oil change INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 4 of 3924

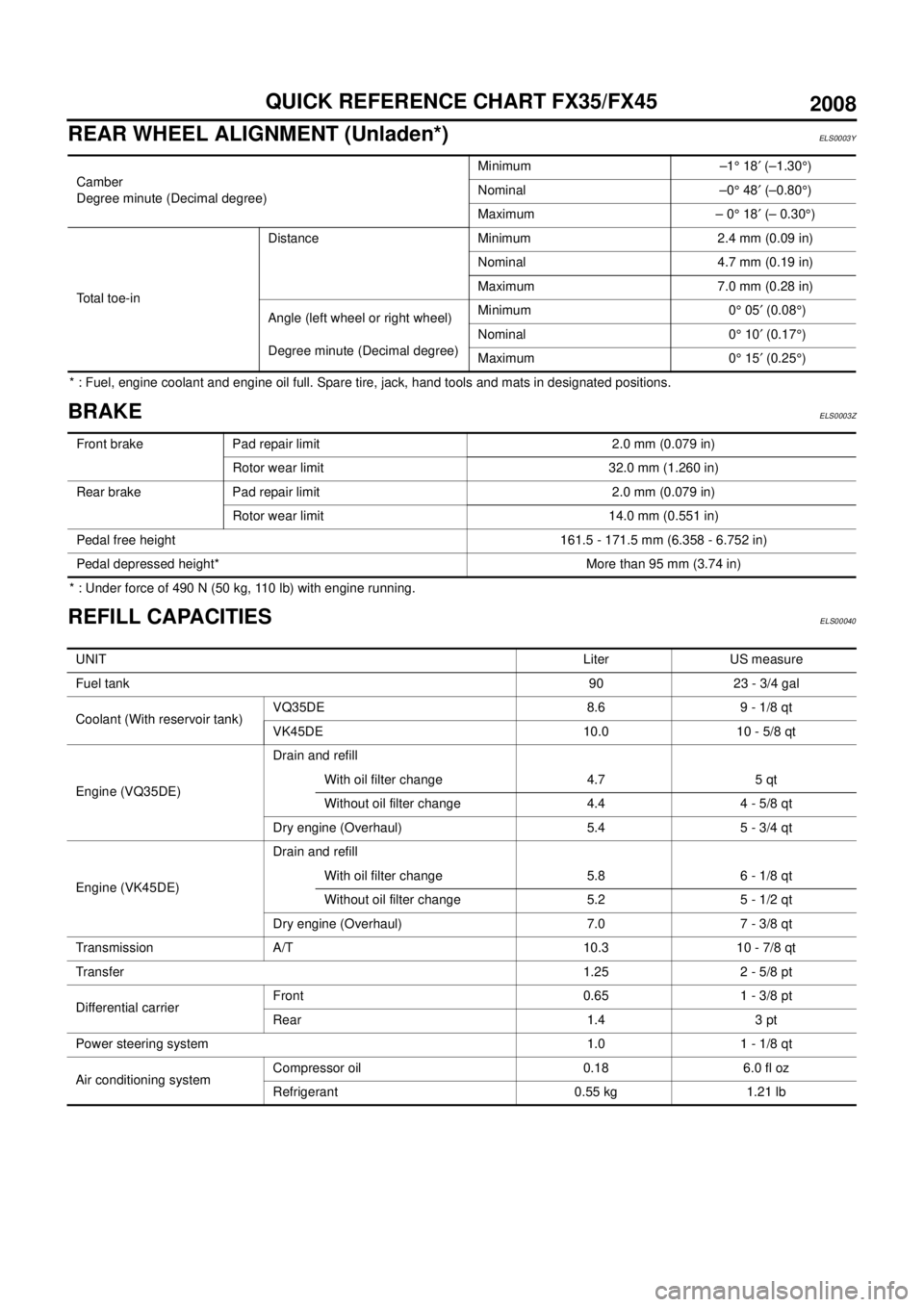

QUICK REFERENCE CHART FX35/FX45

REAR WHEEL ALIGNMENT (Unladen*)

ELS0003Y

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

BRAKEELS0003Z

* : Under force of 490 N (50 kg, 110 lb) with engine running.

REFILL CAPACITIESELS00040

Camber

Degree minute (Decimal degree)Minimum –1° 18′ (–1.30°)

Nominal –0° 48′ (–0.80°)

Maximum – 0° 18′ (– 0.30°)

Total toe-inDistance Minimum 2.4 mm (0.09 in)

Nominal 4.7 mm (0.19 in)

Maximum 7.0 mm (0.28 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree)Minimum 0° 05′ (0.08°)

Nominal 0° 10′ (0.17°)

Maximum 0° 15′ (0.25°)

Front brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 32.0 mm (1.260 in)

Rear brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 14.0 mm (0.551 in)

Pedal free height 161.5 - 171.5 mm (6.358 - 6.752 in)

Pedal depressed height* More than 95 mm (3.74 in)

UNITLiter US measure

Fuel tank90 23 - 3/4 gal

Coolant (With reservoir tank)VQ35DE 8.6 9 - 1/8 qt

VK45DE 10.0 10 - 5/8 qt

Engine (VQ35DE)Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

Engine (VK45DE)Drain and refill

With oil filter change 5.8 6 - 1/8 qt

Without oil filter change 5.2 5 - 1/2 qt

Dry engine (Overhaul) 7.0 7 - 3/8 qt

Transmission A/T 10.3 10 - 7/8 qt

Transfer1.25 2 - 5/8 pt

Differential carrierFront 0.65 1 - 3/8 pt

Rear 1.4 3 pt

Power steering system 1.0 1 - 1/8 qt

Air conditioning systemCompressor oil 0.18 6.0 fl oz

Refrigerant 0.55 kg 1.21 lb

2008

Page 77 of 3924

AT-4

BRAKE SIGNAL CIRCUIT ..............................165

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

165

Diagnosis Procedure .............................................165

A/T INDICATOR CIRCUIT ...............................166

Description ........................................................... ..166

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

166

Diagnosis Procedure .............................................166

TROUBLE DIAGNOSIS FOR SYMPTOMS .....167

Wiring Diagram - AT - NONDTC .......................... ..167

A/T Check Indicator Lamp Does Not Come On .....170

Engine Cannot Be Started in "P" or "N" Position ...170

In "P" Position, Vehicle Moves When Pushed .......171

In "N" Position, Vehicle Moves ..............................172

Large Shock ("N" to "D" Position) ..........................173

Vehicle Does Not Creep Backward in "R" Position ..175

Vehicle Does Not Creep Forward in "D" Position ..178

Vehicle Cannot Be Started from D1 .......................180

A/T Does Not Shift: D1→ D2 ................................ ..182

A/T Does Not Shift: D2→ D3 ................................ ..184

A/T Does Not Shift: D3→ D4 ................................ ..186

A/T Does Not Shift: D4→ D5 ................................ ..188

A/T Does Not Lock-up ......................................... ..190

A/T Does Not Hold Lock-up Condition ...................192

Lock-up Is Not Released .......................................194

Engine Speed Does Not Return to Idle .................194

Cannot Be Changed to Manual Mode ...................195

A/T Does Not Shift: 5th Gear → 4th Gear ........... ..196

A/T Does Not Shift: 4th Gear → 3rd Gear ........... ..197

A/T Does Not Shift: 3rd Gear → 2nd Gear .......... ..199

A/T Does Not Shift: 2nd Gear → 1st Gear ........... ..201

Vehicle Does Not Decelerate by Engine Brake ... ..202

SHIFT CONTROL SYSTEM ............................205

Control Device Removal and Installation ............. ..205

Control Rod Removal and Installation ...................206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................208

Description ........................................................... ..208

Shift Lock System Electrical Parts Location ..........208

Wiring Diagram - AT - SHIFT .................................209

Diagnosis Procedure .............................................209

KEY INTERLOCK CABLE ...............................212

Component .......................................................... ..212

Removal and Installation .......................................212

ON-VEHICLE SERVICE ...................................215

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

215

Parking Component (2WD Models Only) ..............226

Rear Oil Seal .........................................................233

Revolution Sensor Component (2WD Models

Only) .....................................................................

233

AIR BREATHER HOSE ....................................239

Removal and Installation ...................................... .239

TRANSMISSION ASSEMBLY ..........................241

Removal and Installation (2WD Models) .............. .241

Removal and Installation (AWD Models) ..............243

OVERHAUL ......................................................249

Component .......................................................... .249

Oil Channel ...........................................................261

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

264

DISASSEMBLY .............................................. ..267

Disassembly ......................................................... .267

REPAIR FOR COMPONENT PARTS ..............285

Oil Pump .............................................................. .285

Front Sun Gear, 3rd One-Way Clutch ...................287

Front Carrier, Input Clutch, Rear Internal Gear .....289

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

295

High and Low Reverse Clutch ..............................301

Direct Clutch .........................................................303

ASSEMBLY .................................................... ..306

Assembly (1) ........................................................ .306

Adjustment ............................................................320

Assembly (2) .........................................................323

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

330

General Specification ........................................... .330

Vehicle Speed at Which Gear Shifting Occurs .....330

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

331

Stall Speed ............................................................331

Line Pressure ........................................................331

A/T Fluid Temperature Sensor ..............................332

Turbine Revolution Sensor ...................................332

Vehicle Speed Sensor A/T (Revolution Sensor) ...332

Reverse Brake ......................................................332

Total End Play .......................................................332

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 105 of 3924

AT-32

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

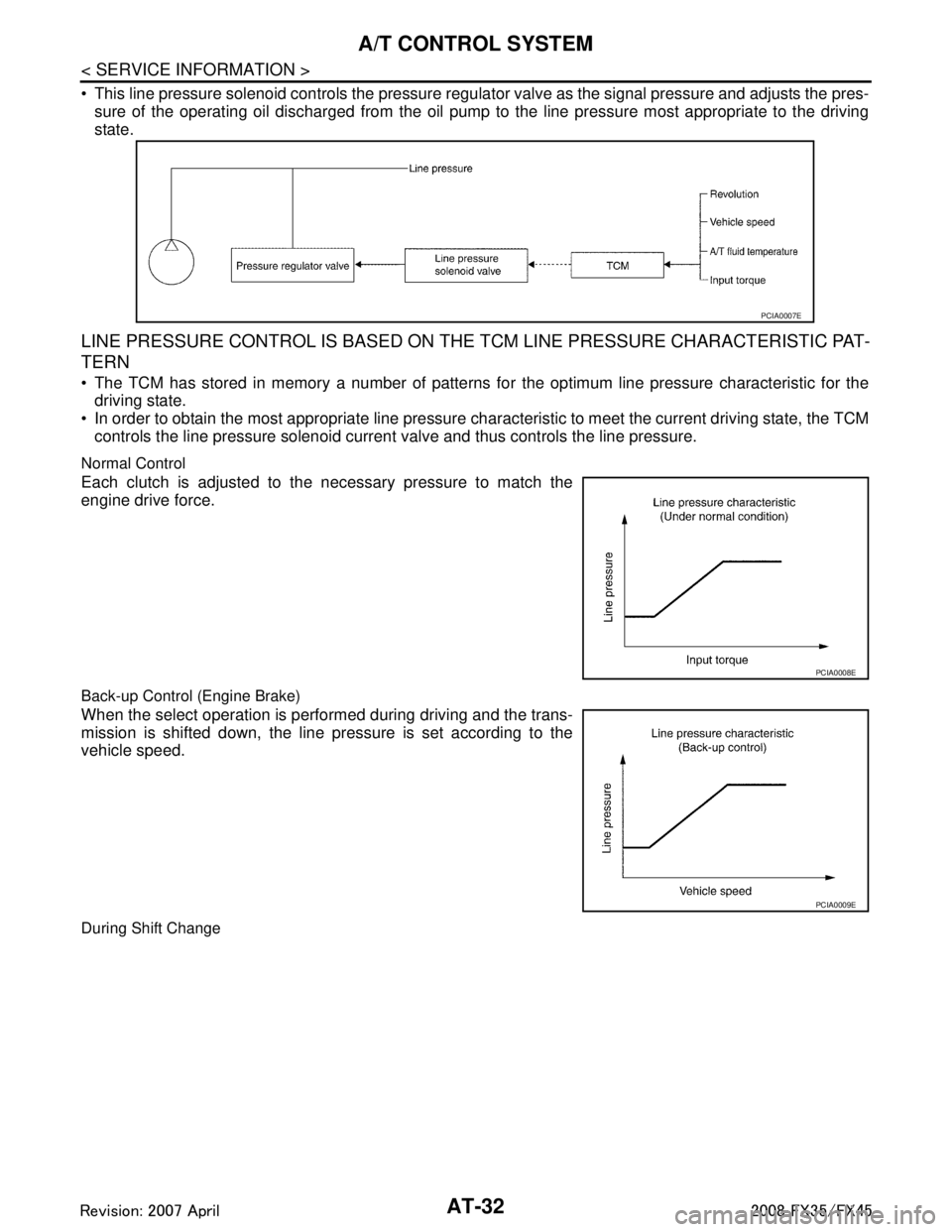

This line pressure solenoid controls the pressure regulator valve as the signal pressure and adjusts the pres-

sure of the operating oil discharged from the oil pump to the line pressure most appropriate to the driving

state.

LINE PRESSURE CONTROL IS BASED ON TH E TCM LINE PRESSURE CHARACTERISTIC PAT-

TERN

The TCM has stored in memory a number of patterns fo r the optimum line pressure characteristic for the

driving state.

In order to obtain the most appropriate line pressure char acteristic to meet the current driving state, the TCM

controls the line pressure solenoid current valve and thus controls the line pressure.

Normal Control

Each clutch is adjusted to the necessary pressure to match the

engine drive force.

Back-up Control (Engine Brake)

When the select operation is performed during driving and the trans-

mission is shifted down, the line pressure is set according to the

vehicle speed.

During Shift Change

PCIA0007E

PCIA0008E

PCIA0009E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 106 of 3924

A/T CONTROL SYSTEMAT-33

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

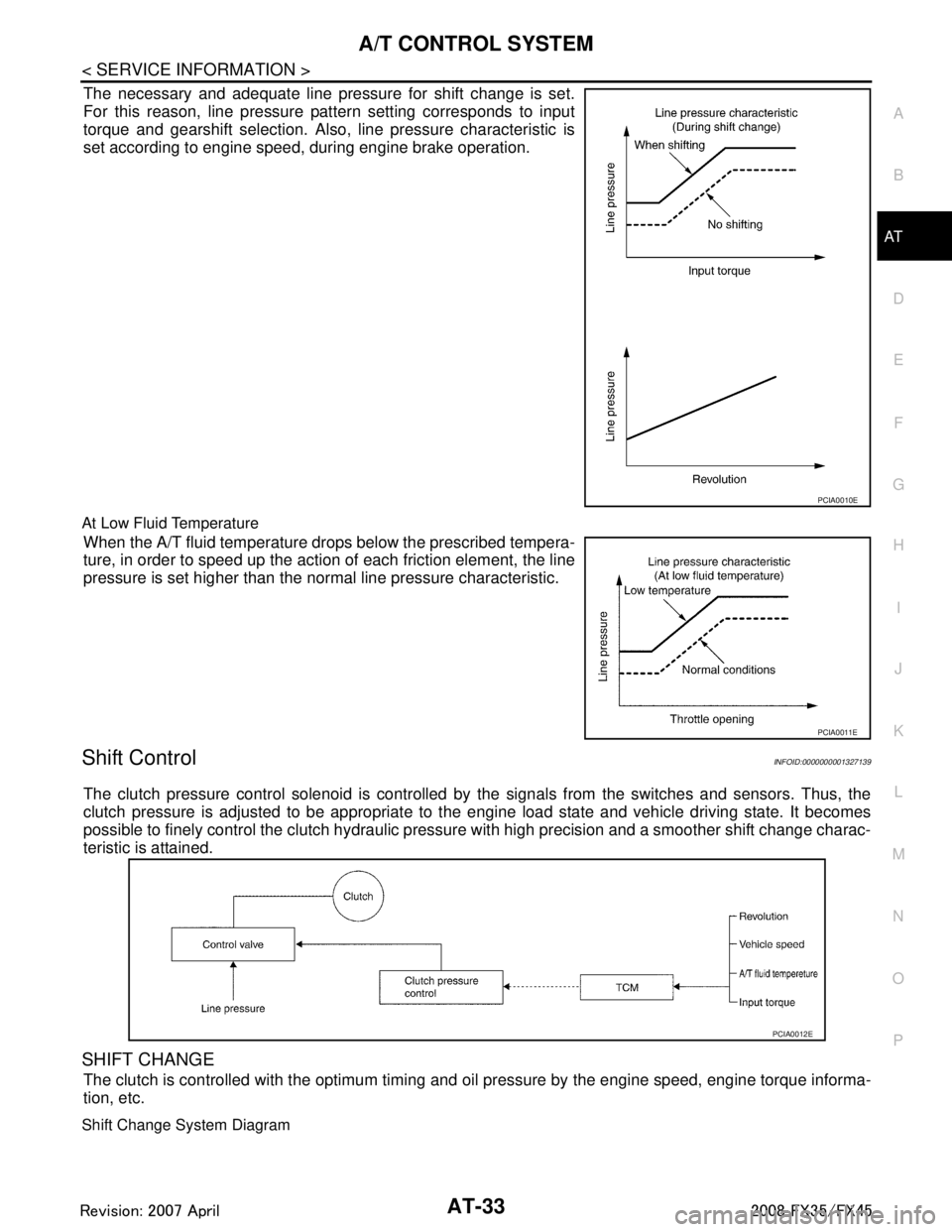

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlINFOID:0000000001327139

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to t he engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressu re with high precision and a smoother shift change charac-

teristic is attained.

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

PCIA0010E

PCIA0011E

PCIA0012E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 107 of 3924

AT-34

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

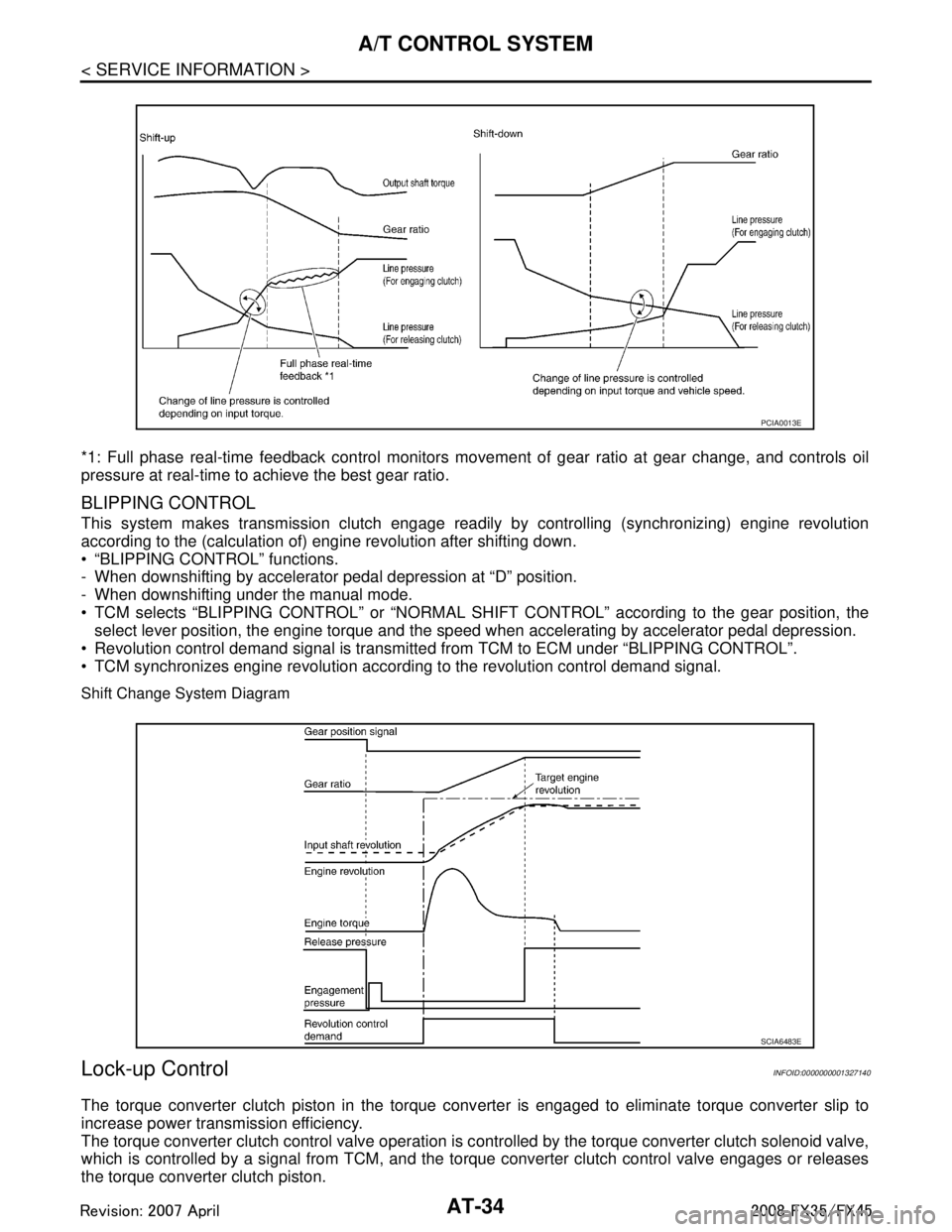

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

BLIPPING CONTROL

This system makes transmission clutch engage readily by controlling (synchronizing) engine revolution

according to the (calculation of) engine revolution after shifting down.

“BLIPPING CONTROL” functions.

- When downshifting by accelerator pedal depression at “D” position.

- When downshifting under the manual mode.

TCM selects “BLIPPING CONTROL” or “NORMAL SHIFT CONTROL” according to the gear position, the

select lever position, the engine torque and the speed when accelerating by accelerator pedal depression.

Revolution control demand signal is transmitted from TCM to ECM under “BLIPPING CONTROL”.

TCM synchronizes engine revolution according to the revolution control demand signal.

Shift Change System Diagram

Lock-up ControlINFOID:0000000001327140

The torque converter clutch piston in the torque conv erter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is c ontrolled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the to rque converter clutch control valve engages or releases

the torque converter clutch piston.

PCIA0013E

SCIA6483E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 109 of 3924

AT-36

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

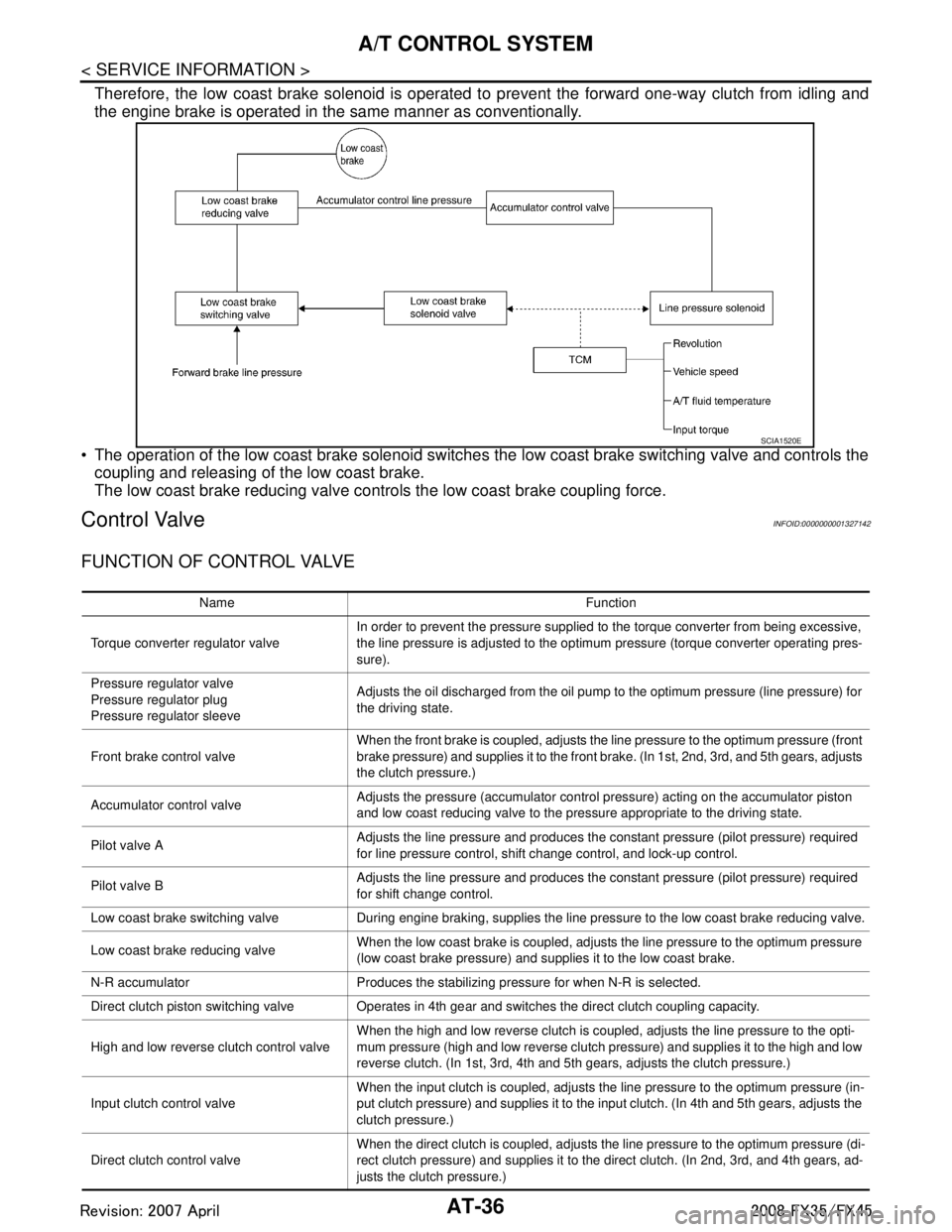

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve contro ls the low coast brake coupling force.

Control ValveINFOID:0000000001327142

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valve In order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regu lator valve

Pressure regulator plug

Pressure regu lator sleeve Adjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valve When the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

the clutch pressure.)

Accumulator control valve Adjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Pilot valve A Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for line pressure control, shift change control, and lock-up control.

Pilot valve B Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valve When the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th ge ar and switches the direct clutch coupling capacity.

High and low reverse clutch control valve When the high and low reverse clutch is coupled, adjusts the line pressure to the opti-

mum pressure (high and low reverse clutch pressure) and supplies it to the high and low

reverse clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Input clutch control valve When the input clutch is coupled, adjusts the line pressure to the optimum pressure (in-

put clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts the

clutch pressure.)

Direct clutch control valve When the direct clutch is coupled, adjusts the line pressure to the optimum pressure (di-

rect clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears, ad-

justs the clutch pressure.)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 141 of 3924

AT-68

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

26Slips/Will

Not En-

gage Lock-up is not re-

leased.

Refer to

AT- 1 9 4 ,

"Lock-up Is Not Re-

leased". ON vehicle1. A/T fluid level and state

AT- 4 9

2. Line pressure testAT- 4 9

3. Engine speed signalAT- 11 2

4. Turbine revolution sensorAT- 1 0 6

5. Torque converter clutch solenoid valveAT- 1 2 4

6. CAN communication line AT- 9 4

7. Control valve with TCMAT- 2 1 5

OFF vehicle8. Torque converter

AT- 2 6 79. Oil pump assemblyAT- 2 8 5

27No shock at all or the

clutch slips when vehi-

cle changes speed D1

→ D

2 or M1 → M2. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 8,

AT- 1 3 7

3. Direct clutch solenoid valve AT- 1 4 7

4. CAN communication line AT- 9 4

5. Line pressure testAT- 4 9

6. Control valve with TCMAT- 2 1 5

OFF vehicle7. Torque converter

AT- 2 6 7

8. Oil pump assemblyAT- 2 8 5

9. 3rd one-way clutchAT- 2 8 7

10. Gear systemAT- 2 4 9

11. Direct clutchAT- 3 0 3

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 6 , "

Cross-

Sectional View (2WD Models)", AT- 1 7 , "Cross-Sectional View

(VQ35DE Models for AWD)" or AT- 1 8 , "Cross-Sectional View

(VK45DE Models for AWD)") AT- 2 6 7

No. Items Symptom Condition Diagnostic Item

Reference

page

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 142 of 3924

TROUBLE DIAGNOSISAT-69

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

28

Slips/Will

Not En-

gage No shock at all or the

clutch slips when vehi-

cle changes speed D2

→ D

3 or M2 → M3. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 8,

AT- 1 3 7

3. High and low reverse clutch solenoid valve AT- 1 4 9

4. CAN communication line AT- 9 4

5. Line pressure testAT- 4 9

6. Control valve with TCMAT- 2 1 5

OFF vehicle7. Torque converter

AT- 2 6 7

8. Oil pump assemblyAT- 2 8 5

9. 3rd one-way clutchAT- 2 8 7

10. Gear systemAT- 2 4 9

11. High and low reverse clutchAT- 3 0 1

12. Forward one-way clutch (Parts behind drum support is im-

possible to perform inspection by disassembly. Refer to AT-

16, "Cross-Sectional View (2WD Models)", AT- 1 7 , "Cross-

Sectional View (VQ35DE Models for AWD)" or AT- 1 8 , "Cross-

Sectional View (VK45DE Models for AWD)") AT- 2 6 7

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to

AT- 1 6 , "

Cross-

Sectional View (2WD Models)", AT- 1 7 , "Cross-Sectional View

(VQ35DE Models for AWD)" or AT- 1 8 , "Cross-Sectional View

(VK45DE Models for AWD)") AT- 2 6 7

29

No shock at all or the

clutch slips when vehi-

cle changes speed D3

→ D

4 or M3 → M4. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 8,

AT- 1 3 7

3.Input clutch solenoid valve AT- 1 4 3

4. Front brake solenoid valve AT- 1 4 5

5. CAN communication line AT- 9 4

6. Line pressure testAT- 4 9

7. Control valve with TCMAT- 2 1 5

OFF vehicle8. Torque converter

AT- 2 6 7

9. Oil pump assemblyAT- 2 8 5

10. Input clutchAT- 2 8 9

11. Gear systemAT- 2 4 9

12. High and low reverse clutchAT- 3 0 1

13. Direct clutchAT- 3 0 3

No. Items Symptom Condition Diagnostic Item Reference

page

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 143 of 3924

AT-70

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

30Slips/Will

Not En-

gage No shock at all or the

clutch slips when vehi-

cle changes speed D4

→ D

5 or M4 → M5. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 8,

AT- 1 3 7

3. Front brake solenoid valve AT- 1 4 5

4. Direct clutch solenoid valveAT- 1 4 7

5. CAN communication line AT- 9 4

6. Line pressure testAT- 4 9

7. Control valve with TCMAT- 2 1 5

OFF vehicle8. Torque converter

AT- 2 6 7

9. Oil pump assemblyAT- 2 8 5

10. Front brake (brake band)AT- 2 6 7

11. Input clutchAT- 2 8 9

12. Gear systemAT- 2 4 9

13. High and low reverse clutchAT- 3 0 1

31When you press the

accelerator pedal and

shift speed D5

→ D4 or

M5 → M4 the engine

idles or the A/T slips. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 8,

AT- 1 3 7

3. Front brake solenoid valve AT- 1 4 5

4. Direct clutch solenoid valveAT- 1 4 7

5. CAN communication line AT- 9 4

6. Line pressure testAT- 4 9

7. Control valve with TCMAT- 2 1 5

OFF vehicle8. Torque converter

AT- 2 6 7

9. Oil pump assemblyAT- 2 8 5

10. Input clutchAT- 2 8 9

11. Gear systemAT- 2 4 9

12. High and low reverse clutchAT- 3 0 1

13. Direct clutchAT- 3 0 3

No. Items Symptom Condition Diagnostic Item Reference

page

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 150 of 3924

TROUBLE DIAGNOSISAT-77

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

45

Slips/Will

Not En-

gage With selector lever in

“D” position, driving is

not possible. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Line pressure testAT- 4 9

3. PNP switchAT- 1 0 2

4. A/T positionAT- 2 0 7

5. Control valve with TCMAT- 2 1 5

OFF vehicle6. Torque converter

AT- 2 6 7

7. Oil pump assemblyAT- 2 8 5

8. 1st one-way clutchAT- 2 9 5

9. Gear systemAT- 2 4 9

10. Reverse brakeAT- 2 6 7

11. Forward one-way clutch (Parts behind drum support is im-

possible to perform inspection by disassembly. Refer to AT-

16, "Cross-Sectional View (2WD Models)", AT- 1 7 , "Cross-

Sectional View (VQ35DE Models for AWD)" or AT- 1 8 , "Cross-

Sectional View (VK45DE Models for AWD)") AT- 2 6 7

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to

AT- 1 6 , "

Cross-

Sectional View (2WD Models)", AT- 1 7 , "Cross-Sectional View

(VQ35DE Models for AWD)" or AT- 1 8 , "Cross-Sectional View

(VK45DE Models for AWD)") AT- 2 6 7

46

With selector lever in

“R” position, driving is

not possible. ON vehicle

1. A/T fluid level and state

AT- 4 9

2. Line pressure testAT- 4 9

3. PNP switchAT- 1 0 2

4. A/T positionAT- 2 0 7

5. Control valve with TCMAT- 2 1 5

OFF vehicle6. Gear system

AT- 2 4 97. Output shaftAT- 2 6 7

8. Reverse brakeAT- 2 6 7

47Does Not

Change Does not change M5

→

M4.

Refer to AT- 1 9 6 , "A/T

Does Not Shift: 5th

Gear → 4th Gear".ON vehicle 1. PNP switch

AT- 1 0 2

2. A/T fluid level and state AT- 4 9

3. A/T positionAT- 2 0 7

4. Manual mode switchAT- 1 5 5

5. CAN communication line AT- 9 4

6. Control valve with TCMAT- 2 1 5

OFF vehicle 7. Front brake (brake band) AT- 2 6 7

No. Items Symptom Condition Diagnostic Item Reference

page

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C