engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2887 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

How to Perform Efficient Diagnos is for an Electrical IncidentINFOID:0000000001325672

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the c onditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

Vehicle vibration

Heat sensitive

Freezing

Water intrusion

Electrical load

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3 Get the proper diagnosis materials together including:

Power Supply Routing

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2888 of 3924

GI-26

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

Vehicle Vibration

The problem may occur or become worse while drivi ng on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an e\

lectrical complaint. Some of the

things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

Heat Sensitive

SGI839

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2896 of 3924

GI-34

< SERVICE INFORMATION >

CONSULT-III/GST CHECKING SYSTEM

CONSULT-III/GST CHECKING SYSTEM

DescriptionINFOID:0000000001572193

When CONSULT-III/GST is connected with a data link connector

(A) equipped on the vehicle side, it will communicate with the con-

trol unit equipped in the vehicle and then enable various kinds of

diagnostic tests.

Refer to CONSULT-III Operation Manual for more information.

CONSULT-III Function a nd System Application*1INFOID:0000000001572194

x: Applicable

*1: If GST application is eq uipped, functions in accordance with SAE J1979 and ISO 15031-5 can be used.

1 : Instrument driver lower panel

JPAIA0066ZZ

Diagnostic test

mode Function

ENGINE

A/T

AIR BAG

REARVIEW CAMERA

METER A/C AMP BCM

AUTO DRIVE POS.

ABS (Including VDC) IPDM E/R

ICC

ALL MODE AWD/4WD INTELLIGENT KEY LDW

Work support This mode enables a technician to adjust some devices faster

and more accurately by following the indications on CON-

SULT-III. xx - x - xxx- x- xx

Self-diagnostic re-

sults Self-diagnostic results can be read and erased quickly. xxx - xxxxxxxxx

Trouble diagnos-

tic record Current self-diagnostic results and all trouble diagnostic

records previously stored can be read.

--x----------

Data monitor Input/Output data in the ECU can be read. xx - xxxxxxxxxx

CAN diagnosis

support monitor The condition of CAN communication line can be read. xx- - xxxxxxxxx

Active test Diagnostic Test Mode in whic

h CONSULT-III drives some ac-

tuators apart from the ECUs and also shifts some parameters

in a specified range. x- -- - xxxxxxxx

DTC & SRT con-

firmation The results of SRT (System Readiness Test) and the self-di-

agnosis status/result can be confirmed.

x- -- ---------

DTC work support This mode enables a technician to monitor the status/results

of self-diagnosis performed by the ECU. xx-- ---------

ECU (ECM/TCM)

part number ECU (ECM/TCM) part number can be read. x x - x - x x x - x x x x

ECU discriminat-

ed No. Classification number of a replacement ECU can be read to

prevent an incorrect ECU from being installed.

-- x- ---------

Function test This mode can show results of self-diagnosis of ECU with ei-

ther 'OK' or 'NG'. For engines, more practical tests regarding

sensors/switches and/or actuators are available.

