ignition switch INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3205 of 3924

COMBINATION SWITCHLT-103

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

CONSULT-III Functions (BCM)INFOID:0000000001328367

CONSULT-III can display each diagnostic item using the diagnostic test mode shown following.

35 W/GCombination

switch output 2 ONLighting, turn,

wiper switch

(Wiper inter-

mittent dial po-

sition 4) OFF

Approx. 7.2 V

Any of the conditions below

Lighting switch 2ND

Lighting switch PASSING (Operates only PASSING switch)

Front wiper switch INT

Front wiper switch HI

Approx. 1.2 V

36 W/R Combination

switch output 1 ONLighting, turn,

wiper switch

(Wiper inter-

mittent dial po-

sition 4) OFF

Approx. 7.2 V

Any of the conditions below

Turn signal switch to right

Turn signal switch to left

Front wiper switch MIST

Front wiper switch LO

Front washer switch Approx. 1.2 V

38 W/L Ignition switch

(ON)

ON — Battery voltage

39 L CAN − H— — —

40 P CAN − L— — —

42 L/R Battery power

supply OFF — Battery voltage

49 B Ground ON — Approx. 0 V

52 B Ground ON — Approx. 0 V

55 G Battery power

supply OFF — Battery voltage

Te r -

mi-nal

No. Wire

color Signal name Measuring condition

Reference value

Igni-

tion

switch Operation or condition

PKIB4960J

PKIB4958J

PKIB4960J

PKIB4958J

BCM diagnosis part Diagnosis mode Description

COMB SW DATA MONITOR Displays BCM input data in real time.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3207 of 3924

COMBINATION SWITCHLT-105

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Example: When the HI BEAM switch is malfuncti oning, confirm that “TURN RH”, “HEAD LAMP 1” and

“LIGHT SW 1 ST” in System 5, to which the HI BEAM switch belongs, turn ON-OFF normally.

Without CONSULT-III

Operating combination switch, and confirm that other switches in malfunctioning system operate normally.

Example: When the HI BEAM switch is malfunctioni ng, confirm that “TURN RH”, “HEAD LAMP 1” and “LIGHT

SW 1 ST” in System 5, to which HI BE AM switch belongs, turn ON-OFF normally.

Check results

Other switches in malfunctioning system operate normally.>>Replace light ing switch or wiper switch.

Other switches in malfunctioning syst em do not operate normally.>>GO TO 3.

