fuel filter Hyundai Santa Fe 2016 Owner's Manual - RHD (UK, Australia)

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: Santa Fe, Model: Hyundai Santa Fe 2016Pages: 699, PDF Size: 15.65 MB

Page 20 of 699

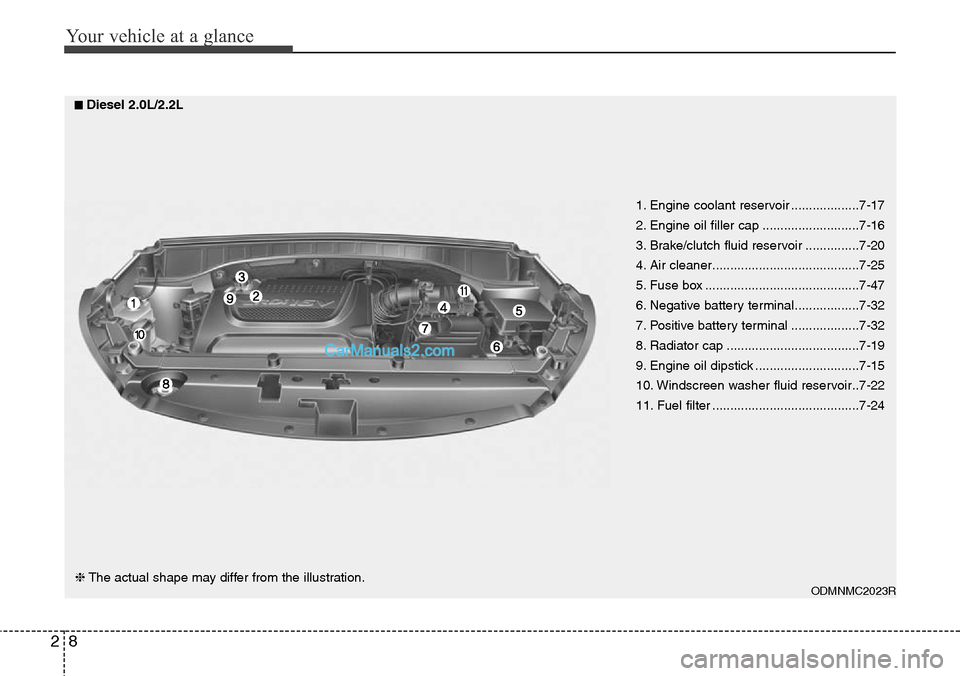

Your vehicle at a glance

8 2

ODMNMC2023R

1. Engine coolant reservoir ...................7-17

2. Engine oil filler cap ...........................7-16

3. Brake/clutch fluid reservoir ...............7-20

4. Air cleaner.........................................7-25

5. Fuse box ...........................................7-47

6. Negative battery terminal..................7-32

7. Positive battery terminal ...................7-32

8. Radiator cap .....................................7-19

9. Engine oil dipstick .............................7-15

10. Windscreen washer fluid reservoir..7-22

11. Fuel filter .........................................7-24

■Diesel 2.0L/2.2L

❈The actual shape may differ from the illustration.

Page 199 of 699

4101

Features of your vehicle

Door Ajar Warning Light

This warning light illuminates:

When a door is not close securely.

Tailgate Open Warning

Light

This warning light illuminates:

When the tailgate is not close

securely.

Fuel Filter Warning Light

(Diesel Engine)

This warning light illuminates:

• Once you set the ignition switch or

Engine Start/Stop Button to the ON

position.

- It illuminates for approximately 3

seconds and then goes off.

• When water has accumulated

inside the fuel filter.

In this case, remove the water from

the fuel filter.

For more details, refer to “Fuel

Filter” in chapter 7.

CAUTION - Fuel Filter

Warning Light

• When the Fuel Filter Warning

Light illuminates, engine

power (vehicle speed & idle

speed) may decrease.

• If you keep driving with the

warning light on, engine parts

(injector, common rail, high

pressure fuel pump) may be

damaged. If this occurs, we

recommend that you have the

vehicle inspected by a

HYUNDAI authorised repairer

as soon as possible.

