adjust Hyundai Terracan 2006 Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Terracan, Model: Hyundai Terracan 2006Pages: 539, PDF Size: 18.11 MB

Page 223 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

8

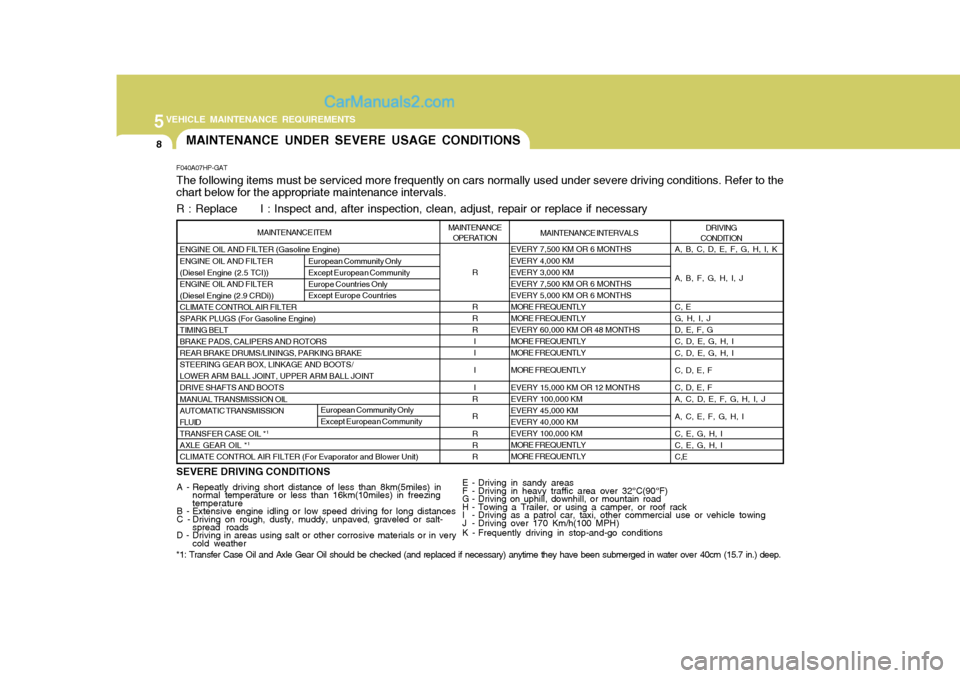

A, B, C, D, E, F, G, H, I, K A, B, F, G, H, I, JC, E G, H, I, JD, E, F, GC, D, E, G, H, I C, D, E, G, H, I C, D, E, F C, D, E, F A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E, G, H, I C, E, G, H, I C,E

ENGINE OIL AND FILTER (Gasoline Engine) ENGINE OIL AND FILTER (Diesel Engine (2.5 TCI))ENGINE OIL AND FILTER(Diesel Engine (2.9 CRDi))CLIMATE CONTROL AIR FILTERSPARK PLUGS (For Gasoline Engine) TIMING BELT BRAKE PADS, CALIPERS AND ROTORSREAR BRAKE DRUMS/LININGS, PARKING BRAKESTEERING GEAR BOX, LINKAGE AND BOOTS/LOWER ARM BALL JOINT, UPPER ARM BALL JOINTDRIVE SHAFTS AND BOOTS MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSIONFLUIDTRANSFER CASE OIL *

1

AXLE GEAR OIL * 1

CLIMATE CONTROL AIR FILTER (For Evaporator and Blower Unit)

European Community Only Except European Community

F040A07HP-GAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

R R R R

I I I I

RRR RR

EVERY 7,500 KM OR 6 MONTHS EVERY 4,000 KM EVERY 3,000 KMEVERY 7,500 KM OR 6 MONTHSEVERY 5,000 KM OR 6 MONTHSMORE FREQUENTLYMORE FREQUENTLY EVERY 60,000 KM OR 48 MONTHS MORE FREQUENTLYMORE FREQUENTLY MORE FREQUENTLY EVERY 15,000 KM OR 12 MONTHS EVERY 100,000 KMEVERY 45,000 KM EVERY 40,000 KM EVERY 100,000 KMMORE FREQUENTLYMORE FREQUENTLY

