wheel Hyundai Matrix 2007 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Matrix, Model: Hyundai Matrix 2007Pages: 490, PDF Size: 12.81 MB

Page 410 of 490

3

IN CASE OF EMERGENCY

11

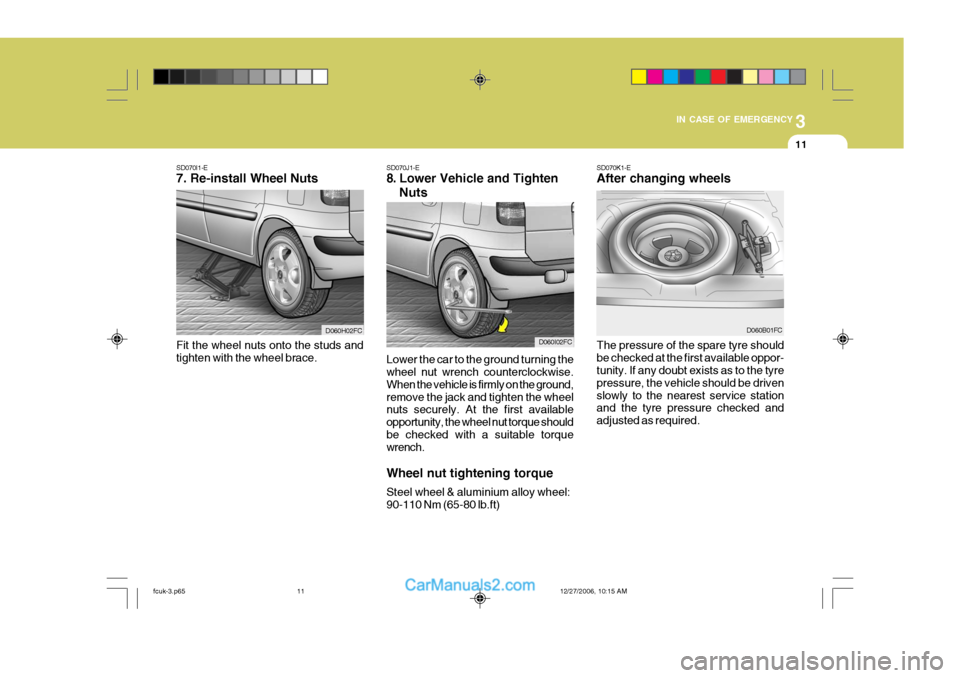

SD070I1-E 7. Re-install Wheel Nuts

Fit the wheel nuts onto the studs and tighten with the wheel brace. Lower the car to the ground turning the wheel nut wrench counterclockwise. When the vehicle is firmly on the ground,remove the jack and tighten the wheel nuts securely. At the first available opportunity, the wheel nut torque shouldbe checked with a suitable torque wrench. Wheel nut tightening torque Steel wheel & aluminium alloy wheel: 90-110 Nm (65-80 lb.ft)

SD070J1-E

8. Lower Vehicle and Tighten

NutsSD070K1-E After changing wheels The pressure of the spare tyre should be checked at the first available oppor- tunity. If any doubt exists as to the tyre pressure, the vehicle should be drivenslowly to the nearest service station and the tyre pressure checked and adjusted as required. D060B01FC

D060H02FCD060I02FC

fcuk-3.p65

12/27/2006, 10:15 AM

11

Page 411 of 490

3 IN CASE OF EMERGENCY

12IF YOUR VEHICLE MUST BE TOWED

D080A01O-GAT If your vehicle has to be towed, it should be done by your Hyundai authorised repairer or a commercial tow truck ser- vice. This will help assure that yourvehicle is not damaged in towing. Also, professionals are generally aware of local laws governing towing. In anycase, rather than risk damage to your car, it is suggested that you show this information to the tow truck operator.Be sure that a safety chain system is used and that all local laws are ob- served.It is recommended that your vehicle be towed with a wheel lift and dollies or flatbed equipment with all the wheelsoff the ground.

! CAUTION:

o Your vehicle can be damaged if towed incorrectly!

o Be sure the transaxle is in neutral.

o When the engine will not start, be sure the steering is unlocked by placing the key in the "ACC" posi- tion. HFC005

1)

2)

3)

dolly

If the valve cap is lost from any of the valves, a replacement should be ob-tained and fitted at the first available opportunity. The valve cap prevents the ingress of dirt which may cause thevalve to stick and therefore leak and is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly located in the boot of thevehicle to prevent damage and noise.

D080B01O-GAT Towing the Vehicle Your vehicle can be towed by wheel lift type truck (1), (2) or flatbed equipment (3).

fcuk-3.p65

12/27/2006, 10:15 AM

12

Page 412 of 490

3

IN CASE OF EMERGENCY

13

HFC004!

CAUTION:

o When towing the vehicle, take care not to cause damage to the bumper or underbody of the vehicle.