xxx- ---x-----

Configuration — -----x------ -

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2899 of 3924

LIFTING POINTGI-37

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PLIFTING POINT

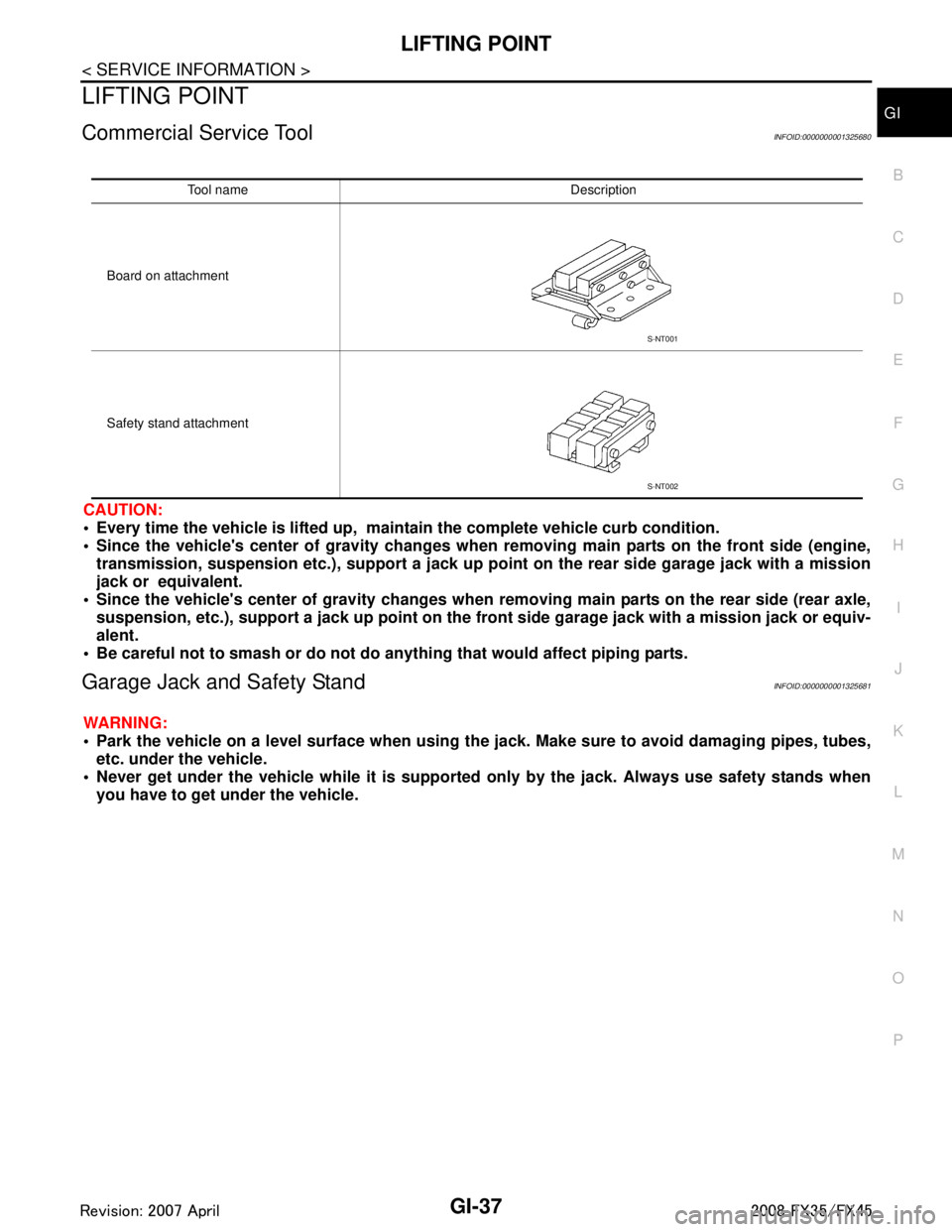

Commercial Service ToolINFOID:0000000001325680

CAUTION:

Every time the vehicle is lifted up, main tain the complete vehicle curb condition.

Since the vehicle's center of gravity changes when removing main parts on the front side (engine,

transmission, suspension etc.), support a jack up poi nt on the rear side garage jack with a mission

jack or equivalent.

Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the fr ont side garage jack with a mission jack or equiv-

alent.

Be careful not to smash or do not do an ything that would affect piping parts.

Garage Jack and Safety StandINFOID:0000000001325681

WARNING:

Park the vehicle on a level surface when using th e jack. Make sure to avoid damaging pipes, tubes,

etc. under the vehicle.

Never get under the vehicle while it is supported only by the jack. Always use safety stands when

you have to get under the vehicle.

