engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3816 of 3924

TF-30

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

AWD Warning Lamp Does Not Turn ON When the Ignition Switch Is Turned to ON

INFOID:0000000001327450

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-28, "DTC U1000 CAN COMM

CIRCUIT".

NO >> GO TO 2.

2.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 3.

NG >> Check AWD control unit pin terminals for dam age or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

3.CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-III.

3. Start the engine, and then make sure that “4WD W/L” display turns from “ON” to “OFF” after several sec-

onds.

OK or NG

OK >> GO TO 4.

NG >> Perform trouble diagnosis for combination meter. Refer to DI-15, "

Trouble Diagnosis".

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-23, "

Disassembly and Assembly of Com-

bination Meter".

AWD Warning Lamp Does Not Turn OFF Several Seconds after Engine Started

INFOID:0000000001327451

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK AWD CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

Monitor item Condition Display value

4WD W/L Ignition switch ON ON

Start engine (after several seconds) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3817 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSTF-31

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

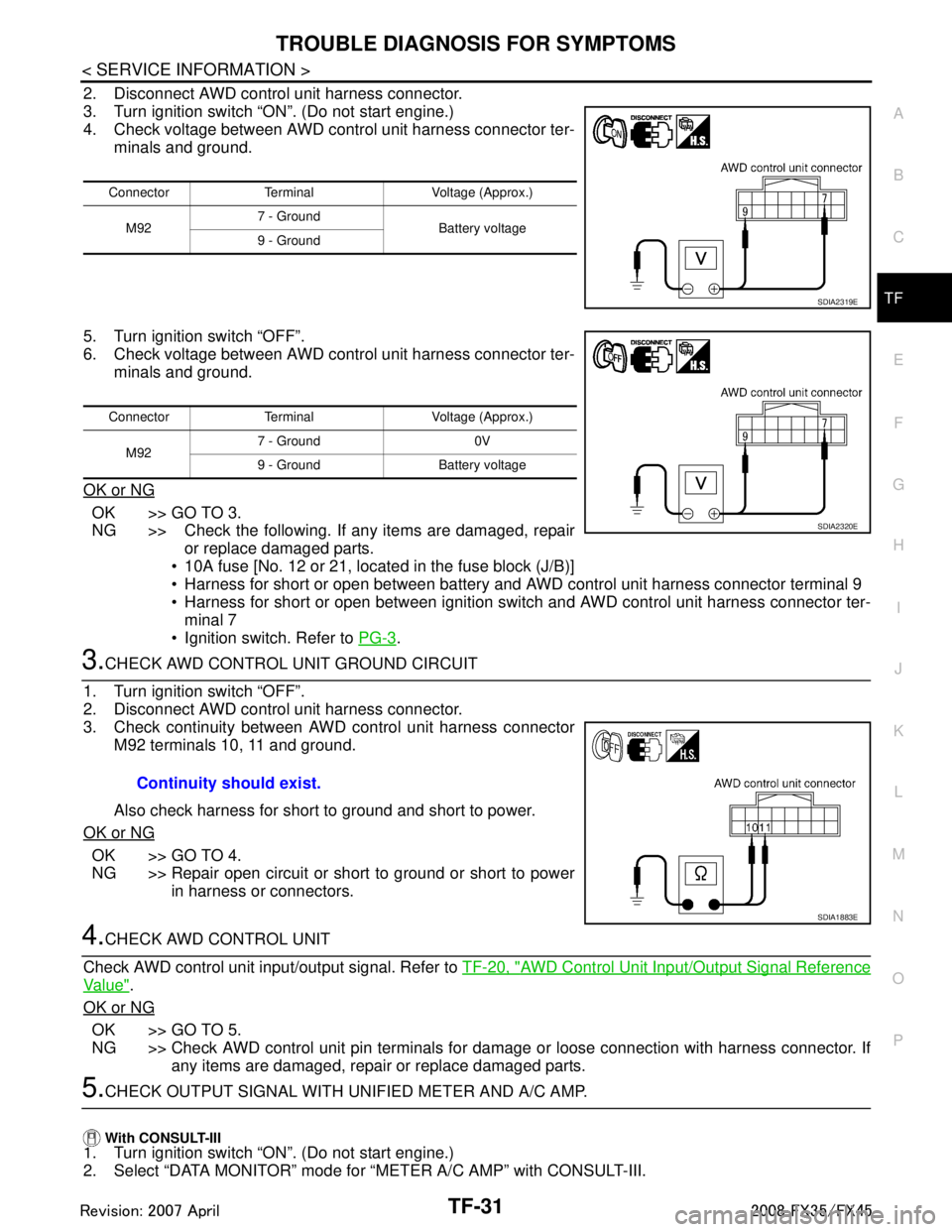

2. Disconnect AWD control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Check voltage between AWD control unit harness connector ter- minals and ground.

5. Turn ignition switch “OFF”.

6. Check voltage between AWD control unit harness connector ter- minals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

10A fuse [No. 12 or 21, located in the fuse block (J/B)]

Harness for short or open between battery and AWD control unit harness connector terminal 9

Harness for short or open between ignition switch and AWD control unit harness connector ter- minal 7

Ignition switch. Refer to PG-3

.

3.CHECK AWD CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect AWD control unit harness connector.

3. Check continuity between AWD control unit harness connector M92 terminals 10, 11 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 5.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If any items are damaged, repair or replace damaged parts.

5.CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-III.

Connector Terminal Voltage (Approx.)

M92 7 - Ground

Battery voltage

9 - Ground

SDIA2319E

Connector Terminal Voltage (Approx.)

M92 7 - Ground 0V

9 - Ground Battery voltage

SDIA2320E

Continuity should exist.

SDIA1883E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3818 of 3924

TF-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. Start the engine, and then make sure that “4WD W/L” display turns from “ON” to “OFF” after several sec-

onds.

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for combination meter. Refer to DI-15, "

Trouble Diagnosis".

6.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-23, "

Disassembly and Assembly of Com-

bination Meter".

Heavy Tight-Corner Braking Symptom Occurs When the Vehicle Is Driven and the

Steering Wheel Is Turned Fu lly to Either Side after the Engine Is Started

INFOID:0000000001327452

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunc-

tion.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-28, "DTC U1000 CAN COMM

CIRCUIT".

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self-diagnosis for ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" (VQ35DE mod-

els) or EC-633, "

Emission-related Diagnostic Information" (VK45DE models).

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-25, "

DTC C1204 4WD SOLENOID".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mec hanical malfunction (clutch sticking etc.). Refer to TF-

40, "Disassembly and Assembly".

NO >> GO TO 5.

Monitor item Condition Display value

4WD W/L Ignition switch ON ON

Start engine (after several seconds) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3820 of 3924

TF-34

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

DIAGNOSTIC PROCEDURE

1.CHECK TIRE

Check the following.

Tire pressure

Wear condition

Longitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Drive at vehicle speed of 20 km/h (12 MPH) or more for 5 seconds or more after repairing or replacing damaged parts. (Initialize improper size tire information.)

2.CHECK INPUT SIGNAL OF TIRE DIAMETER

With CONSULT-III

1. Start engine.

2. Drive at 20 km/h (12 MPH) or more for approx. 200 seconds.

3. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-III.

4. Check monitor “DIS-TIRE MONI”.

Display of

“DIS-TIRE MONI”

“0-4mm”>> INSPECTION END

Except for “0-4mm”>>GO TO 3.

3.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 4.

NG >> Check AWD control unit pin terminals for dam age or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace AWD control unit.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3826 of 3924

TF-40

< SERVICE INFORMATION >

TRANSFER ASSEMBLY

TRANSFER ASSEMBLY

Removal and InstallationINFOID:0000000001327460

REMOVAL

1. Remove tunnel stay with power tool. Refer to RSU-6, "Removal and Installation".

2. Remove exhaust front tube with power tool. Refer to EX-3

.

3. Remove front and rear propeller shaft. Refer to PR-4

and PR-7.

4. Disconnect transfer assembly harness connector and separate harness from transfer assembly.

5. Remove air breather hose. Refer to TF-39

.

6. Support transfer assembly and transmission assembly with a jack.

7. Remove engine rear member with power tool. Refer to EM-112

(VQ35DE) or EM-237 (VK45DE).

8. Remove transfer mounting bolts and se parate transfer from transmission.

CAUTION:

Secure transfer assembly to a jack.

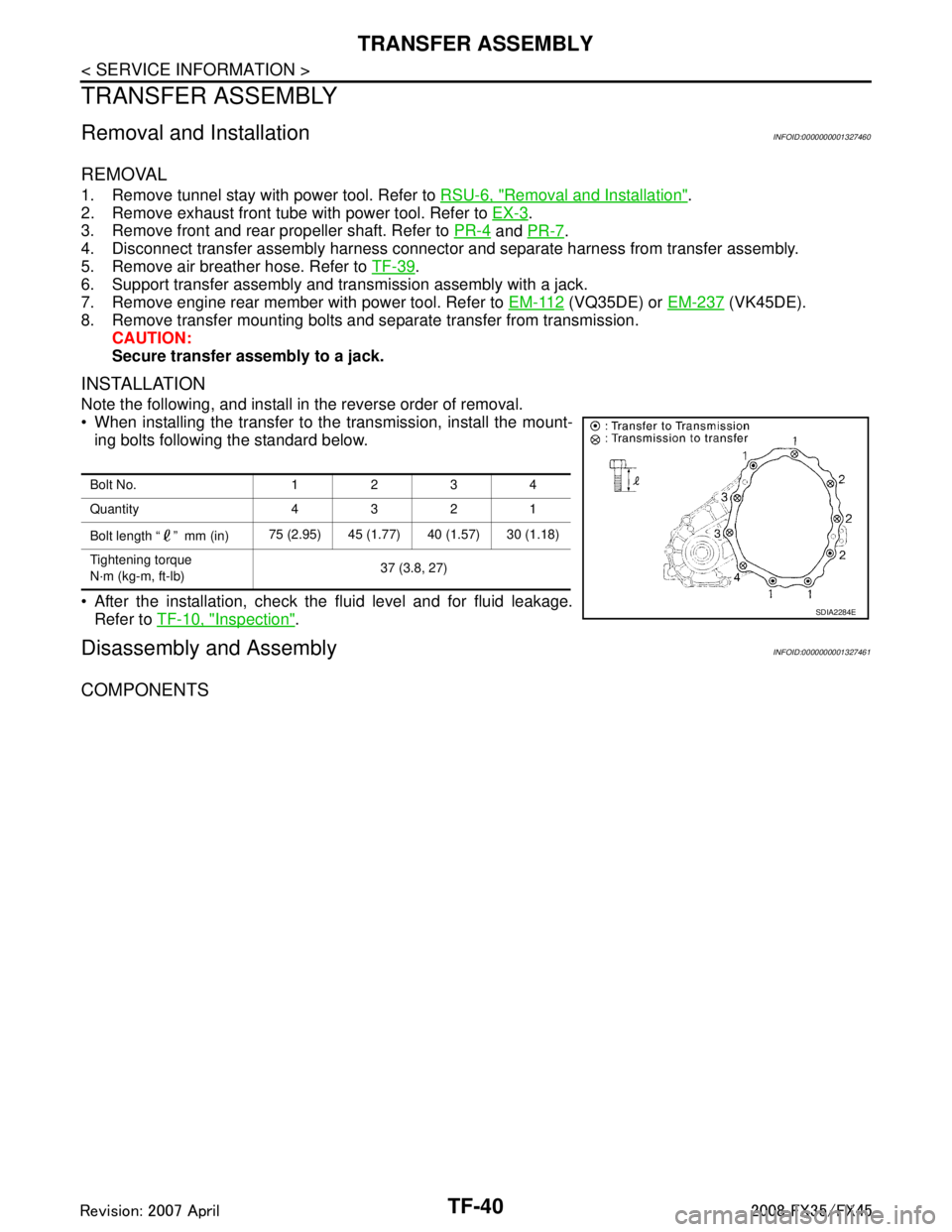

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing the transfer to the transmission, install the mount-

ing bolts following the standard below.

After the installation, check the fluid level and for fluid leakage. Refer to TF-10, "

Inspection".

Disassembly and AssemblyINFOID:0000000001327461

COMPONENTS

Bolt No. 1234

Quantity 4321

Bolt length “ ” mm (in) 75 (2.95) 45 (1.77) 40 (1.57) 30 (1.18)

Tightening torque

N·m (kg-m, ft-lb) 37 (3.8, 27)

SDIA2284E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3879 of 3924

WW-4

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

FRONT WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001328542

System DescriptionINFOID:0000000001328543

All front wiper relays (HI, LO) are included in IPDM E/R (intelligent power distribution module engine room).

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM ( body control module) when switch is turned ON.

BCM controls front wiper LO, HI, and INT (intermittent) operation.

IPDM E/R operates wiper motor according to CAN communication signals from BCM.

OUT LINE

Power is supplied at all times

through 50 A fusible link (letter M, located in fuse, fusible link and relay box.)

to BCM terminal 55,

through 15 A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 30 A fuse (No. 73, located in IPDM E/R)

to front wiper relay, located in IPDM E/R,

through 15 A fuse (No. 78, located in IPDM E/R) and

through 10 A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R.

When the ignition switch is ON or START position, power is supplied

to ignition relay located in IPDM E/R, from battery direct,

through 15 A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through ignition relay, located in IPDM E/R

to front wiper relay, located in IPDM E/R

to front wiper high relay, located in IPDM E/R and

to CPU located in IPDM E/R,

through 10 A fuse (No. 84, located in IPDM E/R)

through IPDM E/R terminal 44

to combination switch terminal 14.

Ground is supplied

PKIC9701E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3905 of 3924

WW-30

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001328576

System DescriptionINFOID:0000000001328577

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM ( body control module) when switch is turned ON.

BCM controls rear wiper ON and INT (intermittent) operation.

Power supplied at all times

through 50 A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15 A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42.

When ignition switch ON or START position, power is supplied

through 15 A fuse [No.1, located in fuse block (J/B)]

to BCM terminal 38,

through 10 A fuse [No. 84, located in IPDM E/R (intelligent power distribution module engine room)]

to combination switch terminal 14.

Ground is supplied

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to combination switch terminal 12

through grounds M35, M45 and M85.

REAR WIPER OPERATION

When the wiper switch is in rear wiper ON position, BCM detects rear wiper ON signal by BCM wiper switch

reading function.

BCM operates rear wiper motor, power is supplied

through BCM terminal 70

to rear wiper motor 4.

Ground is supplied

to rear wiper motor terminal 2

through grounds B15 and B45.

With power and ground supplied, the rear wiper operates.

PKIC9708E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C