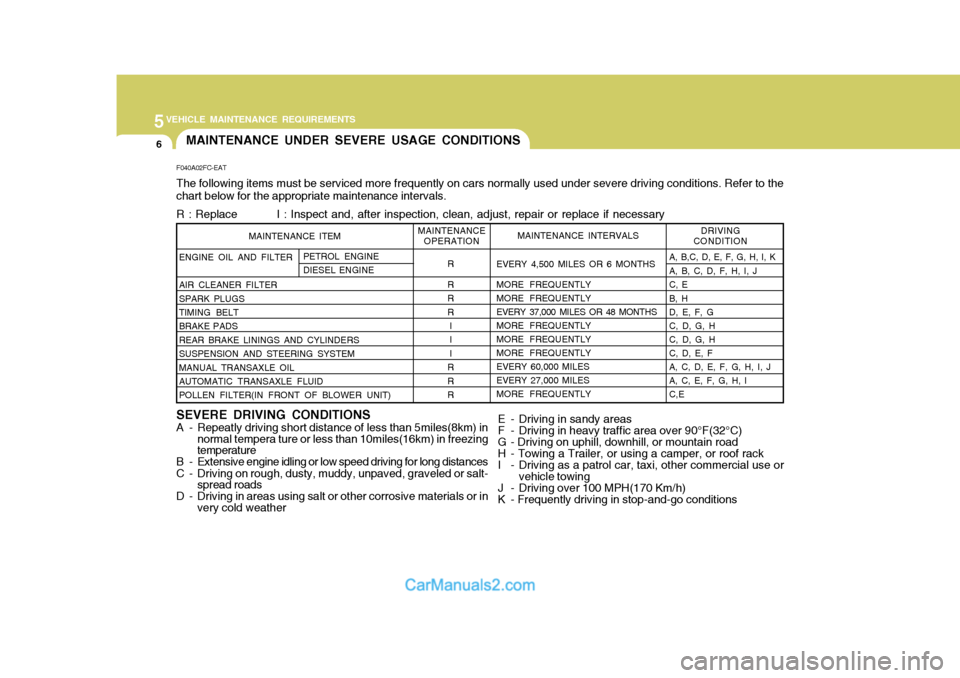

F040A02FC-EAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 5miles(8km) in

normal tempera ture or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

MAINTENANCEOPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 90°F(32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use orvehicle towing

J - Driving over 100 MPH(170 Km/h)

K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

PETROL ENGINE DIESEL ENGINE

Page 444 of 490

6

OWNER MAINTENANCE

15

HGK256

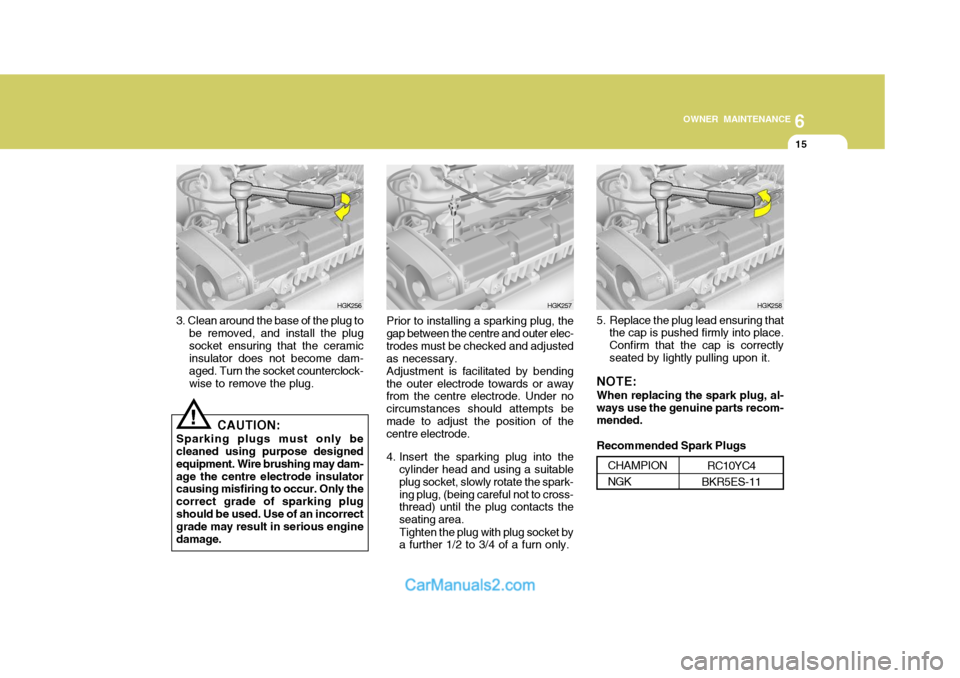

3. Clean around the base of the plug to be removed, and install the plug socket ensuring that the ceramic insulator does not become dam- aged. Turn the socket counterclock-wise to remove the plug.

CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment. Wire brushing may dam-age the centre electrode insulator causing misfiring to occur. Only the correct grade of sparking plugshould be used. Use of an incorrect grade may result in serious engine damage.

! Prior to installing a sparking plug, the

gap between the centre and outer elec- trodes must be checked and adjustedas necessary.

Adjustment is facilitated by bending

the outer electrode towards or away from the centre electrode. Under no circumstances should attempts bemade to adjust the position of the centre electrode.

4. Insert the sparking plug into the cylinder head and using a suitable plug socket, slowly rotate the spark-ing plug, (being careful not to cross- thread) until the plug contacts the seating area. Tighten the plug with plug socket by a further 1/2 to 3/4 of a furn only.

HGK257

5. Replace the plug lead ensuring thatthe cap is pushed firmly into place. Confirm that the cap is correctlyseated by lightly pulling upon it.

NOTE: When replacing the spark plug, al- ways use the genuine parts recom- mended. Recommended Spark PlugsHGK258

CHAMPION NGK RC10YC4

BKR5ES-11

Page 474 of 490

7

EMISSION CONTROL SYSTEMS

3CATALYTIC CONVERTER

SH020A1-E

Catalytic Convertor Operation Precautions ; For a petrol engine

HFC505

Hyundai Matrix models are fitted with

catalytic convertors which require spe- cial operating considerations. The cata- lytic convertor serves to oxidize cer-tain noxious elements of the exhaust gases leaving the engine to reduce the level of pollutants emitted from thevehicle and, provided that care is ex- ercised to prevent damage, the cata- lyst will operate efficiently for the lifeof the vehicle.

Catalytic Converter It is of the utmost importance that the

following information is read and un- derstood by the vehicle operator in order to prevent operational problems arising from damage to the catalyst.

Damage to the catalyst will result if

contamination occurs through the useof leaded fuel. Whilst the vehicle isfitted with a reduced diameter filler neck to prevent charging of the fuel tank with a leaded fuel pump nozzle, itis possible that the use of funnels or jerry cans will permit leaded fuel to be introduced into the fuel tank.

The catalyst is intolerant of unburnt

fuel and therefore if an engine misfirecondition exists, damage to the cata- lyst will occur. It is imperative that if a misfire condition develops, the ve-hicle is immediately presented to a Hyundai authorised repairer for rectifi- cation. Similarly, the practice of cer-tain ignition system diagnosis proce- dures which involve inducing a misfire (cylinder power balance tests for ex-ample) may result in catalyst damage. For these reasons, it is advisable thatthe exhaust gas emission be tested ateach routine service with a gas ana- lyzer having a Hydrocarbon measuring facility to ensure continued reliabilityof the catalyst.Push or tow starting of the vehicle is tobe avoided since unburnt fuel may beenter the catalyst and result in dam- age. (Note, it is impossible to push or tow start a Hyundai model equippedwith fuel injection since the fuel pump safety interlock will prevent the pump from operating under these conditions).Operation of the catalyst involves ex-tremely high temperatures being at-tained within the catalytic convertor, and although the convertor is fitted with heat shields, it is important thatthe vehicle is not parked over combus- tible or volatile material which may result in fire. If the above precautions are not ad- hered to and the catalyst becomes inoperative, the resultant increase incore temperature will result in a "melt down" where the catalyst core will melt and subsequently may block the ex-haust system.

