start engine Hyundai Santa Fe 2014 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: Santa Fe, Model: Hyundai Santa Fe 2014Pages: 711, PDF Size: 14.72 MB

Page 551 of 711

What to do in an emergency

Road warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

• Hazard warning flasher . . . . . . . . . . . . . . . . . . . 6-2

In case of an emergency while driving . . . . . . . . . . 6-3

• If the engine stalls at a crossroad or crossing . . 6-3

• If you have a flat tire while driving . . . . . . . . . . 6-3

• If engine stalls while driving . . . . . . . . . . . . . . . . 6-3

If the engine does not start . . . . . . . . . . . . . . . . . . . 6-4

• If engine doesn’t turn over or turns over

slowly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

• If engine turns over normally but does not

start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Emergency starting . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

• Jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

• Push-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

If the engine overheats . . . . . . . . . . . . . . . . . . . . . . . 6-7

Tire Pressure Monitoring System (TPMS) . . . . . . 6-8

• Low tire pressure (position) telltale . . . . . . . . . . 6-9

• TPMS (Tire Pressure Monitoring System)

malfunction indicator . . . . . . . . . . . . . . . . . . . 6-11

• Changing a tire with TPMS . . . . . . . . . . . . . . . 6-11If you have a flat tire (with spare tire) . . . . . . . . . 6-13

• Jack and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

• Removing and storing the spare tire . . . . . . . . 6-14

• Changing tires . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

• Wheel nut tightening torque . . . . . . . . . . . . . . . 6-19

• Jack label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

• EC declaration of conformity for jack . . . . . . 6-23

If you have a flat tire (with Tire Mobility Kit) . . 6-24

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

• Components of the Tire Mobility Kit . . . . . . . 6-25

• Using the Tire Mobility Kit. . . . . . . . . . . . . . . . 6-26

• Distributing the sealant . . . . . . . . . . . . . . . . . . . 6-28

• Checking the tire inflation pressure. . . . . . . . . 6-28

• Notes on the safe use of the Tire Mobility Kit . . 6-29

• Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

• Towing service . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

• Removable towing hook . . . . . . . . . . . . . . . . . . 6-31

• Emergency towing . . . . . . . . . . . . . . . . . . . . . . . 6-32

Emergency commodity . . . . . . . . . . . . . . . . . . . . . 6-35

• Fire extinguisher . . . . . . . . . . . . . . . . . . . . . . . . 6-35

• First aid kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

• Triangle reflector . . . . . . . . . . . . . . . . . . . . . . . . 6-35

• Tire pressure gauge . . . . . . . . . . . . . . . . . . . . . . 6-35

6

Page 553 of 711

63

What to do in an emergency

IN CASE OF AN EMERGENCY WHILE DRIVING

If the engine stalls at a cross-

road or crossing

• If the engine stalls at a crossroad

or crossing, set the shift lever in the

N (Neutral) position and then push

the vehicle to a safe place.

• If your vehicle has a manual

transaxle not equipped with a igni-

tion lock switch, the vehicle can

move forward by shifting to the

2(second) or 3(third) gear and then

turning the starter without depress-

ing the clutch pedal.

If you have a flat tire while

driving

If a tire goes flat while you are driv-

ing:

1.Take your foot off the accelerator

pedal and let the vehicle slow

down while driving straight ahead.

Do not apply the brakes immedi-

ately or attempt to pull off the road

as this may cause a loss of control.

When the vehicle has slowed to

such a speed that it is safe to do

so, brake carefully and pull off the

road. Drive off the road as far as

possible and park on firm, level

ground. If you are on a divided

highway, do not park in the median

area between the two traffic lanes.

2.When the vehicle is stopped, turn

on your emergency hazard flash-

ers, set the parking brake and put

the transaxle in P (automatic

transaxle) or reverse (manual

transaxle).