Page 598 of 699

Maintenance

7

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-5

• Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

• Owner maintenance precautions . . . . . . . . . . . . . . . . . 7-5

• Engine compartment precautions (Diesel engine) . . . 7-7

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

• Owner maintenance schedule. . . . . . . . . . . . . . . . . . . . 7-8

Scheduled maintenance service. . . . . . . . . . . . . . . 7-10

Explanation of scheduled maintenance items . . . 7-11

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

• Checking the engine oil level . . . . . . . . . . . . . . . . . . . 7-15

• Changing the engine oil and filter . . . . . . . . . . . . . . . 7-16

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

• Checking the coolant level . . . . . . . . . . . . . . . . . . . . . 7-17

• Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

• Checking the brake/clutch fluid level . . . . . . . . . . . . 7-20

Power steering fluid . . . . . . . . . . . . . . . . . . . . . . . . 7-21

• Checking the power steering fluid level . . . . . . . . . 7-21

• Checking the power steering hose . . . . . . . . . . . . . . . 7-21

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

• Checking the washer fluid level . . . . . . . . . . . . . . . . . 7-22

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

• Checking the parking brake. . . . . . . . . . . . . . . . . . . . 7-23

Fuel filter (for Diesel) . . . . . . . . . . . . . . . . . . . . . . . 7-24

• Draining water from fuel filter . . . . . . . . . . . . . . . . . 7-24

Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Climate control air filter . . . . . . . . . . . . . . . . . . . . 7-27

• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

• For best battery service . . . . . . . . . . . . . . . . . . . . . . . 7-32

• Battery capacity label . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

• Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

• Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Tyres and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

• Tyre care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

• Recommended cold tyre inflation pressures . . . . . . . 7-35

• Checking tyre inflation pressure . . . . . . . . . . . . . . . . 7-37

• Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

• Wheel alignment and tyre balance . . . . . . . . . . . . . . 7-39

• Tyre replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

• Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

• Tyre traction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

• Tyre maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

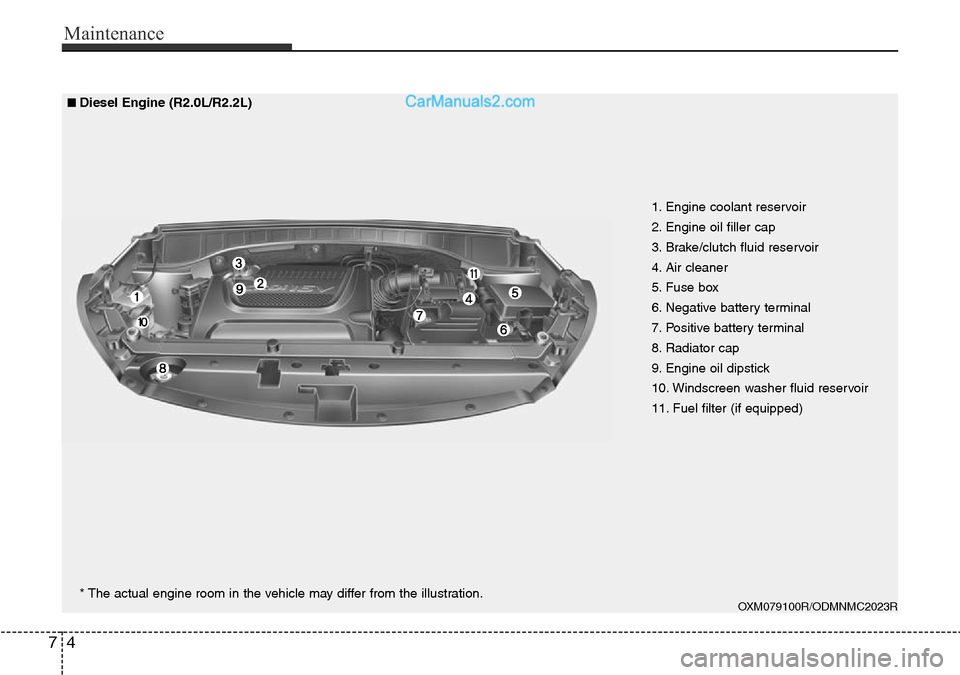

Page 601 of 699

Maintenance

4 7

1. Engine coolant reservoir

2. Engine oil filler cap

3. Brake/clutch fluid reservoir

4. Air cleaner

5. Fuse box

6. Negative battery terminal

7. Positive battery terminal

8. Radiator cap

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

11. Fuel filter (if equipped)

OXM079100R/ODMNMC2023R

■Diesel Engine (R2.0L/R2.2L)

* The actual engine room in the vehicle may differ from the illustration.