Page 487 of 490

10INDEX

2

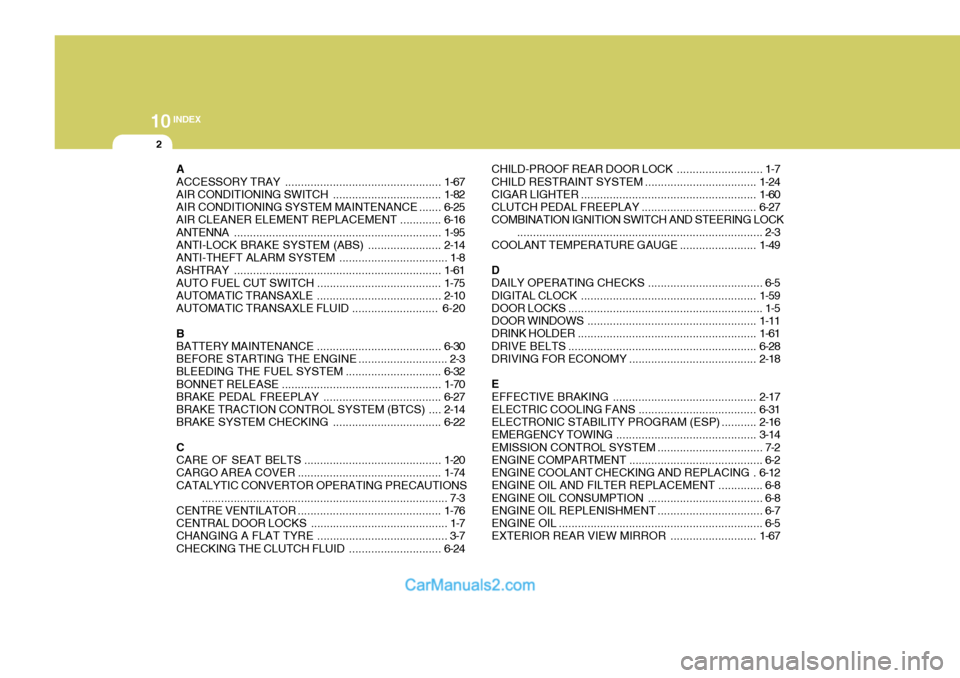

A ACCESSORY TRAY ................................................. 1-67

AIR CONDITIONING SWITCH.................................. 1-82

AIR CONDITIONING SYSTEM MAINTENANCE ....... 6-25

AIR CLEANER ELEMENT REPLACEMENT .............6-16

ANTENNA ................................................................. 1-95

ANTI-LOCK BRAKE SYSTEM (ABS) .......................2-14

ANTI-THEFT ALARM SYSTEM .................................. 1-8

ASHTRAY ................................................................. 1-61

AUTO FUEL CUT SWITCH ....................................... 1-75

AUTOMATIC TRANSAXLE .......................................2-10

AUTOMATIC TRANSAXLE FLUID ........................... 6-20

B BATTERY MAINTENANCE .......................................6-30

BEFORE STARTING THE ENGINE ............................ 2-3

BLEEDING THE FUEL SYSTEM .............................. 6-32

BONNET RELEASE .................................................. 1-70

BRAKE PEDAL FREEPLAY .....................................6-27

BRAKE TRACTION CONTROL SYSTEM (BTCS) .... 2-14

BRAKE SYSTEM CHECKING.................................. 6-22

C

CARE OF SEAT BELTS .... .......................................1-20

CARGO AREA COVER ............................................. 1-74

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............................................................................. 7-3

CENTRE VENTILATOR ............................................. 1-76

CENTRAL DOOR LOCKS ......... .................................. 1-7

CHANGING A FLAT TYRE ......................................... 3-7

CHECKING THE CLUTCH FLU ID .............................6-24CHILD-PROOF REAR DOOR LOCK

........................... 1-7

CHILD RESTRAINT SYSTEM ................................... 1-24

CIGAR LIGHTER ....................................................... 1-60

CLUTCH PEDAL FREEPLAY ....................................6-27

COMBINATION IGNITION SWITCH AND STEERING LOCK

............................................................................. 2-3

COOLANT TEMPERATURE GAUGE ........................1-49

D DAILY OPERATING CHECKS .................................... 6-5

DIGITAL CLOCK ....................................................... 1-59

DOOR LOCKS ............................................................. 1-5

DOOR WINDOWS ..................................................... 1-11

DRINK HOLDER ........................................................ 1-61

DRIVE BELTS ........................................................... 6-28

DRIVING FOR ECONOMY ....... .................................2-18

E EFFECTIVE BRAKING ............................................. 2-17

ELECTRIC COOLING FANS ..................................... 6-31

ELECTRONIC STABILITY PROGRAM (ESP) ...........2-16

EMERGENCY TOWING ............................................ 3-14

EMISSION CONTROL SYSTEM ................................. 7-2

ENGINE COMPARTMENT ....... ................................... 6-2

ENGINE COOLANT CHECKING AND REPLACING . 6-12

ENGINE OIL AND FILTER REPLACEMENT .............. 6-8

ENGINE OIL CONSUMPTION .................................... 6-8

ENGINE OIL REPLENISHMENT ................................. 6-7

ENGINE OIL ................................................................ 6-5 EXTERIOR REAR VIEW MIRROR ........................... 1-67