3.Have all passengers get out of the

vehicle. Be sure they all get out on

the side of the vehicle that is away

from traffic.4.When changing a flat tire, follow

the instruction provided later in this

section.

If engine stalls while driving

1.Reduce your speed gradually,

keeping a straight line. Move cau-

tiously off the road to a safe place.

2.Turn on your emergency flashers.

3.Try to start the engine again. If your

vehicle does not start, we recom-

mend that you consult an author-

ized HYUNDAI dealer.

Page 554 of 711

What to do in an emergency

4 6

IF THE ENGINE WILL NOT START

If engine doesn't turn over or

turns over slowly

1.If your vehicle has an automatic

transaxle, be sure the shift lever is

in N (Neutral) or P (Park) and the

emergency brake is set.

2.Check the battery connections to

be sure they are clean and tight.

3.Turn on the interior light. If the light

dims or goes out when you operate

the starter, the battery is dis-

charged.

4.Check the starter connections to

be sure they are securely tight-

ened.

5.Do not push or pull the vehicle to

start it. See instructions for "Jump

starting".

If engine turns over normally

but does not start

1.Check fuel level.

2.With the ignition switch in the

LOCK/OFF position, check all con-

nectors at ignition, coil and spark

plugs. Reconnect any that may be

disconnected or loose.

3.Check the fuel line in the engine

compartment.

4.If the engine still does not start, we

recommend that you call an

authorized HYUNDAI dealer.

WARNING

If the engine will not start, do

not push or pull the vehicle to

start it. This could result in a

collision or cause other dam-

age. In addition, push or pull

starting may cause the catalytic

converter to be overloaded and

create a fire hazard.

Page 556 of 711

What to do in an emergency

6 6

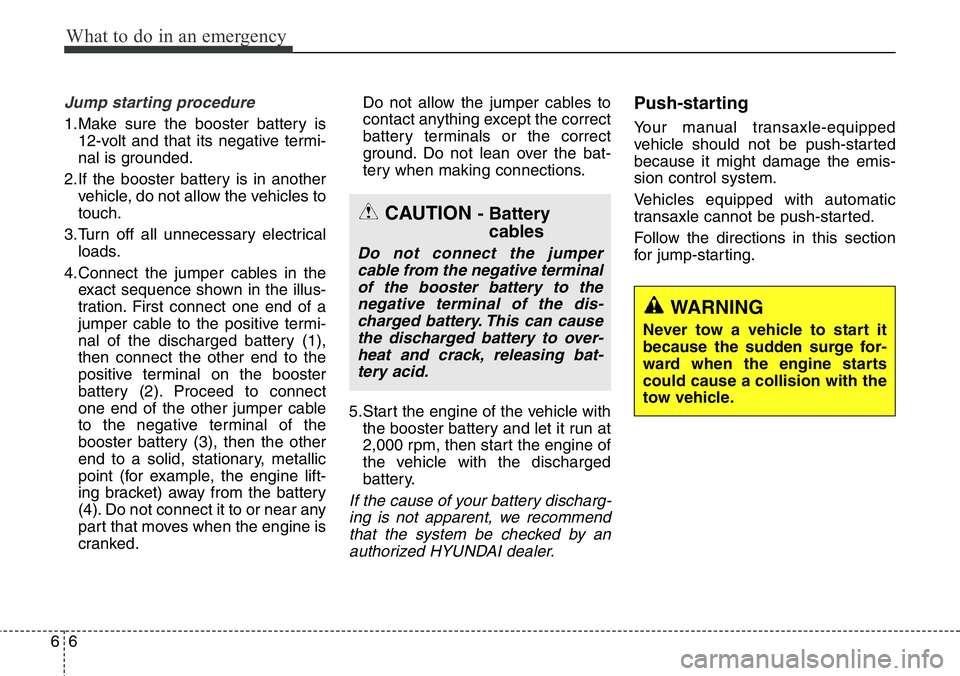

Jump starting procedure

1.Make sure the booster battery is

12-volt and that its negative termi-

nal is grounded.