Page 608 of 699

711

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

We recommend that the fuel filter be

replaced by a HYUNDAI authorised

repairer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. We recommend that the fuel

lines, fuel hoses and connectionsr be

replaced by a HYUNDAI authorised

repairer.

WARNING - Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off

engine. High pressure pump,

rail, injectors and high pressure

pipes are subject to high pres-

sure even after the engine

stopped. The fuel jet produced

by fuel leaks may cause serious

injury, if it touch the body.

People using pacemakers

should not move than 30cm

closer to the ECU or wiring har-

ness within the engine room

whilst engine is running, since

the high currents in the

Common Rail system produce

considerable magnetic fields.

CAUTION

When you are inspecting the

belt, place the ignition switch in

the LOCK/OFF or ACC position.

Page 609 of 699

Maintenance

12 7

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapour hose or fuel filler cap is cor-

rectly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

We recommend that the air cleaner

filter be replaced by a HYUNDAI

authorised repairer.

Spark plugs

(for petrol engine)

Make sure to install new spark plugs

of the correct heat range.

Valve clearance

(for petrol engine)

Inspect excessive valve noise and/or

engine vibration and adjust if neces-

sary. We recommend that the system

be serviced by a HYUNDAI autho-

rised repairer.

WARNING

Do not disconnect and inspect

spark plugs when the engine is

hot. You may burn yourself.

Page 621 of 699

Maintenance

24 7

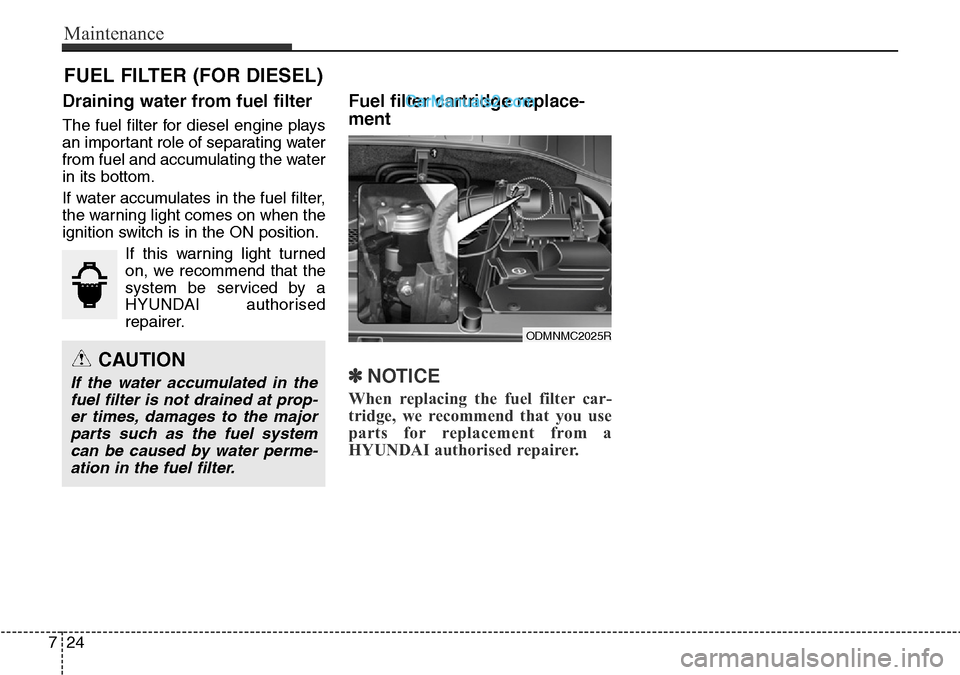

FUEL FILTER (FOR DIESEL)

Draining water from fuel filter

The fuel filter for diesel engine plays

an important role of separating water

from fuel and accumulating the water

in its bottom.

