fuel cap INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3 of 3924

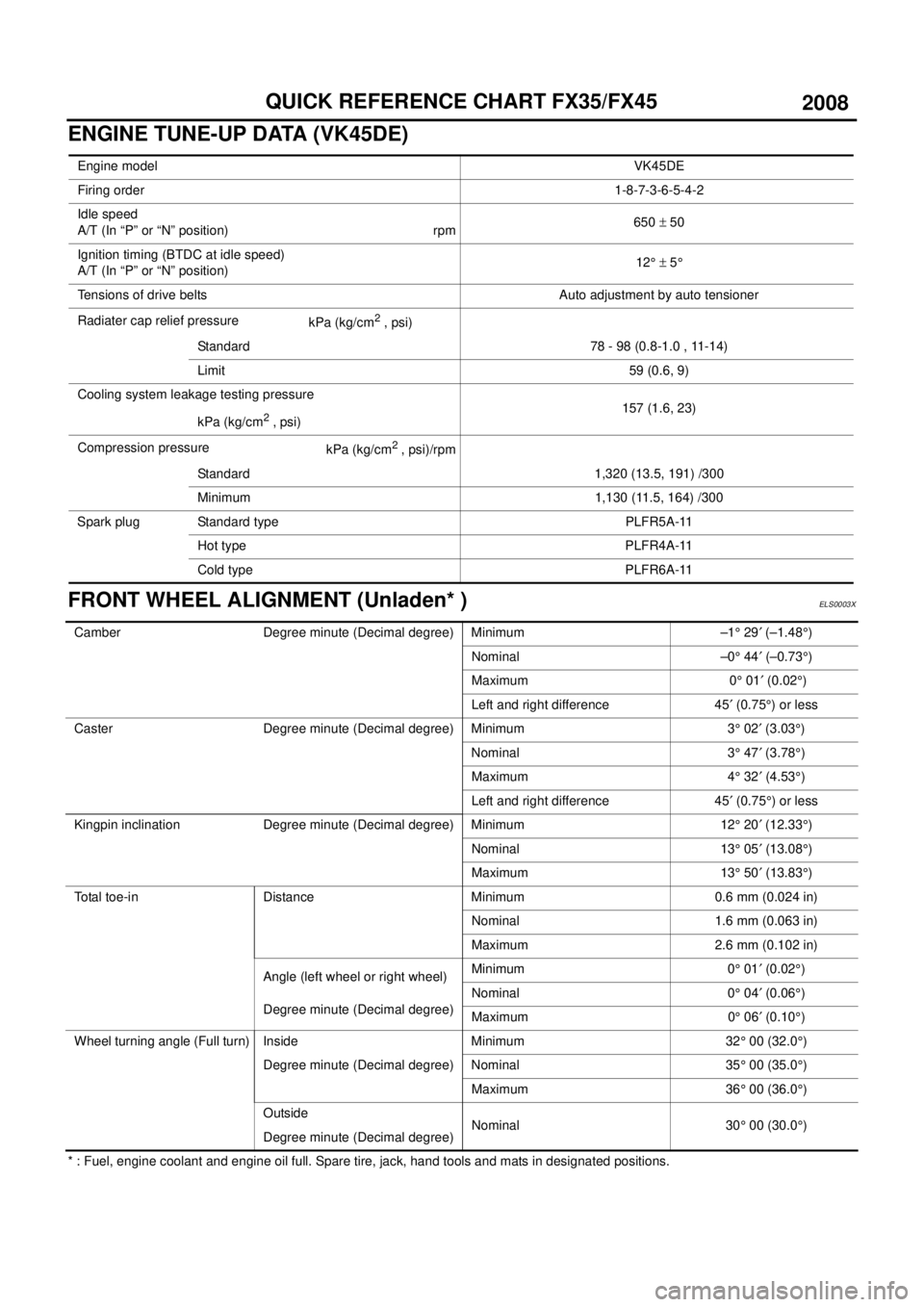

QUICK REFERENCE CHART FX35/FX45

ENGINE TUNE-UP DATA (VK45DE)

FRONT WHEEL ALIGNMENT (Unladen* )

