timing belt Hyundai Terracan 2003 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Terracan, Model: Hyundai Terracan 2003Pages: 349, PDF Size: 4.56 MB

Page 140 of 349

VEHICLE MAINTENANCE REQUIREMENTS

5- 2

F030A01A-GAT SCHEDULED MAINTENANCE The following maintenance services must be performed to assure good vehicle control and performance. Keep receipts for all vehi

cle services to protect

your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever occurs first. F030B01HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (GASOLINE)

ENGINE OIL AND FILTER See Note (1)DRIVE BELT (ALT, DAMPER, TENSIONER, IDLER)FUEL FILTER (MFI TYPE)FUEL LINES, FUEL HOSES AND CONNECTIONSTIMING BELTVAPOR HOSE AND FUEL FILLER CAPVACUUM AND CRANKCASE VENTILATION HOSESAIR CLEANER FILTERSPARK PLUGSSPARK PLUGS (PLATINUM COATED)

NO. DESCRIPTION

1 2 3 4 5 6 7 8 9 120

96

RRR I I I

R I105

84

R I I I90 72

R I I

R I I

RRR75 60

R I I I I60 48

R I

R I III

R45 36

R I I I

R30 24

R I II I

R I

15 12

R I I IKILOMETERS X 1000 MONTHS

Note: (1) European Community Only - API SG, SG/CD, SH OR SH/CD Except European Community - API SE OR ABOVE In case of Gasoline standard engine as recommended oil (API SE or ABOVE) is difficult to obtain in fieId, following oil recomen ded:

API SD - The engine oil and filter should be changed at every 10,000km or 6 months.

Page 141 of 349

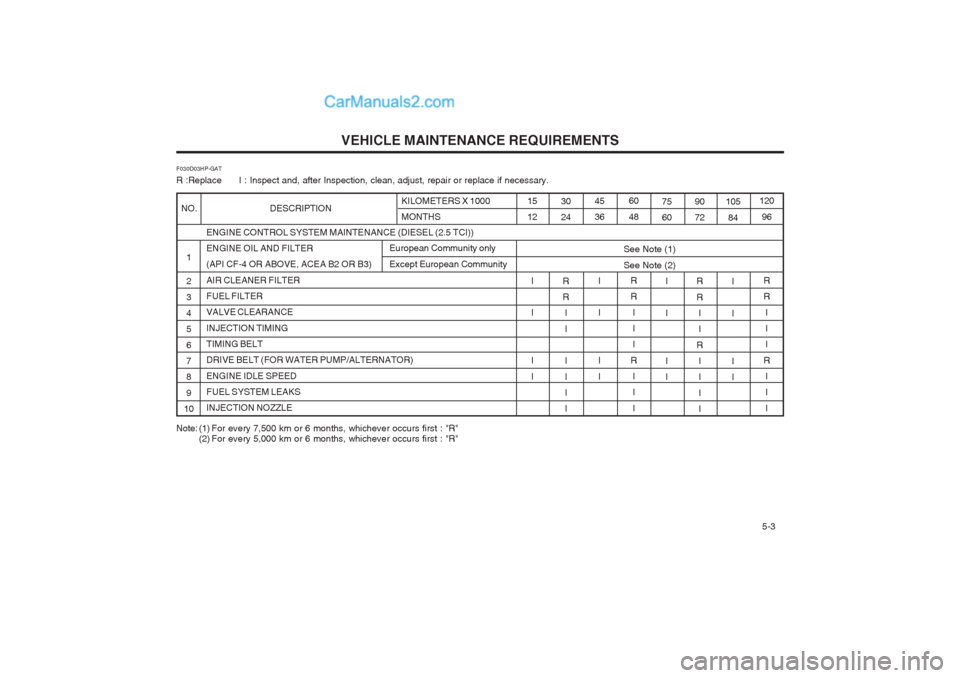

VEHICLE MAINTENANCE REQUIREMENTS 5-3

KILOMETERS X 1000 MONTHS

F030D03HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL (2.5 TCI)) ENGINE OIL AND FILTER(API CF-4 OR ABOVE, ACEA B2 OR B3) AIR CLEANER FILTER FUEL FILTERVALVE CLEARANCE INJECTION TIMING TIMING BELTDRIVE BELT (FOR WATER PUMP/ALTERNATOR) ENGINE IDLE SPEED FUEL SYSTEM LEAKSINJECTION NOZZLE