Tool name Description

Board on attachment

Safety stand attachment

S-NT001

S-NT002

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2907 of 3924

IDENTIFICATION INFORMATIONGI-45

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PIDENTIFICATION INFORMATION

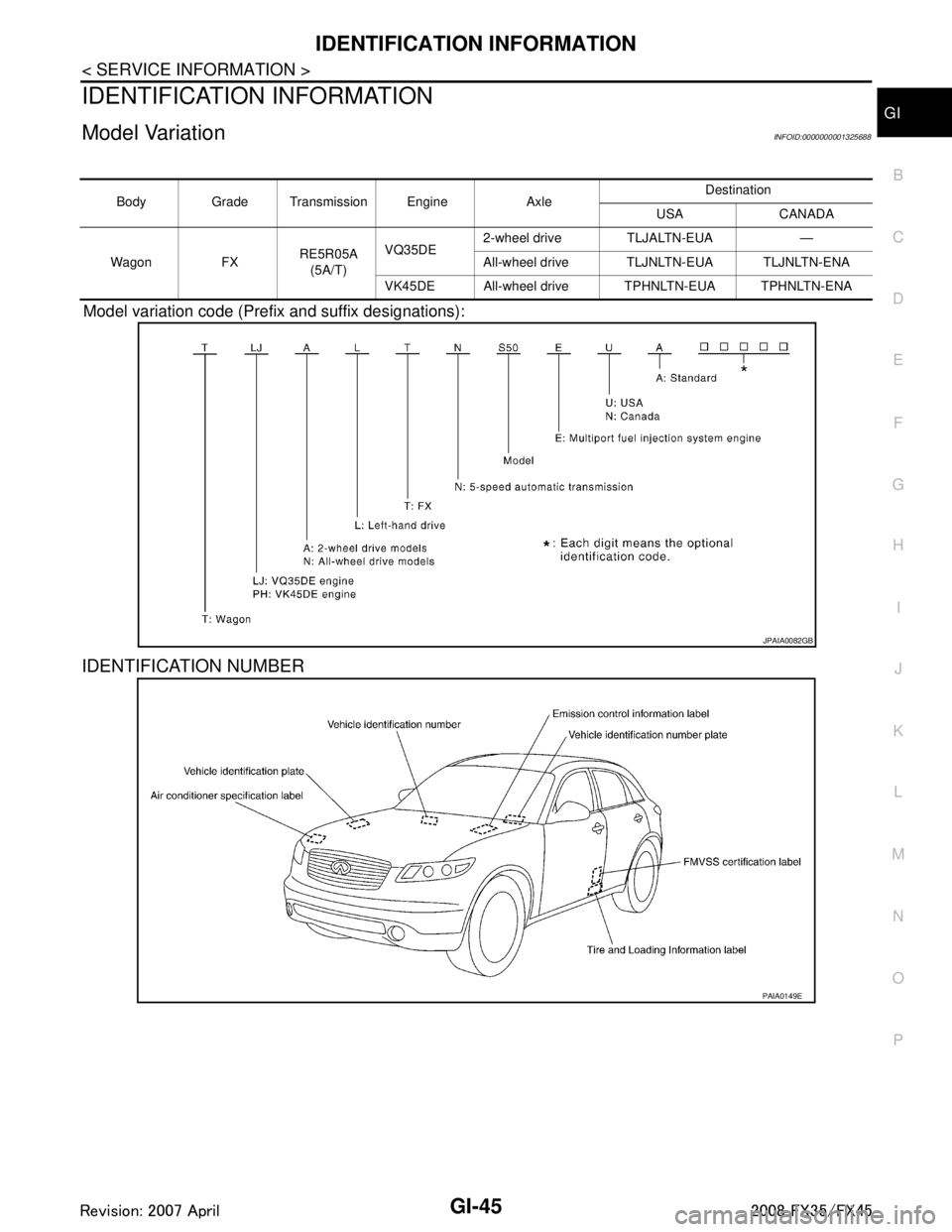

Model VariationINFOID:0000000001325688

Model variation code (Prefix and suffix designations):