ELS0003X

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Engine modelVK45DE

Firing order1-8-7-3-6-5-4-2

Idle speed

A/T (In “P” or “N” position) rpm650 ± 50

Ignition timing (BTDC at idle speed)

A/T (In “P” or “N” position)12° ± 5°

Tensions of drive belts Auto adjustment by auto tensioner

Radiater cap relief pressure

kPa (kg/cm

2 , psi)

78 - 98 (0.8-1.0 , 11-14) Standard

Limit 59 (0.6, 9)

Cooling system leakage testing pressure

157 (1.6, 23)

kPa (kg/cm

2 , psi)

Compression pressure

kPa (kg/cm

2 , psi)/rpm

1,320 (13.5, 191) /300 Standard

Minimum 1,130 (11.5, 164) /300

Spark plug Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Camber Degree minute (Decimal degree) Minimum –1° 29′ (–1.48°)

Nominal –0° 44′ (–0.73°)

Maximum 0° 01′ (0.02°)

Left and right difference 45′ (0.75°) or less

Caster Degree minute (Decimal degree) Minimum 3° 02′ (3.03°)

Nominal 3° 47′ (3.78°)

Maximum 4° 32′ (4.53°)

Left and right difference 45′ (0.75°) or less

Kingpin inclination Degree minute (Decimal degree) Minimum 12° 20′ (12.33°)

Nominal 13° 05′ (13.08°)

Maximum 13° 50′ (13.83°)

Total toe-in Distance Minimum 0.6 mm (0.024 in)

Nominal 1.6 mm (0.063 in)

Maximum 2.6 mm (0.102 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree)Minimum 0° 01′ (0.02°)

Nominal 0° 04′ (0.06°)

Maximum 0° 06′ (0.10°)

Wheel turning angle (Full turn) Inside Minimum 32° 00 (32.0°)

Degree minute (Decimal degree) Nominal 35° 00 (35.0°)

Maximum 36° 00 (36.0°)

Outside

Nominal 30° 00 (30.0°)

Degree minute (Decimal degree)