NO. DESCRIPTION

1 2 3 45 6 78 9

10120

96

R R III

R II I105

84

I I I I90 72R R I I

R II I I75 60

I I I I60 48R R III

R II I45 36

I I I I30 24RR I I I I II15 12

I I I I

See Note (1) See Note (2)

Note: (1) For every 7,500 km or 6 months, whichever occurs first : "R"

(2) For every 5,000 km or 6 months, whichever occurs first : "R"European Community only Except European Community

Page 142 of 349

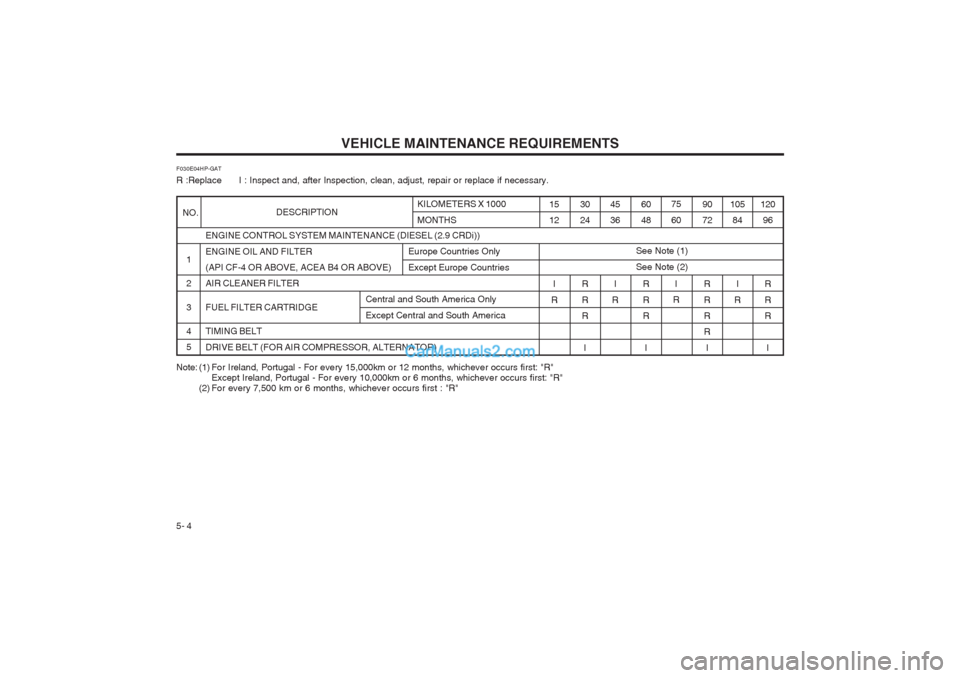

VEHICLE MAINTENANCE REQUIREMENTS

5- 4

F030E04HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL (2.9 CRDi)) ENGINE OIL AND FILTER (API CF-4 OR ABOVE, ACEA B4 OR ABOVE)AIR CLEANER FILTER FUEL FILTER CARTRIDGE TIMING BELT DRIVE BELT (FOR AIR COMPRESSOR, ALTERNATOR)

1 2 3 4 5 120

96

R R R I

105

84

I

R

9072

R R RR I

75 60

I

R

60 48

R R R I

4536

I

R

3024

R R R I

1512

I

R

KILOMETERS X 1000 MONTHS

DESCRIPTION

NO.