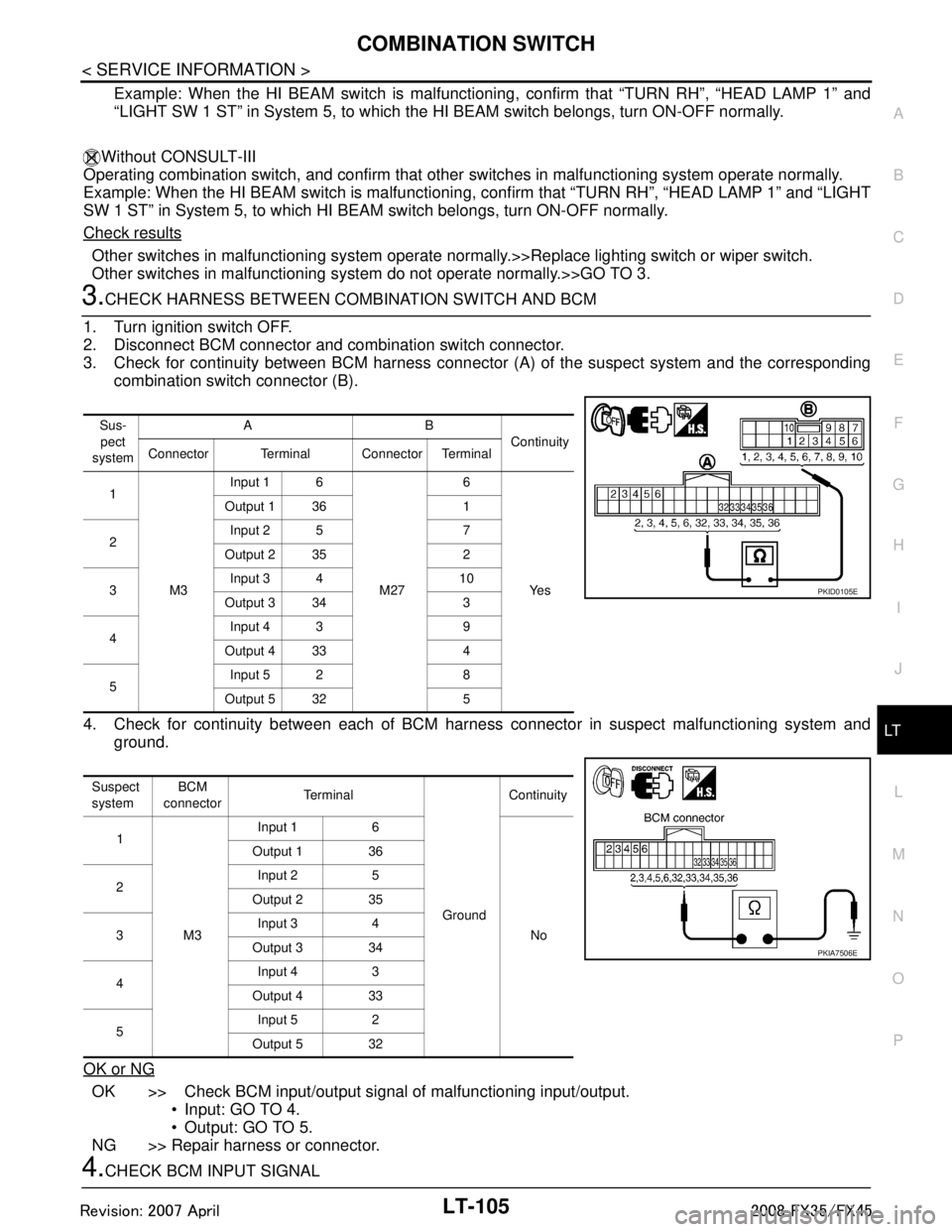

3.CHECK HARNESS BETWEEN COMB INATION SWITCH AND BCM

1. Turn ignition switch OFF.

2. Disconnect BCM connector and combination switch connector.

3. Check for continuity between BCM harness connecto r (A) of the suspect system and the corresponding

combination switch connector (B).

4. Check for continuity between each of BCM harne ss connector in suspect malfunctioning system and

ground.

OK or NG

OK >> Check BCM input/output signal of malfunctioning input/output.

Input: GO TO 4.

Output: GO TO 5.

NG >> Repair harness or connector.