2.If the booster battery is in another

vehicle, do not allow the vehicles to

touch.

3.Turn off all unnecessary electrical

loads.

4.Connect the jumper cables in the

exact sequence shown in the illus-

tration. First connect one end of a

jumper cable to the positive termi-

nal of the discharged battery (1),

then connect the other end to the

positive terminal on the booster

battery (2). Proceed to connect

one end of the other jumper cable

to the negative terminal of the

booster battery (3), then the other

end to a solid, stationary, metallic

point (for example, the engine lift-

ing bracket) away from the battery

(4). Do not connect it to or near any

part that moves when the engine is

cranked.Do not allow the jumper cables to

contact anything except the correct

battery terminals or the correct

ground. Do not lean over the bat-

tery when making connections.

5.Start the engine of the vehicle with

the booster battery and let it run at

2,000 rpm, then start the engine of

the vehicle with the discharged

battery.

If the cause of your battery discharg-

ing is not apparent, we recommend

that the system be checked by an

authorized HYUNDAI dealer.

Push-starting

Your manual transaxle-equipped

vehicle should not be push-started

because it might damage the emis-

sion control system.

Vehicles equipped with automatic

transaxle cannot be push-started.

Follow the directions in this section

for jump-starting.

WARNING

Never tow a vehicle to start it

because the sudden surge for-

ward when the engine starts

could cause a collision with the

tow vehicle.

CAUTION - Battery

cables

Do not connect the jumper

cable from the negative terminal

of the booster battery to the

negative terminal of the dis-

charged battery. This can cause

the discharged battery to over-

heat and crack, releasing bat-

tery acid.

Page 564 of 711

What to do in an emergency

14 6

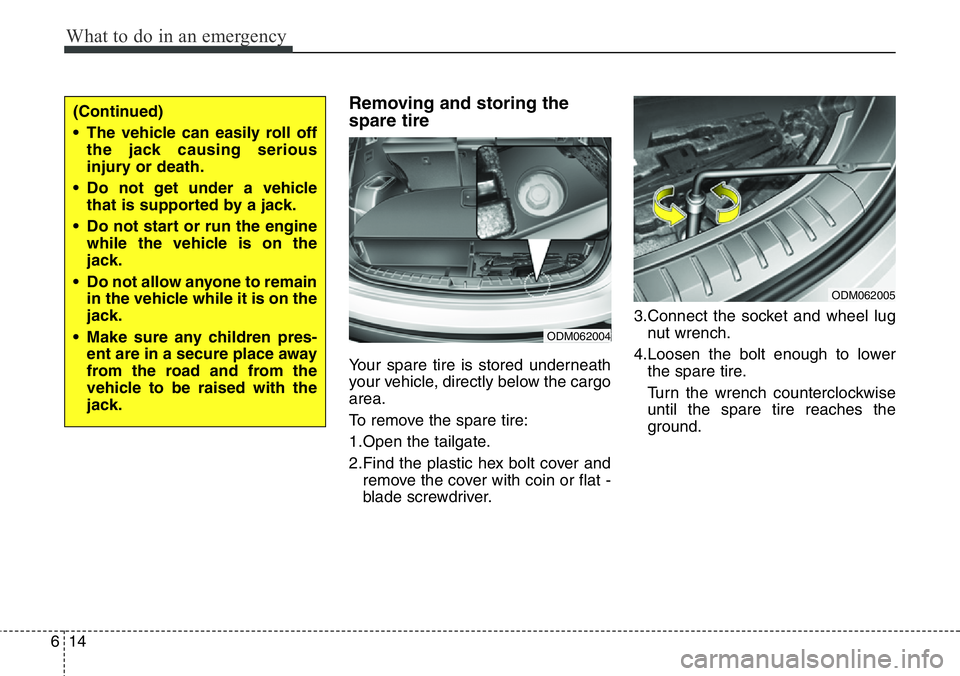

Removing and storing the

spare tire

Your spare tire is stored underneath

your vehicle, directly below the cargo

area.