IDENTIFICATION NUMBER

Body Grade Transmission Engine Axle Destination

USA CANADA

Wagon FX RE5R05A

(5A/T) VQ35DE

2-wheel drive TLJALTN-EUA —

All-wheel drive TLJNLTN-EUA TLJNLTN-ENA

VK45DE All-wheel drive TPHNLTN-EUA TPHNLTN-ENA

JPAIA0082GB

PAIA0149E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2908 of 3924

GI-46

< SERVICE INFORMATION >

IDENTIFICATION INFORMATION

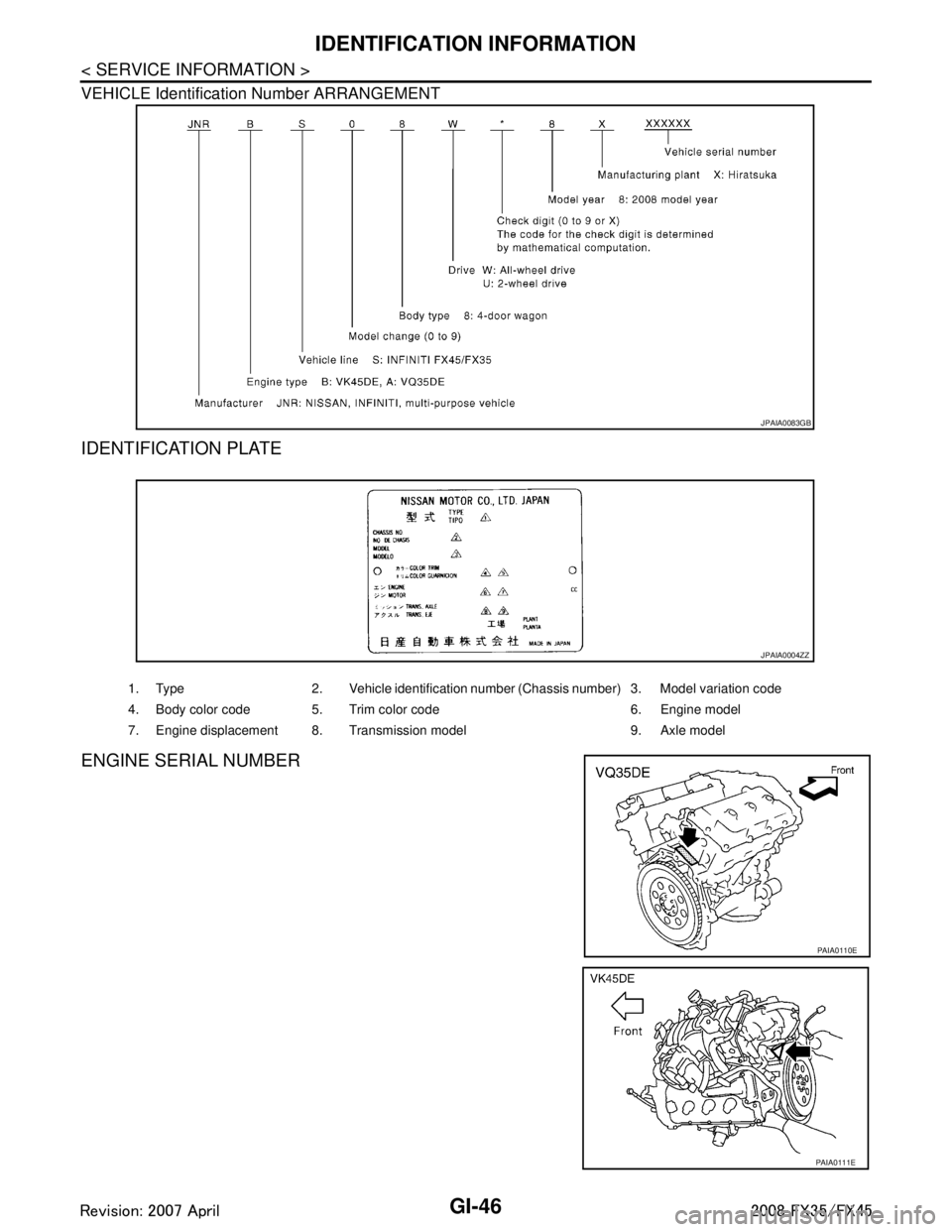

VEHICLE Identification Number ARRANGEMENT

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

JPAIA0083GB

1. Type 2. Vehicle identification number (Chassis number) 3. Model variation code

4. Body color code 5. Trim color code 6. Engine model

7. Engine displacement 8. Transmission model 9. Axle model

JPAIA0004ZZ

PAIA0110E

PAIA0111E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2910 of 3924

GI-48

< SERVICE INFORMATION >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000001325691

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old te rms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONS ULT-II DLC for CONSULT-II Diagno stic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2911 of 3924

TERMINOLOGYGI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Exhaust gas recirculation control-BPT

valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM ***

Flash erasable programmable read only

memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulato r *** Pressure regulator

Fuel pressure regulator control solenoid

valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulato r IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve IACV-AAC valve Auxiliary

air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold su rface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2917 of 3924