If water accumulates in the fuel filter,

the warning light comes on when the

ignition switch is in the ON position.

If this warning light turned

on, we recommend that the

system be serviced by a

HYUNDAI authorised

repairer.

Fuel filter cartridge replace-

ment

✽NOTICE

When replacing the fuel filter car-

tridge, we recommend that you use

parts for replacement from a

HYUNDAI authorised repairer.

ODMNMC2025R

CAUTION

If the water accumulated in the

fuel filter is not drained at prop-

er times, damages to the major

parts such as the fuel system

can be caused by water perme-

ation in the fuel filter.

Page 650 of 699

753

Maintenance

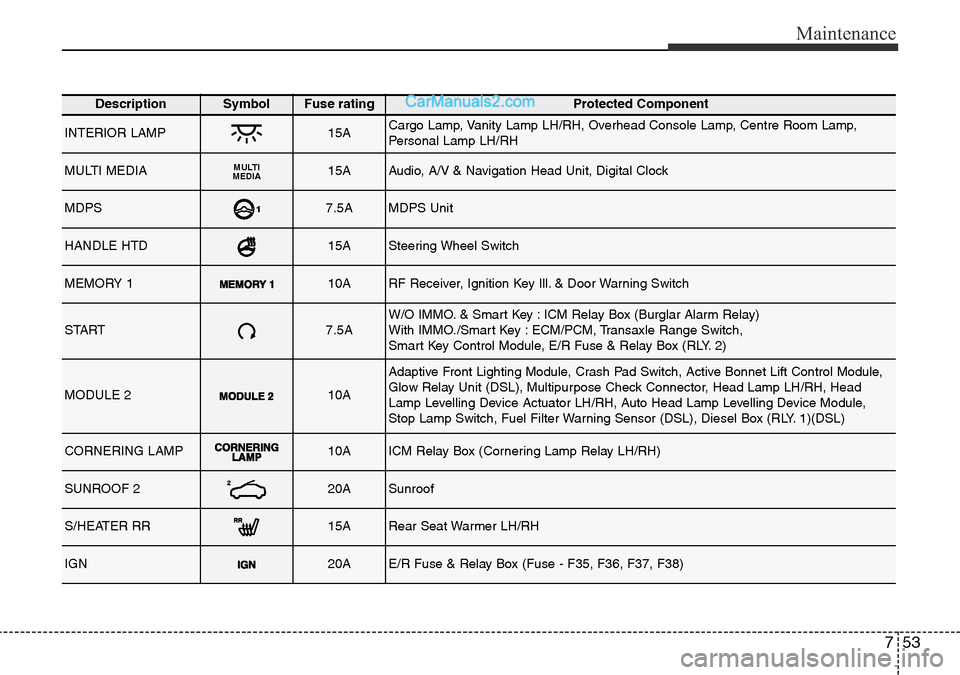

DescriptionSymbol Fuse ratingProtected Component

INTERIOR LAMP15ACargo Lamp, Vanity Lamp LH/RH, Overhead Console Lamp, Centre Room Lamp,

Personal Lamp LH/RH

MULTI MEDIAMULTI

MEDIA15AAudio, A/V & Navigation Head Unit, Digital Clock

MDPS7.5AMDPS Unit

HANDLE HTD15ASteering Wheel Switch

MEMORY 110ARF Receiver, Ignition Key Ill. & Door Warning Switch

START7.5AW/O IMMO. & Smart Key : ICM Relay Box (Burglar Alarm Relay)

With IMMO./Smart Key : ECM/PCM, Transaxle Range Switch,

Smart Key Control Module, E/R Fuse & Relay Box (RLY. 2)

MODULE 210A

Adaptive Front Lighting Module, Crash Pad Switch, Active Bonnet Lift Control Module,