2008

Page 4 of 3924

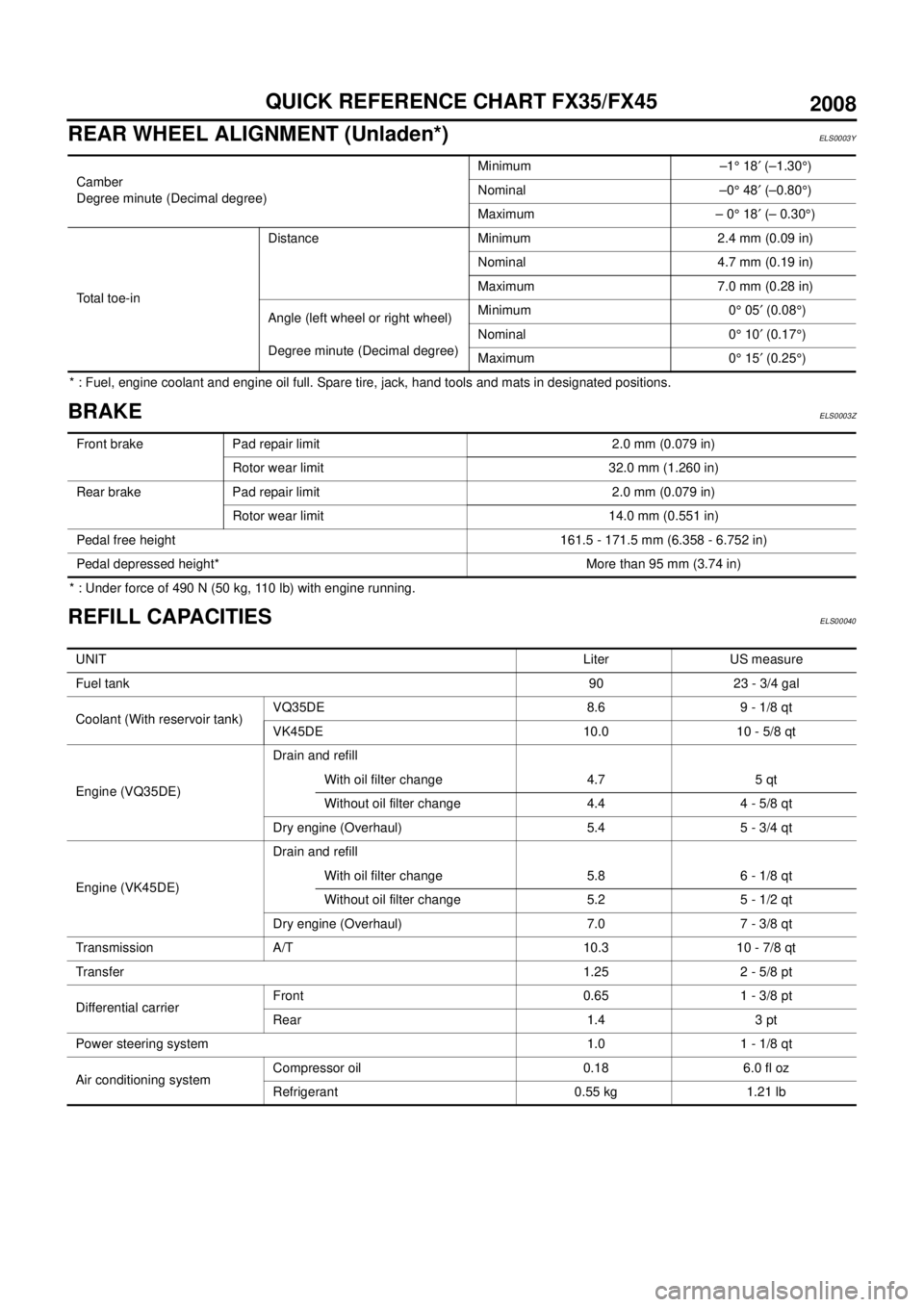

QUICK REFERENCE CHART FX35/FX45

REAR WHEEL ALIGNMENT (Unladen*)

ELS0003Y

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

BRAKEELS0003Z

* : Under force of 490 N (50 kg, 110 lb) with engine running.

REFILL CAPACITIESELS00040

Camber

Degree minute (Decimal degree)Minimum –1° 18′ (–1.30°)

Nominal –0° 48′ (–0.80°)

Maximum – 0° 18′ (– 0.30°)

Total toe-inDistance Minimum 2.4 mm (0.09 in)

Nominal 4.7 mm (0.19 in)

Maximum 7.0 mm (0.28 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree)Minimum 0° 05′ (0.08°)

Nominal 0° 10′ (0.17°)

Maximum 0° 15′ (0.25°)

Front brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 32.0 mm (1.260 in)

Rear brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 14.0 mm (0.551 in)

Pedal free height 161.5 - 171.5 mm (6.358 - 6.752 in)

Pedal depressed height* More than 95 mm (3.74 in)

UNITLiter US measure

Fuel tank90 23 - 3/4 gal

Coolant (With reservoir tank)VQ35DE 8.6 9 - 1/8 qt

VK45DE 10.0 10 - 5/8 qt

Engine (VQ35DE)Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

Engine (VK45DE)Drain and refill

With oil filter change 5.8 6 - 1/8 qt

Without oil filter change 5.2 5 - 1/2 qt

Dry engine (Overhaul) 7.0 7 - 3/8 qt

Transmission A/T 10.3 10 - 7/8 qt

Transfer1.25 2 - 5/8 pt

Differential carrierFront 0.65 1 - 3/8 pt

Rear 1.4 3 pt

Power steering system 1.0 1 - 1/8 qt

Air conditioning systemCompressor oil 0.18 6.0 fl oz

Refrigerant 0.55 kg 1.21 lb

2008

Page 1270 of 3924

![INFINITI FX35 2008 Service Manual

EC-30

< SERVICE INFORMATION >[VQ35DE]

PREPARATION

Commercial Service Tool

INFOID:0000000001325894

Tool name

(Kent-Moore No.) Description

Leak detector

i.e.: (J-41416) Locating EVAP leak

EVAP service INFINITI FX35 2008 Service Manual

EC-30

< SERVICE INFORMATION >[VQ35DE]

PREPARATION

Commercial Service Tool

INFOID:0000000001325894

Tool name

(Kent-Moore No.) Description

Leak detector

i.e.: (J-41416) Locating EVAP leak

EVAP service](/img/42/57017/w960_57017-1269.png)