!

o Do not tow with sling type truck as this may cause damage to the bumper or underbody of the ve- hicle.

1) If the vehicle is being towed with the rear wheels on the ground, be sure the parking brake is released. NOTE: Before towing, check the level of the automatic transaxle fluid. If it is be- low the "HOT" range on the dipstick,add fluid. If you cannot add fluid, a towing dolly must be used.

2) If any of the loaded wheels or sus-

pension components are damaged or the vehicle is being towed with thefront wheels on the ground, use a towing dolly under the front wheels.

o Manual Transaxle: If you do not use a towing dolly, placethe ignition key in the "ACC" position and put the transaxle in "N (Neutral)".

HFC006

CAUTION:

Do not tow with the key removed or in the "LOCK" position when towingfrom the rear without a towing dolly.

o Automatic Transaxle: Be sure to use a towing dolly under the front wheels.

! CAUTION:

A vehicle with an automatic transaxle should never be towed from the rear with the front wheels on the ground. This can cause serious damage tothe transaxle.

3) It is recommended that your vehicle be towed with all the wheels off the ground.

fcuk-3.p65 12/27/2006, 10:15 AM

13

Page 413 of 490

3 IN CASE OF EMERGENCY

14IF YOU LOSE YOUR KEYS

NOTE: Before towing, check the level of the automatic transaxle fluid. If it is be- low the "HOT" range on the dipstick,add fluid. If you cannot add fluid, a towing dolly must be used. D120A01A-EAT Information about the key of immobiliser system will be found on page 1-4.

!

EMERGENCY TOWING

D080D05A-EAT For emergency towing when no com- mercial tow vehicle is available, attach a tow cable, chain or strap to one of thetowing hooks under the front/rear of your vehicle. Do not attempt to tow your vehicle in this manner on any unpavedsurface. This could result in serious damage to your vehicle. Nor should towing be attempted if thewheels, drive train, axles, steering or brakes are damaged. Before towing, be sure the transaxle is in neutral and thekey is in "ACC" (with the engine off) or in the "ON" position (with the engine running). A driver must be in the towedvehicle to steer it and operate the brakes. D080D04FC

Front

Rear CAUTION:

If the car is being towed with all four wheels on the ground, it can be towed only from the front. Be sure that the transaxle is in neutral. Do not tow at speeds greater than 30 mph(50 km/h) and for more than 15 miles (25 km). Be sure the steering is unlocked byplacing the key in the "ACC" posi- tion.

fcuk-3.p65 12/27/2006, 10:15 AM

14

Page 415 of 490

44APPEARANCE CARE

2CORROSION PROTECTION

SE020A1-E Protecting Your Hyundai From Corrosion By using the most advanced design and construction practices, everyHyundai is built to retain the original factory finish for many years. However, long term durability is also greatly de-pendant upon maintaining the various protection systems and coatings used in manufacture since constant, expo-sure to the elements will result in a breakdown and loss of effectiveness. The following suggestions are made toassist in the maintenance of the vehicle bodywork. SE030A1-E Underbody Coatings Every Hyundai passenger car receives a full underbody and cavity injectiontreatment during production. In order that this treatment may retain maxi- mum effectiveness it is recommendedthat the underbody receives a power wash and a thorough inspection after each winter season. In doing so anyaccumulations of mud, which act as moisture traps and combine with road salts to accelerate corrosion will beremoved. In order to maintain the Anti Perforation Warranty, the requirements regarding the retreatment programmemust be observed in accordance with the Terms and Conditions outlined in the separate Anti Perforation WarrantyBooklet. NOTE: The underbody should never be steam cleaned since the underbody coating may be removed by this pro-cess. During the interim period between power washing the underbody, themore vulnerable areas such as wheel arches should be hosed off particu- larly during the winter season toprevent prolonged contact with road salts. Ensure that the various drain pointslocated at the bottom of the door panels and sills are kept clear to prevent water from becoming trappedwithin the cavities. Wherever pos- sible, the parking of the vehicle in a confined, poorly ventilated location(a garage for example) should be avoided when the vehicle is wet or is covered with snow or ice. Underthese conditions, the internal cavi- ties of the vehicle will remain damp for prolonged periods of time whichwill encourage corrosion. Parking the vehicle where good ventilation exists (outside for example) is pref-erable.