Europe Countries Only Except Europe CountriesSee Note (1) See Note (2)

Note: (1) For Ireland, Portugal - For every 15,000km or 12 months, whichever occurs first: "R" Except Ireland, Portugal - For every 10,000km or 6 months, whichever occurs first: "R"

(2) For every 7,500 km or 6 months, whichever occurs first : "R"

Central and South America Only Except Central and South America

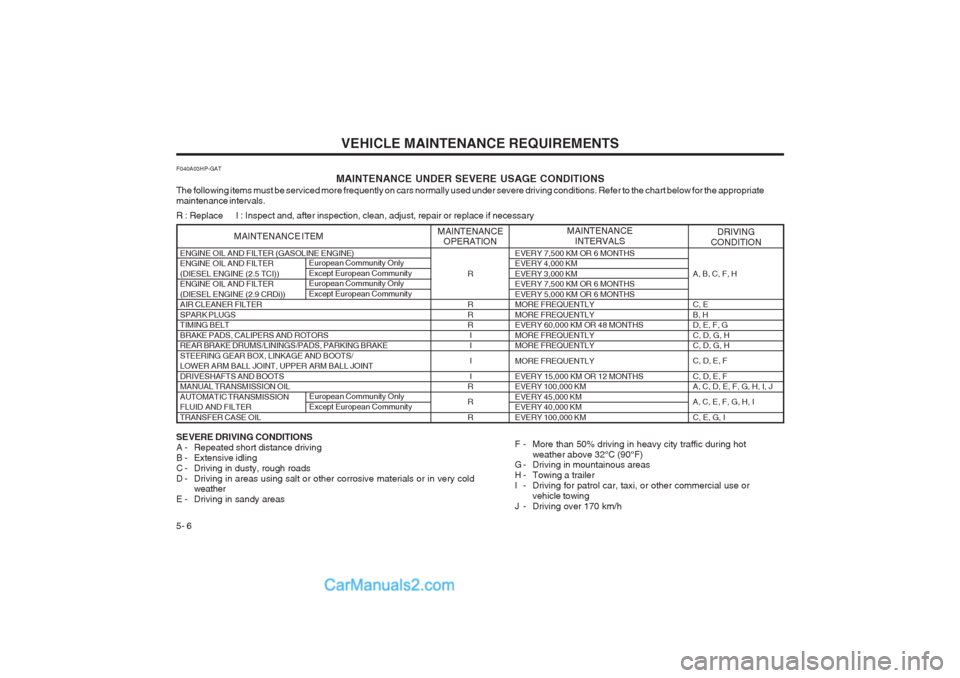

Page 144 of 349

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 ENGINE OIL AND FILTER (GASOLINE ENGINE) ENGINE OIL AND FILTER (DIESEL ENGINE (2.5 TCI)) ENGINE OIL AND FILTER

(DIESEL ENGINE (2.9 CRDi)) AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADS, CALIPERS AND ROTORS REAR BRAKE DRUMS/LININGS/PADS, PARKING BRAKE STEERING GEAR BOX, LINKAGE AND BOOTS/ LOWER ARM BALL JOINT, UPPER ARM BALL JOINT DRIVESHAFTS AND BOOTS MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID AND FILTER TRANSFER CASE OIL

R R R R

II I I

R R R

European Community Only Except European Community European Community Only Except European Community

A, B, C, F, H C, E B, H D, E, F, G C, D, G, H C, D, G, H C, D, E, F C, D, E, F A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E, G, I

F040A03HP-GAT

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas F - More than 50% driving in heavy city traffic during hot

weather above 32°C (90°F)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car, taxi, or other commercial use or

vehicle towing

J - Driving over 170 km/h

MAINTENANCE ITEM

European Community OnlyExcept European Community

DRIVING

CONDITION

MAINTENANCE

OPERATION MAINTENANCE

INTERVALS

EVERY 7,500 KM OR 6 MONTHS EVERY 4,000 KM EVERY 3,000 KM EVERY 7,500 KM OR 6 MONTHS EVERY 5,000 KM OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 60,000 KM OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLY MORE FREQUENTLY EVERY 15,000 KM OR 12 MONTHS EVERY 100,000 KM EVERY 45,000 KM EVERY 40,000 KM EVERY 100,000 KM