Glow Relay Unit (DSL), Multipurpose Check Connector, Head Lamp LH/RH, Head

Lamp Levelling Device Actuator LH/RH, Auto Head Lamp Levelling Device Module,

Stop Lamp Switch, Fuel Filter Warning Sensor (DSL), Diesel Box (RLY. 1)(DSL)

CORNERING LAMP 10AICM Relay Box (Cornering Lamp Relay LH/RH)

SUNROOF 220ASunroof

S/HEATER RR15ARear Seat Warmer LH/RH

IGN20AE/R Fuse & Relay Box (Fuse - F35, F36, F37, F38)

Page 660 of 699

763

Maintenance

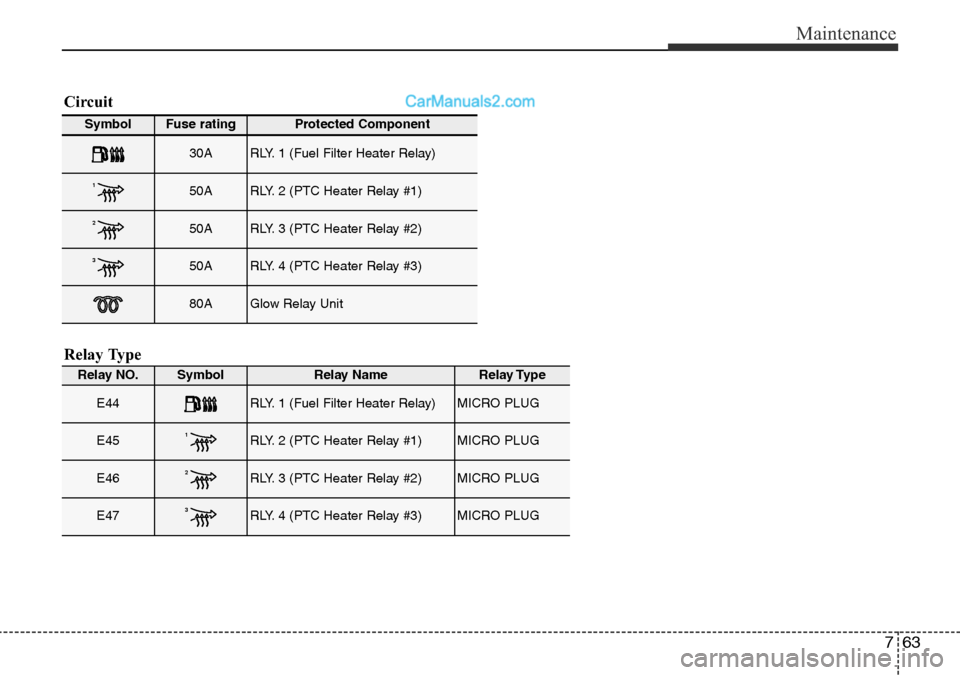

Symbol Fuse ratingProtected Component

30ARLY. 1 (Fuel Filter Heater Relay)

150ARLY. 2 (PTC Heater Relay #1)

250ARLY. 3 (PTC Heater Relay #2)

350ARLY. 4 (PTC Heater Relay #3)

80AGlow Relay Unit

Circuit

Relay Type

Relay NO.SymbolRelay NameRelay Type

E44RLY. 1 (Fuel Filter Heater Relay)MICRO PLUG

E451RLY. 2 (PTC Heater Relay #1)MICRO PLUG

E462RLY. 3 (PTC Heater Relay #2)MICRO PLUG

E473RLY. 4 (PTC Heater Relay #3)MICRO PLUG

Page 684 of 699

787

Maintenance

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty Booklet in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

emission regulations.

There are three emission control

systems which are as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys-

tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

car inspected and maintained by a

HYUNDAI authorised repairer in

accordance with the maintenance

schedule.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

• To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

• After dynamometer testing is

completed, turn the ESC system

back on by pressing the ESC

switch again.

1. Crankcase emission control

system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-

trol system

The Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the

atmosphere.

Canister

Fuel vapours generated inside the

fuel tank are absorbed and stored in

the onboard canister. When the

engine is running, the fuel vapours

absorbed in the canister are drawn

into the surge tank through the purge

control solenoid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

ourated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evapourated fuel

to the engine.