To remove the spare tire:

1.Open the tailgate.

2.Find the plastic hex bolt cover and

remove the cover with coin or flat -

blade screwdriver.3.Connect the socket and wheel lug

nut wrench.

4.Loosen the bolt enough to lower

the spare tire.

Turn the wrench counterclockwise

until the spare tire reaches the

ground.

ODM062004

(Continued)

• The vehicle can easily roll off

the jack causing serious

injury or death.

• Do not get under a vehicle

that is supported by a jack.

• Do not start or run the engine

while the vehicle is on the

jack.

• Do not allow anyone to remain

in the vehicle while it is on the

jack.

• Make sure any children pres-

ent are in a secure place away

from the road and from the

vehicle to be raised with the

jack.

ODM062005

Page 577 of 711

627

What to do in an emergency

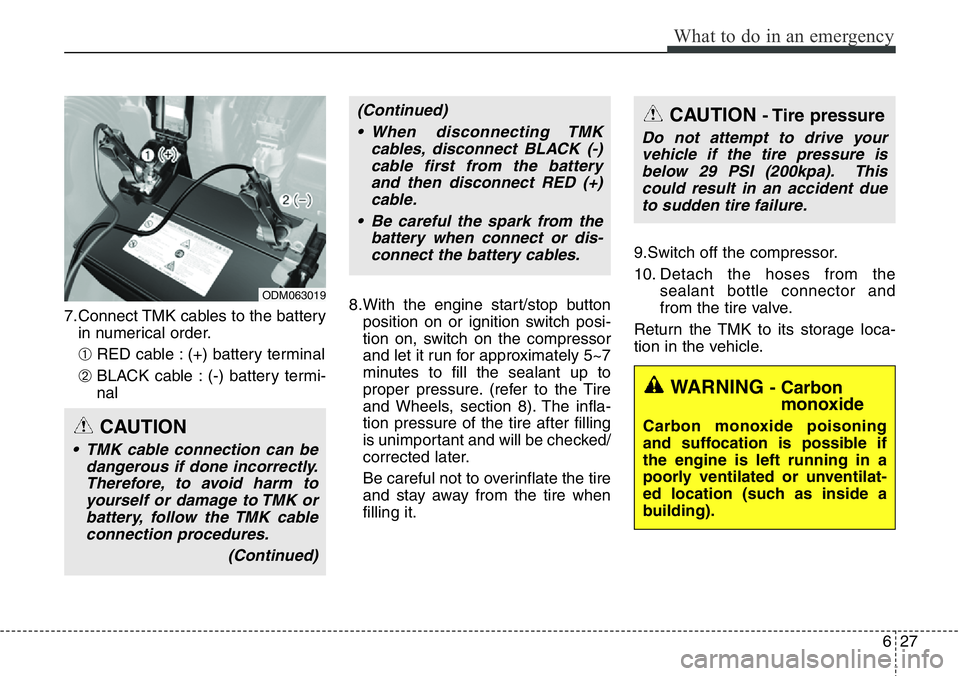

7.Connect TMK cables to the battery

in numerical order.

➀RED cable : (+) battery terminal

➁BLACK cable : (-) battery termi-

nal8.With the engine start/stop button

position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tire

and Wheels, section 8). The infla-

tion pressure of the tire after filling

is unimportant and will be checked/

corrected later.

Be careful not to overinflate the tire

and stay away from the tire when

filling it.9.Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the TMK to its storage loca-

tion in the vehicle.

CAUTION - Tire pressure

Do not attempt to drive your

vehicle if the tire pressure is

below 29 PSI (200kpa). This

could result in an accident due

to sudden tire failure.