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 8km(5miles) in normal temperature or less than 16km(10miles) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very

cold weather

DRIVING

CONDITION

MAINTENANCE INTERVALS

MAINTENANCE

OPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C(90°F)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 170 Km/h(100 MPH)

K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

European Community Only Except European Community Europe Countries Only Except Europe Countries

*1: Transfer Case Oil and Axle Gear Oil should be checked (and replaced if necessary) anytime they have been submerged in water

over 40cm (15.7 in.) deep.

Page 224 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

9EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

F060M01A-AAT

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. F060B01A-AAT

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked periodi-cally for proper tension and adjusted as necessary. F060C01A-AAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam-age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians. WARNING (Diesel only):

Never work on injection system with

engine running or within 30 sec- onds after shutting off engine. High pressure pump, rail, injectors andhigh pressure pipes are subjected to high pressure even after the en- gine has been switched off. The fueljet produced by fuel leaks may cause serious injury, if it contacts with the body. People using pacemakersshould not move closer than 30cm to the ECU or wiring harness within the engine room with the enginerunning, since the high currents in the Common Rail system produce considerable magnetic fields.

F060D01TB-GAT

o Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately.

Page 227 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

12

F070M01B-AAT

o Steering Gear Box, Linkage &Boots/Lower Arm Ball Joint, Upper Arm Ball Joint

With the vehicle stopped and engine off, check for excessive free-play inthe steering wheel.Check the linkage for bends or dam-age. Check the dust boots and ball joints for deterioration, cracks, or dam- age. Replace any damaged parts. F070N01A-AAT

o Power Steering Pump, Belt and Hoses

Check the power steering pump and hoses for leakage and damage. Re- place any damaged or leaking partsimmediately. Inspect the power steer- ing belt for evidence of cuts, cracks, excessive wear, oiliness and propertension. Replace or adjust it if neces- sary. F070P01A-AAT

o Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, ordamage. Replace any damaged parts and, if necessary, repack the grease.

F070Q01A-AAT

o Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and damage. Check air conditioning performance according to the relevant shop manualif necessary.

Page 228 of 539

Engine Compartment .................................................... 6-2

General Checks ........................................................... 6-5

Checking the Engine Oil .............................................. 6-6 Changing the Engine Oil and Filter ............................. 6-10

Checking and Changing the Engine Coolant ..............6-11

Changing the Air Cleaner Filte r ...................................6-14

Checking the Transmission Oil (Manual)................... 6-17

Checking the Transmission Fluid (Automatic)............6-18

Checking the Brakes .................................................. 6-21

Checking the Clutch Fluid ........................................... 6-22

Air Conditioning Care .................................................. 6-23

Changing the Climate Control Air Filter .. ....................6-24

Checking Drive Belts .................................................. 6-27

Checking and Replacing Fuses ..................................6-28

Checking The Battery ................................................. 6-31

Checking The Electric Cooling Fans ..........................6-33

Power Steering Fluid Level ......................................... 6-33

Fuel Filter ..................................................................... 6-34