EC-30

< SERVICE INFORMATION >[VQ35DE]

PREPARATION

Commercial Service Tool

INFOID:0000000001325894

Tool name

(Kent-Moore No.) Description

Leak detector

i.e.: (J-41416) Locating EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applying positive pressure through EVAP service

port

Fuel filler cap adapter

i.e.: (MLR-8382) Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant tempera- ture sensor

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12) Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirco-

nia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Tita-

nia Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM

133AR or equivalent

meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

S-NT703

S-NT704

S-NT815

S-NT705

AEM488

S-NT779

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1283 of 3924

![INFINITI FX35 2008 Service Manual

EVAPORATIVE EMISSION SYSTEMEC-43

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check EVAP canister as follows:

1. Block port

B.

2. Blow air into port A and check that it flows fr INFINITI FX35 2008 Service Manual

EVAPORATIVE EMISSION SYSTEMEC-43

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check EVAP canister as follows:

1. Block port

B.

2. Blow air into port A and check that it flows fr](/img/42/57017/w960_57017-1282.png)

EVAPORATIVE EMISSION SYSTEMEC-43

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check EVAP canister as follows:

1. Block port

B.

2. Blow air into port A and check that it flows freely out of port C.

3. Release blocked port B.

4. Apply vacuum pressure to port B and check that vacuum pres-

sure exists at the ports A and C.

5. Block port A and B.

6. Apply pressure to port C and check that there is no leakage.

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FILLER CAP)

1. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

3. If out of specificat ion, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may come on.

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to EC-360, "Component Inspection".

FUEL TANK TEMPERATURE SENSOR

Refer to EC-297, "Component Inspection".

EVAP CANISTER VENT CONTROL VALVE

Refer to EC-364, "Component Inspection".

EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-380, "Component Inspection".

EVAP SERVICE PORT

PBIB1044E

SEF445Y

Pressure:

15.3 - 20.0 kPa (0.156 - 0.204 kg/cm2, 2.22 -

2.90 psi)

Vacuum: −6.0 to −3.3 kPa ( −0.061 to −0.034 kg/cm

2,

− 0.87 to −0.48 psi)

SEF943S

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1333 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISEC-93

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such con INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISEC-93

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such con](/img/42/57017/w960_57017-1332.png)

TROUBLE DIAGNOSISEC-93

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about a incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the MI

L to come on steady or blink and

DTC to be detected. Examples:

Vehicle ran out of fuel, which caused the engine to misfire.

Fuel filler cap was left off or incorrectly screwed on, allowing fuel to evaporate into the atmosphere.

Worksheet Sample

DTC Inspection Priority ChartINFOID:0000000001325928

If some DTCs are displayed at the same time, per form inspections one by one based on the following priority

chart.

NOTE:

SEF907L

MTBL0017

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1339 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISEC-99

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5 E INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISEC-99

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5 E](/img/42/57017/w960_57017-1338.png)

TROUBLE DIAGNOSISEC-99

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5 EM-26

,

EX-

3Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

55555 55 5 EM-30

,

LU-

15, LU-8,

LU-12

Oil level (Low)/Filthy oil LU-5

Cooling

Radiator/Hose/Radiator filler cap

55555 55 45 CO-13,

CO-16

Thermostat 5 CO-27

Water pumpCO-22

Water galleryCO-29

Cooling fan 5EC-210

Coolant level (Low)/Contaminat-

ed coolant5

CO-10

IVIS (Infiniti Vehicle Immobilizer System —

NATS) 11 EC-53 or

BL-185

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1378 of 3924

![INFINITI FX35 2008 Service Manual

EC-138

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

Disconnection, looseness, and INFINITI FX35 2008 Service Manual

EC-138

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

Disconnection, looseness, and](/img/42/57017/w960_57017-1377.png)

EC-138

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

Disconnection, looseness, and cracks in air duct

Looseness of oil filler cap

Disconnection of oil level gauge

Open stuck, breakage, hose disconnecti

on, or cracks of PCV valve

Disconnection or cracks of EVAP purge hose, open stuc k of EVAP canister purge volume control solenoid

valve

Malfunctioning seal of rocker cover gasket

Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

Malfunctioning seal of intake air system, etc.