CAUTION

• TMK cable connection can be

dangerous if done incorrectly.

Therefore, to avoid harm to

yourself or damage to TMK or

battery, follow the TMK cable

connection procedures.

(Continued)

ODM063019

WARNING - Carbon

monoxide

Carbon monoxide poisoning

and suffocation is possible if

the engine is left running in a

poorly ventilated or unventilat-

ed location (such as inside a

building).

(Continued)

• When disconnecting TMK

cables, disconnect BLACK (-)

cable first from the battery

and then disconnect RED (+)

cable.

• Be careful the spark from the

battery when connect or dis-

connect the battery cables.

Page 592 of 711

77

Maintenance

Engine compartment precau-

tions (Diesel engine)

• The piezo injector operates at high

voltage (maximum 200v).

Therefore, the following accidents

may occur.

- Direct contact with the injector or

injector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from

the operating injector may cause

the artificial heart pacemaker to

malfunction.

• Follow the safety tips provided

below, when you are checking the

engine room while the engine is

running.

- Do not touch the injector, injector

wirings, and the engine computer

while the engine is running.

- Do not remove the injector con-

nector while the engine is run-

ning.

- People using pacemakers must

not go near the engine while the

engine is starting or running.

WARNING- Diesel Engine

Never work on injection system

with engine running or within 30

seconds after shutting off

engine. High-pressure pump,

rail, injectors and high-pressure

pipes are subject to high pres-

sure even after the engine

stopped. The fuel jet produced

by fuel leaks may cause serious

injury, if it touches the body.

People using pacemakers

should not move than 30cm

closer to the ECU or wiring har-

ness within the engine room

while engine is running, since

the high currents in the elec-

tronic engine control system

produce considerable magnetic

fields.(Continued)

• When you remove the interior

trim cover with a flat head (-)

driver, be careful not to dam-

age the cover.

• Be careful when you replace

and clean bulbs to avoid

burns or electrical shock.

Page 596 of 711

711

Maintenance

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE, EXCEPT RUSSIA

The following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all

vehicle emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is deter-

mined by whichever occurs first.

*

1: Check the engine oil level and leak every 500 km (350

miles) or before starting a long trip.

*

2: This maintenance schedule depends on fuel quality. It is

applicable only when using a qualified fuel <"EN590 or

equivalent">. If the diesel fuel specifications don't meet the

EN590, it must be replaced according to the severe mainte-

nance schedule.

*

3: If the recommended oil is not available, replace engine oil

and engine oil filter every 20,000 km or 12 months.

*

4: If the recommended oil is not available, replace engine oil

and filter every 15,000 km or 12 months for 2.4L engine.

*

5: The engine oil level should be checked regularly and main-

tained properly. Operating with an insufficient amount of oil

can damage the engine, and such damage is not covered

by warranty.

*

6: This maintenance schedule depends on fuel quality. It is

applicable only when using a qualified fuel <"EN590 or

equivalent">. If the diesel fuel specifications don't meet the

EN590, it must be replaced more frequently. If there are

some important safety matters like fuel flow restriction,

surging, loss of power, hard starting problem etc., replace

the fuel filter immediately regardless of maintenance sched-

ule and we recommanded that you consult an authorized

HYUNDAI dealer for details.*

7: The fuel filter is considered to be maintenance free but peri-

odic inspection is recommended for this maintenance

schedule depends on fuel quality. If there are some impor-

tant matters like fuel flow restriction, surging, loss of power,

hard starting problem etc, replace the fuel filter immediately

regardless of maintenance schedule and we recommanded

that you consult an authorized HYUNDAI dealer for details.

*

8: Manual transaxle fluid, transfer case oil and differential oil

should be changed anytime they have been submerged in

water.

*

9: Inspect and if necessary correct or replace. Inspect drive

belt tensioner, idler and alternator pulley and if necessary

correct or replace.

