Window INFINITI FX35 2004 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: FX35, Model: INFINITI FX35 2004Pages: 4449, PDF Size: 99.66 MB

Page 3220 of 4449

POWER WINDOW SYSTEM

GW-61

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2004 November 2004 FX35/FX45

Encoder Circuit Check (Driver Side) AIS004QQ

1. CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between front power window motor (driver side)

connector D8 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY 1

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window motor (driver side).

3. Check continuity between power window main switch connector

D6 terminal 15 and front power window motor (driver side) con-

nector D8 terminal 4.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness between power window main

switch and front power window motor (driver side).

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window motor (driver side) connector.

3. Check continuity between front power window motor (driver

side) connector D8 terminal 6 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.4 (W) – Ground : Approx.10V

PIIA9973E

15 (W) – 4 (W) : Continuity should exist.

PIIA9974E

6 (SB) – Ground : Continuity should exist.

PIIA9961E

Page 3221 of 4449

GW-62

POWER WINDOW SYSTEM

Revision: 2004 November 2004 FX35/FX45

4. CHECK HARNESS CONTINUITY 2

1. Disconnect power window main switch connector.

2. Check continuity between power window main switch connector

D6 terminal 2 and front power window motor (driver side) con-

nector D8 terminal 6.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness between power window main

switch and front power window motor (driver side).

5. CHECK ENCODER SIGNAL

1. Connect front power window motor (driver side) connector.

2. Turn ignition switch ON.

3. Check signal between power window main switch connector and ground with oscilloscope.

OK or NG

OK >> Replace power window main switch.

NG >> GO TO 6.

6. CHECK HARNESS CONTINUITY 3

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window motor (driver side) connector.

3. Check continuity between power window main switch connector

D6 terminal 13 and front power window motor (driver side) con-

nector D8 terminal 3.

OK or NG

OK >> Replace front power window motor (driver side).

NG >> Repair or replace harness between power window main

switch and front power window motor (driver side). 2 (SB) – 6 (SB) : Continuity should exist.

PIIA9962E

Connec-

torTerminals (Wire color)

ConditionSignal

(Reference value)

(+) (-)

D6 13 (PU) GroundWindow

DOWN

PIIA4205EOCC3383D

13 (PU) – 3 (PU) : Continuity should exist.

PIIA9975E

Page 3222 of 4449

POWER WINDOW SYSTEM

GW-63

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2004 November 2004 FX35/FX45

Encoder Circuit Check (Passenger Side)AIS004QR

1. CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between front power window motor (passenger

side) connector D38 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY 1

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) and front power window motor (passenger side)

connector.

3. Check continuity between front power window switch (passen-

ger side) connector D36 terminal 4 and front power window

motor (passenger side) connector D38 terminal 4.

OK or NG

OK >> Replace front power window switch (passenger side).

NG >> Repair or replace harness between front power window

switch (passenger side) and front power window motor

(passenger side).

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window motor (passenger side) connector.

3. Check continuity between front power window motor (passenger

side) connector D38 terminal 6 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.4 (R) – Ground : Approx.10V

PIIA9976E

4 (R) – 4 (R) : Continuity should exist.

PIIA9977E

6 (SB) – Ground : Continuity should exist.

PIIA9966E

Page 3223 of 4449

GW-64

POWER WINDOW SYSTEM

Revision: 2004 November 2004 FX35/FX45

4. CHECK HARNESS CONTINUITY 2

1. Disconnect front power window switch (passenger side) connector.

2. Check continuity between front power window switch (passen-

ger side) connector D36 terminal 3 and front power window

motor (passenger side) connector D38 terminal 6.

OK or NG

OK >> Replace front power window switch (passenger side).

NG >> Repair or replace harness between front power window

switch (passenger side) and front power window motor

(passenger side).

5. CHECK ENCODER SIGNAL

1. Connect front power window motor (passenger side) connector.

2. Turn ignition switch ON.

3. Check signal between front power window switch (passenger side) connector and ground with oscillo-

scope.

OK or NG

OK >> Replace front power window switch (passenger side).

NG >> GO TO 6.

6. CHECK HARNESS CONTINUITY 3

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) and front power window motor (passenger side)

connector.

3. Check continuity between front power window switch (passen-

ger side) connector D36 terminal 12 and front power window

motor (passenger side) connector D38 terminal 3.

OK or NG

OK >> Replace front power window motor (passenger side).

NG >> Repair or replace harness between front power window

switch (passenger side) and front power window motor

(passenger side). 3 (SB) – 6 (SB) : Continuity should exist.

PIIA9967E

Connec-

torTerminals (Wire color)

ConditionSignal

(Reference value)

(+) (-)

D36 12 (PU) GroundWindow

DOWN

PIIA4209EOCC3383D

12 (PU) – 3 (PU) : Continuity should exist.

PIIA9978E

Page 3224 of 4449

POWER WINDOW SYSTEM

GW-65

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2004 November 2004 FX35/FX45

Encoder Circuit Check (Rear LH or RH) / With Front and Rear Power Window

Anti-pinch System

AIS004QS

1. CHECK REAR POWER WINDOW MOTOR (LH OR RH) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between rear power window switch connector

D58 (LH), D78 (RH) terminal 4 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace rear power window switch (LH or RH).

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window motor (LH or RH) connector.

3. Check continuity between rear power window motor (LH or RH)

connector D59 (LH), D79 (RH) terminal 4 and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3. CHECK HARNESS CONTINUITY 1

1. Disconnect rear power window switch (LH or RH) connector.

2. Check continuity between rear power window switch (LH or RH)

connector D58 (LH), D78 (RH) terminal 3 and rear power win-

dow motor (LH or RH) connector D59 (LH), D79 (RH) terminal 4.

OK or NG

OK >> Replace rear power window switch (LH or RH).

NG >> Repair or replace harness between rear power window

switch (LH or RH) and rear power window motor (LH or

RH). 4 (PU) – Ground : Approx. 10V

PIIA6305E

4 (OR) – Ground : Continuity should exist.

PIIA9970E

3 (OR) – 4 (OR) : Continuity should exist.

PIIA9971E

Page 3225 of 4449

GW-66

POWER WINDOW SYSTEM

Revision: 2004 November 2004 FX35/FX45

4. CHECK ENCODER SIGNAL

1. Connect rear power window motor (LH or RH) connector.

2. Turn ignition switch ON.

3. Check signal between rear power window switch (LH or RH) connector and ground with oscilloscope.

OK or NG

OK >> Replace rear power window switch (LH or RH).

NG >> GO TO 5.

5. CHECK HARNESS CONTINUITY 2

1. Turn ignition switch OFF.

2. Disconnect rear power window switch (LH or RH) and rear power window motor (LH or RH) connector.

3. Check continuity between rear power window switch (LH or RH)

connector D58 (LH), D78 (RH) terminal 12 and rear power win-

dow motor (LH or RH) connector D59 (LH), D79 (RH) terminal 5.

OK or NG

OK >> Replace rear power window motor (LH or RH).

NG >> Repair or replace harness between rear power window

switch (LH or RH) and rear power window motor (LH or

RH).

Connec-

torTerminals (Wire color)

ConditionSignal

(Reference value)

(+) (-)

D58 (LH)

D78 (RH)12 (GY) GroundWindow

DOWN

PIIA6302EOCC3383D

12 (GY) – 5 (GY) : Continuity should exist.

PIIA9979E

Page 3226 of 4449

POWER WINDOW SYSTEM

GW-67

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2004 November 2004 FX35/FX45

Door Switch Check AIS004QT

1. CHECK DOOR SWITCH INPUT SIGNAL

With CONSULT-II

Check (“DOOR SW-DR” and “DOOR SW-AS”) in “DATA MONITOR” mode with CONSULT-II.

Without CONSULT-II

Check voltage between BCM connector M3, B14 terminals 12, 62 and ground.