Page 488 of 490

10

INDEX

3

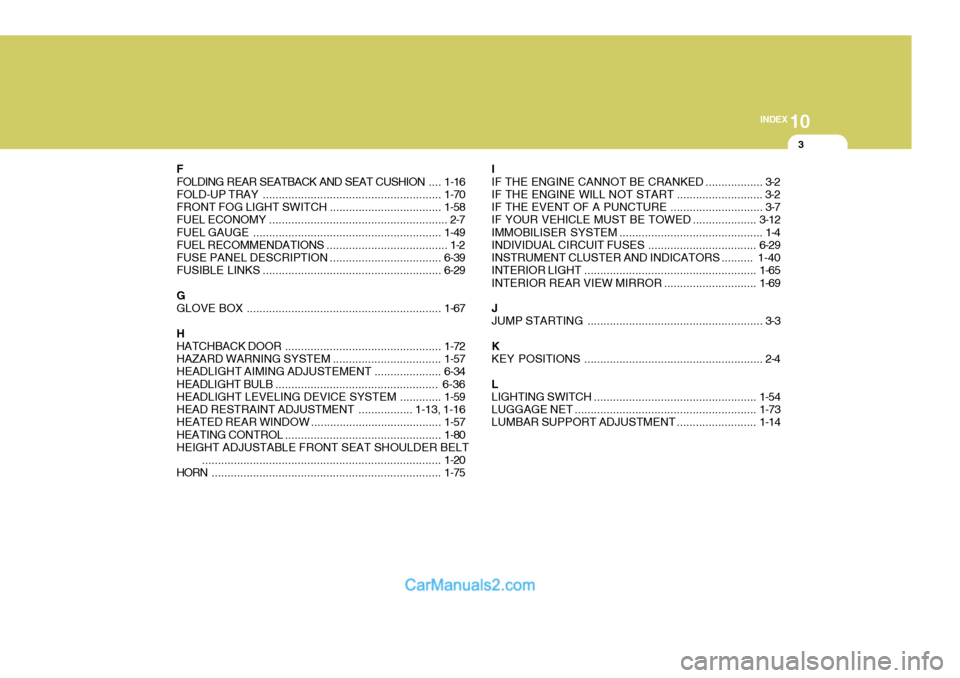

F FOLDING REAR SEATBACK AND SEAT CUSHION ....1-16

FOLD-UP TRAY ........................................................ 1-70

FRONT FOG LI GHT SWITCH ................................... 1-58

FUEL ECONOMY ........................................................ 2-7

FUEL GAUGE ........................................................... 1-49

FUEL RECOMMENDATIONS ...................................... 1-2

FUSE PANEL D ESCRIPTION................................... 6-39

FUSIBLE LINKS ........................................................ 6-29

GGLOVE BOX ............................................................. 1-67

H HATCHBACK DOOR ................................................. 1-72

HAZARD WARNING SYST EM ..................................1-57

HEADLIGHT AIMING ADJUSTEMENT ..................... 6-34

HEADLIGHT BULB ................................................... 6-36

HEADLIGHT LEVELING DEVICE SYSTEM ............. 1-59

HEAD RESTRAINT ADJUSTMENT .................1-13, 1-16

HEATED REAR WINDOW ......................................... 1-57

HEATING CONTROL ................................................. 1-80

HEIGHT ADJUSTABLE FRONT SEAT SHOULDER BELT

........................................................................... 1-20

HORN ........................................................................ 1-75I

IF THE ENGINE CANNOT BE CRANKED

.................. 3-2

IF THE ENGINE WILL NOT START ........................... 3-2

IF THE EVENT OF A PUNCTURE ............................. 3-7

IF YOUR VEHICLE MUST BE TOWED ....................3-12

IMMOBILISER SYSTEM ............................................. 1-4

INDIVIDUAL CIRCUIT FUSES .................................. 6-29

INSTRUMENT CLUSTER AND INDICATORS.......... 1-40

INTERIOR LIGHT ...................................................... 1-65

INTERIOR REAR VIEW MIRROR ............................. 1-69

J JUMP STAR TING ....................................................... 3-3

K KEY POSITIONS ........................................................ 2-4

L LIGHTING SWITCH ................................................... 1-54

LUGGAGE NET ......................................................... 1-73

LUMBAR SUPPORT ADJUSTMENT .........................1-14

Page 490 of 490

10

INDEX

5

T

TOWING ATTACHMENTS . .......................................2-22

TRAILER AND CARAVAN TOWING .........................2-21

TRIP COMPUTER ..................................................... 1-52

TYPE PRESSURES .................................................... 8-3

TYRE BALANCING ..................................................... 8-4

TYRE CHAINS ............................................................ 8-3

TYRE REPLACEMENT ............................................... 8-5

TYRE ROTATION ....................................................... 8-4

UUNDER TRAY ........................................................... 1-15

V VEHICLE IDENTIFICATION NUMBER ........................ 8-2

W

WHEEL REPLACEMENT ............................................ 8-5

WINDSCREEN WASHER OPERATION ....................1-56

WINDSCREEN WASHER RESERVOIR REPLENISHMENT ................................................ 6-18

WINDSCREEN WIPER BLADES ............................. 6-16

WINDSCREEN WIPER/WASHER SWITCH ..............1-55

WINTER MOTORING ................................................ 2-19