GW-4

< SERVICE INFORMATION >

PREPARATION

PREPARATION

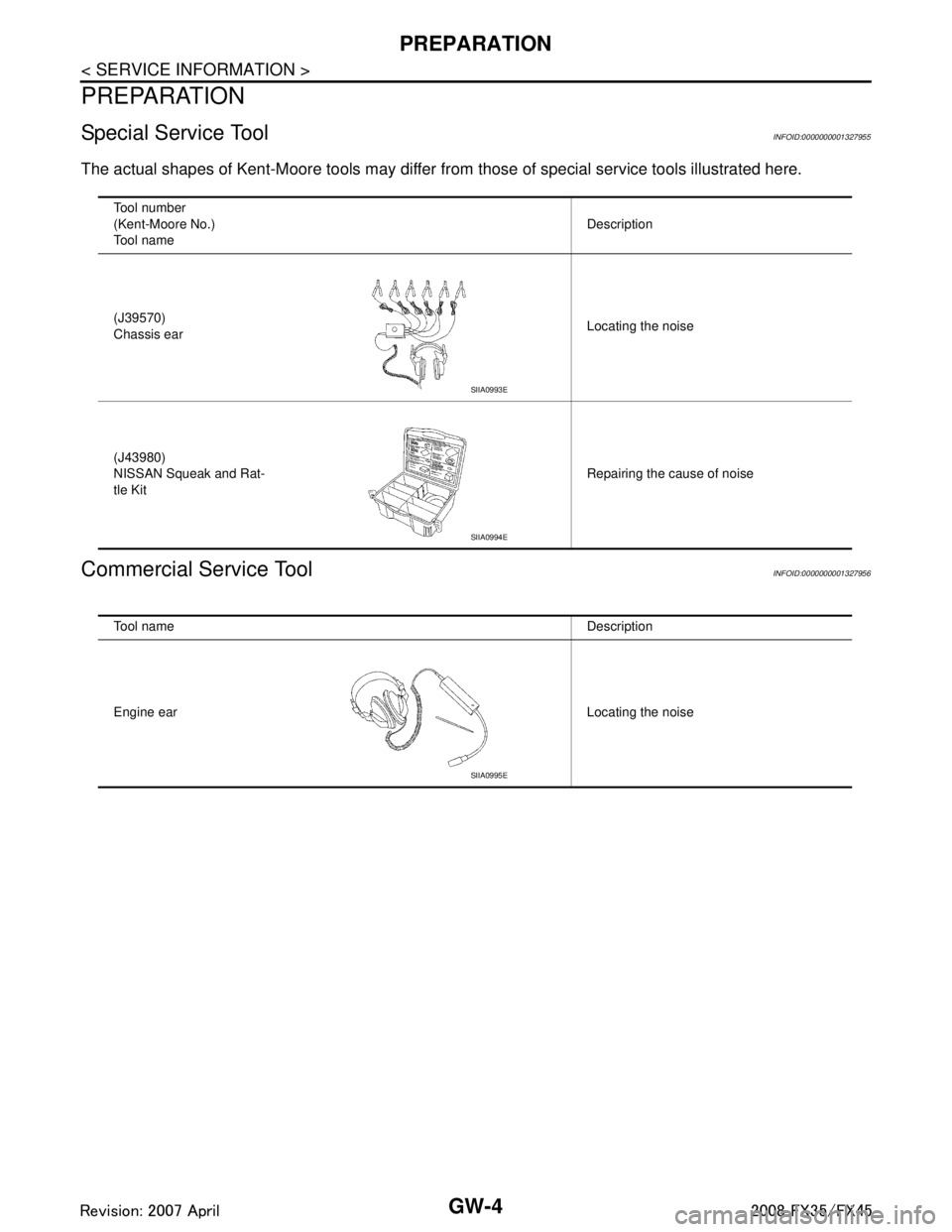

Special Service ToolINFOID:0000000001327955

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001327956

Tool number

(Kent-Moore No.)

Tool name Description

(J39570)

Chassis ear Locating the noise

(J43980)

NISSAN Squeak and Rat-

tle Kit Repairing the cause of noise

SIIA0993E

SIIA0994E

Tool name Description

Engine ear Locating the noise

SIIA0995E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2919 of 3924

GW-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to helpidentify the source of the noise, try to dupli-

cate the noise with the vehiclestopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears tobe coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditi ons thecustomer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowlyon an undulating or rough road to stress the vehi-

cle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technica lService Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, fo llow the procedure to repair thenoise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the causeof the noise by:

removing the components in the area that you suspect the noiseis coming from. Do not use too much force when removing clips and fasteners, otherwiseclips and fastener can be broken or

lost during the repair, resulting in thecreation of new noise.

tapping or pushing/pulling the component t hat you suspect is causingthe noise.

Do not tap or push/pull the component with excessive force, otherwisethe noise will be eliminated only tem-

porarily.

feeling for a vibration with your hand by touching t he component(s)that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect arecausing the noise.

looking for loose components and contact marks. Refer to GW-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or l oosening and retighteningthe component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A Nissan Squeak and Rattle Kit (J43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plasticand may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J43980). Each item can be ordered

separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02: 15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials, not found in the kit, can al so be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C