*

10: When adding coolant, use only deionized water or soft

water for your vehicle and never mix hard water in the

coolant filled at the factory. An improper coolant mixture

can result in serious malfunction or engine damage.

*

11: Inspect for excessive valve noise and/or engine vibration

and adjust if necessary. We recommended that the system

should be checked by an authorized HYUNDAI dealer.

*

12: If good quality gasolines that meet Europe Fuel standards

(EN228) or equivalents including fuel additives is not avail-

able, one bottle of additive is recommended. Additives are

available from your authorized HYUNDAI dealer along with

information on how to use them. Do not mix other additives.

Page 607 of 711

Maintenance

22 7

NORMAL MAINTENANCE SCHEDULE - EXCEPT EUROPE, FOR RUSSIA

The following maintenance services must be performed to ensure good emission control and performance. Keep

receipts for all vehicle emission services to protect your warranty. Where both mileage and time are shown, the fre-

quency of service is determined by whichever occurs first.

*1: Inspect drive belt tensioner, idler and alternator pulley and

if necessary correct or replace.

*

2: Check the engine oil level and leak every 500 km (350

miles) or before starting a long trip.

*

3: The engine oil level should be checked regularly and main-

tained properly. Operating with an insufficient amount of oil

can damage the engine, and such damage is not covered

by warranty.

*

4: This maintenance schedule depends on fuel quality. It is

applicable only when using a qualified fuel <"EN590 or

equivalent">. If the diesel fuel specifications don't meet the

EN590, it must be replaced more frequently. HYUNDAI rec-

ommends "every 7,500km inspection, every 15,000km

replacement". If there are some important safety matters

like fuel flow restriction, surging, loss of power, hard starting

problem etc., replace the fuel filter immediately regardless

of maintenance schedule and we recommand that you con-

sult an authorized HYUNDAI dealer for details

*

5: For your convenience, it can be replaced prior to it's interval

when you do maintenance of other items.

*

6: Inspect for excessive valve noise and/or engine vibration

and adjust if necessary. We recommended that the system

should be checked by an authorized HYUNDAI dealer.*

7: The fuel filter is considered to be maintenance free but peri-

odic inspection is recommended for this maintenance

schedule depends on fuel quality. If there are some impor-

tant matters like fuel flow restriction, surging, loss of power,

hard starting problem etc, replace the fuel filter immediate-

ly regardless of maintenance schedule and we recommand

that you consult an authorized HYUNDAI dealer for details.

*

8: When adding coolant, use only deionized water or soft

water for your vehicle and never mix hard water in the

coolant filled at the factory. An improper coolant mixture can

result in serious malfunction or engine damage.

*

9: Inspect and if necessary correct or replace. Inspect drive

belt tensioner, idler and alternator pulley and if necessary

correct or replace.

*

10: If good quality gasolines that meet Europe Fuel standards

(EN228) or equivalents including fuel additives is not avail-

able, one bottle of additive is recommended. Additives are

available from your authorized HYUNDAI dealer along with

information on how to use them. Do not mix other additives.

*

11: Manual transaxle fluid, transfer case oil and differential oil

should be changed anytime they have been submerged in

water.

Page 619 of 711

Maintenance

34 7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

We recommend that the fuel filter be

replaced by an authoized HYUNDAI

dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. We recommend that the fuel

lines, fuel hoses and connectionsr be

replaced by an authoized HYUNDAI

dealer.

WARNING - Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off

engine. High pressure pump,

rail, injectors and high pressure

pipes are subject to high pres-

sure even after the engine

stopped. The fuel jet produced

by fuel leaks may cause serious

injury, if it touch the body.

People using pacemakers

should not move than 30cm

closer to the ECU or wiring har-

ness within the engine room

while engine is running, since

the high currents in the

Common Rail system produce

considerable magnetic fields.

CAUTION

When you are inspecting the

belt, place the ignition switch in

the LOCK/OFF or ACC position.