4.CHECK BCM INPUT SIGNAL

Sus-

pect

system AB

Continuity

Connector Terminal Connector Terminal

1

M3 Input 1 6

M276

Ye s

Output 1 36 1

2 Input 2 5 7

Output 2 35 2

3 Input 3 4 10

Output 3 34 3

4 Input 4 3 9

Output 4 33 4

5 Input 5 2 8

Output 5 32 5

Suspect

system BCM

connector Te r m i n a l

GroundContinuity

1

M3 Input 1 6

No

Output 1 36

2 Input 2 5

Output 2 35

3 Input 3 4

Output 3 34

4 Input 4 3

Output 4 33

5 Input 5 2

Output 5 32

PKID0105E

PKIA7506E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3208 of 3924

LT-106

< SERVICE INFORMATION >

COMBINATION SWITCH

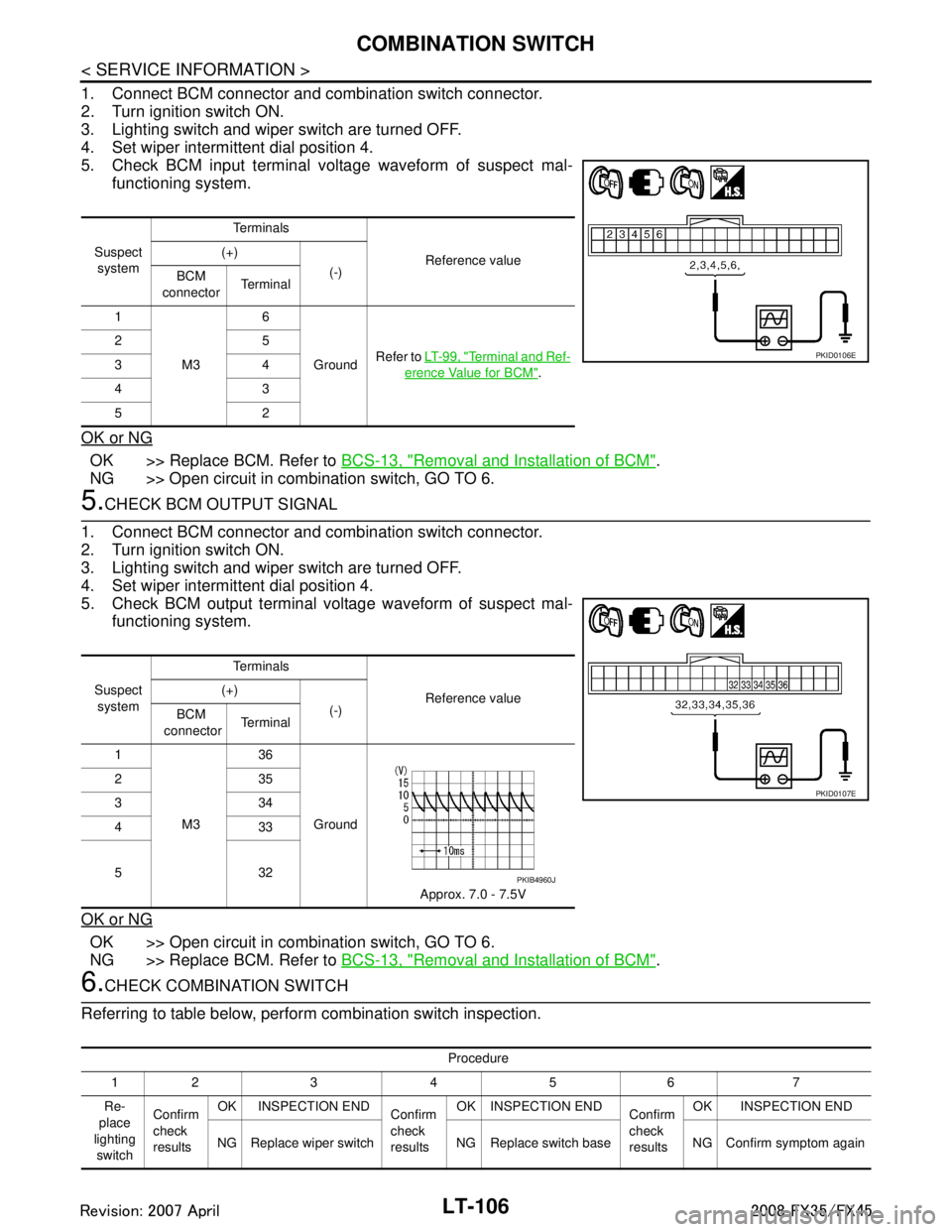

1. Connect BCM connector and combination switch connector.

2. Turn ignition switch ON.

3. Lighting switch and wiper switch are turned OFF.

4. Set wiper intermittent dial position 4.

5. Check BCM input terminal voltage waveform of suspect mal-functioning system.

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NG >> Open circuit in combination switch, GO TO 6.

5.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector and combination switch connector.

2. Turn ignition switch ON.

3. Lighting switch and wiper switch are turned OFF.

4. Set wiper intermittent dial position 4.

5. Check BCM output terminal voltage waveform of suspect mal- functioning system.

OK or NG

OK >> Open circuit in combination switch, GO TO 6.

NG >> Replace BCM. Refer to BCS-13, "

Removal and Installation of BCM".

6.CHECK COMBINATION SWITCH

Referring to table below, perform combination switch inspection.

Suspect system Te r m i n a l s

Reference value

(+)

(-)

BCM

connector Te r m i n a l

1

M3 6

Ground Refer to

LT- 9 9 , "

Terminal and Ref-

erence Value for BCM".

25

34

43

52

PKID0106E

Suspect

system Te r m i n a l s

Reference value

(+)

(-)

BCM

connector Te r m i n a l

1

M3 36

Ground Approx. 7.0 - 7.5V

235

334

433

532

PKID0107E

PKIB4960J

Procedure

12 3 4 5 6 7

Re-

place

lighting switch Confirm

check

results

OK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NG Replace wiper switch NG Replace switch base NG Confirm symptom again

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3215 of 3924

STOP LAMPLT-113

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

OK or NG

OK >> GO TO 2.

NG >> GO TO 6.

2.CHECK FUSE

Check fuse No.20 is blow out.

OK or NG

OK >> GO TO 3.

NG >> If fuse is blow out, be sure to eliminate cause of problem before installing new fuse.

