check engine light INFINITI FX35 2008 Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2731 of 3924

![INFINITI FX35 2008 Owners Manual

CYLINDER BLOCKEM-247

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

5. Install crankshaft to cylinder block.

While turning crankshaft by hand, make sure it turns smoothly.

6. In INFINITI FX35 2008 Owners Manual

CYLINDER BLOCKEM-247

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

5. Install crankshaft to cylinder block.

While turning crankshaft by hand, make sure it turns smoothly.

6. In](/img/42/57017/w960_57017-2730.png)

CYLINDER BLOCKEM-247

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

5. Install crankshaft to cylinder block.

While turning crankshaft by hand, make sure it turns smoothly.

6. Install main bearing caps. Align the identification number to the journal position to install.

Install the upper side of the identification number facing thefront of engine. (The number shall be read correctly from the

rear of engine.)

Using plastic hammer or similar tool, tap them lightly to seat them on the installation position.

NOTE:

Main bearing cap cannot be replaced as a single parts, because

it is machined together with cylinder block.

7. Install each main bearing cap bolt as follows:

a. Apply new engine oil to threads and seating surface of main bearing cap bolts, and tighten all bolts temporarily.

b. Tighten main bearing cap bolt (M12) in order of 1 to 10.

c. Tighten main bearing cap sub bolt (M9) in order of 11 to 20.

d. Tighten main bearing cap bolt (M12) to 40 degrees clockwise in order of 1 to 10. (Angle tightening)

CAUTION:

Use angle wrench (SST) to ch eck tightening angle in step

“d” and “e”. Do not make judg ment by visual inspection.

e. Tighten main bearing cap sub bolt (M9) to 30 degrees clockwise in order of 11 to 20. (Angle tightening)

f. Tighten side bolt (M10) in order of 21 to 30. After installing main bearing cap bolts, make sure that crankshaft can be rotated smoothly.

Check the crankshaft end play. Refer to EM-256, "

Inspection After Disassembly".

g. Install cover of cylinder block rear left side (next to the starter motor housing).

8. Install new rear oil seal on rear oil seal retainer. Install new rear oil seal so that each seal lip is oriented asshown in the figure.

PBIC0095E

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

: 29.4 N·m (3.0 kg-m, 22 ft-lb)

PBIC0090E

PBIC0096E

: 49 N·m (5.0 kg-m, 36 ft-lb)

SEM715A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2888 of 3924

GI-26

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

Vehicle Vibration

The problem may occur or become worse while drivi ng on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an e\

lectrical complaint. Some of the

things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

Heat Sensitive

SGI839

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2911 of 3924

TERMINOLOGYGI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Exhaust gas recirculation control-BPT

valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM ***

Flash erasable programmable read only

memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulato r *** Pressure regulator

Fuel pressure regulator control solenoid

valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulato r IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve IACV-AAC valve Auxiliary

air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold su rface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2919 of 3924

GW-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to helpidentify the source of the noise, try to dupli-

cate the noise with the vehiclestopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears tobe coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditi ons thecustomer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowlyon an undulating or rough road to stress the vehi-

cle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technica lService Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, fo llow the procedure to repair thenoise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the causeof the noise by:

removing the components in the area that you suspect the noiseis coming from. Do not use too much force when removing clips and fasteners, otherwiseclips and fastener can be broken or

lost during the repair, resulting in thecreation of new noise.

tapping or pushing/pulling the component t hat you suspect is causingthe noise.

Do not tap or push/pull the component with excessive force, otherwisethe noise will be eliminated only tem-

porarily.

feeling for a vibration with your hand by touching t he component(s)that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect arecausing the noise.

looking for loose components and contact marks. Refer to GW-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or l oosening and retighteningthe component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A Nissan Squeak and Rattle Kit (J43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plasticand may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J43980). Each item can be ordered

separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02: 15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials, not found in the kit, can al so be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3006 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-5

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J39570, Engine Ea r and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration with your hand by touching t he component(s) that you suspect is (are) causing the

noise.