>> GO TO 30.

29.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-96, "

Symptom Matrix Chart".

30.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITO R” mode, and then make sure that the indication is

within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-96, "

Symptom Matrix Chart".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1452 of 3924

![INFINITI FX35 2008 Service Manual

EC-212

< SERVICE INFORMATION >[VQ35DE]

DTC P0130, P0150

A/F SENSOR 1

DTC P0130, P0150 A/F SENSOR 1

Component DescriptionINFOID:0000000001326045

The air fuel ratio (A/F) sensor is a planar dual-cell INFINITI FX35 2008 Service Manual

EC-212

< SERVICE INFORMATION >[VQ35DE]

DTC P0130, P0150

A/F SENSOR 1

DTC P0130, P0150 A/F SENSOR 1

Component DescriptionINFOID:0000000001326045

The air fuel ratio (A/F) sensor is a planar dual-cell](/img/42/57017/w960_57017-1451.png)

EC-212

< SERVICE INFORMATION >[VQ35DE]

DTC P0130, P0150

A/F SENSOR 1

DTC P0130, P0150 A/F SENSOR 1

Component DescriptionINFOID:0000000001326045

The air fuel ratio (A/F) sensor is a planar dual-cell limit current sen-

sor. The sensor element of the air fuel ratio (A/F) sensor is the com-

bination of a Nernst concentrati on cell (sensor cell) with an oxygen-

pump cell, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range (0.7 <

< air).

The exhaust gas components diffuse through the diffusion gap at the

electrode of the oxygen pump and Nernst concentration cell, where

they are brought to thermodynamic balance.

An electronic circuit controls the pump current through the oxygen-

pump cell so that the composition of the exhaust gas in the diffusion

gap remains constant at = 1. Therefore, the air fuel ratio (A/F) sen-

sor is able to indicate air/fuel ratio by this pumping of current. In

addition, a heater is integrated in the sensor to ensure the required

operating temperature of 700 - 800 °C (1,292 - 1,472 °F).

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001326046

Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000001326047

To judge the malfunction, the diagnosis checks that the A/ F signal computed by ECM from the air fuel ratio (A/

F) sensor 1 signal fluctuates ac cording to fuel feedback control.

DTC Confirmation ProcedureINFOID:0000000001326048

Perform PROCEDURE FOR MALFUNCTION A first.

If the DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

PROCEDURE FOR MALFUNCTION A

SEF579Z

SEF580Z

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1)

A/F SEN1 (B2) Engine: After warming up

Maintaining engine speed at

2,000 rpm Fluctuates around 1.5V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0130

0130

(Bank 1) Air fuel ratio (A/F) sensor 1

circuit A)

The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly in the range other

than approx. 1.5V.

Harness or connectors

(The A/F sensor 1 circuit is open

or shorted.)

Air fuel ratio (A/F) sensor 1

P0150

0150

(Bank 2) B)

The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 1.5V.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1460 of 3924

![INFINITI FX35 2008 Service Manual

EC-220

< SERVICE INFORMATION >[VQ35DE]

DTC P0131, P0151

A/F SENSOR 1

DTC P0131, P0151 A/F SENSOR 1

Component DescriptionINFOID:0000000001326053

The air fuel ratio (A/F) sensor is a planar dual-cell INFINITI FX35 2008 Service Manual

EC-220

< SERVICE INFORMATION >[VQ35DE]

DTC P0131, P0151

A/F SENSOR 1

DTC P0131, P0151 A/F SENSOR 1

Component DescriptionINFOID:0000000001326053

The air fuel ratio (A/F) sensor is a planar dual-cell](/img/42/57017/w960_57017-1459.png)

EC-220

< SERVICE INFORMATION >[VQ35DE]

DTC P0131, P0151

A/F SENSOR 1

DTC P0131, P0151 A/F SENSOR 1

Component DescriptionINFOID:0000000001326053

The air fuel ratio (A/F) sensor is a planar dual-cell limit current sen-

sor. The sensor element of the air fuel ratio (A/F) sensor is the com-

bination of a Nernst concentrati on cell (sensor cell) with an oxygen-

pump cell, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range (0.7 <

< air).