fcuk-4.p65

12/27/2006, 10:15 AM

2

Page 416 of 490

4

CORROSION PREVENTION AND APPEARANCE CARE

3

4

APPEARANCE CARE

3VALETING

SE040A2-E Regular cleaning of the exterior paintwork serves two important func- tions. Firstly, the removal of abrasive dirt and contaminants will maintain thelustre of the paintwork and will prevent discolouration and dulling due to pro- longed contact.Secondly, the presence of damage through impact or abrasion will be ap- parent allowing early rectification to bemade thus preventing corrosion from becoming established and spreading beneath the paint film. To avoid "waterspotting" the vehicle should not be washed in direct sunlight particularly in the case of vehicles having dark bodycolours. The heat from the sun rays is absorbed by the paint film increasing the surface temperature. This actioncauses water used for washing to evaporate quickly leaving behind the deposits from the water and the sham-poo used. Use only a shampoo intended for the purpose and ensure that the body workis thoroughly wet to soften the dirt film prior to attempting to remove this. After removing the dirt film with a soft sponge, the body work should be thor-oughly rinsed and then dried with a good quality chamois leather to prevent streak- ing or spotting of the paint work.Household detergents, solvents and abra- sive cleaning materials should not be used in order to avoid damaging the paint film.Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels should be cleaned using a mildsoap or neutral detergent. Abrasive compounds must not be used since in the event of these damaging the lac-

quer coating, oxidization of the aluminium wheel will occur, spoiling the appearance. The use of a toothbrush will facilitatecleaning between the wheel "spokes".

CAUTION:

!

o Water washing in the engine com- partment including high pressure water washing may cause the fail- ure of electrical circuits located in the engine compartment.

o Never allow water or other liquids to come in contact with electrical/electronic components inside thevehicle as this may damage them.

OJB037800

fcuk-4.p65 12/27/2006, 10:15 AM

3

Page 423 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

5

F030C02FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

GENERAL MAINTENANCE COOLING SYSTEMCOOLANTENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

NO.

123456789

10111213141516171819

60 72

I I I

R I

RR IIII

R IIIIII

5060

I I IIIII I II

R IIIIII

4048

I I II

RR IIII

R IIIIII

3036

I I IIIII I II

R IIIIII

2024

I I III

RR IIII

R IIIIII

1012

I I IIIII I II

R IIIIII

MILES X 1,000 MONTHS

See Note (1)

Note :(1) FOR THE FIRST TIME, REPLACE THE COOLANT AT 60,000 MILES OR 60 MONTHS. AFTER THAT, REPLACE IT EVERY 30,000 MILES OR 24 MONTHS.

fcuk-5.p65 12/27/2006, 10:15 AM

5

Page 428 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

10

6ZF070L1-A

o Suspension Mounting Bolts Check the suspension connections for looseness or damage. Retighten to thespecified torque.6ZF070J1-A

o Brake Pads, Calipers and Rotors

Check the pads for excessive wear,

discs for run out and wear, and cali- pers for fluid leakage.

6ZF070K1-A

o Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

silencer and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070M1-A

o Steering Gear Box, Linkage &

Boots/Lower arm Ball Joint

With the vehicle stopped and engine

off, check for excessive freeplay in the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and balljoints for deterioration, cracks, or dam- age. Replace any damaged parts.

6ZF070N1-A

o Power Steering Pump, Belt

and Hoses

Check the power steering pump and

hoses for leakage and damage. Re- place any damaged or leaking parts immediately. Inspect the power steer-ing belt for evidence of cuts, cracks, excessive wear, oil contamination and proper tension. Replace or adjust it ifnecessary. 6ZF070P1-A

o Driveshafts and Boots

Check the drive shafts, boots andclamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease. 6ZF070Q1-A

o Air conditioning Refrigerant

Check the air conditioning lines and connections for leakage and damage.Check air conditioning performance according to the relevant shop manual if necessary.

fcuk-5.p65 12/27/2006, 10:15 AM

10

Page 454 of 490

6 OWNER MAINTENANCE

26CHECKING THE FREEPLAY

SG160A1-E

Clutch Pedal

G160A01E

0.24 ~ 0.51 in. (6 ~ 13 mm)

The clutch pedal freeplay should bechecked against the specified value. If the freeplay is not correct, the clutchshould be adjusted by a Hyundai authorised repairer.

SG150A1-E

Steering Wheel

G150A01FC

Steering wheel freeplay should be

checked to ensure that the specified value is not exceeded. 1.18 in. (30 mm)

3. Replace the pollen filter with a new

one.

4. Installation is the reverse order of disassembly.

CAUTION:

Be sure to install the pollen filter in the direction of the arrow sign.

! KQNA020B

fcuk-6.p65

12/27/2006, 10:16 AM

26

Page 474 of 490

Vehicle Identification Number (VIN) ............................. 8-2

Engine Number ............................................................. 8-2

Tyre Pressures ............................................................ 8-3

Snow Tyres .................................................................. 8-3

Tyre Chains .................................................................. 8-3

Tyre Rotation ................................................................ 8-4

Tyre Balancing ............................................................. 8-4

Tyre Replacement ........................................................ 8-5

Wheel Replacement ..................................................... 8-5

Spare Tyre and Tools .................................................. 8-6

8

CONSUMER INFORMATION

8

fcuk-8.p6512/27/2006, 10:17 AM

1