Placing a piece of paper between components that you suspect are causing the noise.

Looking for loose components and contact marks. Refer to IP-6, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISS AN Squeak and Rattle Kit (J43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/ 76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/76884-71L02: 15 ×

25 mm (0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00: 10 mm (0.39 in) think, 50

× 50 mm (1.97 × 1.97 in)

INSULATOR (Light foam block)

80845 - 71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not oc cur.Ideal for instrument panel applications.

68370 - 4B000: 15 × 25 mm (0.59 × 0.98 in) pad / 68239-13E00: 5 mm (0.20 in) wide tape roll The following

materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3069 of 3924

![INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TY INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TY](/img/42/57017/w960_57017-3068.png)

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TYPE 5/TYPE 7

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Signal name/Connecting unitECM

4WD

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T R R R R R

Engine status signal T R

Fuel consumption monitor signal TR

RT

Malfunction indicator lamp signal T R

Wide open throttle position signal T R

AWD warning lamp signal T R

A/C switch/indicator signal TR

RT

System setting signal TR R

RT T

A/T CHECK indicato r lamp signal T R

A/T self-diagnosis signal R T

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range signal T R R

Shift position indicator signal T R

Turbine revolution signal R T

A/C switch signal R T

Buzzer output signal TR

TR

Blower fan motor switch signal R T

Day time running light request signal T R

Door lock/unlock status signal T R

Door switch signal R T R R R R

Front fog light request signal T R

Front wiper request signal T R

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3119 of 3924

HEADLAMP - XENON TYPE -LT-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

NOTE:

1. Vehicles without auto light system display this item, but cannot be monitored.

2. Vehicles without daytime light system display this item, but cannot be monitored.

3. This item is displayed, but cannot be monitored.

ACTIVE TEST

Display Item List

NOTE:

1. Vehicles without daytime light lamp system display this item, but cannot be tested.

2. This item is displayed, but cannot be tested.

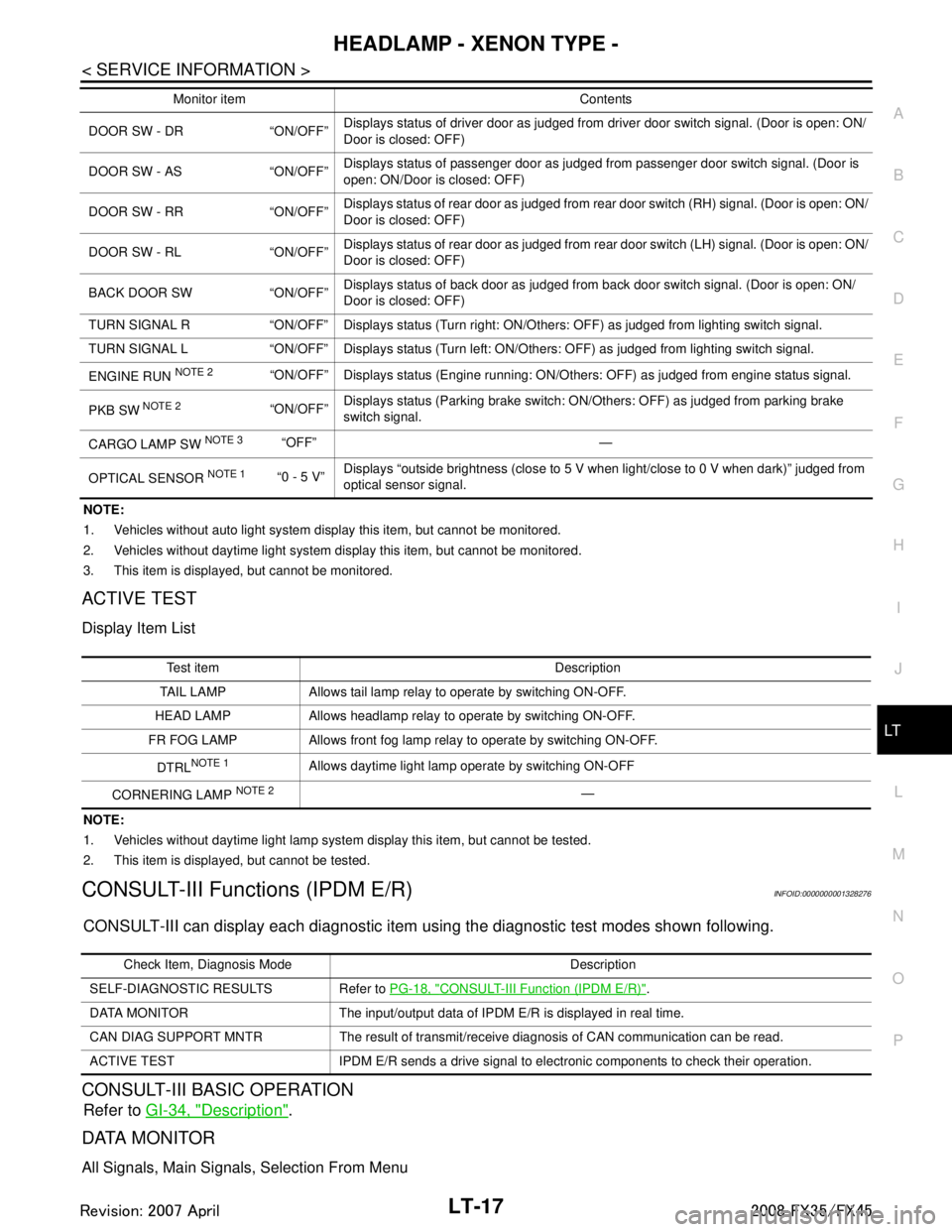

CONSULT-III Functions (IPDM E/R)INFOID:0000000001328276

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

CONSULT-III BASIC OPERATION

Refer to GI-34, "Description".

DATA MONITOR

All Signals, Main Signals, Selection From Menu

DOOR SW - DR “ON/OFF” Displays status of driver door as judged from driver door switch signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - AS “ON/OFF” Displays status of passenger door as judged from passenger door switch signal. (Door is

open: ON/Door is closed: OFF)

DOOR SW - RR “ON/OFF” Displays status of rear door as judged from rear door switch (RH) signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - RL “ON/OFF” Displays status of rear door as judged from rear door switch (LH) signal. (Door is open: ON/

Door is closed: OFF)

BACK DOOR SW “ON/OFF” Displays status of back door as judged from back door switch signal. (Door is open: ON/

Door is closed: OFF)

TURN SIGNAL R “ON/OFF” Display s status (Turn right: ON/Others: OFF) as judged from lighting switch signal.

TURN SIGNAL L “ON/OFF” Display s status (Turn left: ON/Others: OFF) as judged from lighting switch signal.

ENGINE RUN

NOTE 2“ON/OFF” Displays status (Engine running: ON/Others: OFF) as judged from engine status signal.

PKB SW

NOTE 2“ON/OFF” Displays status (Parking brake switch: ON/Others: OFF) as judged from parking brake

switch signal.

CARGO LAMP SW

NOTE 3 “OFF” —

OPTICAL SENSOR

NOTE 1 “0 - 5 V” Displays “outside brightness (close to 5 V when light/close to 0 V when dark)” judged from

optical sensor signal.

Monitor item Contents

Te s t i t e m D e s c r i p t i o n

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

HEAD LAMP Allows headlamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF.

DTRL

NOTE 1Allows daytime light lamp operate by switching ON-OFF

CORNERING LAMP

NOTE 2—

Check Item, Diagnosis Mode Description

SELF-DIAGNOSTIC RESULTS Refer to PG-18, "

CONSULT-III Function (IPDM E/R)".

DATA MONITOR The input/output data of IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST IPDM E/R sends a drive signal to electronic components to check their operation.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3129 of 3924

HEADLAMP - XENON TYPE -LT-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Xenon Headlamp Trouble DiagnosisINFOID:0000000001328286

1.CHECK 1: XENON HEADLAMP LIGHTING

Install normal xenon bulb to corresponding xenon bulb headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon bulb.

NG >> GO TO 2.

2.CHECK 2: XENON HEADLAMP LIGHTING

Install normal HID control unit to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace HID control unit.

NG >> GO TO 3.

3.CHECK 3: XENON HEADLAMP LIGHTING

Install normal xenon lamp housing assembly to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon headlamp housing assembly. [Malfunction in starter (boosting circuit) in xenon headlamp housing]

NG >> INSPECTION END

Aiming AdjustmentINFOID:0000000001328287

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level ground.

3. Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

PKIC9684E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3146 of 3924

LT-44

< SERVICE INFORMATION >

DAYTIME LIGHT SYSTEM

NOTE:

1. Vehicles without auto light system display this item, but cannot be monitored.

2. Vehicles without daytime light system display this item, but cannot be monitored.

3. This item is displayed, but cannot be monitored.

ACTIVE TEST

Display Item List

NOTE:

1. Vehicles without daytime light lamp system display this item, but cannot be tested.

2. This item is displayed, but cannot be tested.

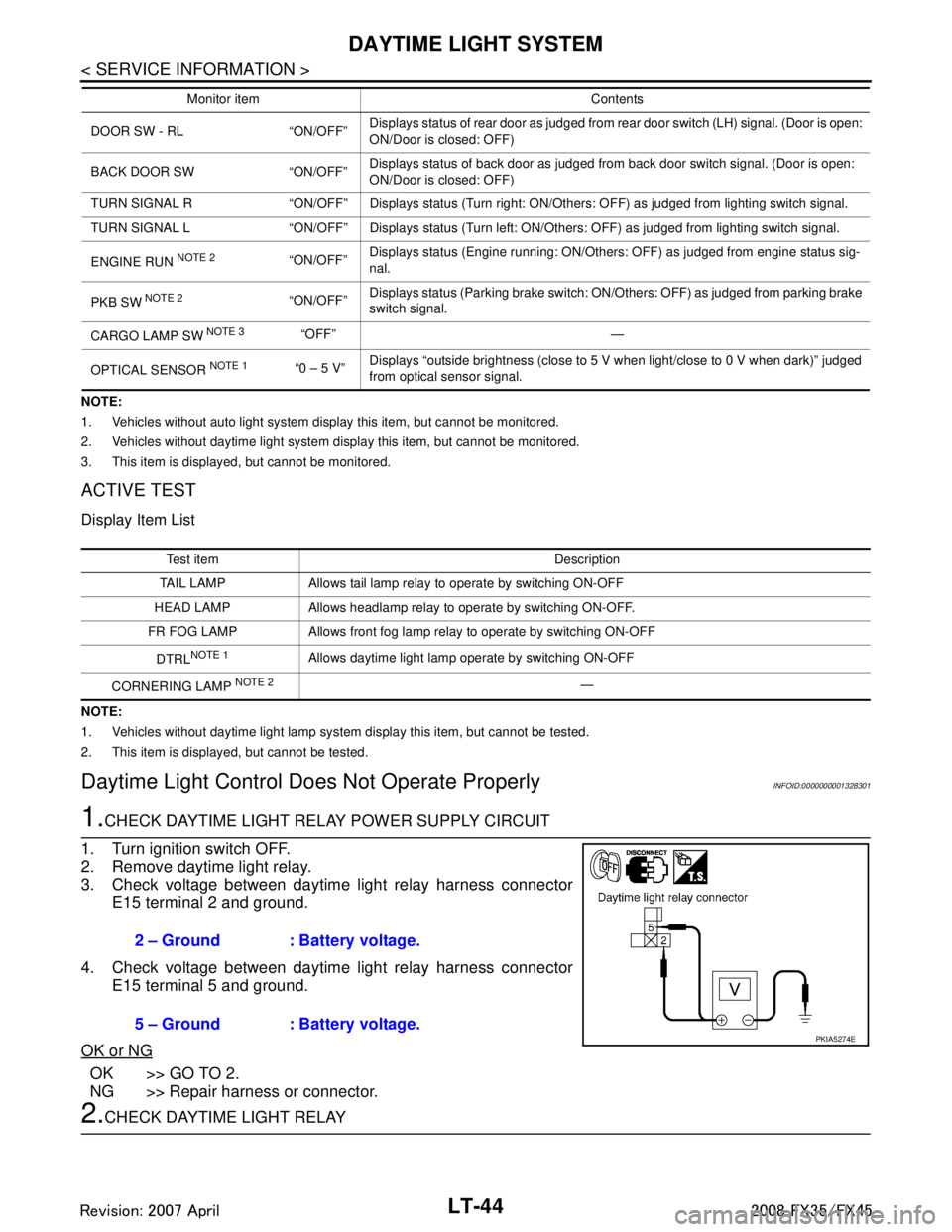

Daytime Light Control Does Not Operate ProperlyINFOID:0000000001328301

1.CHECK DAYTIME LIGHT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Remove daytime light relay.

3. Check voltage between daytime light relay harness connector E15 terminal 2 and ground.

4. Check voltage between daytime light relay harness connector E15 terminal 5 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

2.CHECK DAYTIME LIGHT RELAY

DOOR SW - RL “ON/OFF” Displays status of rear door as judged from rear door switch (LH) signal. (Door is open:

ON/Door is closed: OFF)

BACK DOOR SW “ON/OFF” Displays status of back door as judged from back door switch signal. (Door is open:

ON/Door is closed: OFF)

TURN SIGNAL R “ON/OFF” Displays status (Turn right: ON/Others: OFF) as judged from lighting switch signal.

TURN SIGNAL L “ON/OFF” Displays status (Turn left: ON/Others: OFF) as judged from lighting switch signal.