The exhaust gas components diffuse through the diffusion gap at the

electrode of the oxygen pump and Nernst concentration cell, where

they are brought to thermodynamic balance.

An electronic circuit controls the pump current through the oxygen-

pump cell so that the composition of the exhaust gas in the diffusion

gap remains constant at = 1. Therefore, the air fuel ratio (A/F) sen-

sor is able to indicate air/fuel ratio by this pumping of current. In

addition, a heater is integrated in the sensor to ensure the required

operating temperature of 700 - 800 °C (1,292 - 1,472 °F).

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001326054

Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000001326055

To judge the malfunction, the diagnosis checks that the A/ F signal computed by ECM from the air fuel ratio (A/

F) sensor 1 signal is not inordinately low.

DTC Confirmation ProcedureINFOID:0000000001326056

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” or “A/F SEN1 (B2)” in “DATA MONITOR” mode with CONSULT-III.

SEF579Z

SEF580Z

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1)

A/F SEN1 (B2) Engine: After warming up

Maintaining engine speed at

2,000 rpm Fluctuates around 1.5V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0131

0131

(Bank 1) Air fuel ratio (A/F) sensor 1

circuit low voltage The A/F signal computed by ECM from the air

fuel ratio (A/F) sensor 1 signal is constantly ap-

prox. 0V. Harness or connectors

[Air fuel ratio (A/F) sensor 1 circuit is

open or shorted.]

Air fuel ratio (A/F) sensor 1

P0151

0151

(Bank 2)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1468 of 3924

![INFINITI FX35 2008 Service Manual

EC-228

< SERVICE INFORMATION >[VQ35DE]

DTC P0132, P0152

A/F SENSOR 1

DTC P0132, P0152 A/F SENSOR 1

Component DescriptionINFOID:0000000001326060

The air fuel ratio (A/F) sensor is a planar dual-cell INFINITI FX35 2008 Service Manual

EC-228

< SERVICE INFORMATION >[VQ35DE]

DTC P0132, P0152

A/F SENSOR 1

DTC P0132, P0152 A/F SENSOR 1

Component DescriptionINFOID:0000000001326060

The air fuel ratio (A/F) sensor is a planar dual-cell](/img/42/57017/w960_57017-1467.png)

EC-228

< SERVICE INFORMATION >[VQ35DE]

DTC P0132, P0152

A/F SENSOR 1

DTC P0132, P0152 A/F SENSOR 1

Component DescriptionINFOID:0000000001326060

The air fuel ratio (A/F) sensor is a planar dual-cell limit current sen-

sor. The sensor element of the air fuel ratio (A/F) sensor is the com-

bination of a Nernst concentrati on cell (sensor cell) with an oxygen-

pump cell, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range (0.7 <

< air).

The exhaust gas components diffuse through the diffusion gap at the

electrode of the oxygen pump and Nernst concentration cell, where

they are brought to thermodynamic balance.

An electronic circuit controls the pump current through the oxygen-

pump cell so that the composition of the exhaust gas in the diffusion

gap remains constant at = 1. Therefore, the air fuel ratio (A/F) sen-

sor is able to indicate air/fuel ratio by this pumping of current. In

addition, a heater is integrated in the sensor to ensure the required

operating temperature of 700 - 800 °C (1,292 - 1,472 °F).

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001326061

Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000001326062

To judge the malfunction, the diagnosis checks that the A/ F signal computed by ECM from the air fuel ratio (A/

F) sensor 1 signal is not inordinately high.

DTC Confirmation ProcedureINFOID:0000000001326063

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” or “A/F SEN1 (B2)” in “DATA MONITOR” mode with CONSULT-III.

SEF579Z

SEF580Z

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1)

A/F SEN1 (B2) Engine: After warming up

Maintaining engine speed at

2,000 rpm Fluctuates around 1.5V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0132

0132

(Bank 1) Air fuel ratio (A/F) sensor 1

circuit high voltage The A/F signal computed by ECM from the air fuel

ratio (A/F) sensor 1 signal is constantly approx.

5V. Harness or connectors

[Air fuel ratio (A/F) sensor 1 circuit is

open or shorted.]

Air fuel ratio (A/F) sensor 1

P0152

0152

(Bank 2)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C