Page 145 of 349

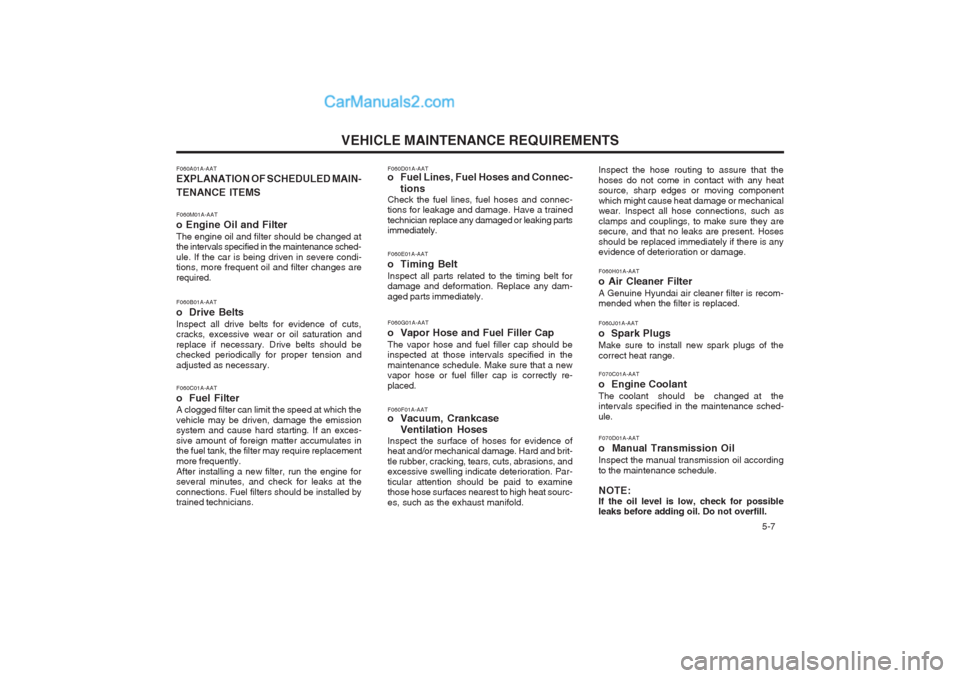

VEHICLE MAINTENANCE REQUIREMENTS 5-7

F060A01A-AAT EXPLANATION OF SCHEDULED MAIN- TENANCE ITEMS F060M01A-AAT o Engine Oil and FilterThe engine oil and filter should be changed at

the intervals specified in the maintenance sched- ule. If the car is being driven in severe condi- tions, more frequent oil and filter changes are required. F060B01A-AAT

o Drive BeltsInspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked periodically for proper tension and adjusted as necessary. F060C01A-AAT

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emission system and cause hard starting. If an exces- sive amount of foreign matter accumulates in the fuel tank, the filter may require replacement more frequently.After installing a new filter, run the engine for several minutes, and check for leaks at the connections. Fuel filters should be installed by trained technicians.

F060D01A-AAT

o Fuel Lines, Fuel Hoses and Connec-

tions

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately. F060E01A-AAT

o Timing BeltInspect all parts related to the timing belt for damage and deformation. Replace any dam- aged parts immediately. F060G01A-AAT

o Vapor Hose and Fuel Filler CapThe vapor hose and fuel filler cap should be inspected at those intervals specified in the maintenance schedule. Make sure that a new vapor hose or fuel filler cap is correctly re- placed. F060F01A-AAT

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evidence ofheat and/or mechanical damage. Hard and brit- tle rubber, cracking, tears, cuts, abrasions, and excessive swelling indicate deterioration. Par- ticular attention should be paid to examine those hose surfaces nearest to high heat sourc- es, such as the exhaust manifold. Inspect the hose routing to assure that thehoses do not come in contact with any heat source, sharp edges or moving component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence of deterioration or damage. F060H01A-AAT o Air Cleaner FilterA Genuine Hyundai air cleaner filter is recom- mended when the filter is replaced. F060J01A-AAT o Spark PlugsMake sure to install new spark plugs of the correct heat range. F070C01A-AAT o Engine CoolantThe coolant should be changed at the intervals specified in the maintenance sched- ule. F070D01A-AAT o Manual Transmission OilInspect the manual transmission oil according to the maintenance schedule. NOTE: If the oil level is low, check for possible leaks before adding oil. Do not overfill.

Page 306 of 349

VEHICLE MAINTENANCE REQUIREMENTS

5- 2 YF010A2-E

REGULAR SERVICING

In order to ensure continued reliability, safety and longevity, regular

maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed andmileage covered since the previous maintenance service was per-formed. However, under severe operating conditions, certain scheduledoperations should be performed at shorter intervals. Regular maintenance should be entrusted to a Hyundai dealer who is

best able to provide the expertise required to ensure optimum opera-tional performance.