OK or NG

OK >> Door switch is OK.

NG >> GO TO 2.

Monitor item Condition

DOOR SW-DROPEN : ON

CLOSE : OFF

DOOR SW-ASOPEN : ON

CLOSE : OFF

PIIA2464E

ItemTerminals (Wire color)

Door conditionVoltage [V]

(Approx.)

(+) (–)

Passenger side

door switch 12 (P/B)

GroundOPEN 0

CLOSE Battery voltage

Driver side door

switch62 (W)OPEN 0

CLOSE Battery voltage

PIIA6158E

Page 3227 of 4449

GW-68

POWER WINDOW SYSTEM

Revision: 2004 November 2004 FX35/FX45

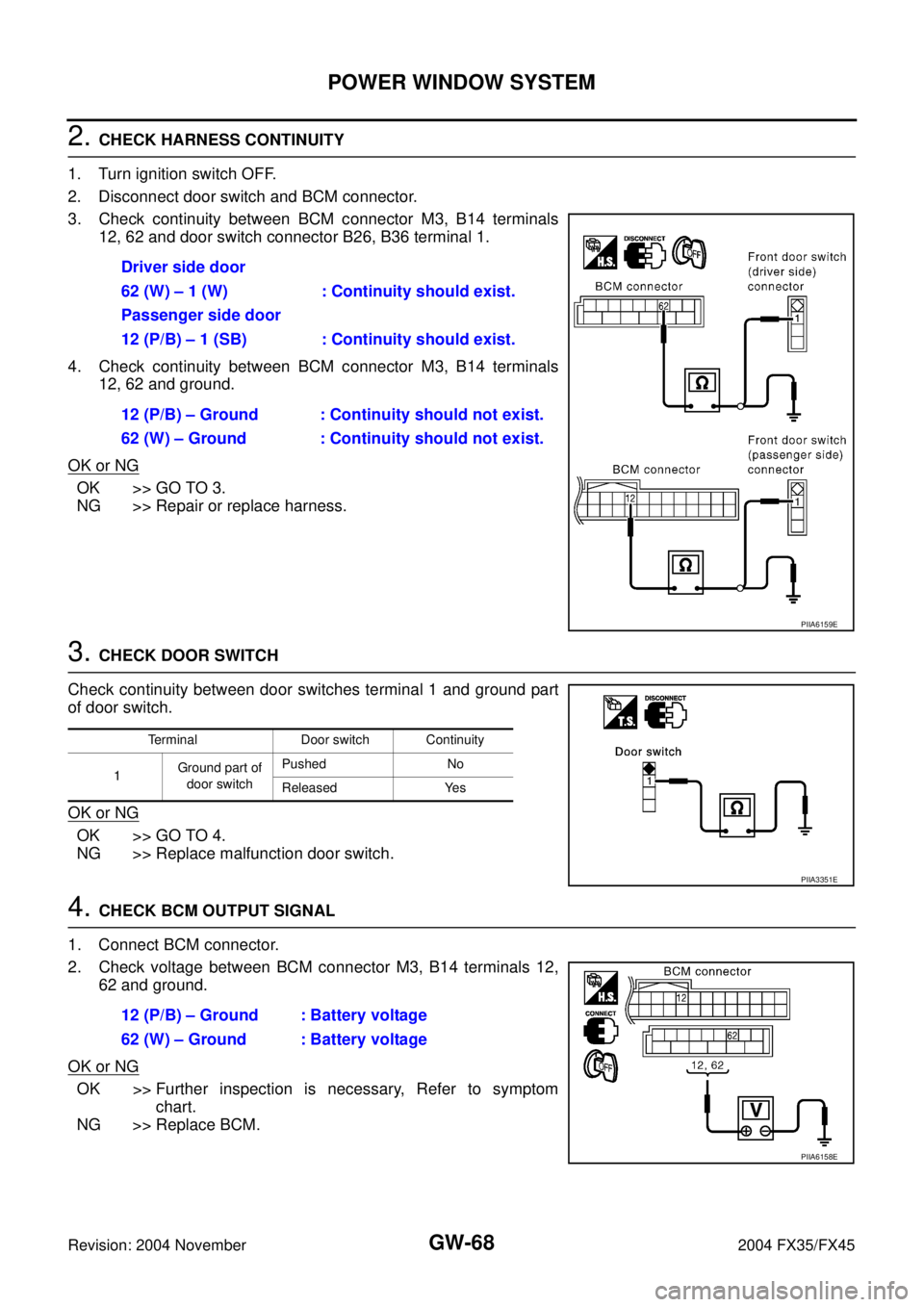

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect door switch and BCM connector.

3. Check continuity between BCM connector M3, B14 terminals

12, 62 and door switch connector B26, B36 terminal 1.

4. Check continuity between BCM connector M3, B14 terminals

12, 62 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3. CHECK DOOR SWITCH

Check continuity between door switches terminal 1 and ground part

of door switch.

OK or NG

OK >> GO TO 4.

NG >> Replace malfunction door switch.

4. CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM connector M3, B14 terminals 12,

62 and ground.

OK or NG

OK >> Further inspection is necessary, Refer to symptom

chart.

NG >> Replace BCM.Driver side door

62 (W) – 1 (W) : Continuity should exist.

Passenger side door

12 (P/B) – 1 (SB) : Continuity should exist.

12 (P/B) – Ground : Continuity should not exist.

62 (W) – Ground : Continuity should not exist.

PIIA6159E

Terminal Door switch Continuity

1Ground part of

door switchPushed No

Released Yes

PIIA3351E

12 (P/B) – Ground : Battery voltage

62 (W) – Ground : Battery voltage

PIIA6158E

Page 3228 of 4449

POWER WINDOW SYSTEM

GW-69

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2004 November 2004 FX35/FX45

Front Door Key Cylinder Switch Check AIS004QU

1. CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

With CONSULT-II

Check (“KEY CYL LK-SW”, “KEY CYL UN-SW”) in “DATA MONITOR” mode for “POWER DOOR ROCK SYS-

TEM” with CONSULT-II. Refer to BL-40, "

Data Monitor"

Without CONSULT-II

Check voltage between power window main switch connector and ground.

OK or NG

OK >> Further inspection is necessary. Refer to symptom

chart.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front door key lock assembly (driver side) connector.

3. Check continuity between power window main switch connector

D6 terminals 4, 6 and front door lock assembly (driver side) con-

nector D10 terminals 1, 6.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between power window main

switch and front door key lock assembly (driver side).

Monitor item Condition

KEY CYL LK-SWLock : ON

Neutral / Unlock : OFF

KEY CYL UN-SWUnlock : ON

Neutral / Lock : OFF

PIIA6285E

ConnectorTerminals (Wire color)

Key position Voltage [V]

(Approx.)

(+) (–)

D64 (P)

GroundLock 0

Neutral / Unlock 5

6 (OR)Unlock 0

Neutral / Lock 5

PIIA4211E

4 (P) – 1 (P) : Continuity should exist.

6 (OR) – 6 (OR) : Continuity should exist.

PIIA4212E

Page 3229 of 4449

GW-70

POWER WINDOW SYSTEM

Revision: 2004 November 2004 FX35/FX45

3. CHECK DOOR KEY CYLINDER SWITCH GROUND

Check continuity between front door lock assembly (driver side) con-

nector D10 terminal 5 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK DOOR KEY CYLINDER SWITCH

Check continuity between door lock assembly terminals 1, 6 and 5.

OK or NG

OK >> Further inspection is necessary. Refer to symptom

chart.

NG >> Replace front door key cylinder (driver side) switch.5 (B) – Ground : Continuity should exist.

PIIA4213E

Terminals Key position Continuity

1

5Lock Yes

Neutral / Unlock No

6Unlock Yes

Neutral / Lock No

PIIA4214E