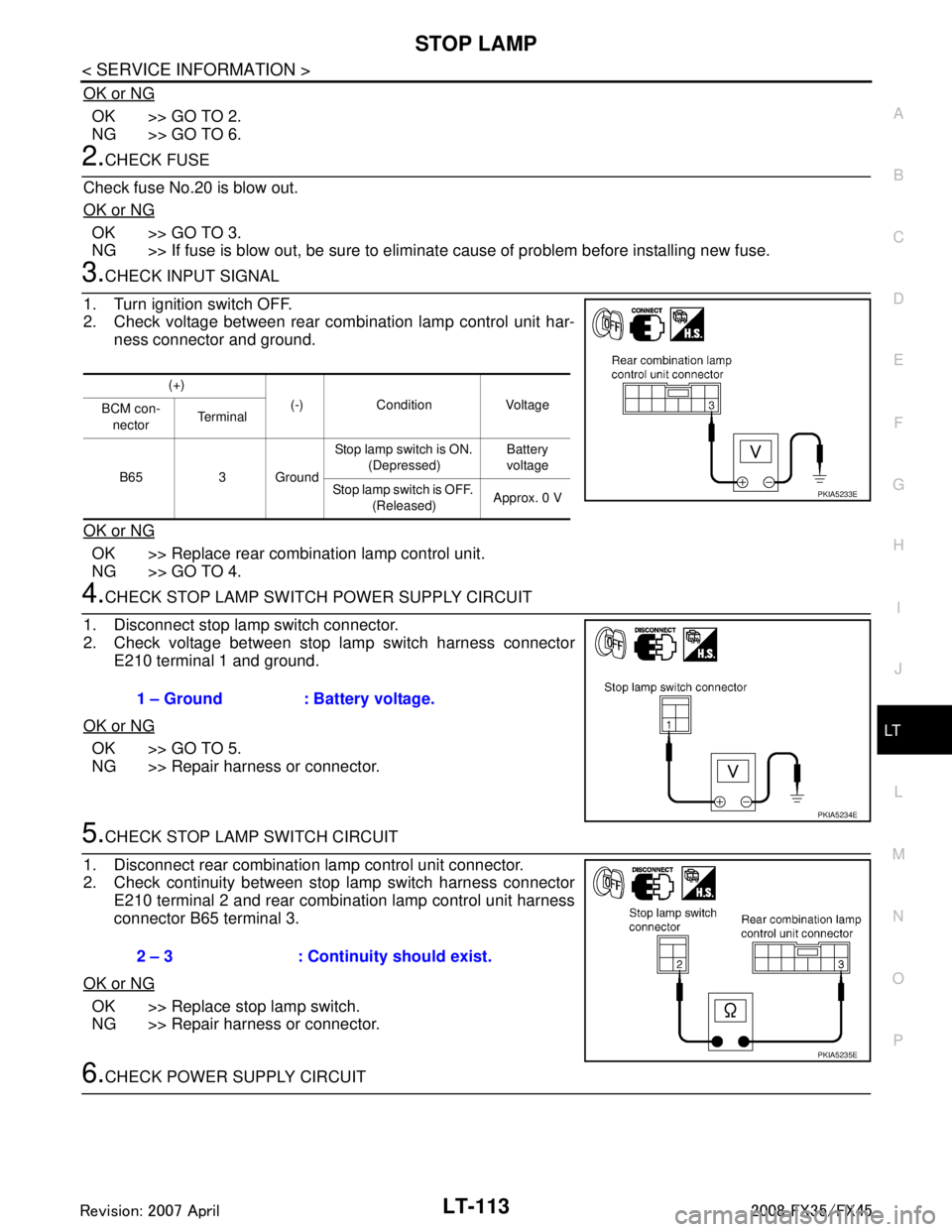

3.CHECK INPUT SIGNAL

1. Turn ignition switch OFF.

2. Check voltage between rear combination lamp control unit har- ness connector and ground.

OK or NG

OK >> Replace rear combination lamp control unit.

NG >> GO TO 4.

4.CHECK STOP LAMP SWIT CH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch connector.

2. Check voltage between stop lamp switch harness connector E210 terminal 1 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK STOP LAMP SWITCH CIRCUIT

1. Disconnect rear combination lamp control unit connector.

2. Check continuity between stop lamp switch harness connector E210 terminal 2 and rear combi nation lamp control unit harness

connector B65 terminal 3.

OK or NG

OK >> Replace stop lamp switch.

NG >> Repair harness or connector.

6.CHECK POWER SUPPLY CIRCUIT

(+) (-) Condition Voltage

BCM con-

nector Te r m i n a l

B65 3 Ground Stop lamp switch is ON.

(Depressed) Battery

voltage

Stop lamp switch is OFF. (Released) Approx. 0 V

PKIA5233E

1 – Ground : Battery voltage.

PKIA5234E

2 – 3 : Continuity should exist.

PKIA5235E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3220 of 3924

LT-118

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

PARKING, LICENSE PLATE AND TAIL LAMPS

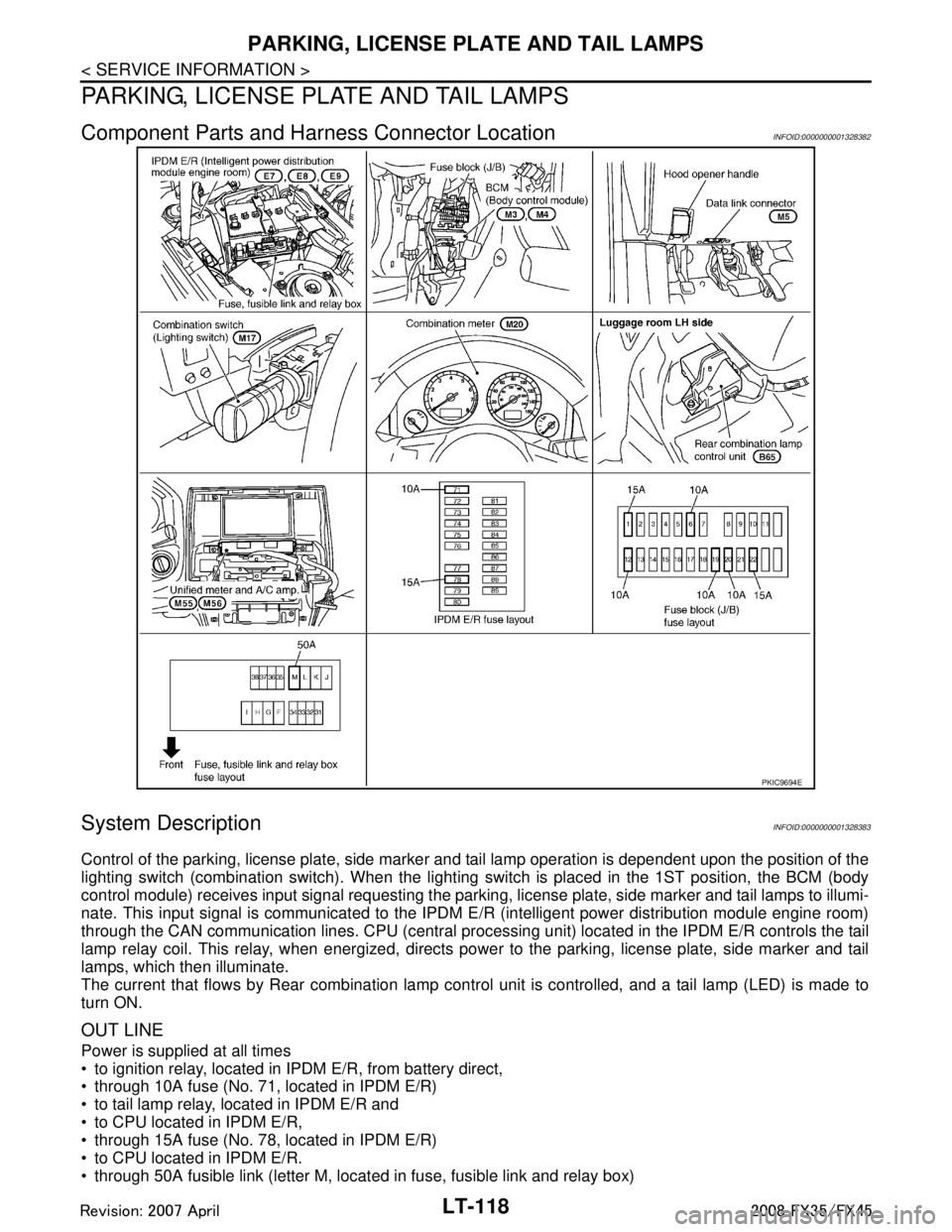

Component Parts and Harness Connector LocationINFOID:0000000001328382

System DescriptionINFOID:0000000001328383

Control of the parking, license plate, side marker and tail lamp operation is dependent upon the position of the

lighting switch (combination switch). When the lighting switch is placed in the 1ST position, the BCM (body

control module) receives input signal requesting the parki ng, license plate, side marker and tail lamps to illumi-

nate. This input signal is communicated to the IPDM E/R (intelligent power distribution module engine room)

through the CAN communication lines. CPU (central processi ng unit) located in the IPDM E/R controls the tail

lamp relay coil. This relay, when energized, directs pow er to the parking, license plate, side marker and tail

lamps, which then illuminate.

The current that flows by Rear combination lamp cont rol unit is controlled, and a tail lamp (LED) is made to

turn ON.

OUT LINE

Power is supplied at all times

to ignition relay, located in IP DM E/R, from battery direct,

through 10A fuse (No. 71, located in IPDM E/R)

to tail lamp relay, located in IPDM E/R and

to CPU located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R.

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

PKIC9694E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3221 of 3924

![INFINITI FX35 2008 Service Manual

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-119

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal INFINITI FX35 2008 Service Manual

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-119

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal](/img/42/57017/w960_57017-3220.png)

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-119

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 10A fuse [No. 20, located in fuse block (J/B)]

to rear combination lamp control unit terminal 1,

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8 and

to unified meter and A/C amp. terminal 21.

With the ignition switch in ON or START position, power is supplied

through ignition relay, located in IPDM E/R, from battery direct,

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

to combination meter terminal 7 and

through 10A fuse [No. 12, located in fuse block (J/B)]

to unified meter and A/C amp. terminal 22.

With ignition switch in ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to BCM terminal 11.

Ground is supplied

to rear combination lamp control unit terminal 7 and

to IPDM E/R terminals 38 and 60

through grounds E21, E50 and E51,

to BCM terminals 49 and 52

to combination meter terminals 5, 6 and 15, and

to unified meter and A/C amp. terminals 29 and 30

through grounds M35, M45 and M85.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the parking, license plate, side ma rker and tail lamps to illuminate. This input signal is

communicated to the IPDM E/R through the CAN communi cation. The CPU located in the IPDM E/R controls

the tail lamp relay coil, which when energized, directs power.

through IPDM E/R terminal 22

to front side marker lamp LH terminal 1

to parking lamp LH terminal 2

to license plate lamp LH terminal 1

to rear combination lamp LH terminal 1

to rear combination lamp control unit terminal 2

to front side marker lamp RH terminal 1

to parking lamp RH terminal 2

to license plate lamp RH terminal 1 and

to rear combination lamp RH terminal 1.

Ground is supplied at all times

to front side marker lamp LH terminal 2

through grounds E21, E50 and E51,

to parking lamp LH terminal 3

through grounds E21, E50 and E51,

to license plate lamp LH terminal 2

through grounds B15 and B45,

to rear combination lamp LH terminal 2

through grounds B15 and B45,

to front side marker lamp RH terminal 2

through grounds E21, E50 and E51,

to parking lamp RH terminal 3

through grounds E21, E50 and E51,

to license plate lamp RH terminal 2

through grounds B15 and B45,

to rear combination lamp RH terminal 2

through grounds B203 and B210,

to rear combination lamp control unit terminal 7

through grounds E21, E50 and E51.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3222 of 3924

LT-120

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

With power and ground supplied, the parking, license plate, side marker and tail lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 1ST (or 2ND) position, and the ignition switch is turned

from ON or ACC to OFF, the battery saver control feature is activated.

Under this condition, the parking, license, side marker and tail lamps remain illuminated for 5 minutes, then the

parking, license plate, side marker and tail lamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-III.

CAN Communication System DescriptionINFOID:0000000001328384

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328385

Refer to LAN-43, "CAN System Specification Chart".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3229 of 3924

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-127

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

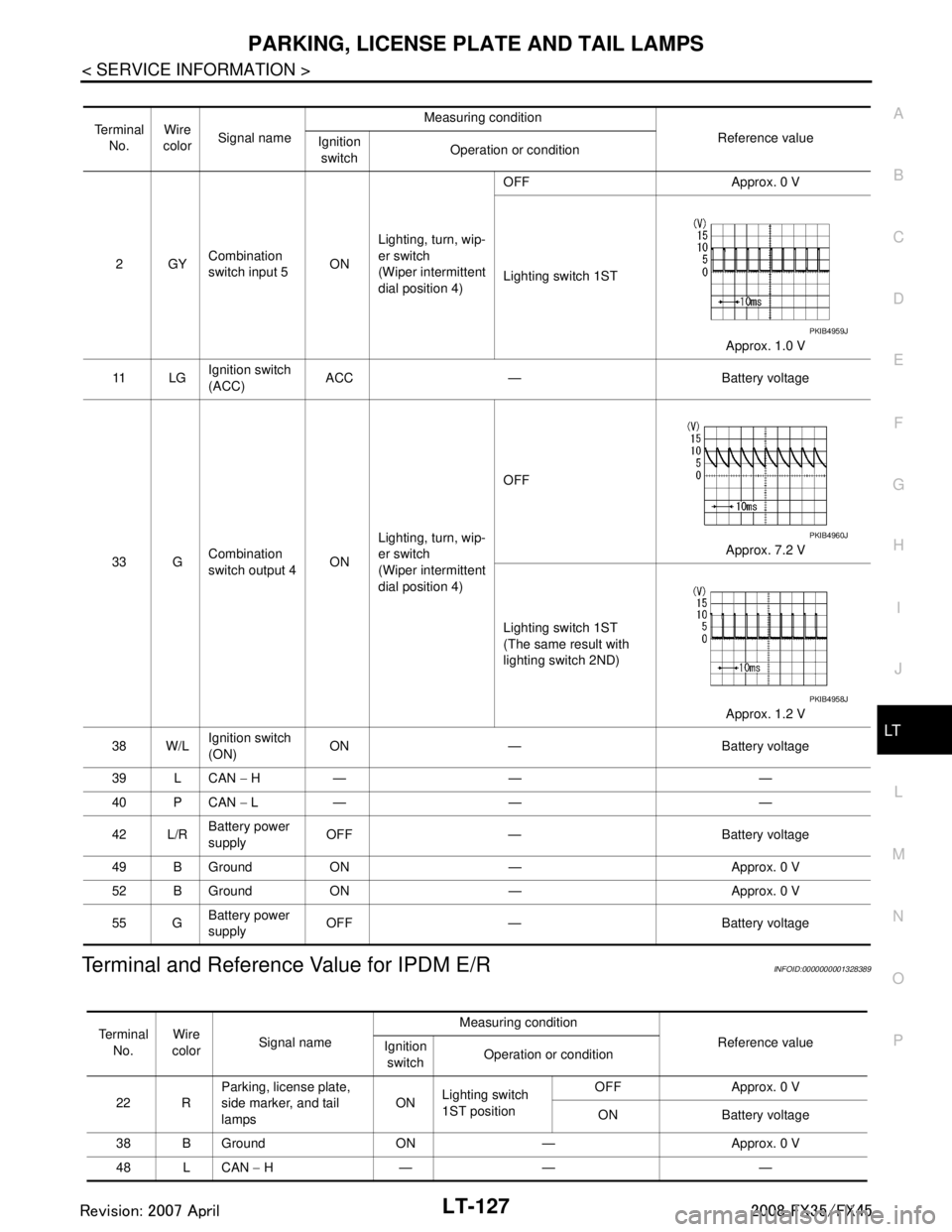

Terminal and Reference Value for IPDM E/RINFOID:0000000001328389

Te r m i n a l No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

2GY Combination

switch input 5

ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF Approx. 0 V

Lighting switch 1ST

Approx. 1.0 V

11 L G Ignition switch

(ACC)

ACC — Battery voltage

33 G Combination

switch output 4 ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.2 V

Lighting switch 1ST

(The same result with

lighting switch 2ND) Approx. 1.2 V

38 W/L Ignition switch

(ON)

ON — Battery voltage

39 L CAN − H— — —

40 P CAN − L— — —

42 L/R Battery power

supply OFF — Battery voltage

49 B Ground ON — Approx. 0 V

52 B Ground ON — Approx. 0 V

55 G Battery power

supply OFF — Battery voltage

PKIB4959J

PKIB4960J

PKIB4958J

Te r m i n a l

No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

22 R Parking, license plate,

side marker, and tail

lamps ON

Lighting switch

1ST position OFF Approx. 0 V

ON Battery voltage

38 B Ground ON — Approx. 0 V

48 L CAN − H— — —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3230 of 3924

LT-128

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

Terminal and Reference Value for Re ar Combination Lamp Control Unit

INFOID:0000000001328390

Refer to LT-86, "Terminal and Reference Value for Rear Combination Lamp Control Unit".

How to Proceed with Trouble DiagnosisINFOID:0000000001328391

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-118, "

System Description".

3. Perform Preliminary Check. Refer to LT-128, "

Preliminary Check".

4. Check symptom and repair or r eplace the cause of malfunction.

5. Do parking, license plate, side marker and tail lamps operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckINFOID:0000000001328392

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES

Check for blown fuses.

Refer to LT- 1 2 2 , "Wiring Diagram - TAIL/L -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

49 R CAN − L— — —

60 B Ground ON — Approx. 0 V

Te r m i n a l

No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

Unit Power source Fuse and fusible link No.

BCM Battery

M

22

Ignition switch ON or START position 1 Ignition switch ACC or ON position 6

IPDM E/R Battery 71

Rear combination lamp control unit Battery 20

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3231 of 3924

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-129

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

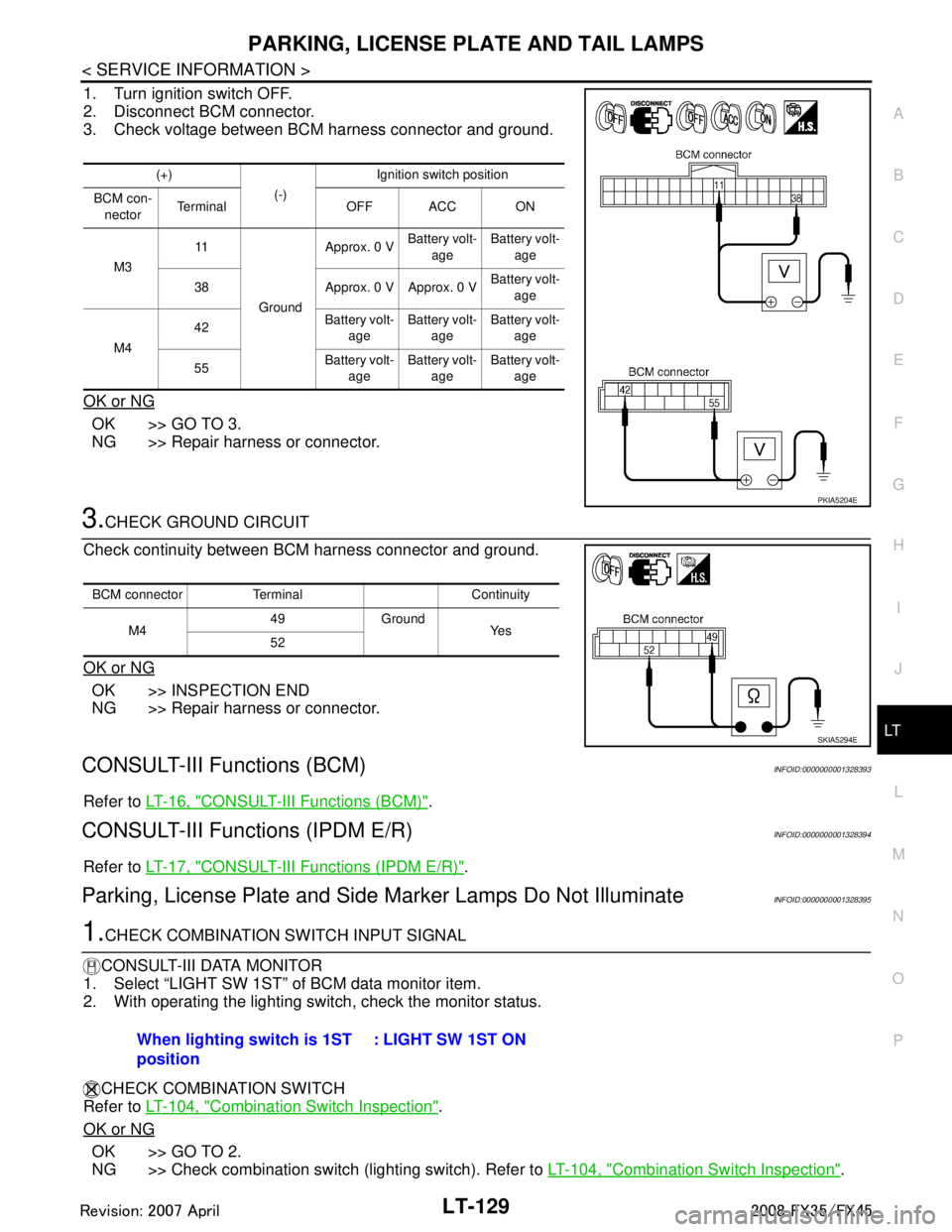

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

CONSULT-III Functions (BCM)INFOID:0000000001328393

Refer to LT-16, "CONSULT-III Functions (BCM)".

CONSULT-III Functions (IPDM E/R)INFOID:0000000001328394

Refer to LT-17, "CONSULT-III Functions (IPDM E/R)".

Parking, License Plate and Side Marker Lamps Do Not IlluminateINFOID:0000000001328395

1.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “LIGHT SW 1ST” of BCM data monitor item.

2. With operating the lighting switch, check the monitor status.

CHECK COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

(+)

(-)Ignition switch position

BCM con- nector Te r m i n a l O F F A C C O N

M3 11

Ground Approx. 0 V

Battery volt-

age Battery volt-

age

38 Approx. 0 V Approx. 0 V Battery volt-

age

M4 42

Battery volt-

age Battery volt-

age Battery volt-

age

55 Battery volt-

age Battery volt-

age Battery volt-

age

PKIA5204E

BCM connector Terminal Continuity

M4 49 Ground

Ye s

52

SKIA5294E

When lighting switch is 1ST

position : LIGHT SW 1ST ON

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C