In addition the use of Hyundai replacement parts and service consumables

will ensure that the original build quality, operational performance andsafety are maintained.

F030B01HP-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL) ENGINE OIL & FILTER (API SG, SG/CD, SH OR SH/CD) DRIVE BELT (ALT, DAMPER, TENSIONER, IDLER) FUEL FILTER (MPI TYPE) FLUID LEAKS TIMING BELT VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS (PLATINUM COATED)

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1000 MONTHS

R

I I

l

R R

R

I

R

I

R

l

R

I

R

R

I I I I

R

l

I

R

R

I I1 2 3 4 5 6 7 8

Page 307 of 349

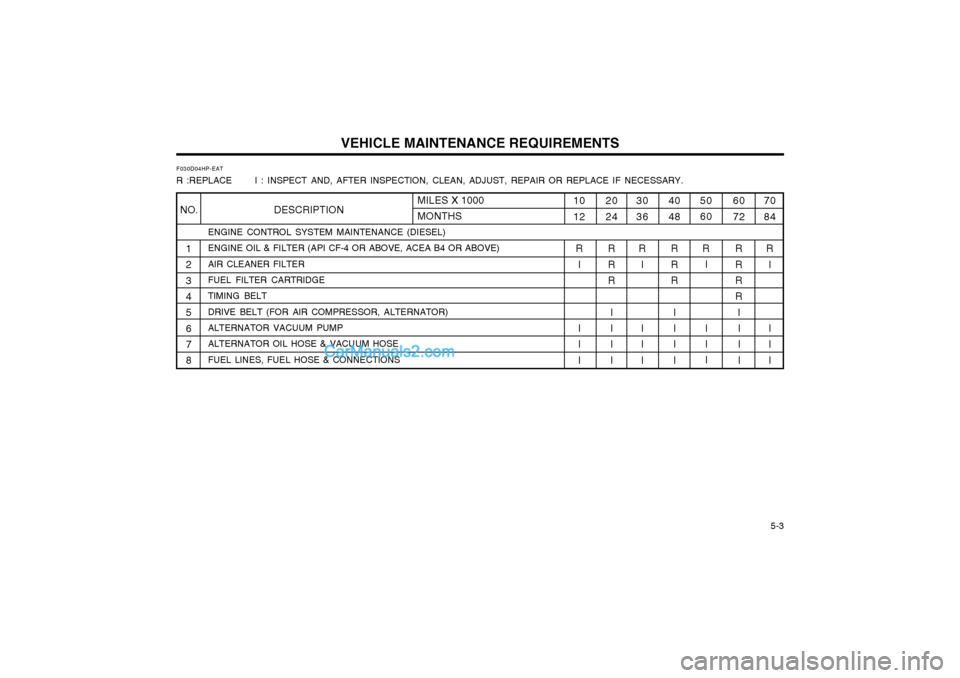

VEHICLE MAINTENANCE REQUIREMENTS 5-3

F030D04HP-EAT R :REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL) ENGINE OIL & FILTER (API CF-4 OR ABOVE, ACEA B4 OR ABOVE) AIR CLEANER FILTERFUEL FILTER CARTRIDGE TIMING BELT DRIVE BELT (FOR AIR COMPRESSOR, ALTERNATOR)ALTERNATOR VACUUM PUMP ALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