ENGINE RUN

NOTE 2“ON/OFF” Displays status (Engine running: ON/Others: OFF) as judged from engine status sig-

nal.

PKB SW

NOTE 2“ON/OFF” Displays status (Parking brake switch: ON/Others: OFF) as judged from parking brake

switch signal.

CARGO LAMP SW

NOTE 3 “OFF” —

OPTICAL SENSOR

NOTE 1 “0 – 5 V” Displays “outside brightness (close to 5 V when light/close to 0 V when dark)” judged

from optical sensor signal.

Monitor item Contents

Test item Description

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF

HEAD LAMP Allows headlamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF

DTRL

NOTE 1Allows daytime light lamp operate by switching ON-OFF

CORNERING LAMP

NOTE 2—

2 – Ground : Battery voltage.

5 – Ground : Battery voltage.

PKIA5274E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3148 of 3924

LT-46

< SERVICE INFORMATION >

DAYTIME LIGHT SYSTEM

7.CHECK INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “HEAD LAMP” of BCM data monitor item.

2. With the engine running or stopped, check the monitor status.

3. Select “HEAD LAMP” of BCM data monitor item.

4. With operating the parking brake switch, check the monitor status.

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NG >> GO TO 8.

8.CHECKING CAN COMMUNICATIONS

1. Select “self-diagnosis” of BCM”.

2. Check display content in self-diagnosis results.

Displayed self

-diagnosis results

NO DTC>> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

CAN COMM CIRCUIT>> Check BCM CAN communication system. Refer to PG-24, "

U1000 CAN COMM

CIRCUIT".

Aiming AdjustmentINFOID:0000000001328302

Refer to LT-27, "Aiming Adjustment".

Bulb ReplacementINFOID:0000000001328303

Refer to LT-28, "Bulb Replacement".

Removal and InstallationINFOID:0000000001328304

Refer to LT-30, "Removal and Installation".

Disassembly and AssemblyINFOID:0000000001328305

Refer to LT-30, "Disassembly and Assembly".

Engine running : ENGINE RUN ON

Engine stop : ENGINE RUN OFF

Parking brake ON : PKB SW ON

Parking brake OFF : PKB SW OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C