Replacement of Headlight Bulbs ................................. 6-38

Headlight Aiming Adjustment ...................................... 6-39

Bulb Wattages ............................................................. 6-42

Fuse Panel D escription ............................................... 6-43

DO-IT-YOURSELF MAINTENANCE

6

6

Page 251 of 539

6 DO-IT-YOURSELF MAINTENANCE

24

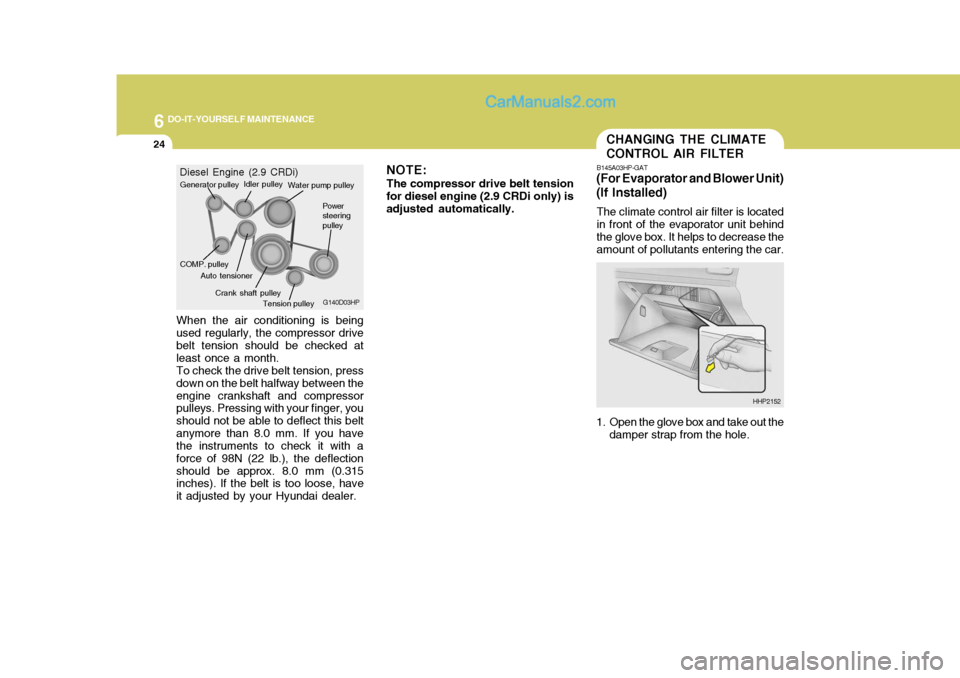

When the air conditioning is being used regularly, the compressor drive belt tension should be checked at least once a month.To check the drive belt tension, pressdown on the belt halfway between theengine crankshaft and compressor pulleys. Pressing with your finger, you should not be able to deflect this beltanymore than 8.0 mm. If you have the instruments to check it with a force of 98N (22 lb.), the deflectionshould be approx. 8.0 mm (0.315 inches). If the belt is too loose, have it adjusted by your Hyundai dealer. G140D03HP

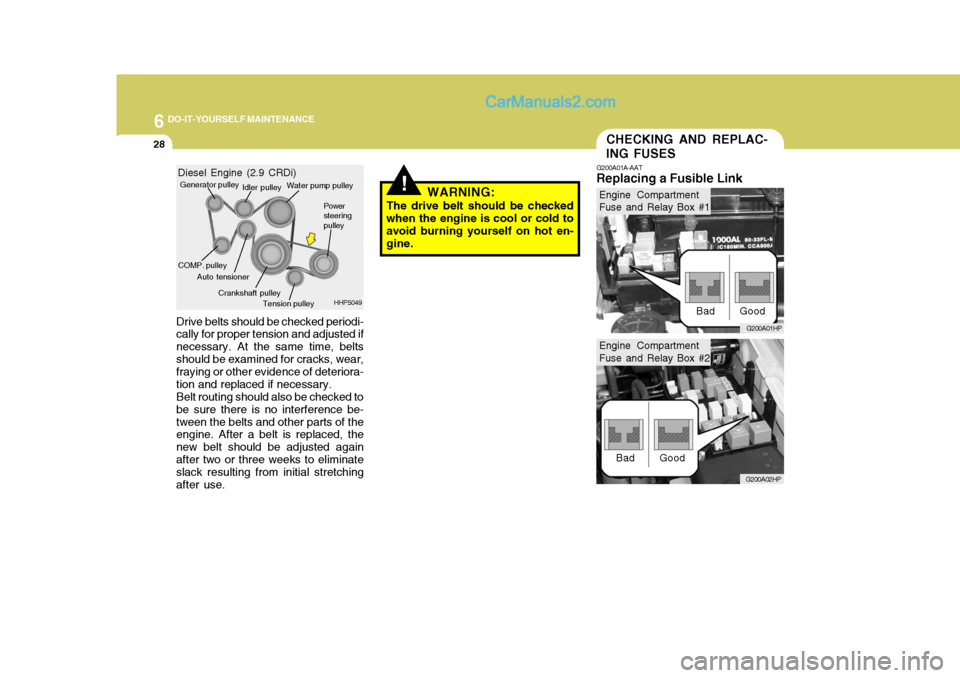

Diesel Engine (2.9 CRDi)

Generator pulley

Water pump pulley

Tension pulley

COMP. pulley Power steeringpulley

Idler pulley

Auto tensioner Crank shaft pulley

CHANGING THE CLIMATE CONTROL AIR FILTER

B145A03HP-GAT

(For Evaporator and Blower Unit)(If Installed)

The climate control air filter is located in front of the evaporator unit behind the glove box. It helps to decrease the amount of pollutants entering the car.

1. Open the glove box and take out the damper strap from the hole. HHP2152

NOTE: The compressor drive belt tension

for diesel engine (2.9 CRDi only) is adjusted automatically.

Page 253 of 539

6 DO-IT-YOURSELF MAINTENANCE

26

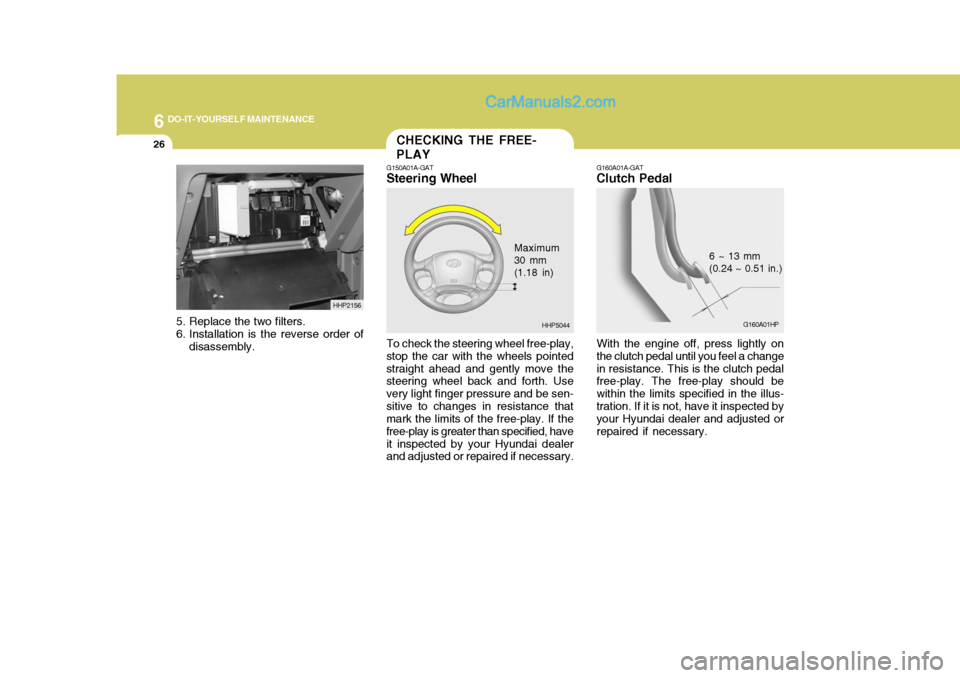

5. Replace the two filters.

6. Installation is the reverse order of

disassembly. HHP2156

CHECKING THE FREE- PLAY

G150A01A-GAT

Steering Wheel

To check the steering wheel free-play,

stop the car with the wheels pointed straight ahead and gently move the steering wheel back and forth. Use very light finger pressure and be sen-sitive to changes in resistance that mark the limits of the free-play. If the free-play is greater than specified, haveit inspected by your Hyundai dealer and adjusted or repaired if necessary. G160A01A-GAT

Clutch Pedal

With the engine off, press lightly on the clutch pedal until you feel a changein resistance. This is the clutch pedal free-play. The free-play should be within the limits specified in the illus-tration. If it is not, have it inspected by your Hyundai dealer and adjusted or repaired if necessary.

Maximum 30 mm (1.18 in)

6 ~ 13 mm(0.24 ~ 0.51 in.)

HHP5044 G160A01HP

Page 254 of 539

6

DO-IT-YOURSELF MAINTENANCE

27CHECKING DRIVE BELTSCHECKING BRAKE PEDAL CLEARANCE

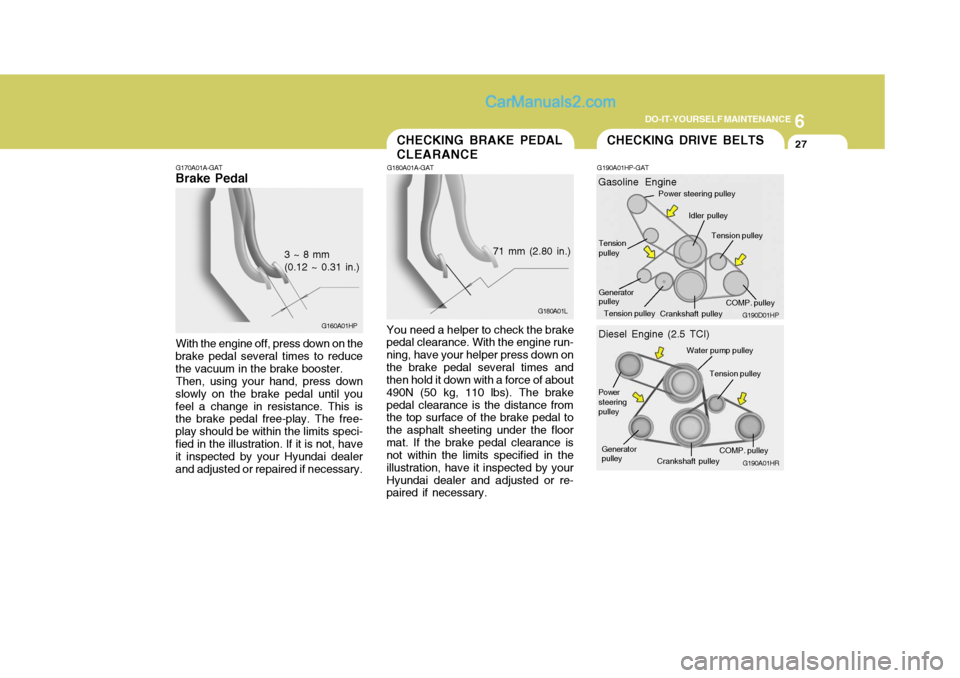

G170A01A-GAT

Brake Pedal

With the engine off, press down on the

brake pedal several times to reduce the vacuum in the brake booster. Then, using your hand, press down

slowly on the brake pedal until youfeel a change in resistance. This is the brake pedal free-play. The free- play should be within the limits speci-fied in the illustration. If it is not, have it inspected by your Hyundai dealer and adjusted or repaired if necessary. 3 ~ 8 mm (0.12 ~ 0.31 in.)

G160A01HP G180A01A-GAT

You need a helper to check the brake

pedal clearance. With the engine run- ning, have your helper press down onthe brake pedal several times and then hold it down with a force of about 490N (50 kg, 110 lbs). The brakepedal clearance is the distance from the top surface of the brake pedal to the asphalt sheeting under the floormat. If the brake pedal clearance is not within the limits specified in the illustration, have it inspected by yourHyundai dealer and adjusted or re- paired if necessary. 71 mm (2.80 in.)

G190A01HP-GAT

G180A01L

G190A01HR

G190D01HP

Diesel Engine (2.5 TCI)

Gasoline Engine

Water pump pulley

Power steering pulley

Crankshaft pulley

Generator pulley Tension pulley

COMP. pulley

Idler pulley

Power steering pulley

Crankshaft pulley

Generator pulley Tension pulley

COMP. pulleyTension pulley

Tension pulley

Page 255 of 539

6 DO-IT-YOURSELF MAINTENANCE

28

Drive belts should be checked periodi- cally for proper tension and adjusted if necessary. At the same time, beltsshould be examined for cracks, wear, fraying or other evidence of deteriora- tion and replaced if necessary.Belt routing should also be checked tobe sure there is no interference be-tween the belts and other parts of the engine. After a belt is replaced, the new belt should be adjusted againafter two or three weeks to eliminate slack resulting from initial stretching after use. HHP5049

Diesel Engine (2.9 CRDi)

Generator pulley

Water pump pulley

Tension pulley

COMP. pulley Power steeringpulley

Idler pulley

Auto tensioner Crankshaft pulley

CHECKING AND REPLAC- ING FUSES

G200A01A-AAT

Replacing a Fusible Link

G200A01HP

G200A02HP

!WARNING:

The drive belt should be checked when the engine is cool or cold to avoid burning yourself on hot en- gine.

Bad GoodBad GoodEngine Compartment Fuse and Relay Box #1

Engine Compartment Fuse and Relay Box #2

Page 266 of 539

6

DO-IT-YOURSELF MAINTENANCE

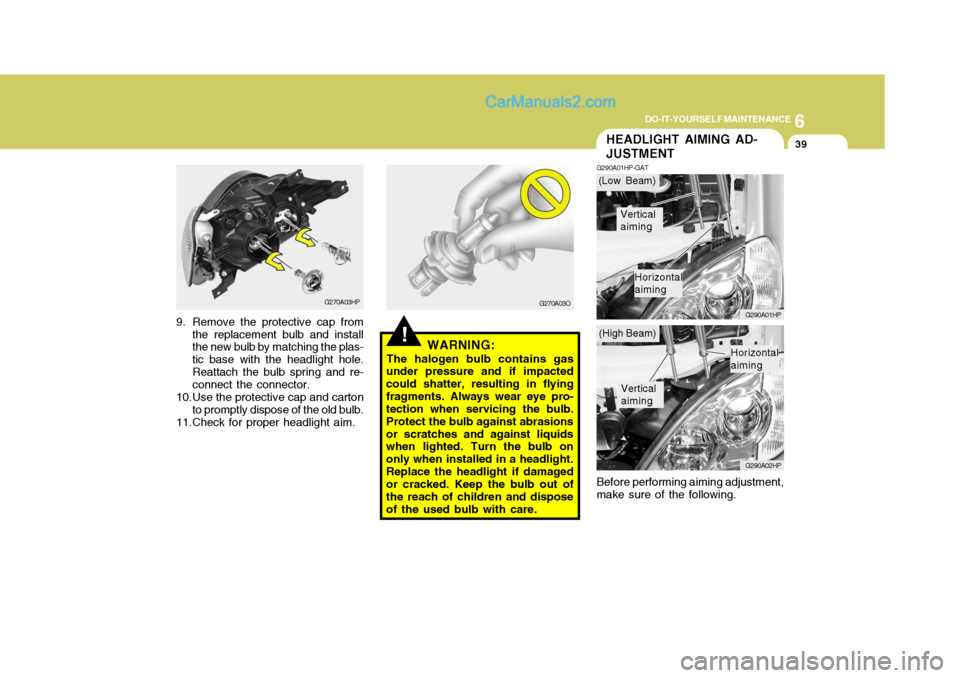

39HEADLIGHT AIMING AD- JUSTMENT

G290A01HP-GAT

G290A01HP G290A02HP

Before performing aiming adjustment, make sure of the following.

!WARNING:

The halogen bulb contains gas

under pressure and if impacted could shatter, resulting in flyingfragments. Always wear eye pro- tection when servicing the bulb. Protect the bulb against abrasionsor scratches and against liquids when lighted. Turn the bulb on only when installed in a headlight.Replace the headlight if damaged or cracked. Keep the bulb out of the reach of children and disposeof the used bulb with care.

G270A03HP

9. Remove the protective cap from the replacement bulb and install the new bulb by matching the plas- tic base with the headlight hole.Reattach the bulb spring and re- connect the connector.

10.Use the protective cap and carton to promptly dispose of the old bulb.

11.Check for proper headlight aim. G270A03O(Low Beam)

(High Beam)

Vertical aiming

Horizontal aiming

Vertical aiming

Horizontal aiming

Page 267 of 539

6 DO-IT-YOURSELF MAINTENANCE

40

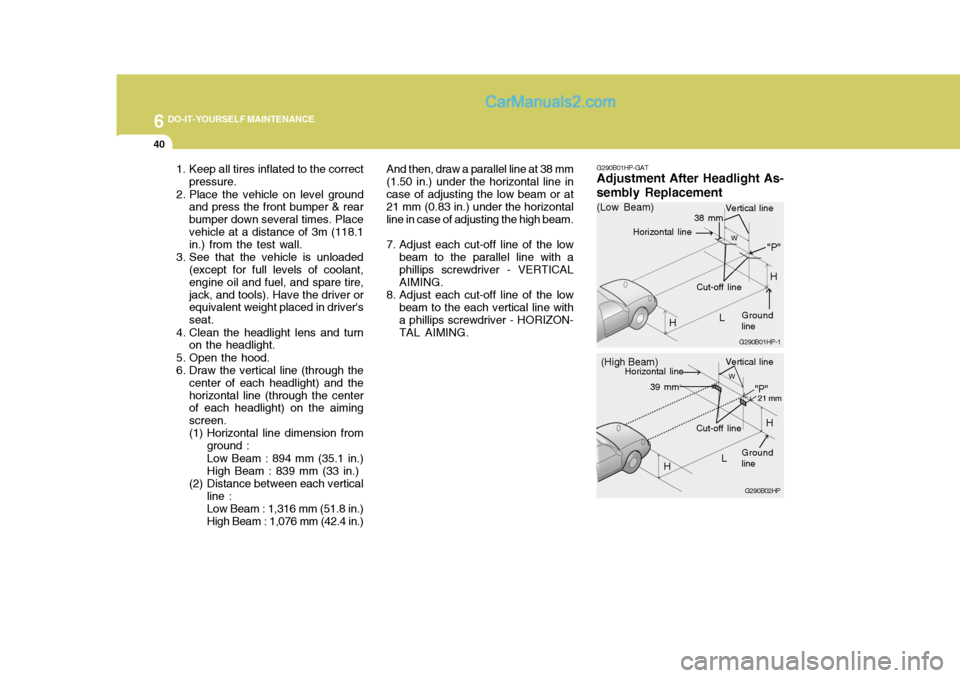

1. Keep all tires inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down several times. Placevehicle at a distance of 3m (118.1 in.) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire,jack, and tools). Have the driver or equivalent weight placed in driver's seat.

4. Clean the headlight lens and turn on the headlight.

5. Open the hood.

6. Draw the vertical line (through the center of each headlight) and thehorizontal line (through the center of each headlight) on the aiming screen.

(1) Horizontal line dimension from

ground : Low Beam : 894 mm (35.1 in.) High Beam : 839 mm (33 in.)

(2) Distance between each vertical line : Low Beam : 1,316 mm (51.8 in.) High Beam : 1,076 mm (42.4 in.) And then, draw a parallel line at 38 mm

(1.50 in.) under the horizontal line incase of adjusting the low beam or at 21 mm (0.83 in.) under the horizontal line in case of adjusting the high beam.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to the each vertical line witha phillips screwdriver - HORIZON-TAL AIMING. G290B01HP-GAT

Adjustment After Headlight As- sembly Replacement

G290B02HP

LW

H Cut-off line

"P"

Vertical line

Horizontal line

Ground line

21 mm39 mm

(High Beam)

H

G290B01HP-1

LW

"P"

38 mm

H

H

(Low Beam)

Vertical line

Ground line

Cut-off line

Horizontal line