1 23 4 56 7 8

6072

RRR R l I I I

50 60

R I I I I40 48

RRR II I I20 24RRR II I IMILES X 1000 MONTHS70 84R I I I INO. DESCRIPTION 10 12

R I I I I 3036

R I I I I

Page 309 of 349

VEHICLE MAINTENANCE REQUIREMENTS 5-5

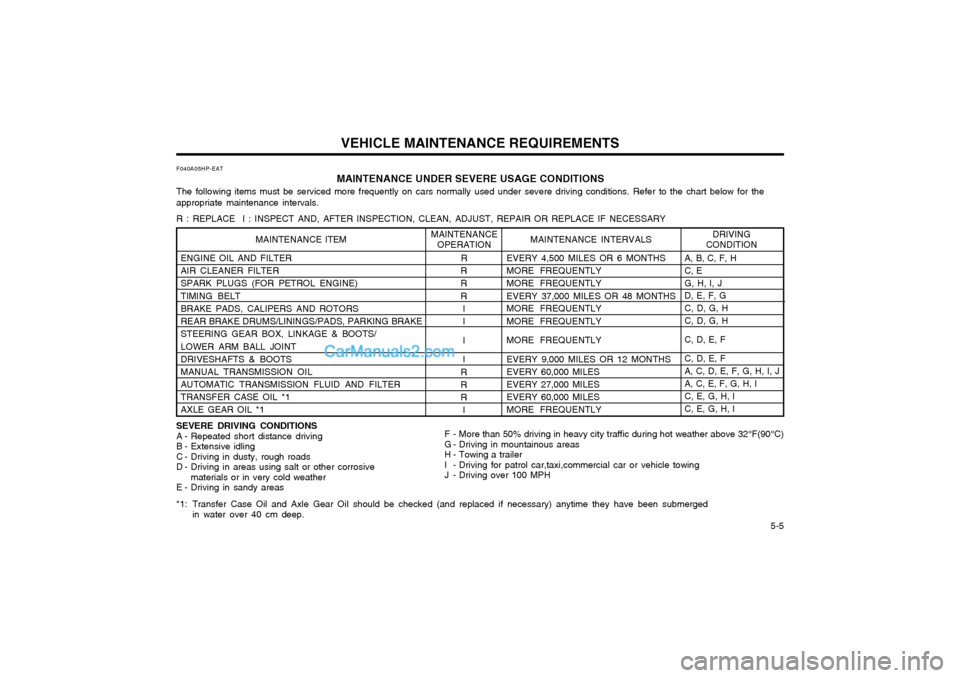

F040A05HP-EAT

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS (FOR PETROL ENGINE) TIMING BELT BRAKE PADS, CALIPERS AND ROTORS REAR BRAKE DRUMS/LININGS/PADS, PARKING BRAKE STEERING GEAR BOX, LINKAGE & BOOTS/ LOWER ARM BALL JOINT DRIVESHAFTS & BOOTS MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID AND FILTERTRANSFER CASE OIL *1AXLE GEAR OIL *1

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000 MILES OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLY MORE FREQUENTLYEVERY 9,000 MILES OR 12 MONTHS EVERY 60,000 MILESEVERY 27,000 MILESEVERY 60,000 MILES MORE FREQUENTLY

MAINTENANCE

OPERATIONMAINTENANCE ITEM

R

R R R II II

R R R I A, B, C, F, H C, EG, H, I, J D, E, F, G C, D, G, HC, D, G, H C, D, E, FC, D, E, F A, C, D, E, F, G, H, I, JA, C, E, F, G, H, I C, E, G, H, I C, E, G, H, I

MAINTENANCE INTERVALS

DRIVING

CONDITION

F - More than 50% driving in heavy city traffic during hot weather above 32°F(90°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car,taxi,commercial car or vehicle towing

J - Driving over 100 MPH

*1: Transfer Case Oil and Axle Gear Oil should be checked (and replaced if necessary) anytime they have been submerged in water over 40 cm deep.

Page 310 of 349

VEHICLE MAINTENANCE REQUIREMENTS

5- 6

F060B01A-AAT

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil and replace ifnecessary. Drive belts should be checkedperiodically for proper tension and adjusted asnecessary. F060C01A-AAT

o Fuel filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently. After installing a new filter, run the engine for several minutes, and check for leaks at theconnections. Fuel filters should be installed bytrained technicians.

F060M01A-AAT o Engine oil and filterThe engine oil and filter should be changed at the intervals specified in the maintenanceschedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

F060D01TB-AAT

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connec-tions for leakage and damage. Have a trainedtechnician replace any damaged or leakingparts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. F060E01A-AAT

o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam-aged parts immediately. F060G01A-EAT

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced.

F060F01A-AAT

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions,and excessive swelling indicate deterioration.Particular attention should be paid to examinethose hose surfaces nearest to high heatsources, such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

F060A01A-AAT

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS