relay INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2973 of 3924

GW-60

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER

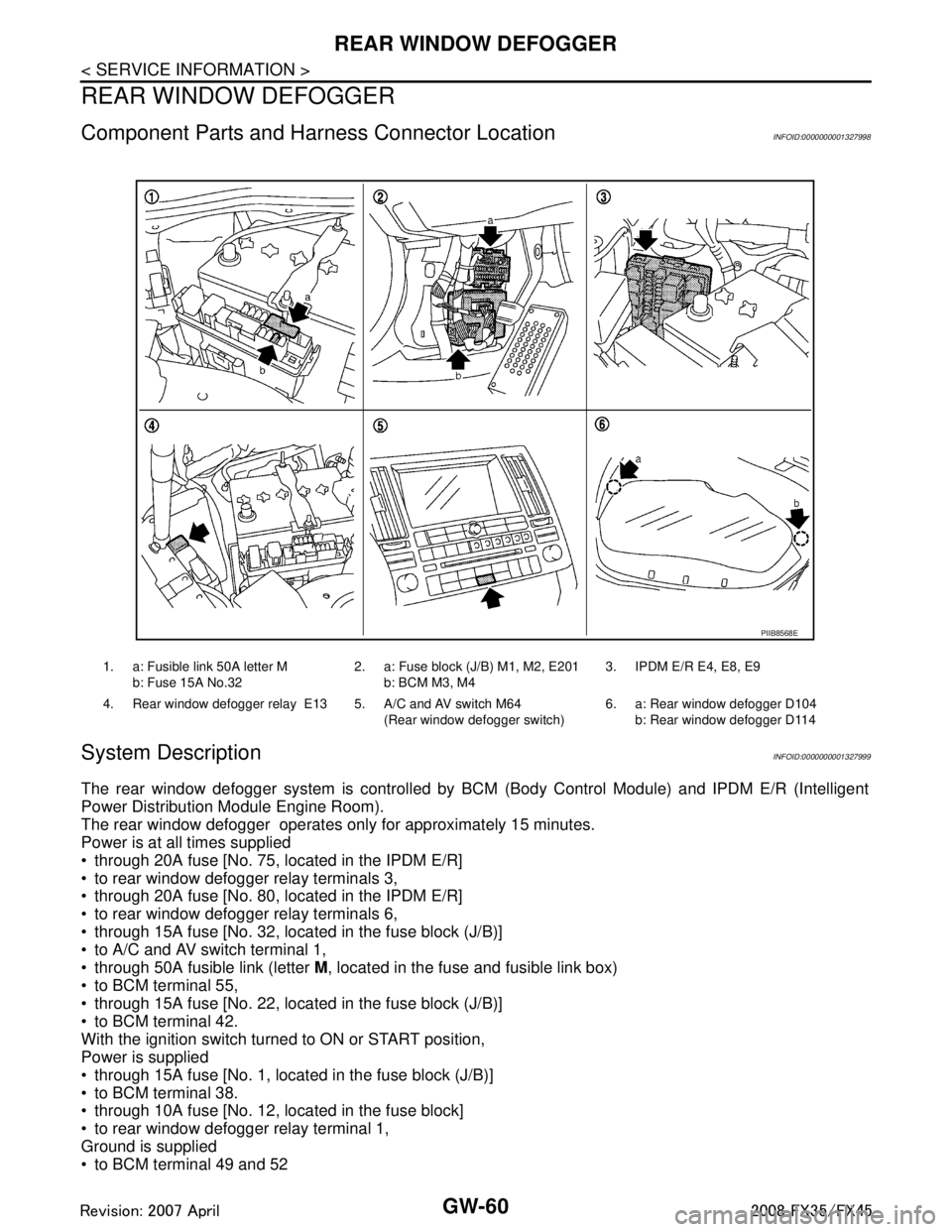

Component Parts and Harness Connector LocationINFOID:0000000001327998

System DescriptionINFOID:0000000001327999

The rear window defogger system is controlled by BC M (Body Control Module) and IPDM E/R (Intelligent

Power Distribution Module Engine Room).

The rear window defogger operates only for approximately 15 minutes.

Power is at all times supplied

through 20A fuse [No. 75, located in the IPDM E/R]

to rear window defogger relay terminals 3,

through 20A fuse [No. 80, located in the IPDM E/R]

to rear window defogger relay terminals 6,

through 15A fuse [No. 32, located in the fuse block (J/B)]

to A/C and AV switch terminal 1,

through 50A fusible link (letter M, located in the fuse and fusible link box)

to BCM terminal 55,

through 15A fuse [No. 22, located in the fuse block (J/B)]

to BCM terminal 42.

With the ignition switch turned to ON or START position,

Power is supplied

through 15A fuse [No. 1, located in the fuse block (J/B)]

to BCM terminal 38.

through 10A fuse [No. 12, located in the fuse block]

to rear window defogger relay terminal 1,

Ground is supplied

to BCM terminal 49 and 52

1. a: Fusible link 50A letter M

b: Fuse 15A No.32 2. a: Fuse block (J/B) M1, M2, E201

b: BCM M3, M4 3. IPDM E/R E4, E8, E9

4. Rear window defogger relay E13 5. A/C and AV switch M64 (Rear window defogger switch)6. a: Rear window defogger D104

b: Rear window defogger D114

PIIB8568E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2974 of 3924

REAR WINDOW DEFOGGERGW-61

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

through body grounds M35, M45 and M85,

to A/C and AV switch terminal 5

through body grounds M35, M45 and M85,

to IPDM E/R terminals 38 and 60

through body grounds E21, E50 and E51.

When rear window defogger switch in A/C and AV switch is turned to ON,

Ground is supplied

to BCM terminal 9

through A/C and AV switch terminal 16

through A/C and AV switch terminal 5 and

through body grounds M35, M45 and M85.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R, display control unit via DATA LINE (CAN H,

CAN L).

When display control unit receives rear window defogger switch signals, and display on the screen.

When IPDM E/R receives rear window defogger switch signals,

Ground is supplied

to rear window defogger relay terminal 2

through IPDM E/R terminal 52

through IPDM E/R terminals 38 and 60 and

through body grounds E21, E50 and E51.

And then rear window defogger relay is energized.

When rear window defogger relay is turned ON, signals are transmitted.

through rear window defogger relay terminals 5 and 7

to rear window defogger terminal 1

Rear window defogger terminal 2 is grounded through grounds B15 and B45.

With power and ground supplied, rear window def ogger filaments heat and defog the rear window.

When rear window defogger relay is turned to ON,

Power is supplied

through rear window defogger relay terminal 7

through fuse block (J/B) terminal 2C

through 15A fuse [No. 8, located in the fuse block (J/B)] and

through fuse block (J/B) terminal 5B

to door mirror defogger (driver side and passenger side) terminal 4.

Door mirror defogger (driver side and passenger side) terminal 3 is grounded through body grounds M35, M45

and M85.

With power and ground supplied, rear window defogger filaments heat and defog the rear window and door

mirror defogger filaments heat and defog the mirror.

CAN Communication System DescriptionINFOID:0000000001328000

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328001

Refer to LAN-43, "CAN System Specification Chart".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2980 of 3924

REAR WINDOW DEFOGGERGW-67

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

Terminal and Reference Value for BCMINFOID:0000000001328004

Terminal and Reference Value for IPDM E/RINFOID:0000000001328005

CONSULT-III Function (BCM)INFOID:0000000001328006

DATA MONITOR

ACTIVE TEST

Te r m i n a l Wire col-

or ItemSignal In-

put/

Output Condition

Voltage (V)

(Approx.)

9L/W Rear window defogger

switch signal InputWhen rear window defogger switch is

pressed.

0

When rear window defogger switch is OFF. 5

38 W/L Ignition switch ON or START Input Ignition switch (ON or START position) Battery voltage

39 L CAN − H Input/

Output ——

40 P CAN − L Input/

Output ——

42 L/R Power source (Fuse) Input — Battery voltage

49 B Ground (signal) — — 0

52 B Ground (power) — — 0

55 G Power source (Fusible link) Input — Battery voltage

Te r m i n a l Wire col-

or Item Signal

Input/

Output Condition

Voltage (V)

(Approx.)

5 R Battery power supply Output — Battery voltage

6 W Battery power supply Output — Battery voltage

38 B Ground (Power) — — 0

48 L CAN − H Input/

Output ——

49 R CAN − L Input/

Output ——

52 G Rear window defogger relay

control signal

InputWhen rear window defogger switch is ON. 0

When rear window defogger switch is

OFF.

Battery voltage

60 B Ground (Signal) — — 0

BCM diagnostic test item Check item diagnostic test mode Content

REAR DEFOGGER Data monitor Displays the input data of BCM in real time.

Active test Gives a drive signal to a load to check the operation.

Monitor item Content

REAR DEF SW Displays “Press (ON)/others (OFF)” status determined with the rear window defogger switch.

IGN ON SW Displays “IGN (ON)/OFF” status determined with the ignition switch signal.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2984 of 3924

REAR WINDOW DEFOGGERGW-71

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

2. Remove rear window defogger relay.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger relay connector E13 terminals 1, 3, 6 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK REAR WINDOW DEFOGGER RELAY

Check continuity between rear wi ndow defogger terminals 3 and 5, 6

and 7.

OK or NG

OK >> GO TO 4.

NG >> Replace rear window defogger relay.

4.CHECK REAR WINDOW DEFOGG ER RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Installation rear window defogger relay.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> Rear window defogger power supply circuit is OK.

NG >> GO TO 5.

5.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and rear window defogger relay. 1 (OR) – Ground : Battery voltage

3 (W) – Ground : Battery voltage

6 (R) – Ground : Battery voltage

PIIA4233E

Terminal Condition Continuity

35 12V direct current supply

between terminals 1 and 2

Ye s

No current supply No

67 12V direct current supply

between terminals 1 and 2

Ye s

No current supply No

SEC202B

Connector Terminals (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

E9 52 (G) Ground When rear window defog-

ger switch ON

0

When rear window defog-

ger switch OFF Battery

voltage

PIIA6210E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2985 of 3924

GW-72

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

3. Check continuity between IPDM E/R connector E9 terminal 52and rear window defogger relay connector E13 terminal 2.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness.

6.CHECK REAR WINDOW DEFOGGER RELAY OUTPUT SIGNAL

1. Connect IPDM E/R connector and rear window defogger relay.

2. Turn ignition switch ON.

3. Check voltage between IPDM E/R connector E9 terminal 52 and ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace IPDM E/R.

Check Rear Window Defogger CircuitINFOID:0000000001328013

1.CHECK POWER SUPPLY CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect rear window defogger connector.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger connector and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF. 52 (G) – 2 (G) : Continuity should exist.

PIIA6211E

52 (G) – Ground : Battery voltage

PIIA6210E

Connector

Terminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

D104 1(W) Ground Rear window defogger

switch ON.

Battery voltage

Rear window defogger

switch OFF. 0

PIIA9347E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2986 of 3924

REAR WINDOW DEFOGGERGW-73

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

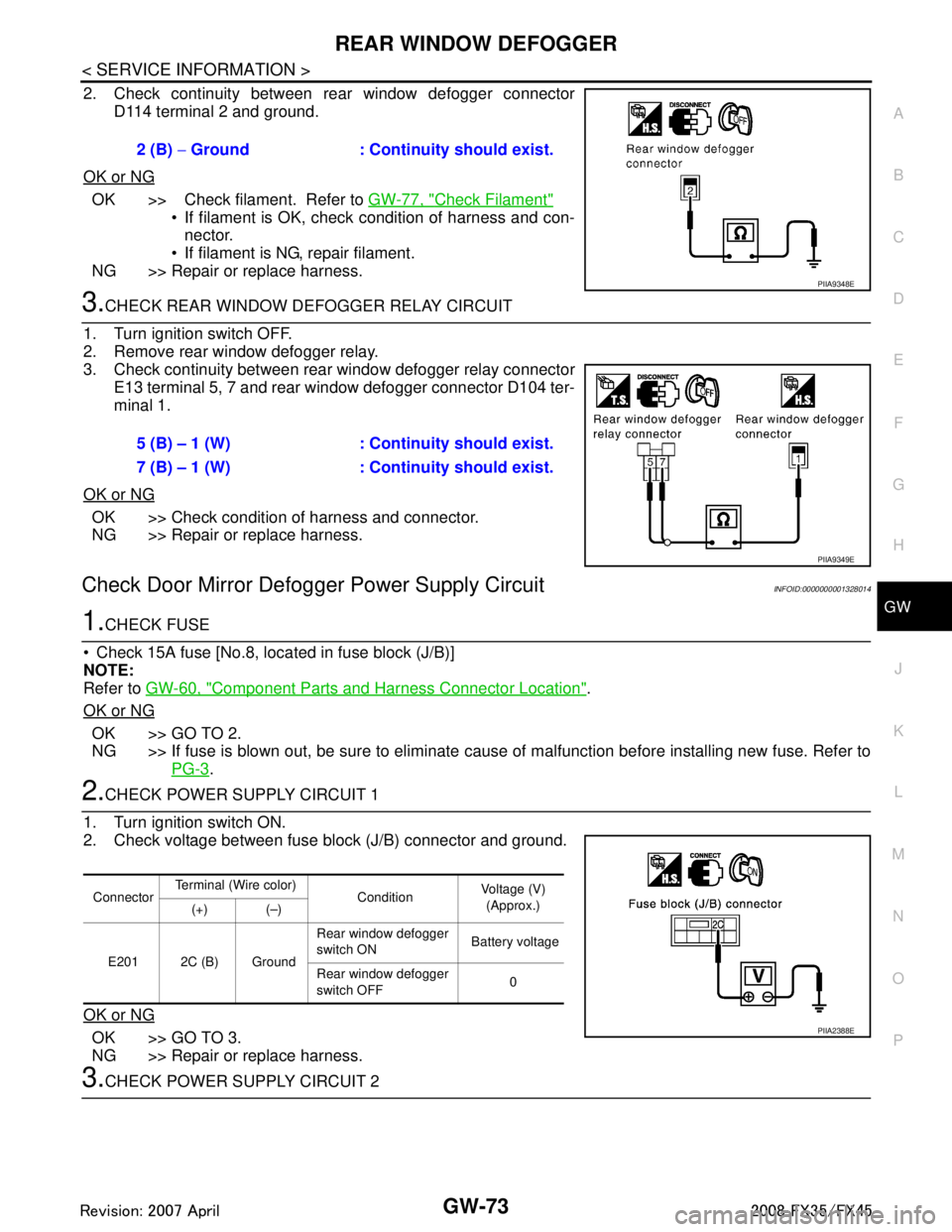

2. Check continuity between rear window defogger connector D114 terminal 2 and ground.

OK or NG

OK >> Check filament. Refer to GW-77, "Check Filament"

If filament is OK, check condition of harness and con-

nector.

If filament is NG, repair filament.

NG >> Repair or replace harness.

3.CHECK REAR WINDOW DEFOGGER RELAY CIRCUIT

1. Turn ignition switch OFF.

2. Remove rear window defogger relay.

3. Check continuity between rear window defogger relay connector E13 terminal 5, 7 and rear window defogger connector D104 ter-

minal 1.

OK or NG

OK >> Check condition of harness and connector.

NG >> Repair or replace harness.

Check Door Mirror Defogger Power Supply CircuitINFOID:0000000001328014

1.CHECK FUSE

Check 15A fuse [No.8, loca ted in fuse block (J/B)]

NOTE:

Refer to GW-60, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate c ause of malfunction before installing new fuse. Refer to

PG-3

.

2.CHECK POWER SUPPLY CIRCUIT 1

1. Turn ignition switch ON.

2. Check voltage between fuse block (J/B) connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK POWER SUPPLY CIRCUIT 2 2 (B)

− Ground : Continuity should exist.

PIIA9348E

5 (B) – 1 (W) : Cont inuity should exist.

7 (B) – 1 (W) : Cont inuity should exist.

PIIA9349E

ConnectorTerminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

E201 2C (B) Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

PIIA2388E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3107 of 3924

HEADLAMP - XENON TYPE -LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

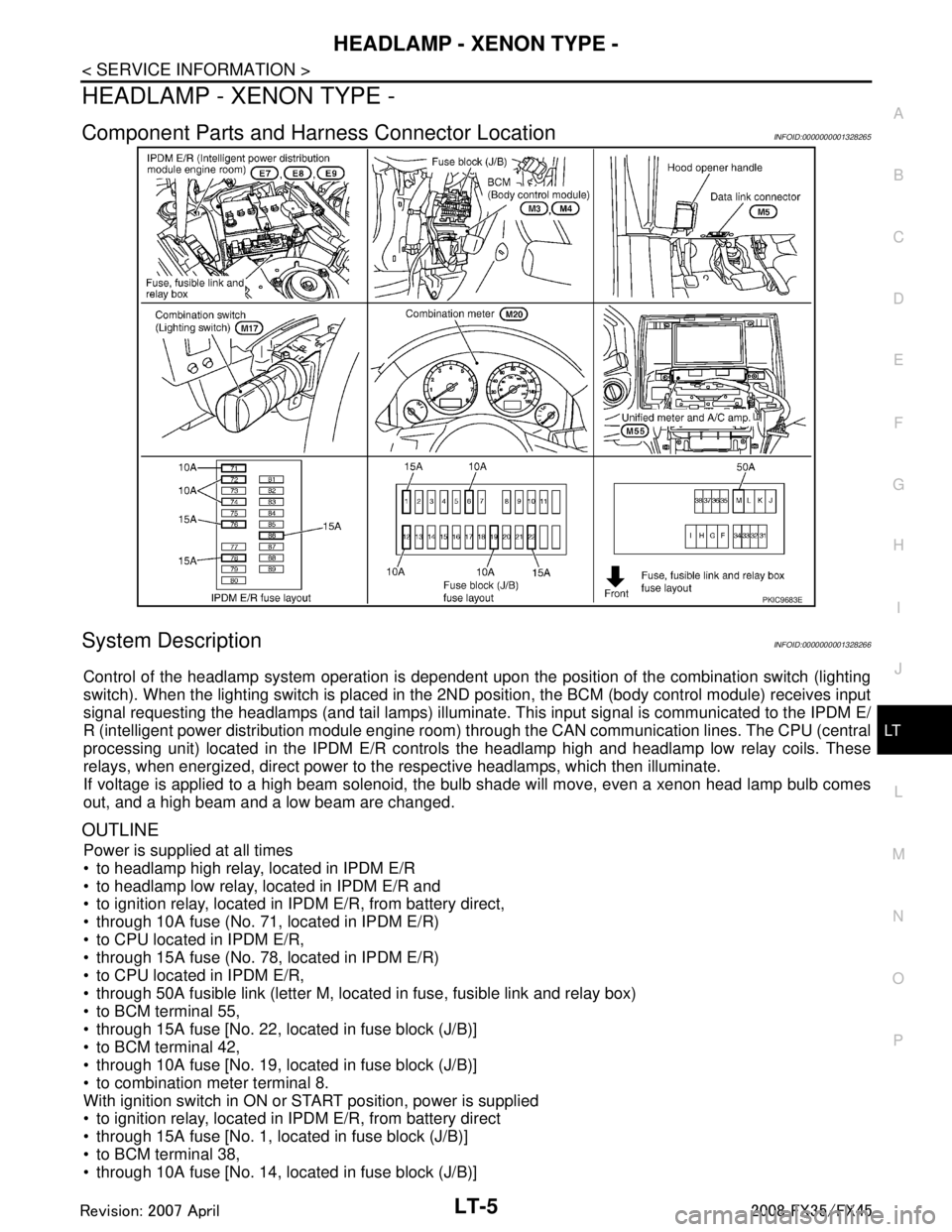

HEADLAMP - XENON TYPE -

Component Parts and Har ness Connector LocationINFOID:0000000001328265

System DescriptionINFOID:0000000001328266

Control of the headlamp system operation is dependent upon t he position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the IPDM E/

R (intelligent power distribution module engine room) through the CAN communication lines. The CPU (central

processing unit) located in the IPDM E/R contro ls the headlamp high and headlamp low relay coils. These

relays, when energized, direct power to the respective headlamps, which then illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

OUTLINE

Power is supplied at all times

to headlamp high relay, located in IPDM E/R

to headlamp low relay, located in IPDM E/R and

to ignition relay, located in IPDM E/R, from battery direct,

through 10A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R,

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8.

With ignition switch in ON or START position, power is supplied

to ignition relay, located in IPDM E/R, from battery direct

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

PKIC9683E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3108 of 3924

LT-6

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

to combination meter terminal 7.

With ignition switch in ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to BCM terminal 11.

Ground is supplied

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to IPDM E/R terminals 38 and 60

through grounds E21, E50 and E51,

to combination meter terminals 5, 6 and 15

through grounds M35, M45 and M85.

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in the 2ND position, the BCM receives input signal requesting the headlamps to illumi-

nate. This input signal is communicated to the IP DM E/R through the CAN communication lines. The CPU

located in the IPDM E/R controls the headlamp lo w relay coil, which when energized, directs power

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 6,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 6.

Ground is supplied

to front combination lamp RH and LH terminals 7

through grounds E21, E50 and E51,

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in the 2ND position and placed in the HIGH or PASS position, the BCM receives input

signal requesting the headlamp high beams to illuminate. Th is input signal is communicated to the IPDM E/R

through the CAN communication lines. The CPU located in the IPDM E/R controls the headlamp high relay

coil and low relay coil, which when energized, directs power

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 6,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 6,

through 10A fuse (No. 72, located in IPDM E/R)

through IPDM E/R terminal 27

to front combination lamp RH terminal 5,

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 5.

Ground is supplied

to front combination lamp RH and LH terminals 7

through grounds E21, E50 and E51,

With power and ground supplied, the high beam headlamps illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

The unified meter and A/C amp. that received the hi gh beam request signal by BCM through the CAN commu-

nication makes a high beam indicator lamp turn on in combination meter.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 2ND position (ON), and the ignition switch is turned

from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the headlamps remain illumi nated for 5 minutes, then the headlamps are turned OFF.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3119 of 3924

HEADLAMP - XENON TYPE -LT-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

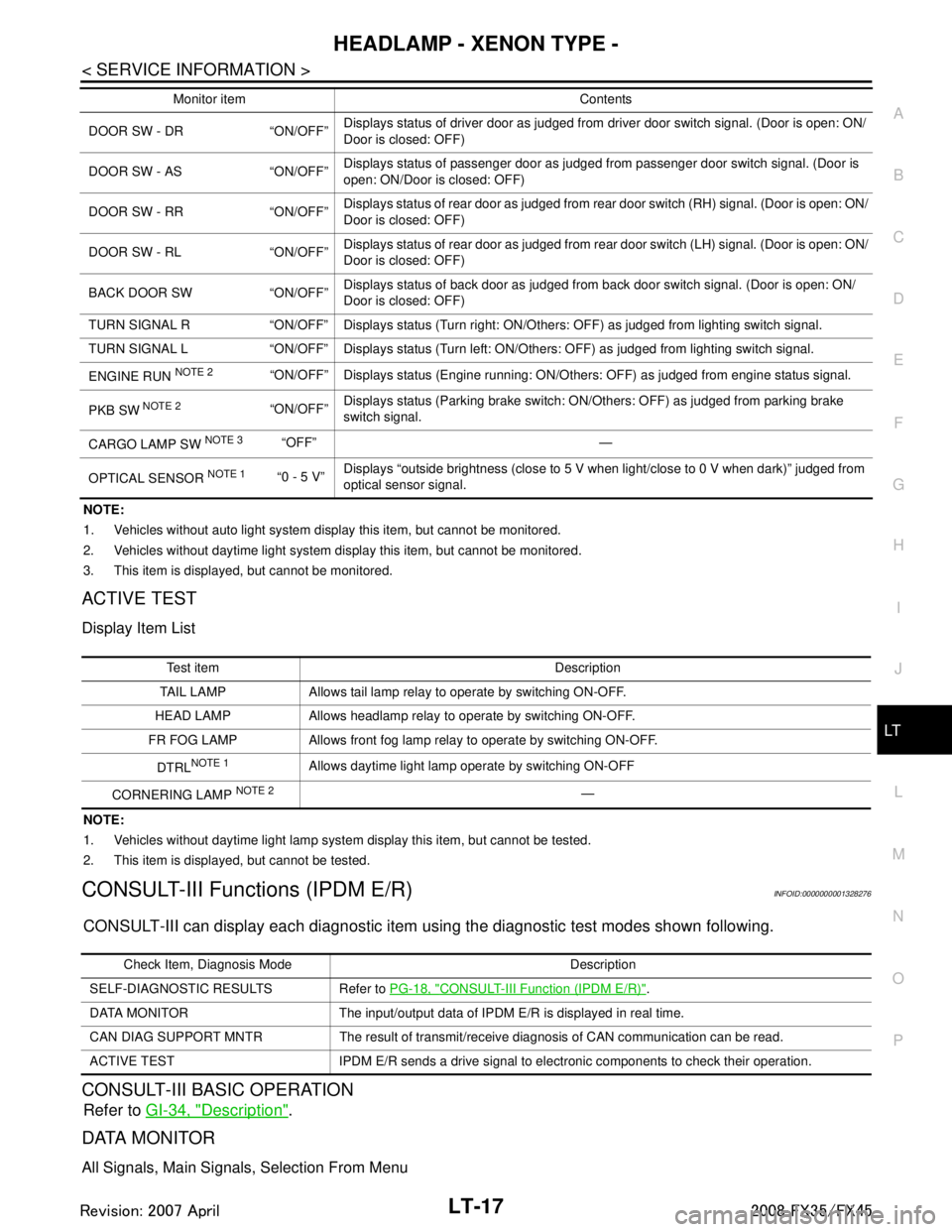

NOTE:

1. Vehicles without auto light system display this item, but cannot be monitored.

2. Vehicles without daytime light system display this item, but cannot be monitored.

3. This item is displayed, but cannot be monitored.

ACTIVE TEST

Display Item List

NOTE:

1. Vehicles without daytime light lamp system display this item, but cannot be tested.

2. This item is displayed, but cannot be tested.

CONSULT-III Functions (IPDM E/R)INFOID:0000000001328276

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

CONSULT-III BASIC OPERATION

Refer to GI-34, "Description".

DATA MONITOR

All Signals, Main Signals, Selection From Menu

DOOR SW - DR “ON/OFF” Displays status of driver door as judged from driver door switch signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - AS “ON/OFF” Displays status of passenger door as judged from passenger door switch signal. (Door is

open: ON/Door is closed: OFF)

DOOR SW - RR “ON/OFF” Displays status of rear door as judged from rear door switch (RH) signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - RL “ON/OFF” Displays status of rear door as judged from rear door switch (LH) signal. (Door is open: ON/

Door is closed: OFF)

BACK DOOR SW “ON/OFF” Displays status of back door as judged from back door switch signal. (Door is open: ON/

Door is closed: OFF)

TURN SIGNAL R “ON/OFF” Display s status (Turn right: ON/Others: OFF) as judged from lighting switch signal.

TURN SIGNAL L “ON/OFF” Display s status (Turn left: ON/Others: OFF) as judged from lighting switch signal.

ENGINE RUN

NOTE 2“ON/OFF” Displays status (Engine running: ON/Others: OFF) as judged from engine status signal.

PKB SW

NOTE 2“ON/OFF” Displays status (Parking brake switch: ON/Others: OFF) as judged from parking brake

switch signal.

CARGO LAMP SW

NOTE 3 “OFF” —

OPTICAL SENSOR

NOTE 1 “0 - 5 V” Displays “outside brightness (close to 5 V when light/close to 0 V when dark)” judged from

optical sensor signal.

Monitor item Contents

Te s t i t e m D e s c r i p t i o n

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

HEAD LAMP Allows headlamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF.

DTRL

NOTE 1Allows daytime light lamp operate by switching ON-OFF

CORNERING LAMP

NOTE 2—

Check Item, Diagnosis Mode Description

SELF-DIAGNOSTIC RESULTS Refer to PG-18, "

CONSULT-III Function (IPDM E/R)".

DATA MONITOR The input/output data of IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST IPDM E/R sends a drive signal to electronic components to check their operation.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3120 of 3924

LT-18

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

NOTE:

Perform monitoring of IPDM E/R data with ignition switch ON. When ignition switch is at ACC, display may not

be correct.

ACTIVE TEST

Headlamp Does Not Change To High Beam (Both Sides)INFOID:0000000001381742

1.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “HI BEAM SW” of BCM data monitor item.

2. With operating the lighting switch, check the monitor status.

CHECK THE COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

2.HEADLAMP ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “LAMPS” of IPDM E/R active test item.

2. With operating the test item, check the headlamp high beam operation.

IPDM E/R AUTO ACTIVE TEST

1. Start auto active test. Refer to PG-20, "

Auto Active Test".

2. Check that the headlamp high beam operation.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

Item name CONSULT-III

screen display Display

or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Position lights request TAIL & CLR REQ ON/OFF ×× ×Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF ×× ×Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF ×× ×Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF ×× ×Signal status input from BCM

Te s t i t e mCONSULT-III

screen display Description

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON,

LO ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows front fog lamp relay to operate by switching operation ON-OFF at your op-

tion.

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

When lighting switch is

HIGH BEAM : HI BEAM SW ON

Headlamp high beam should operate.

(Headlamp high beam repeats ON-OFF every 1 second).

Headlamp high beam should operate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C